Fax: 866.882.9475

www.raproducts.com

Instruction # 53375 Page 6 OF 8

K&A Manufacturing

6703 Zinser Street Schofield, WI 54476

Phone: 800.298.4351

Step 13: If your unit has power options, see Sheet 8.

Insert the (8) slim fix bolts 1in the kick panel 4into

the connector cams 2pre-installed in the left side

panel 5and the right side panel 6. You may need to

move the side panels slightly to align the bolts with the

cams.

Step 14: Insert the (8) slim fix bolts 1in the back panel

3into the connector cams 2pre-installed in the left side

panel 5and the right side panel 6. You may need to

move the side panels slightly to align the bolts with the

cams. Fully tighten all the camlocks in both side panels.

Important Note: When tightening the camlocks, they

will stop at a detent in the mechanism before they are

fully tightened. Be sure to tighten them past the detent.

Leveling Glide

monitor mounting plates until

Your workstation is now

ready for use.

they lock in place. See page 2.

4

5

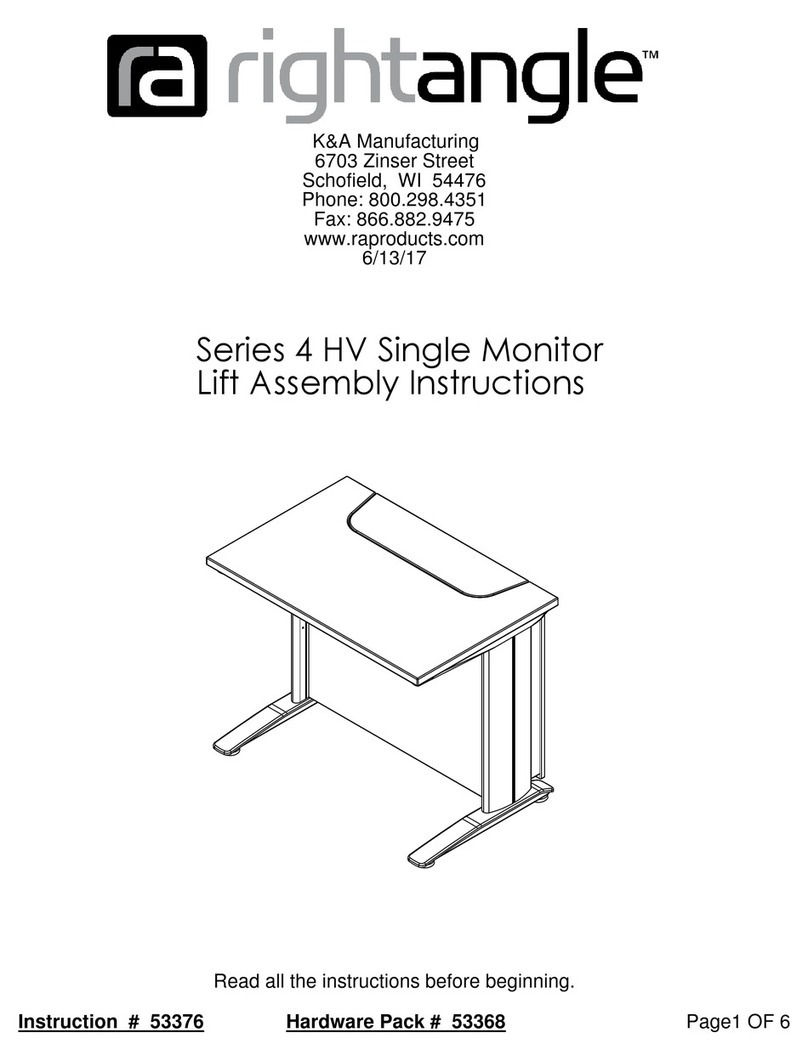

Step 15: Make sure all the

panels are square and level.

Fully tighten the machine

screws 14 holding the side

panels 5and 6to the leg

assemblies 10 and 11 .

Fully tighten the machine

screws 12 holding the leg

assemblies to the work

surface 7 .

Step 16: With the help of an

assistant, set the workstation

upright in its final location.

Level the workstation if re-

quired by turning the leveling

glides clockwise ( from the top)

on the low corners of the unit.

If your workstation has casters,

level it by turning the bolts at

the top of the casters.

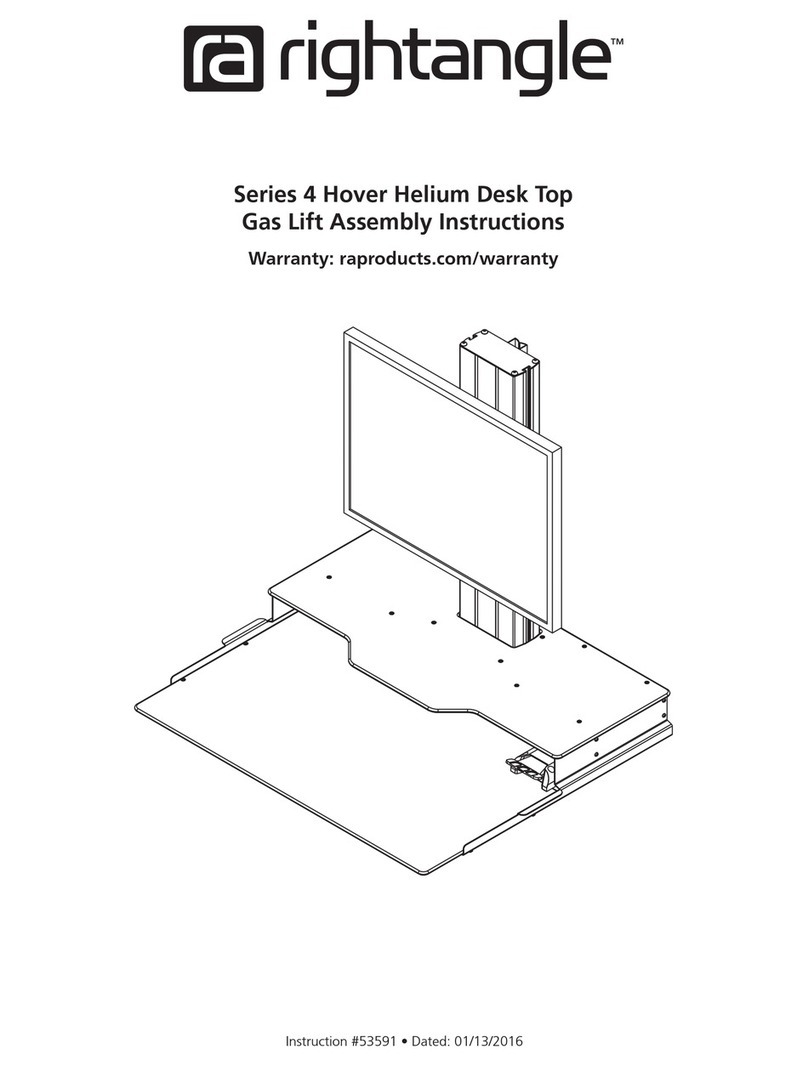

Step 17: Raise the top panels

9to their full height and slide

the monitors and the quick

connect brackets 15 onto the

6

9

14

3

12

shown for clarity.

Toe kick not

1

5

6

7

15