RIGEL MEDICAL VenTest 800 Series USER MANUAL

TESTED, 9

3.1.3. Principle of flow measurement

Flowintheflowchannelisdeterminedbydifferentialpressuremeasurement.Tobuild up

differential pressure a plastic screen is used to provide flow resistance.

ƞ: dynamic viscosity of the gas [Pa s]

ρ: gas density [kg/m3]

c1, c2: device-specific constants

(channel geometry)

Dynamic viscosity

The viscosity of a medium is its resistance to the flow and shear of the current. Viscosity is

extremely dependent on temperature. The viscosity of a medium is slightly dependent on

the pressure and moisture content of the medium.

Density

Density is the unit for the mass per unit volume of the medium. Density is very dependent

on pressure and temperature.

The impact of ambient conditions is hence the reason why flow is occasionally converted to

standard conditions. (3.2 Gas standards for flow and volume measurement)

3.1.4. Special functions

Automatic battery operation in theeventofa power failure.

3.1.5. Communication interfaces

USB, RS-232 port for firmware download, remote control functions and connection to

MultiGasAnalyser OR-703 (optional), trigger input (digital) for external trigger

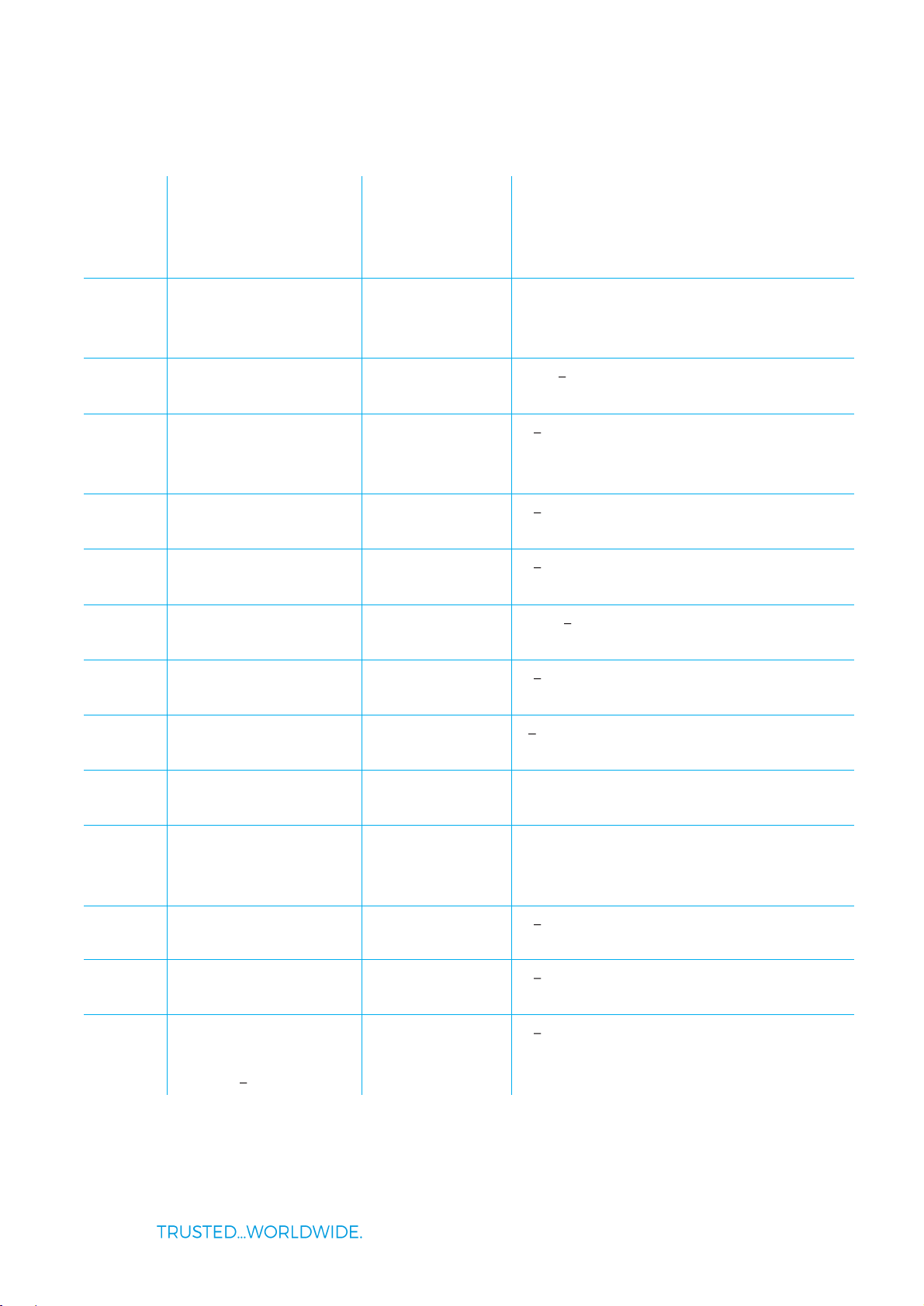

3.1.6. Physical data

Weight: 3.7 kg

Size (l × w × h): 22 × 25 × 12 cm

Gas types: Air, O2, N2O, He, N2, CO2 and mixtures: Air/O2, N2O/O2, He/O2

3.1.7. Calibration by user

Offset calibration of the pressure sensors, calibration of the oxygen sensor.

3.1.8. Operating data

Temperature: 15 40°C (59 104°F)

Air humidity: 10% 90% RH

Atmospheric pressure: 700 1060 mbar

Storage and transport conditions: -10 60°C (14 140°F) at 5 95% RH