iii

TABLE OF CONTENTS

SEPTEMBER 2010

32DSKE02.B.1

S/K-SERIES EXPORT USE SERVICE MANUAL

Chapter Page

I. INTRODUCTION ....................................................................................................................1-1

A. RICON PRODUCT SUPPORT........................................................................................................1-1

B. RICON PRODUCT WARRANTY.....................................................................................................1-2

C. SHIPMENT INFORMATION............................................................................................................1-3

D. GENERAL SAFETY PRECAUTIONS.............................................................................................1-3

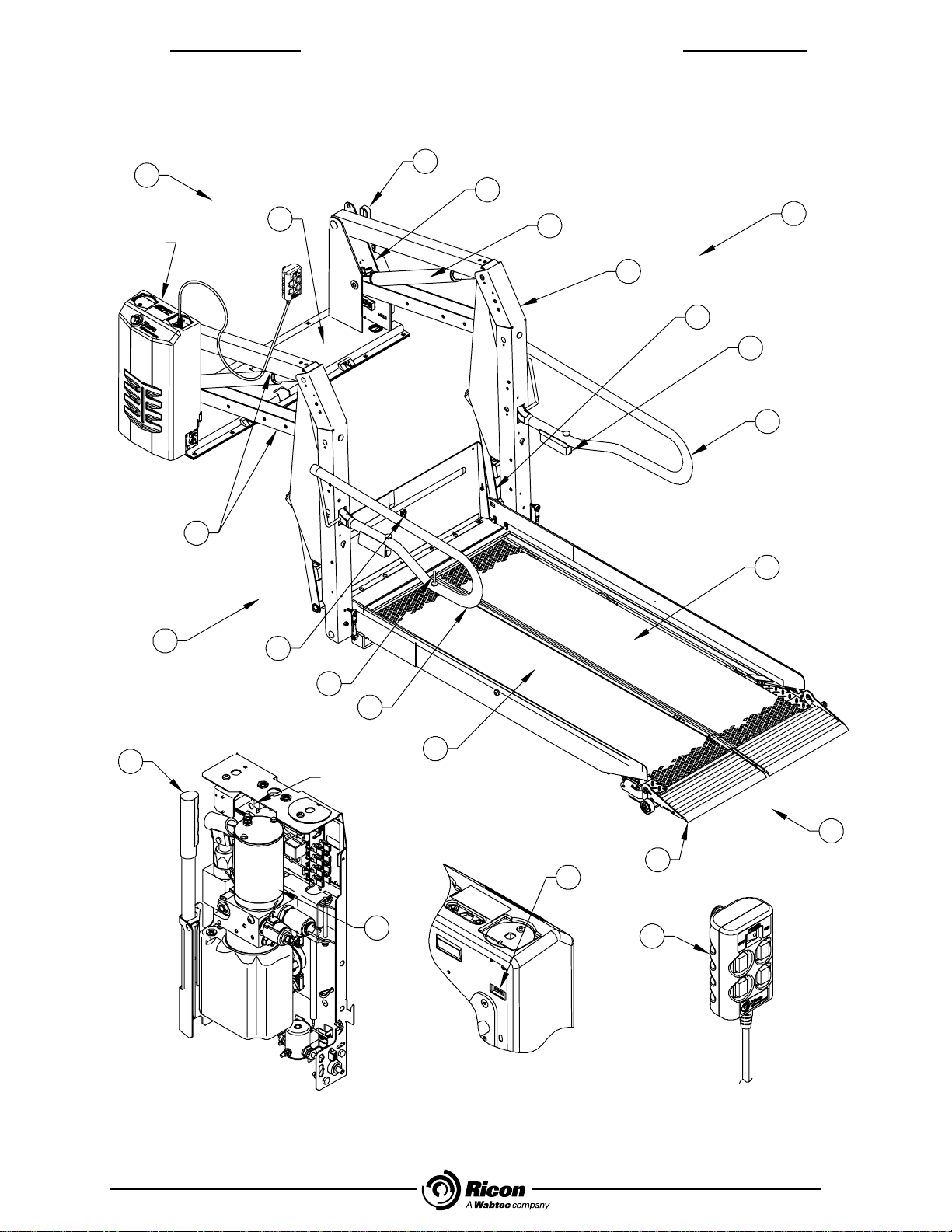

E. S-SERIES EXPORT USE MAJOR LIFT COMPONENTS...............................................................1-4

F. K-SERIES EXPORT USE MAJOR LIFT COMPONENTS ..............................................................1-6

II. INSTALLATION .....................................................................................................................2-1

A. MECHANICAL INSTALLATION .....................................................................................................2-1

1. LIFT LOCATION.........................................................................................................................................2-1

2. VEHICLE STRUCTURAL REQUIREMENTS ............................................................................................2-1

3. LIFT INSTALLATION GUIDELINES ..........................................................................................................2-1

4. LIFT INSTALLATION INTO VANS.............................................................................................................2-2

5. LIFT INSTALLATION INTO BUSES ..........................................................................................................2-5

B. ELECTRICAL INSTALLATION.......................................................................................................2-7

1. INSTALL MAIN CIRCUIT BREAKER.........................................................................................................2-8

2. ROUTE AND CONNECT MAIN POWER CABLE......................................................................................2-8

3. GROUND CONNECTIONS........................................................................................................................2-9

4. CONTROL PENDANT .............................................................................................................................2-10

5. INSTALLATION OF INTERLOCK DEVICE .............................................................................................2-11

C. FINAL ADJUSTMENTS ................................................................................................................2-12

1. LIMIT SWITCH ADJUSTMENT................................................................................................................2-12

2. PLATFORM TILT ADJUSTMENT............................................................................................................2-14

3. SPLIT PLATFORM TIE ROD ASSEMBLY INSTALLATION AND ADJUSTMENT.................................2-14.

4. K-SERIES PLATFORM FOLDING LINKAGE ADJUSTMENT.................................................................2-15

5. K-SERIES OUTER ROLLSTOP BARRIER ADJUSTMENT....................................................................2-16

6. PLATFORM PRESSURE SWITCH CHECK AND ADJUSTMENT..........................................................2-16

7. EMERGENCY RELEASE CABLE ADJUSTMENT..................................................................................2-18

D. VERIFY INSTALLATION...............................................................................................................2-19

III. MAINTENANCE AND REPAIR.............................................................................................. 3-1

A. LUBRICATION................................................................................................................................3-1

B. CLEANING......................................................................................................................................3-1

C. MAINTENANCE SCHEDULE..........................................................................................................3-2

D. TROUBLESHOOTING ....................................................................................................................3-3

1. LIFT TROUBLESHOOTING.......................................................................................................................3-3

2. LIFT TROUBLESHOOTING – ALARM WARNING INDICATOR...............................................................3-4

3. PUMP SOLENOID LED STATUS INDICATOR.........................................................................................3-5

4. BRIDGEPLATE CABLE ASSEMBLY REPLACEMENT.............................................................................3-5

5. S/K-SERIES LIMIT SWITCH STATES.......................................................................................................3-6

6. REAR SPRING REPLACEMENT ..............................................................................................................3-7

7. HYDRAULIC CYLINDER, GLAND NUT AND PISTON REPLACEMENT.................................................3-8

E. HYDRAULIC CIRCUIT DIAGRAM..................................................................................................3-9