7

2.0 DescripTion of The machine

dEscrIptIon of thE machInE

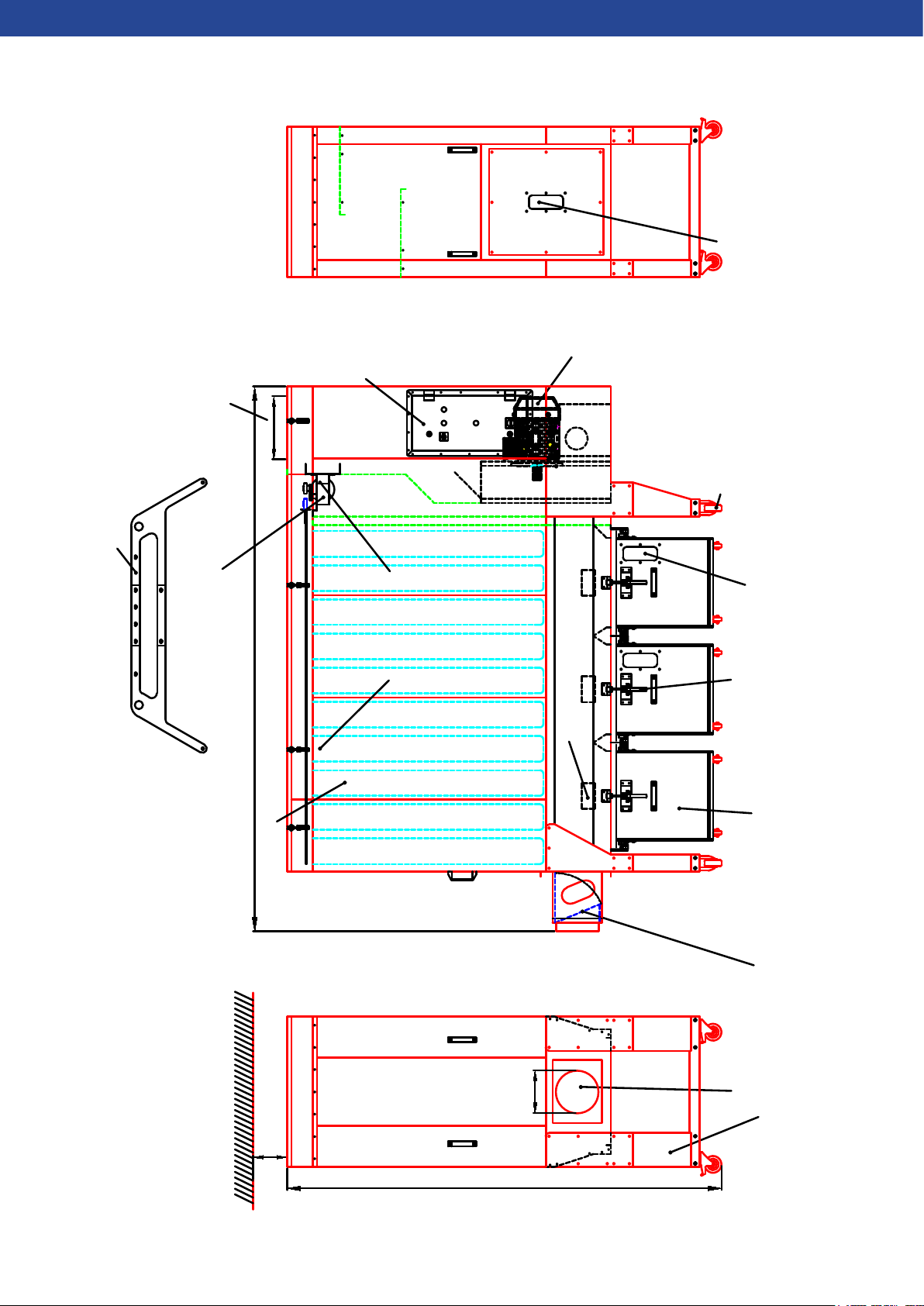

The DM-250 is a machine that can be used for the following purposes:

The extraction of non-spark-generating* woodworking machines with recirculation of the used air.

The extraction unit consists of lter sleeves with an underlying reservoir and a fan that is based

on negative pressure. The waste is collected by means of a plastic bag. This plastic bag is placed

in the waste container for use. See Figure 1.

*According to the BGI 739 standard, the following machines are dened as spark-generating: crushers, multi-blade circular

saws and broadband sanders used in chipboard, door, frame and parquet production.

Any other use of the extraction unit than descri-

bed in this manual is not permitted!

NOTE The manufacturer of the extrac-

tion unit has done everything to

provide you with a safe product.

Bear in mind that the extraction

unit is only safe if it is used cor-

rectly. Therefore, read this manual

carefully and make sure that eve-

ryone who starts using the extrac-

tion unit has done the same.

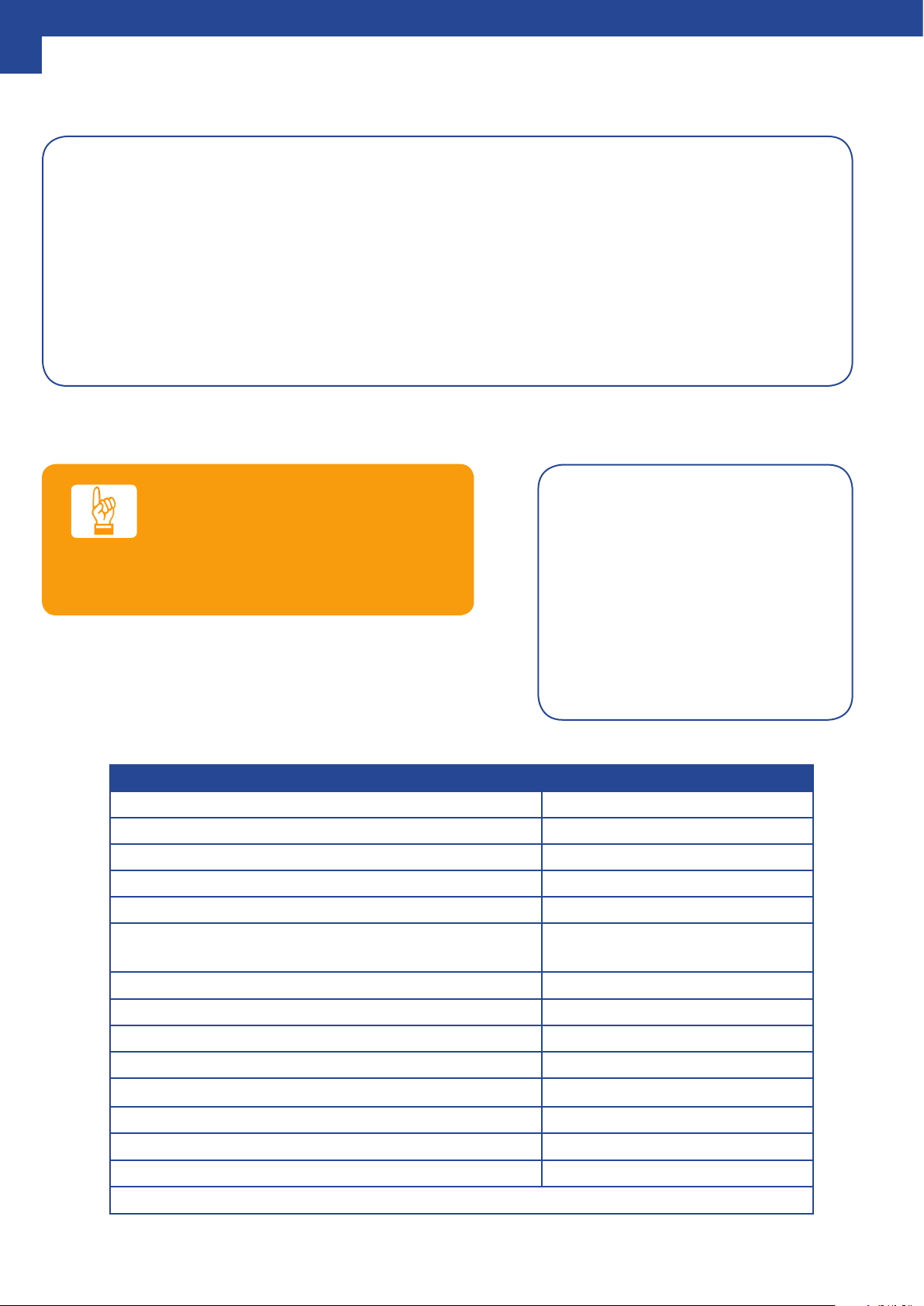

Technical data DM-250

Motor 5,5 kW

Air ow (min.) 3534 m/h

Pressure at inlet 2100 Pa

Air ow (max.) 5000 m/h

Filter area 25,4 m

Filter regeneration Automatic, oine;

option online (DM-250jet)*

Residual dust content <0,1 mg/m³

Bin volume 480 Liter

Noise level 70 dB(A)

Voltage 400V/50Hz

Current 10,5 [A]

Weight 580 kg

Dimensions (LxBxH), inlet included 3190 x 880 x 2545 mm

Inlet diameter 250 mm

* Compressed air connection required, not certied