2SSCBL-RPBL-IOM (10-22) 149159-C

TABLE OF CONTENTS

GENERAL INFORMATION .............................................................................4

References ........................................................................................4

Important Safety Information........................................................................... 4

Warranty ..........................................................................................5

Installation Codes ...................................................................................5

Dimensions ........................................................................................6

Weights........................................................................................... 7

Clearances ........................................................................................8

Package Configurations ..............................................................................8

Location ..........................................................................................8

Hazards of Chlorine ................................................................................. 8

INSTALLATION ......................................................................................9

Uncrating/Unpacking................................................................................. 9

Shipped-Separate Parts .............................................................................. 9

Mounting Support Structure ...........................................................................9

Curb Cap Base .................................................................................10

Optional Curb (Option CJ1, CJ2, CJ4, or CJ5) Assembly (Model RPBL) .....................................10

Field-Supplied Support Assembly ................................................................... 13

Mounting .........................................................................................14

Suspension (Model SSCBL) .......................................................................14

Mounting (Model SSCBL) .........................................................................15

Mounting (Model RPBL) .......................................................................... 15

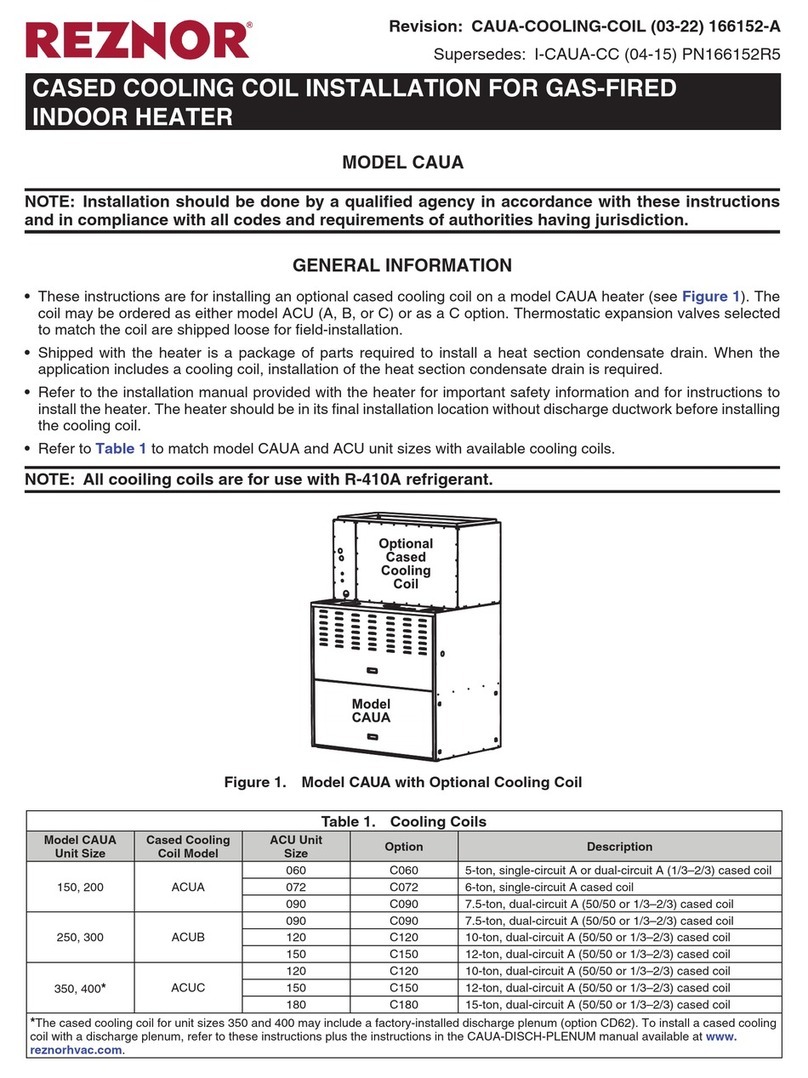

Field-Installation of Cooling Coil Cabinet and Downturn Plenum .............................................. 16

Duct Connections ..................................................................................22

Requirements and Suggestions for Connecting and Installing Ducts ........................................ 23

Bottom Duct Connections (Model RPBL) ............................................................. 24

100% Outside Air Hood (Model RPBL with Option AS2).................................................. 25

Screened Air Hood for 30% Outside Air Opening (Model RPBL with Option AR6 or AR7)........................ 25

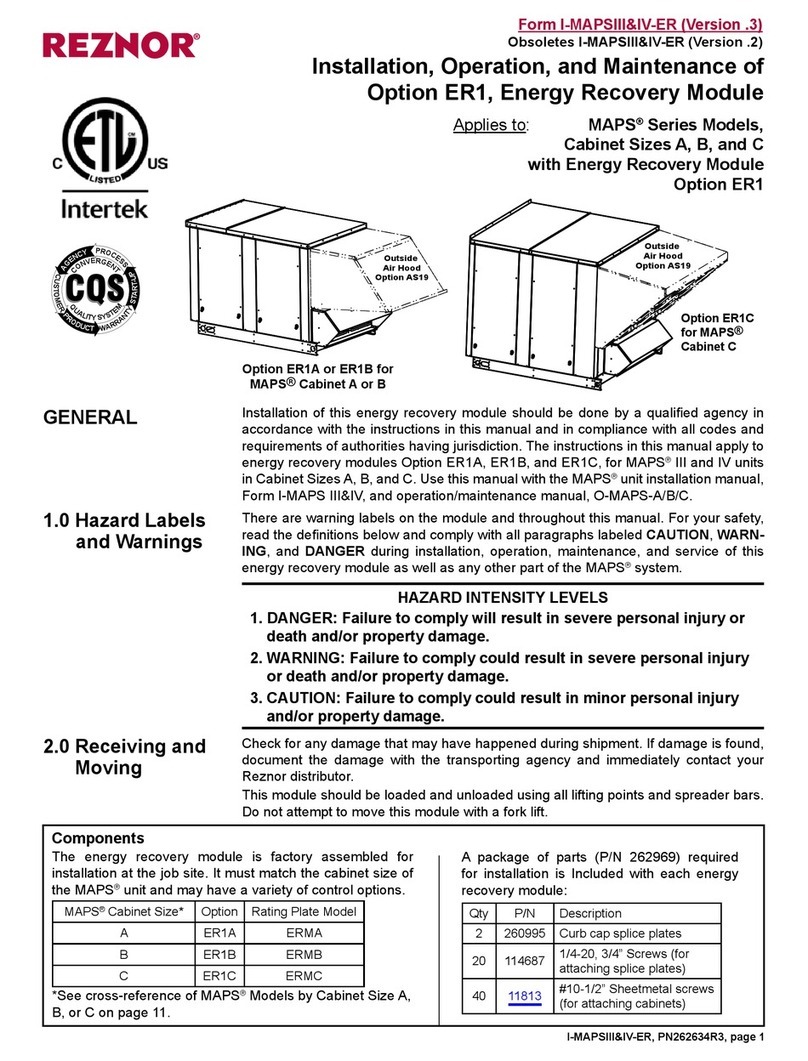

Evaporative Cooling Module (Option AS3, AS4, AS5, or AS8) .............................................25

Discharge Air Temperature Sensor Installation.........................................................25

Venting/Combustion Air Connections (Model SSCBL) ......................................................27

Specific Venting Requirements: Piping ............................................................... 27

Specific Venting Requirements: Venter Outlet and Combustion Air Inlet Connections...........................28

Specific Venting Requirements: Joints and Sealing .....................................................28

Specific Venting Requirements: Support.............................................................. 29

Specific Venting Requirements: Clearance ............................................................ 30

Specific Venting Requirements: Concentric Adapter Box ................................................. 30

Specific Venting Requirements: Concentric Adapter Box Pipe Connections ..................................31

Vent Terminal Options............................................................................ 32

Vertical Vent Terminal (Option CC2) Installation........................................................32

Horizontal Vent Terminal (Option CC6) Installation...................................................... 37

Venting Connections (Model RPBL) ....................................................................41

Piping Connections................................................................................. 42

Gas Supply Pressure............................................................................. 42

Gas Supply Piping............................................................................... 43

Supply Piping Connections ........................................................................ 43

Electrical Connections ..............................................................................45

Control Wiring ..................................................................................46

CONTROLS ........................................................................................49

Thermostat .......................................................................................49

Remote Console ...................................................................................49

Combustion Air Proving Switch........................................................................ 49

Blower Fan Control .................................................................................49

High Temperature Limit Control .......................................................................50