4H-IOM (01-23) 1042427-0

INSTALLATION

Unpacking and Inspection

The unit was test-operated and inspected at the factory prior to packaging and was in operating condition. If, upon

removing it from its packaging, the unit is found to have incurred any damage in shipment, document the damage

with the transporting agency and contact an authorized Factory Distributor. If you are an authorized Distributor, follow

the FOB freight policy procedures.

Pre-Installation Checklist

Read this manual and become familiar with the installation requirements.

Before beginning, make preparations for necessary supplies, tools, and manpower.

Check to see if there are any field-installed options (refer to Table 5) that need to be assembled/installed prior

to unit installation. Ensure that all options ordered are at the installation site.

Table 5. Field-Installed Options

Option Description

IT13 Unit-mounted thermostat

CL31, CL32 Multiple fan control: option CL31 includes components for one control unit and one additional

unit—option CL32 includes components for each additional non-control unit

CL1 Single-stage thermostat

CL22 Two-stage thermostat

CL90 BACnet-capable thermostat

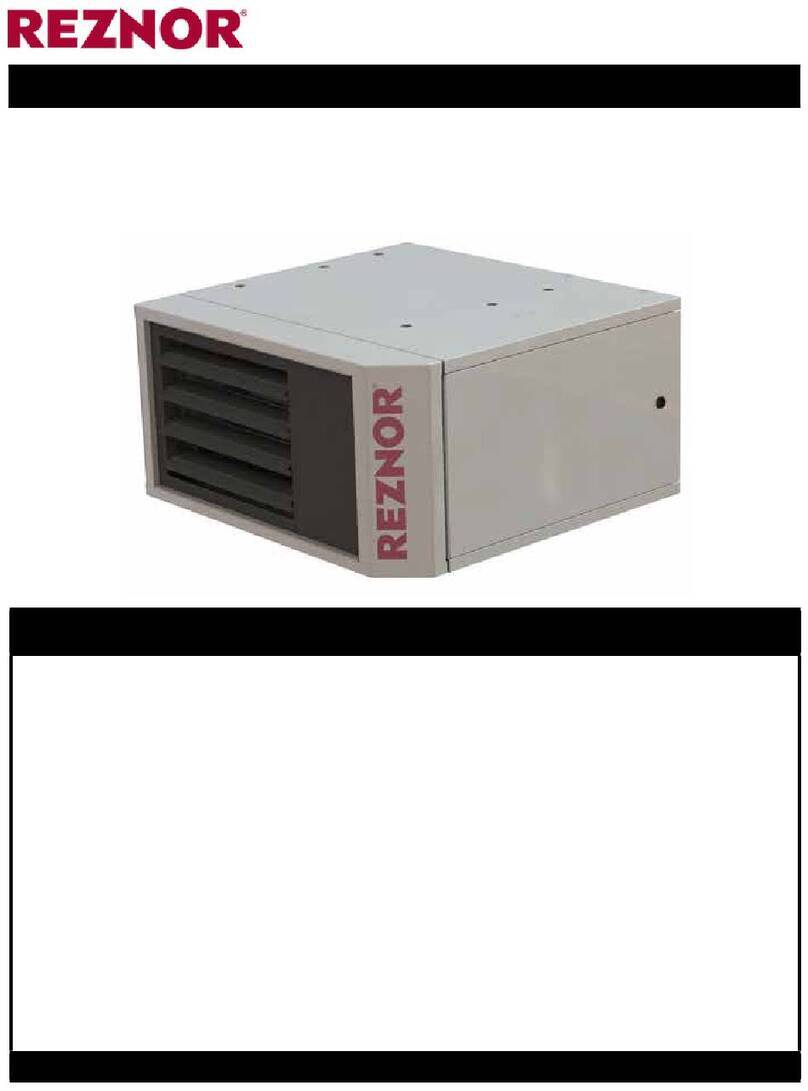

Unit Suspension

⚠ WARNING ⚠

• Before suspending the unit, check the supporting structure to verify that it has sufficient load-

carrying capacity to support the weight of the unit (refer to Weights section).

• DO NOT add additional weight to a suspended unit.

NOTE: An accessory kit (PN 1042414) that contains hanger bracket assemblies, a Reznor logo,

and hole plugs is shipped with the unit. Hangers and hardware are not factory-installed. Intall hole

plugs if the Reznor logo is not used.

Suspend the unit using 3/8-inch field-supplied threaded rods (maximum length is 10 feet (3 meters)) and hex nuts.

The rods are secured to two hanger brackets (see Figure 1) that are shipped with the unit in the accessory kit. The

hanger brackets may be rotated to one of six positions in order to mount the unit at a desired angle.

1. If Reznor logo from accessory kit is desired, snap logo into two sets of holes located on front face of unit. If logo

is not used, install hole plugs from accessory kit in holes.

2. Remove rubber cap from threaded stud on each side of unit and slide center hole of hanger brackets from

accessory kit over studs—each stud acts as pivot when adjusting bracket angle. Install 5/16-inch hex nuts (see

Figure 1) from accessory kit on studs to secure brackets.

3. Position hanger brackets to desired angle and secure each bracket using two 1/4-inch bolts (see Figure 1) from

accessory kit installed in selected threaded holes in each bracket.

4. Install field-supplied hex nut on each field-supplied threaded rod about 6 inches from bottom of rod. Insert rod

into top hole of each hanger bracket and install second and third field-supplied hex nuts.

5. Insert rod into bottom hole of each hanger bracket and install fourth field-supplied hex nut. Adjust rods/nuts for

desired mounting height and tighten all hex nuts flush against brackets (see Figure 1).

6. Install threaded rods and hex nuts to unistrut, metal framing, or other structurally-sound attachment points to

suspend unit. Ensure that load-bearing structure adequately supports weight of unit(s) and suspension hardware.