Introduction 1

1.0 Introduction

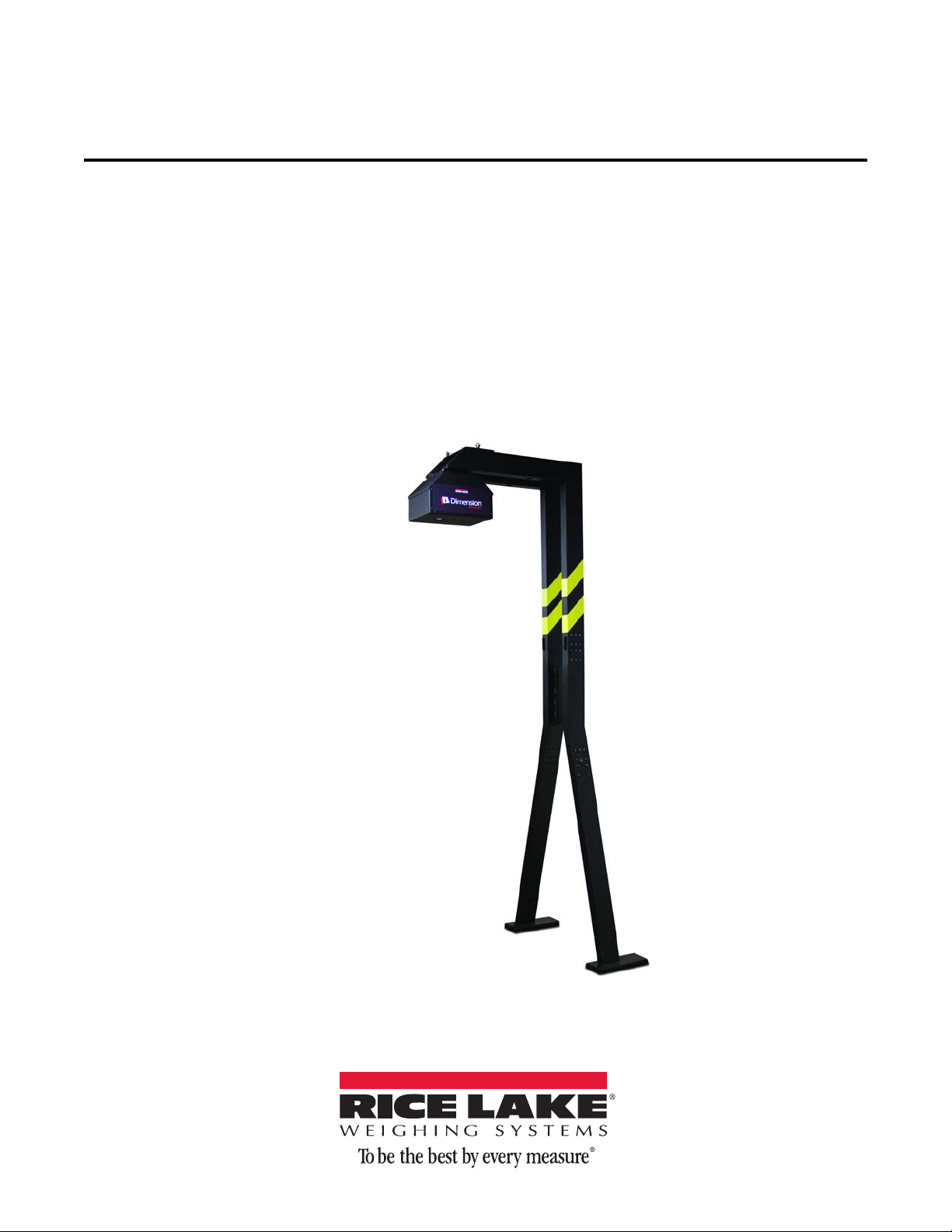

The iDimension 300 is designed to capture dimensions, bar codes and images of items placed under the scanning

head. Parcels (boxes), flats, documents and irregular shapes can be supported.

1.1 Safety

Safety Symbol Definitions:

Indicates a potentially hazardous situation that, if not avoided, could result in serious injury or death and

includes hazards that are exposed when guards are removed.

Indicates a potentially hazardous situation that, if not avoided, may result in minor or moderate injury.

Indicates information about procedures that, if not observed, could result in damage to equipment or

corruption of and loss of data.

General Safety

Do not operate or work on this equipment unless you have read and understand the instructions and

warnings in this manual. Failure to follow the instructions or heed the warnings could result in injury or

death. Contact Rice Lake Weighing Systems for replacement manuals. Proper care is your

responsibility.

Failure to heed may result in serious injury or death.

Electric shock hazard!

• For pluggable equipment the socket outlet must be installed near the equipment and must be easily accessible.

• Always disconnect from main power before performing any work on the device.

• Check the power cable for damage regularly and replace it immediately if it is damaged.

• On the side of the device, maintain a clearance of at least 1.5'' in order to prevent damage to the cable.

DO NOT allow minors (children) or inexperienced persons to operate this unit.

DO NOT operate without all shields and guards in place.

DO NOT place fingers into slots or possible pinch points.

DO NOT use this product if any of the components are cracked.

DO NOT make alterations or modifications to the unit.

DO NOT remove or obscure warning labels.

Keep hands, feet and loose clothing away from moving parts.

Do not use iDimension 300 in hazardous areas!

Do not open the scanning head!

The warranty and certification is void if this stipulation is ignored.

The device may only be opened by authorized persons.