Rheem PowerVent Commercial Gas Water Heater Reference manual

Other Rheem Water Heater manuals

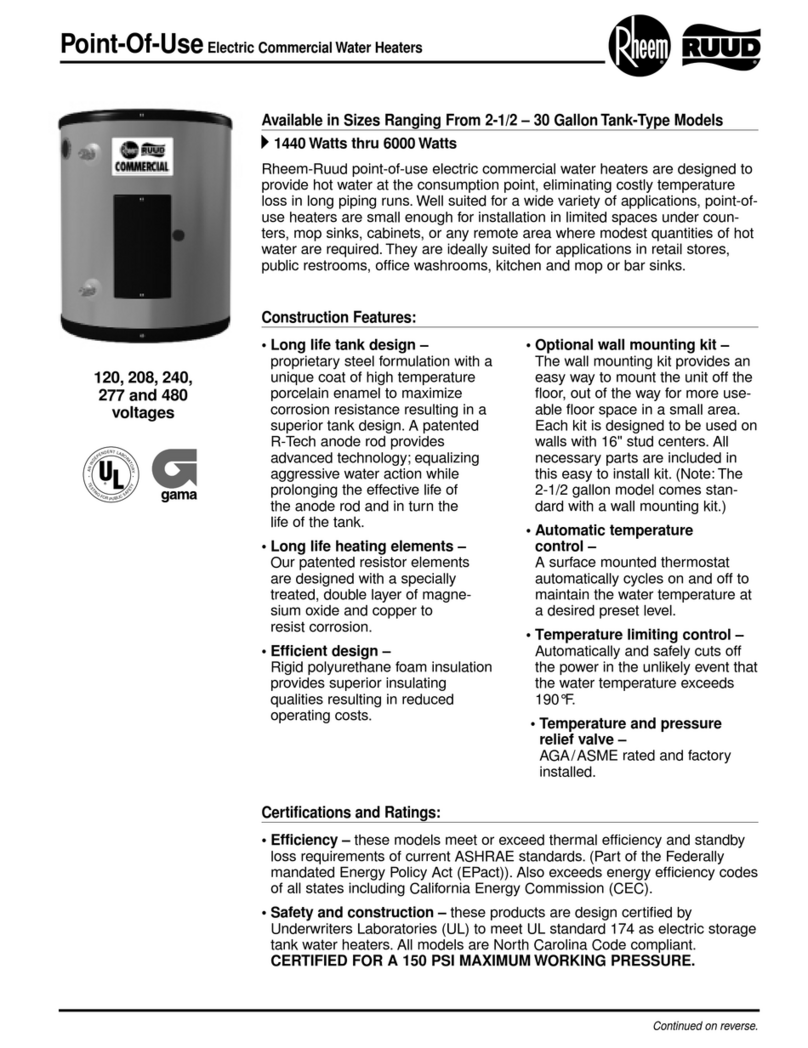

Rheem

Rheem 115 User manual

Rheem

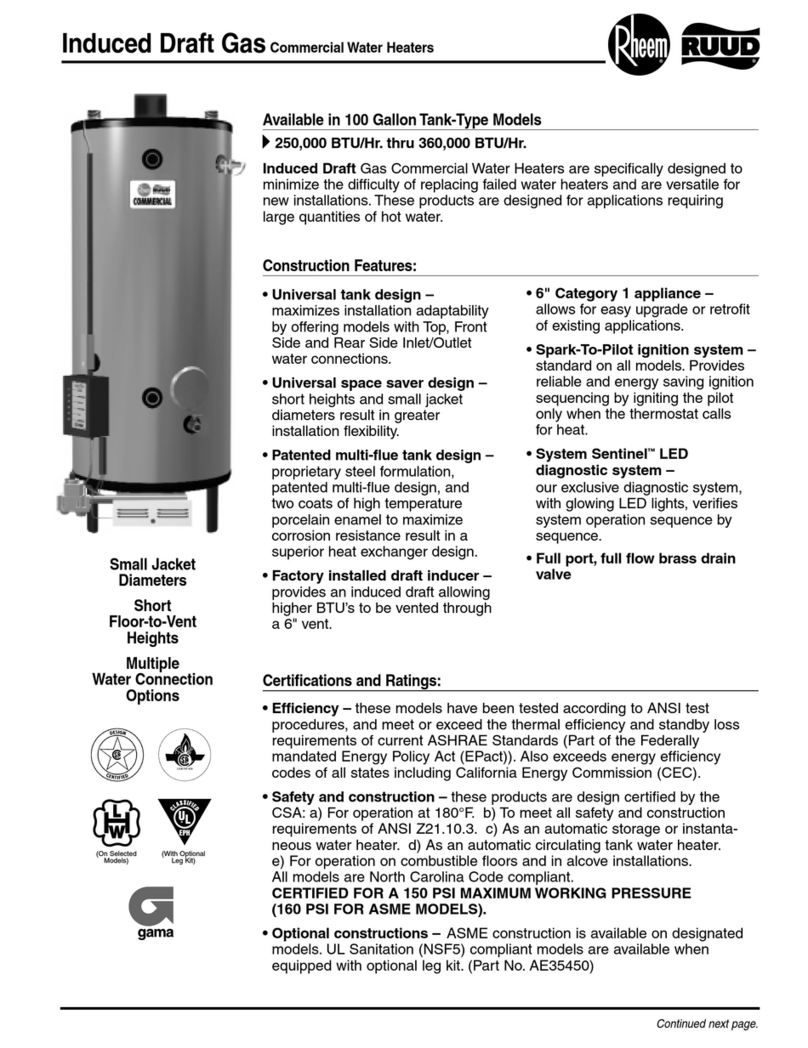

Rheem Induced Draft User manual

Rheem

Rheem 54KW User manual

Rheem

Rheem Loline 325 Instruction Manual

Rheem

Rheem 27 874 Series Technical Document

Rheem

Rheem Optima Technical Document

Rheem

Rheem RT1000C6 Technical Document

Rheem

Rheem Solar Hiline 52D180 Technical Document

Rheem

Rheem RTE 3 Technical Document

Rheem

Rheem Residential 40 & 50 Gallon User manual

Rheem

Rheem 864 Series Technical Document

Rheem

Rheem 613050 Technical Document

Rheem

Rheem Ecosense ECO-180DV User manual

Rheem

Rheem RTE 3 User manual

Rheem

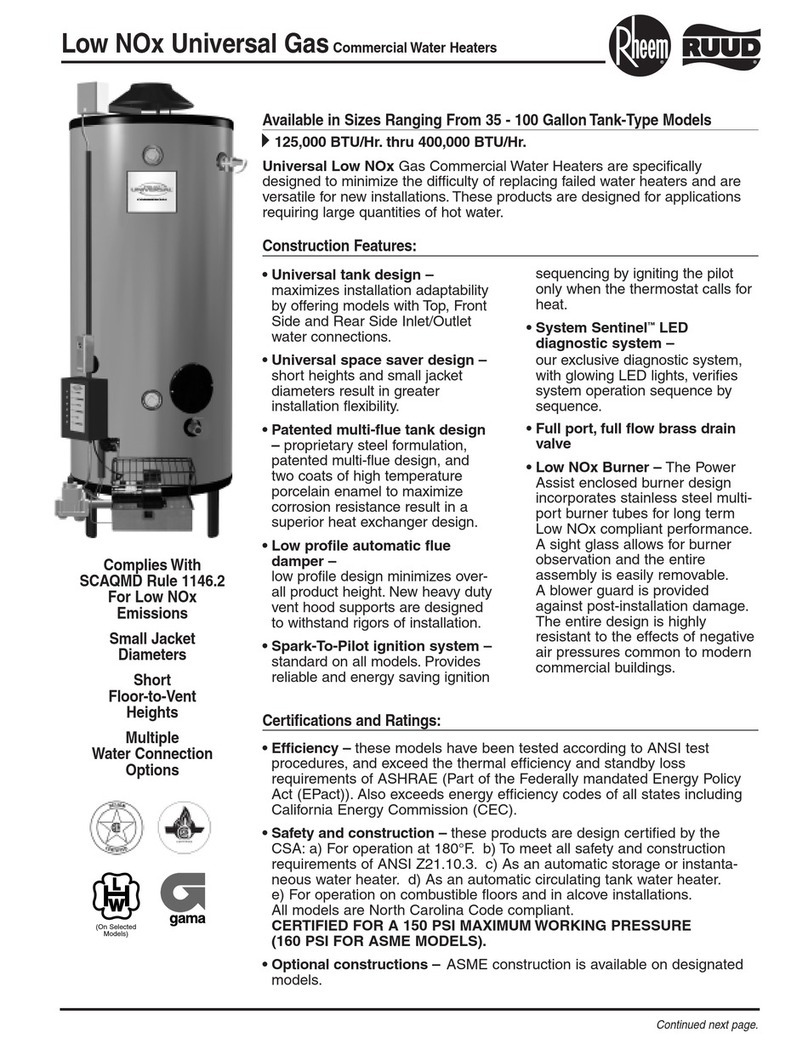

Rheem Low NOX User manual

Rheem

Rheem MHD75245 User manual

Rheem

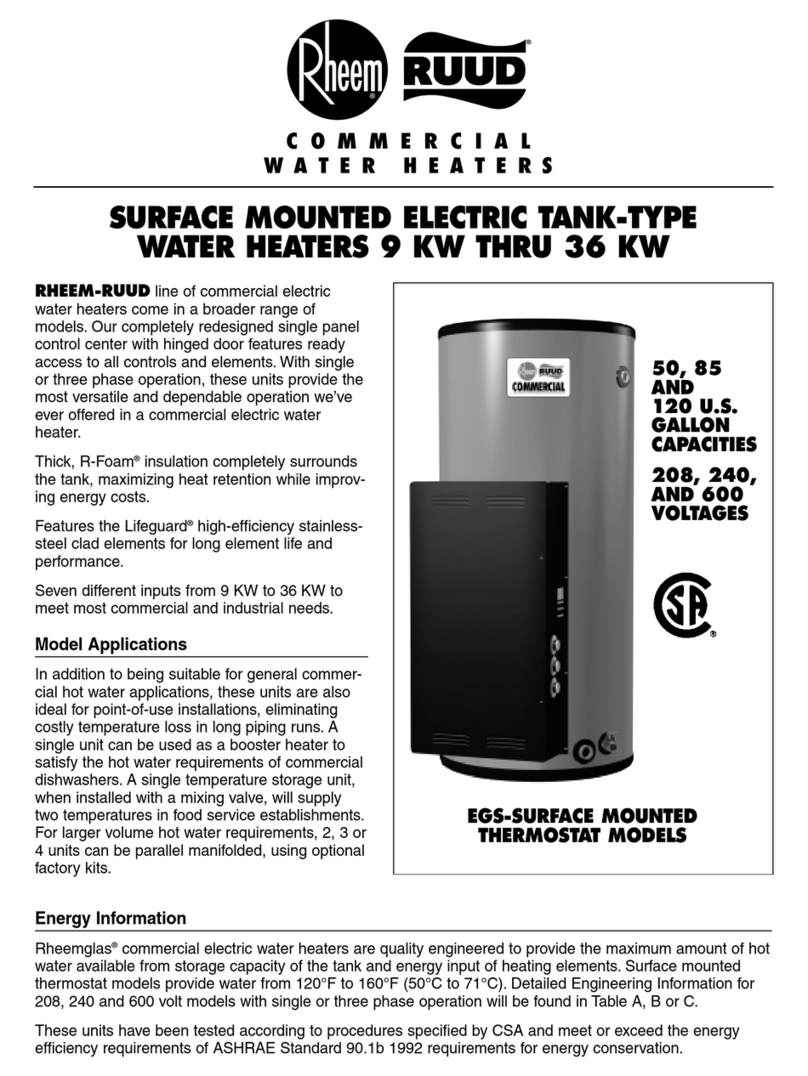

Rheem 9 Kw Thru 36 Kw User manual

Rheem

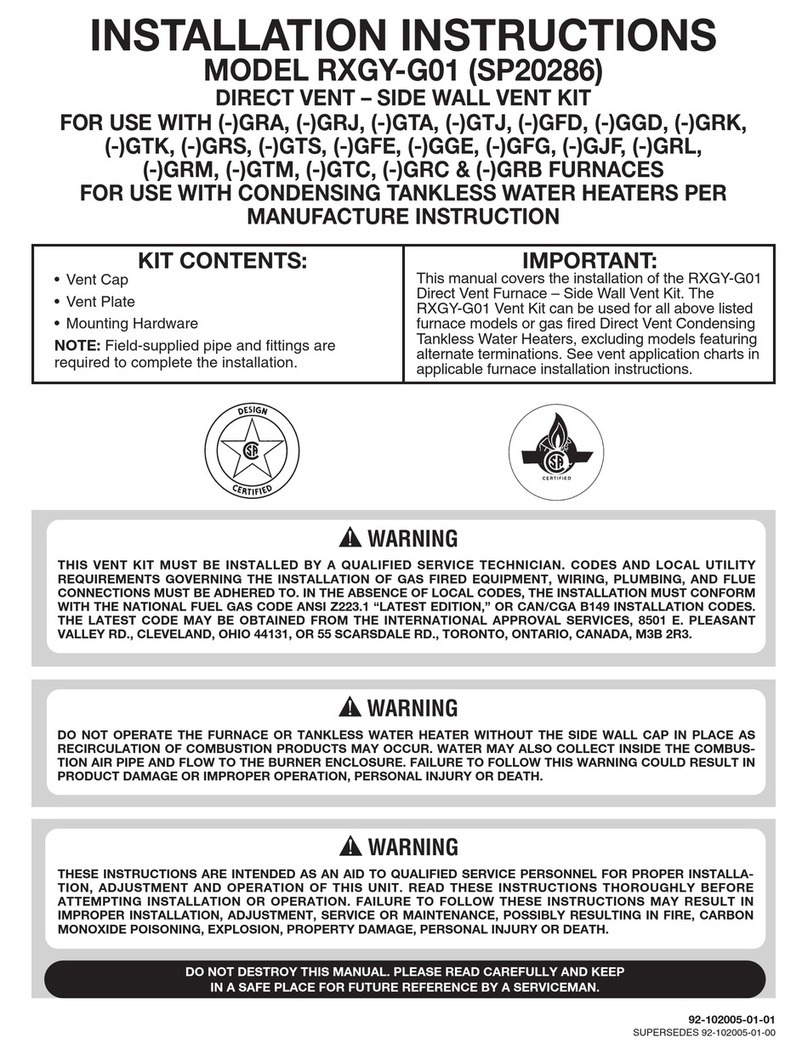

Rheem RXGY-G01 User manual

Rheem

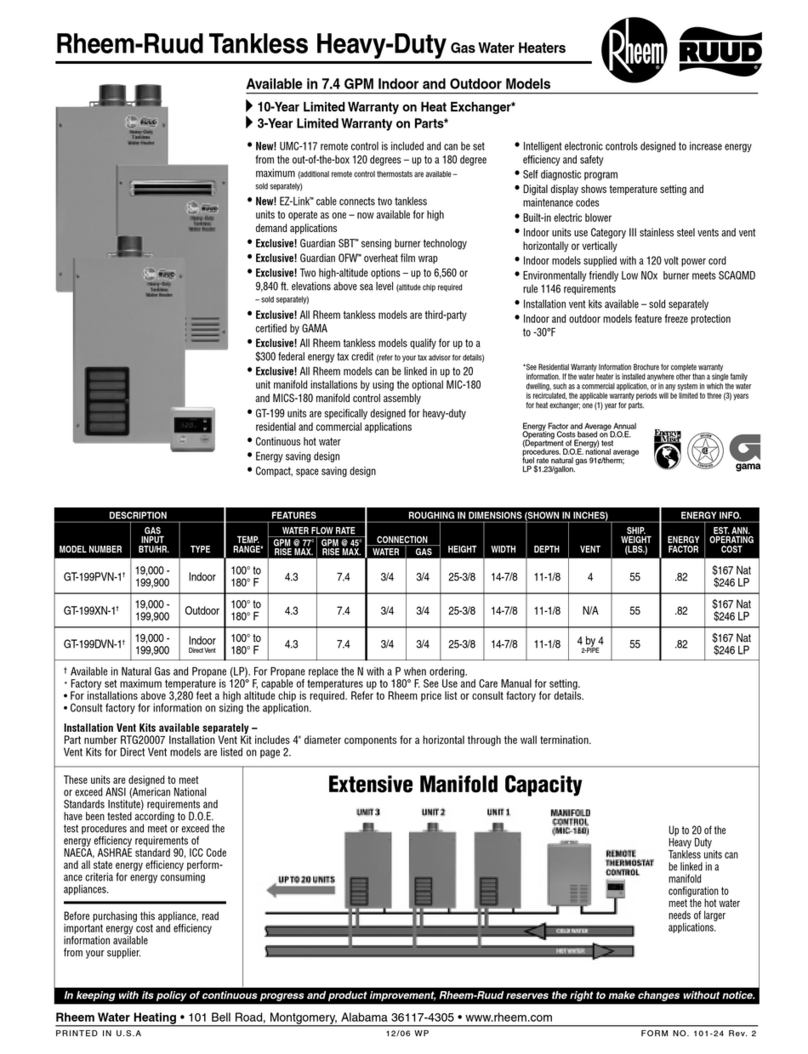

Rheem Ruud GT-199DVN-1 User manual

Rheem

Rheem Maximus User manual

Popular Water Heater manuals by other brands

TESY

TESY GCV7/4S 10047 Instructions for use and maintenance

A.O. Smith

A.O. Smith Gphe 50 instruction manual

Toyotomi

Toyotomi Oil Miser OM-148 (Type D) Operation and maintenance instructions

Koryo

Koryo KWHZF15Y user manual

Pentair

Pentair PSC-14-4-02 Installation and operation manual

GE

GE 40M06AAG Energy guide