Linear 1500 burn media installation: 13570-C | 1

Experience has shown that the majority of performance problems are caused by burn media being

installed incorrectly. Please take the time to read and follow these instructions as malfunctioning

due to incorrect burn media placement is not covered by warranty.

• The Linear MUST NEVER be used with other burn media or burn media that is damaged.

• The Linear burn media sets are dierent and cannot be interchanged, ensure you have ordered

the correct set before installation.

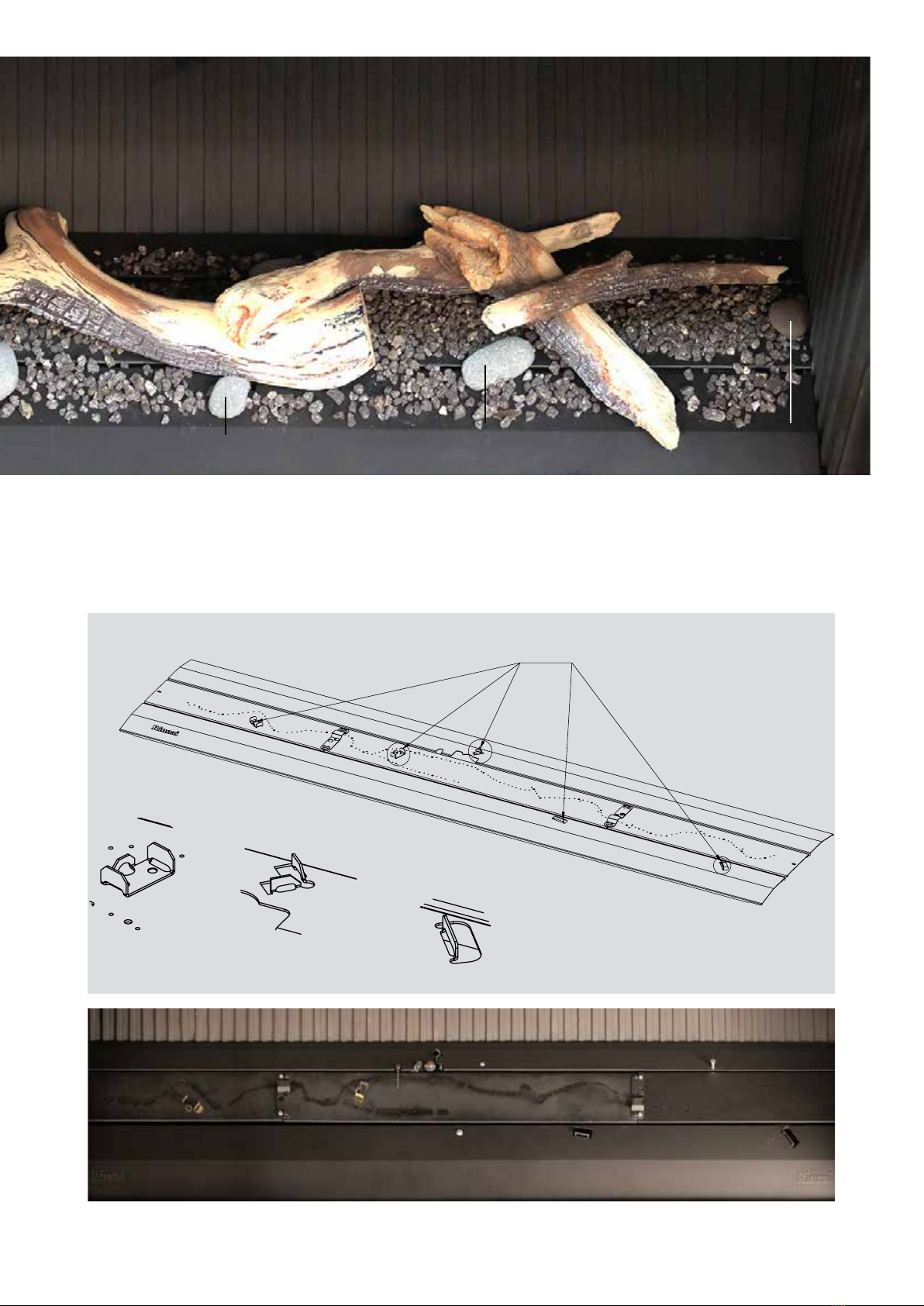

Correct placement

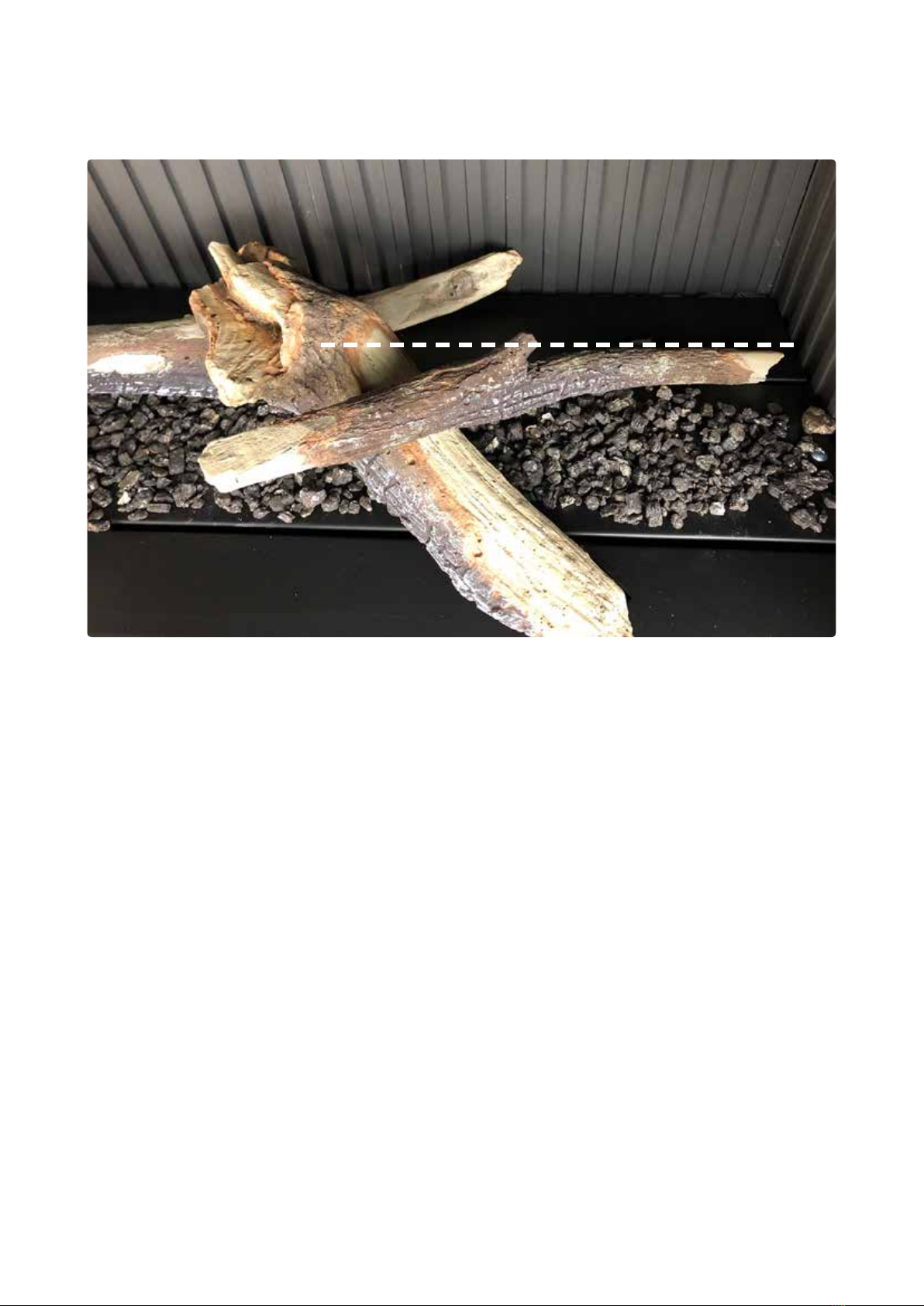

It is important to place the burn media in the correct position. Incorrect placement can create

carbon build-up and aect performance.

Single-sided/double-sided

When installing the burn media you will ALWAYS be working on the side where the pilot assembly

is to the back of the rebox.

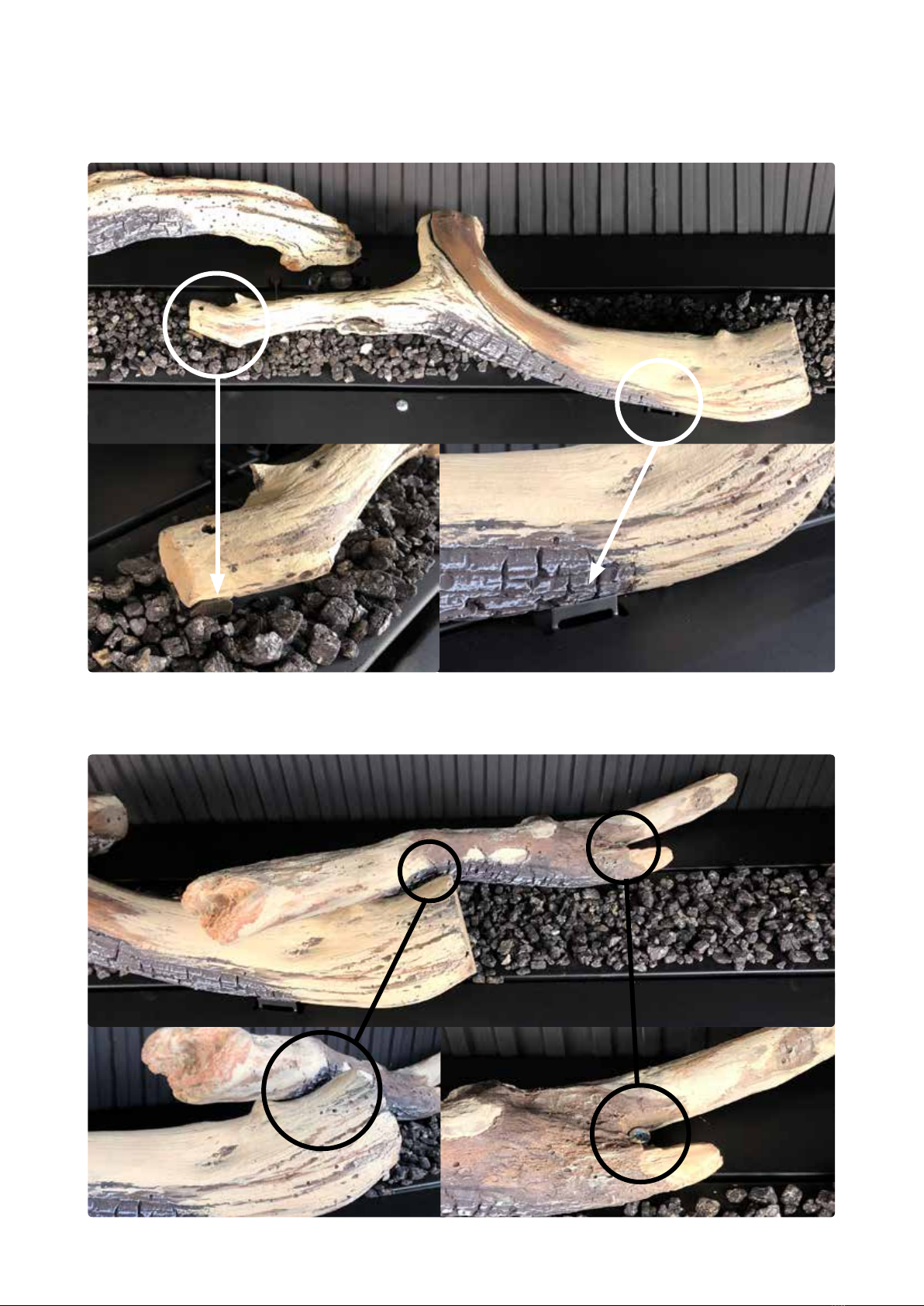

R2903 Linear 1500 driftwood log set kit contents

Part number Description Quantity

13044 Vermiculite 1 bag (approx. 0.75 L)

13476 Wire wool (glowing ash) 1 bag (approx. 3 g)

13480 Log set A and stone set14 logs and 9 stones

13481 Log set B 3 logs

1Log set A and stone set come packaged in the same box

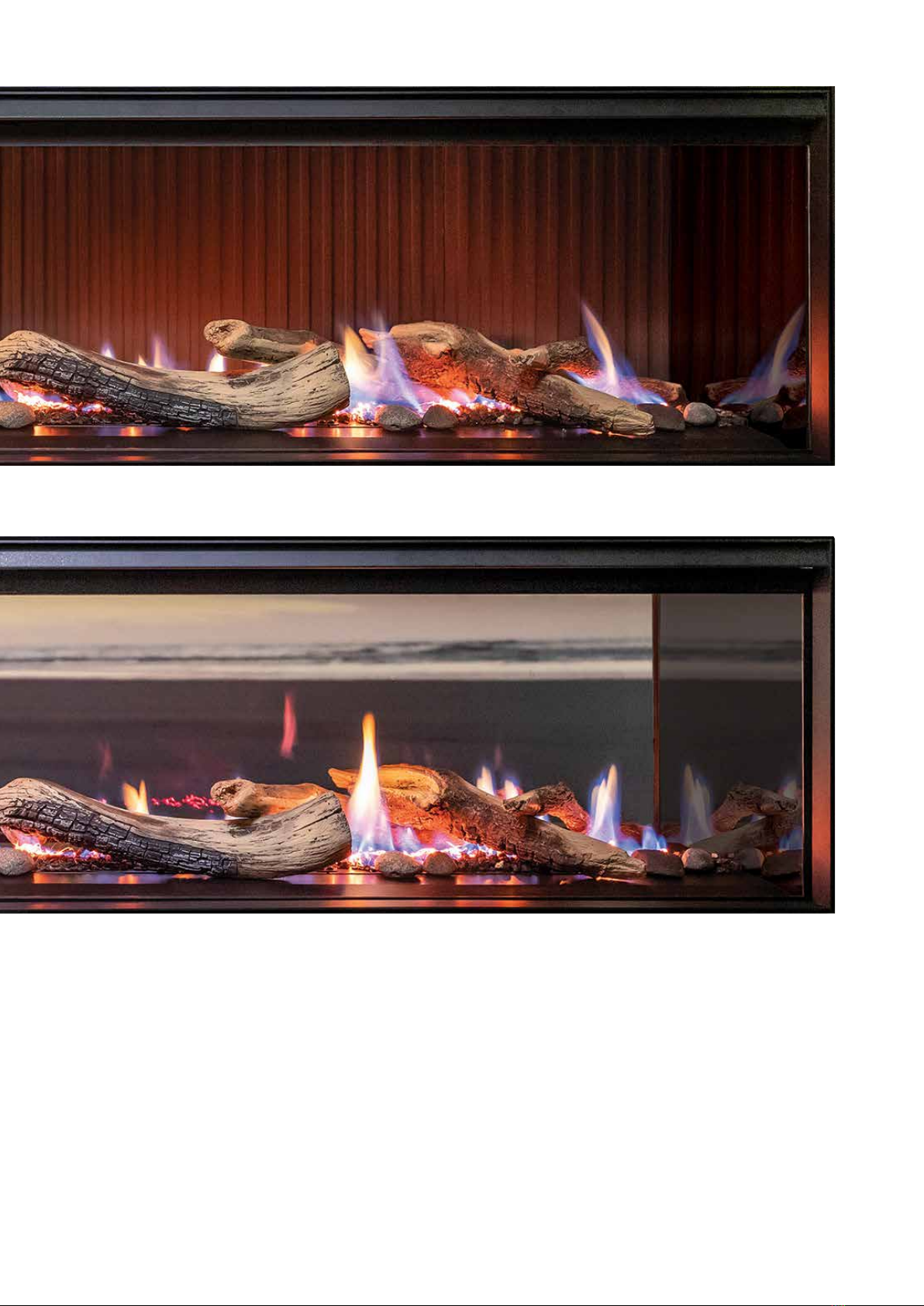

R2905 Linear 1500 modern media kit contents

Part number Description Quantity

13473 Crushed black glass 3 bags (approx. 3.5 kg)

13476 Wire wool (glowing ash) 1 bag (approx. 3 g)

Linear 1500

Burn media installation

Ensure the gaps between the burners are kept clear of any vermiculite or crushed glass. This is

important as these gaps provide secondary air to the unit.

A tip to stop any burn media going into the gaps is to place the installation guide in the burner

gap while placing the vermiculite or crushed glass over the burner.

Important