1

// Table Of Contents

1. Important Cautions...............................................................................

1.1 Serial No. Position............................................................................

1.1.1 Vehicle Identification No.1.1.2 Motor No....................

1.1.2 Motor No......................................................................................

1.1.3 Definition of Vehicle Identification No......................

1.2 General Technological Conditions......................................

1.2.1 Vehicle Specification...........................................................

1.2.2 Torque..........................................................................................

1.2.3 Torque Reference................................................................

2. Regular Maintenance........................................................................

2.1 Vehicle Wheel Maintenance....................................................

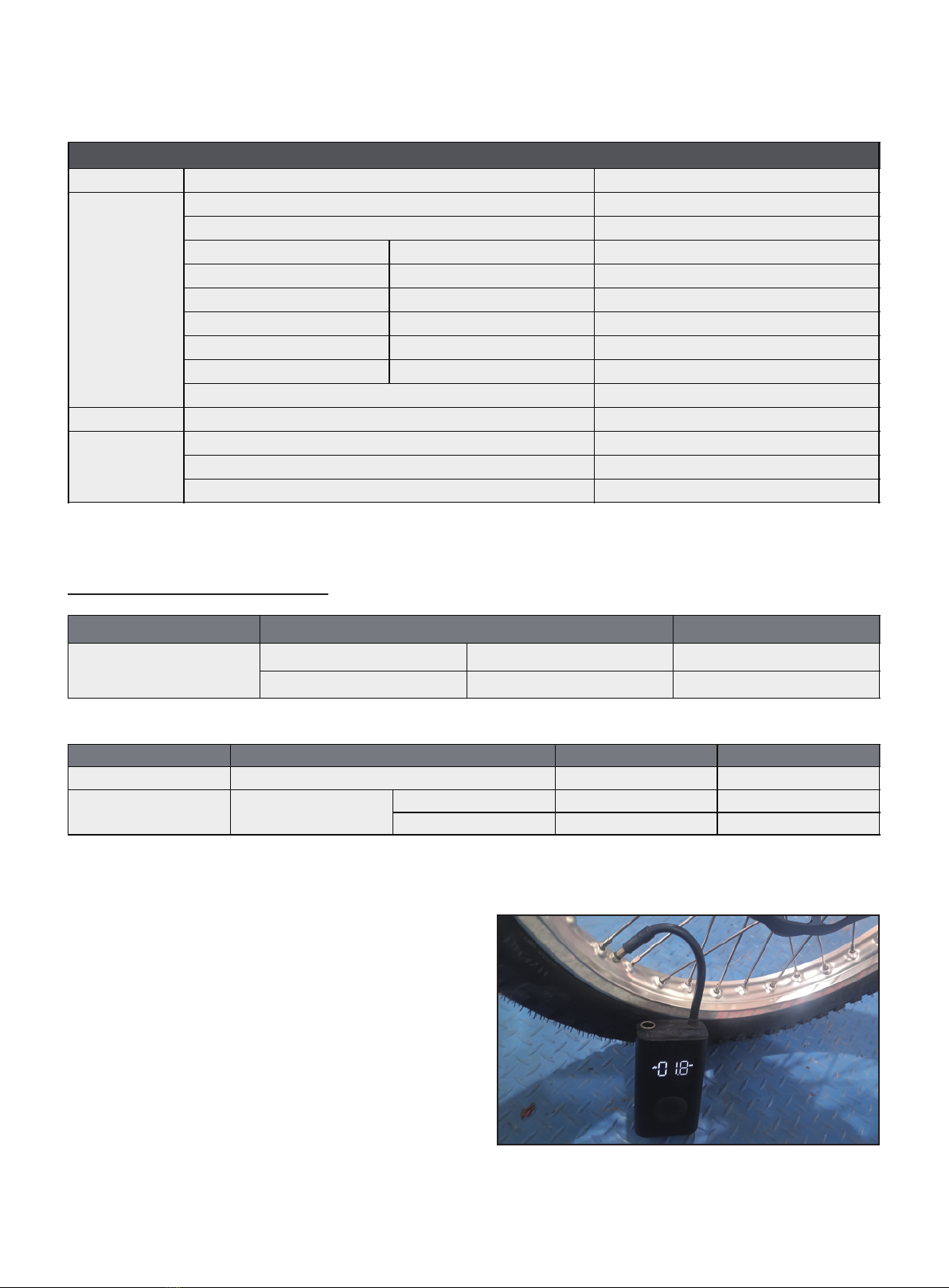

2.1.1 Inspection on Tyre Pressure..........................................

2.1.2 Inspection on Wheel Axle and Damage of

Wheel Axle...............................................................................

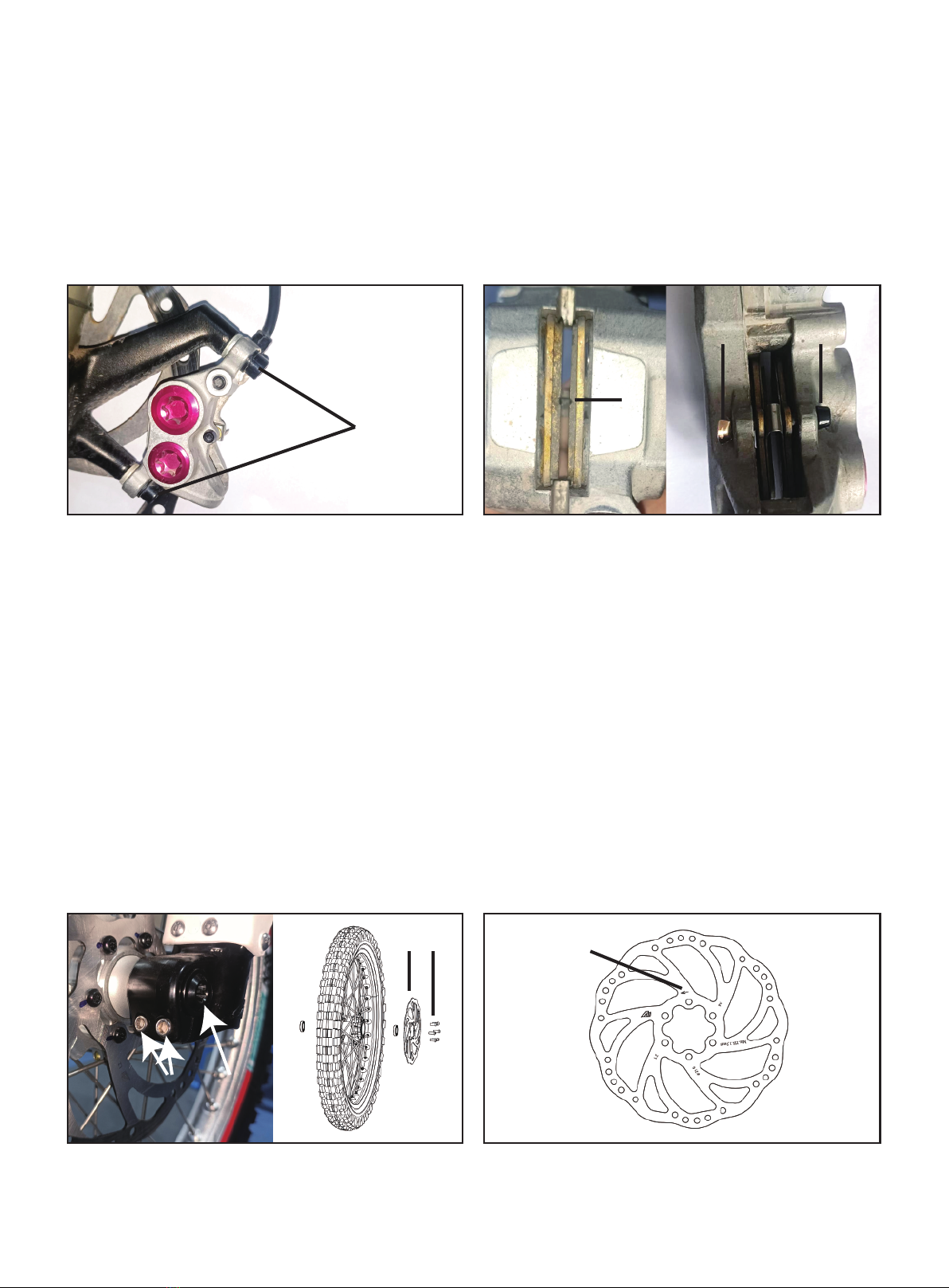

2.2 Brake Maintenance......................................................................

2.2.1 Inspection on Brake Fluid...............................................

2.2.2 Replacement of Brake Fluid.........................................

2.2.3 Inspection on and Replacement of Brake Pad.

2.2.4 Inspection on and Replacement of Front

Brake Disc................................................................................

2.2.5 Inspection on and Replacement of Rear

Brake Disc................................................................................

2.2.6 Replacement of Main Brake Cylinder....................

2.2.7 Replacement of Brake Calliper...................................

2.2.8 Replacement of Brake Line.........................................

2.2.9 Adjustment of Brake Rod..............................................

2.3 Maintenance of Transmission Chain...............................

2.3.1 Inspection on Slackness of Transmission

Chain...........................................................................................

2.3.2 Adjustment of Slackness of Transmission

Chain...........................................................................................

2.3.3 Transmission Chain Lubrication...............................

2.3.4 Inspection on Abrasion of Transmission

Chain...........................................................................................

2.3.5 Replacement of Transmission Chain....................

2.4 Maintenance of Suspension Parts....................................

2.4.1 Inspection on Front Shock Absorber......................

2.4.2 Inspection on Leakage of Damping Oil.................

2.4.3 Inspection on Rear Shock Absorber .....................

2.4.4 Inspection on Leakage of Rear Shock

Absorber.......14

2.5 Maintenance of Steering..........................................................

2.5.1 Inspection on Steering Bearing..................................

2.5.2 Lubrication of Steering Bearing................................

2.6 Electrical Maintenance..............................................................

2.6.1 Maintenance of Battery...................................................

2.6.2 Fuse.............................................................................................

2.6.3 Inspection on Operation of Key Sets.....................

3. Repair and Diagnosis.........................................................................

3.1 Electric System................................................................................

3.1.1 Caution for Operation..........................................................

3.1.2 Caution before Maintenance.......................................

3.1.3 Fault Phenomenon and Fault Shooting.................

3.1.4 Instrument................................................................................

3.1.5 Turn on /o Power Supply.............................................

3.1.6 Switch of Gear........................................................................

2

3

3

3

3

4

4

5

5

6

7

7

8

8

8

8

9

9

10

10

11

11

12

12

12

12

12

13

13

13

13

13

14

14

14

14

14

15

15

15

16

17

17

18

18

19

20

20

20

3.1.7 Lithium Battery, Step for removing the

battery.........................................................................................

3.1.8 Description of Lithium Battery Interface..............

3.1.9 Charge.........................................................................................

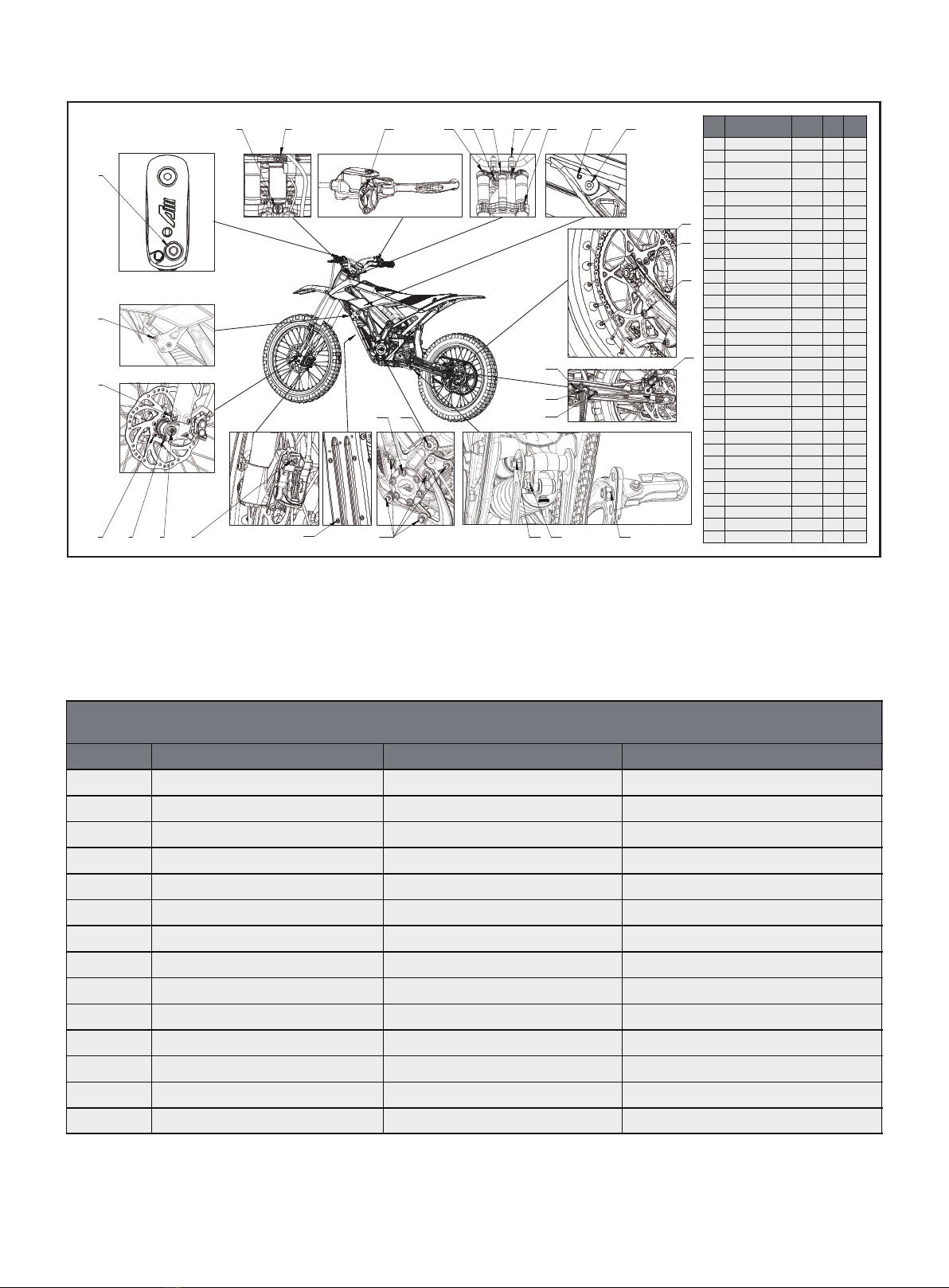

3.1.10 Motor..........................................................................................

3.1.11 Controller..................................................................................

3.1.12 Charger.....................................................................................

3.1.13 Electrical Schematic Diagram...................................

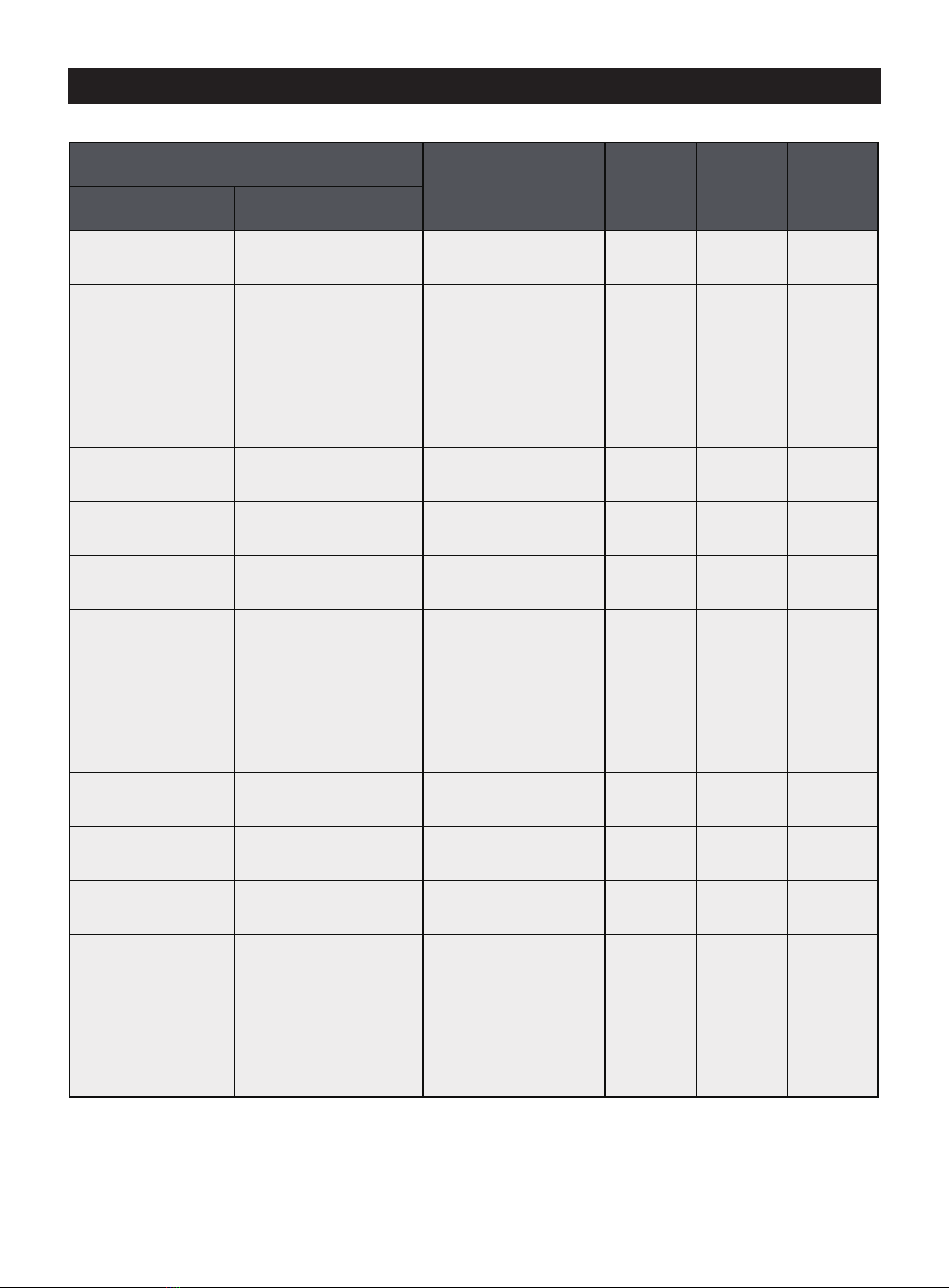

3.2 Chassis.................................................................................................

3.2.1 Chassis Exploded View / Parts Location -

Chassis.................................................................................................

3.2.2 Replacement of Chassis................................................

3.2.3 Replacement of Pedal.....................................................

3.2.4 Exploded Vide / Part Location - Seat

Cushion.....................................................................................

3.2.5 Replacement of Seat Cushion...................................

3.3 Wheel and Tyre...............................................................................

3.3.1 Exploded Vide / Part Location - Front Wheel.....

3.3.2 Exploded Vide / Part Location - Rear Wheel.....

3.3.3 Clearing of Fault..................................................................

3.3.4 Rim..............................................................................................

3.3.5 Spoke..........................................................................................

3.3.6 Replacement of Tyre........................................................

3.3.7 Disassembly of Front Wheel and Replacement

of Front Wheel Axle............................................................

3.3.8 Disassembly of Rear Wheel and Replacement

of Rear Wheel Axle.............................................................

3.3.9 Inspection on Wheel Axle..............................................

3.3.10 Inspection on Wheel Axle............................................

3.3.11 Inspection on Rim..............................................................

3.4 Brake......................................................................................................

3.4.1 Exploded View - Part Location - Front Brake......

3.4.2 Clearing of Fault...................................................................

3.4.3 Brake Fluid...............................................................................

3.4.4 Brake Hose.............................................................................

3.4.5 Inspection on Brake Pad................................................

3.4.6 Replacement of Brake Rod..........................................

3.5 Suspension.......................................................................................

3.5.1 Exploded View - Part Location - Front

Suspension..............................................................................

3.5.1 Torque Table...........................................................................

3.5.2 Specification of Front Shock Absorber...............

3.5.3 Replacement of Front Shock Absorbe.................

3.5.4 Replacement of Shock Absorbing Yoke Plate

and Steering Axle...............................................................

3.5.5 Replacement of Electrical Shifter............................

3.5.6 Exploded View/ Part Location - Rear

Suspension............................................................................

3.5.7 Specification of Rear Shock Absorber..................

3.5.8 Clearing of Fault...................................................................

3.5.9 Replacement of Rear Shock Absorber...............

3.5.10 Replacement of Rear Swing Arm...........................

21

22

22

22

22

23

24

25

25

25

26

26

26

27

27

27

28

28

28

28

29

29

30

30

30

30

30

31

31

31

31

32

32

32

33

33

33

34

34

35

35

36

36

37