www.rhodanmarine.comRhodan Marine Systems • 8297 Blaikie Court • Sarasota, Florida 34240 • Phone 941-706-4578 • Fax 941-706-4579 CUSTOMER SERVICE: 1-888-434-7726 1716

Batteries produce and contain harmful materials that may result in personal

injury and/or property damage if improperly used. Refer to your battery manu-

facturer’s guidelines for charging, discharging, storage and care instructions.

Be sure all switches/circuit breakers are in the OFF position and fuses are

removed when making battery connections. Failure to do so may result in

personal injury and/or property damage.

Verify that all conductors and connectors are rated for at least 50 Amperes and

36VDC, 24VDC or 12VDC (depending on model). All circuits MUST be protected

using a 50A fuse or circuit breaker in series with the positive lead. Failure to do so

may result in personal injury and/or property damage.

DO NOT connect the trolling motor batteries to any other device, including the

main outboard engine.

The HD GPS ANCHOR+ requires one 12V battery for the 12V units, two 12V battery in

series for the 24V units and three12V battery in series for the 36V units.

LUG (BASIC) INSTALLATION

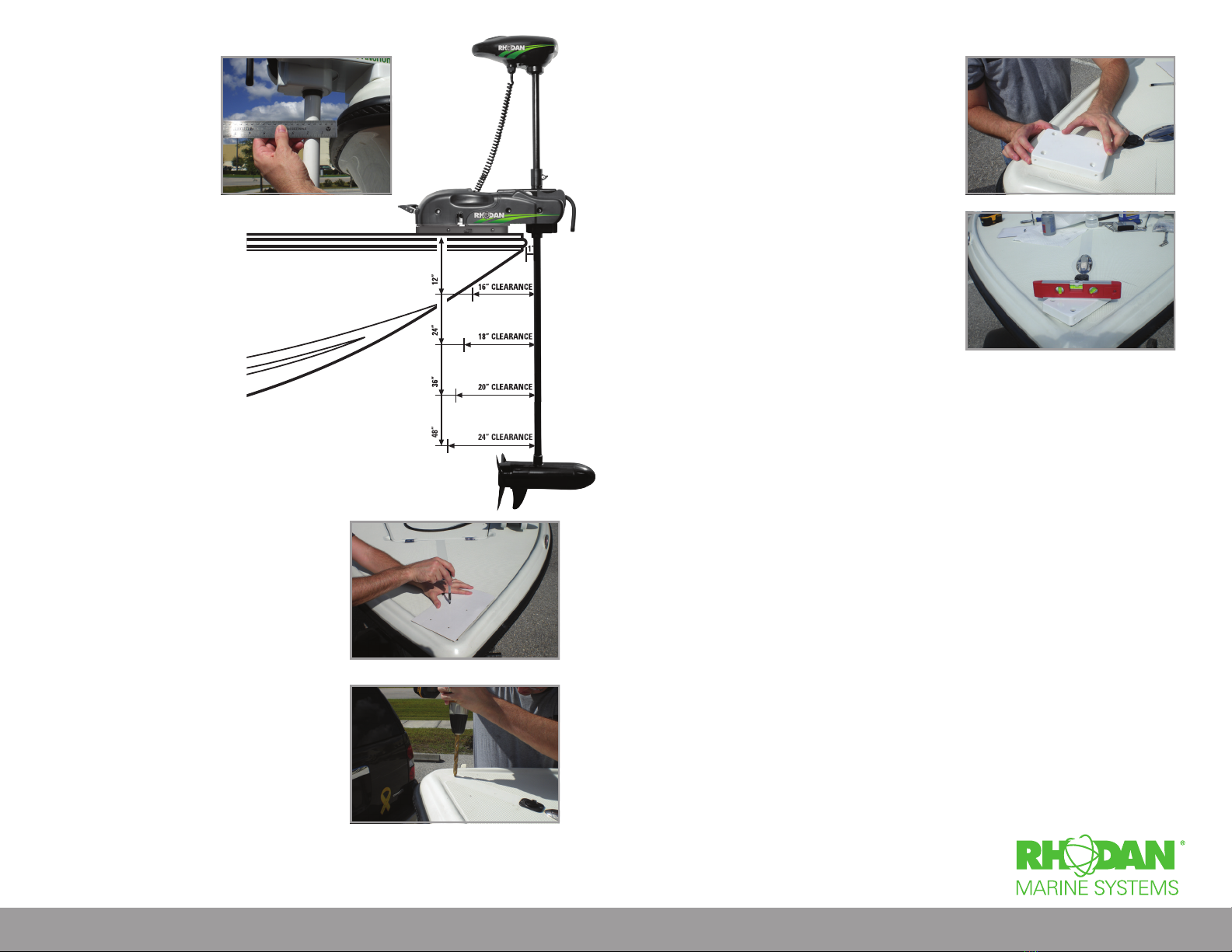

Your GPS Anchor system is provided with a factory installed 6’ power cord with 5/16”

ring terminals for connection to breaker/battery terminals or power lugs. Please

note that it is mandatory to install a fuse or breaker protection for the system circuit.

This protection should be rated for 50A, 36V, 24V or 12V (depending on model). If

you boat is already wired with a 36V, 24V or 12V (depending on model) power system

with appropriate circuit protection, simply connect the white wire to the positive lug

and the black wire to the negative lug. Should your boat use a trolling motor plug or

not have a 36V, 24V or 12V (depending on model) trolling motor circuit, please refer to

additional instructions below or contact an approved system installer.

PLUG INSTALLATION

If your boat is already wired with a 36V, 24V or 12V (depending on model) trolling mo-

tor battery system it may be necessary to install a plug on the end of the main power

conductor in order to work with your boat.

There are many different plugs on the market, but generally it is possible to obtain the

appropriate plug from your local boating supply store. Please make sure that the plug

you install is rated for 50A, 36V, 24V or 12V (depending on model). Should you have

difficulty locating the appropriate plug, please contact Rhodan Marine Systems, and

we will do our best to assist you.

APPENDIX D:

ELECTRICAL INSTALLATION

The following process is of moderate difficulty. Should you not feel comfort-

able performing the steps listed below, we recommend that you contact an

authorized installer to complete this process for you.

Once the appropriate plug is obtained, it will need to be installed on the power cord.

Depending on the location of the socket relative to your system it may be appropriate

to trim the main power conductor to a shorter length. If shortening the power cable,

be sure to leave adequate length to complete the connection to the plug and allow

for the plug to be inserted with a small amount of slack remaining. Generally you

should have 6” to 12” of slack in the cable when plugged in.

Using a volt meter, determine the positive 36V, 24V or 12V (depending on model)

and ground (negative) terminals on the socket and plug. Following the instructions

provided with the plug, connect the white power wire to the positive 36V, 24V or 12V

(depending on model) terminal and the black power wire to the negative terminal.

When complete, reinstall any fuses or turn on your circuit breaker and insert the plug

into the socket. At this point you should hear the system beep indicating that it is

getting power.

COMPLETE ELECTRICAL INSTALLATION

If your boat is not already equipped with a 36V, 24V or 12V (depending on model) bat-

tery power system it will be necessary to install one.

36 VOLT TROLLING MOTOR BATTERY SYSTEM

A 36 volt trolling motor battery system

will generally consist of three, 12 volt

deep cycle batteries, #6 (or larger for

long runs) power conductors, a 36V, 50A

rated circuit breaker, a 36V, 50A rated

receptacle, and optionally a permanently

installed 36V battery charger as per the

following wiring schematic.

24 VOLT TROLLING MOTOR BATTERY SYSTEM

A 24 volt trolling motor battery system will generally

consist of two, 12 volt deep cycle batteries, #6 (or

larger for long runs) power conductors, a 24V, 50A

rated circuit breaker, a 24V, 50A rated receptacle, and

optionally a permanently installed 24V battery charger

as per the following wiring schematic.

12 VOLT TROLLING MOTOR BATTERY SYSTEM

A 12 volt trolling motor battery system will generally consist of

a 12 volt deep cycle battery, #6 (or larger for long runs) power

conductors, a 12V, 50A rated circuit breaker, a 12V, 50A rated

receptacle, and optionally a permanently installed 12V battery

charger as per the following wiring schematic.

If you plan to attempt a complete installation yourself, please

feel free to contact Rhodan Marine Systems for additional

guidance and information.

This process is of moderate difficulty and should only be attempted by

experienced technicians. We recommend that you contact an authorized

installer to complete this process for you.