Rio Grande Sentry Express User manual

Sharing your passion for making jewelr

y.

Products. Service. Know-how.

800.545.6566 www.riogrande.com

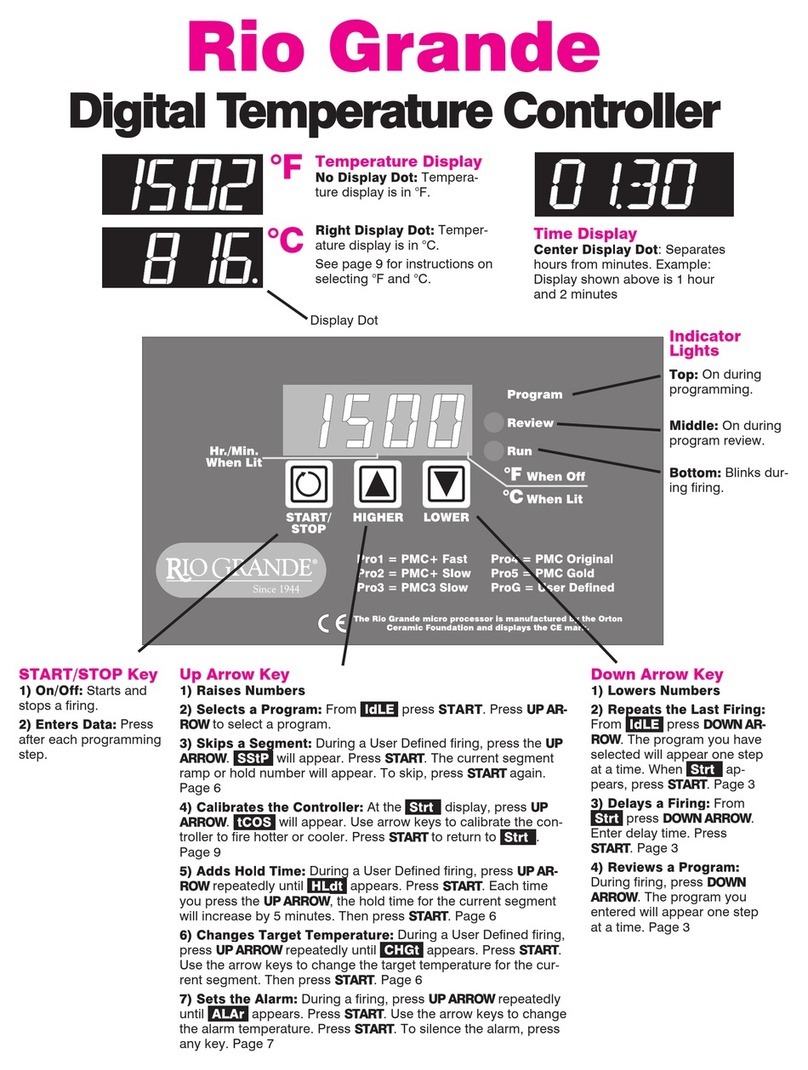

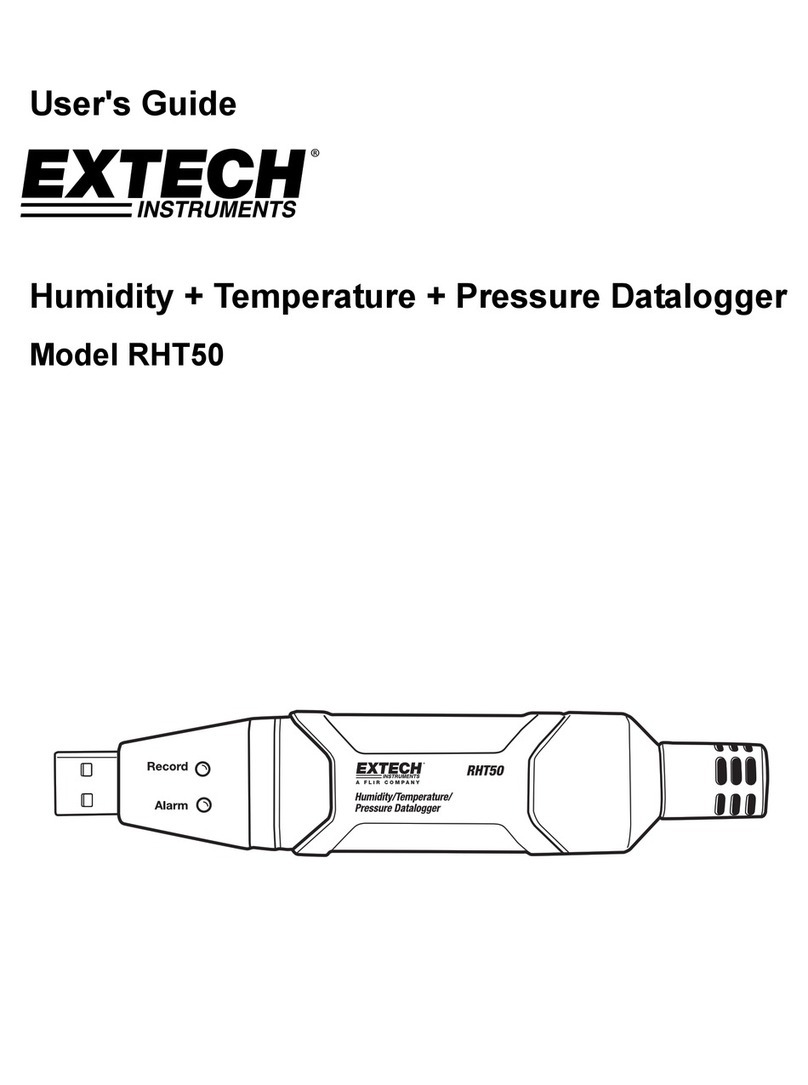

Sentry Express Digital Temperature Controller

Temperature Display

No Display Dot: Temperature

display in °F.

Right-Hand Display Dot:

Temperature display is in °C. See

page 7 for instructions on select-

ing °F or °C.

START/STOP Key

1) On/O : Starts and

stops a ring.

2) Enter Data: Press after

each programming step. It

works like the Enter key on

a computer.

Down Arrow Key

1) Lowers Numbers

2) Reviews a Program:

From IdLE or during ring,

press Down Arrow. The

program you have selected

will appear one step at a

time.

3) Delays a Firing: From

Strt press Down Arrow.

°F

°C

°C Display Dot

Time Display

Center Display Dot: Sepa-

rates hours from minutes.

Example: Display shown above is

1 hour and 30 minutes.

Indicator

Lights

Top: On during

programming.

Middle: On

during program

review.

Bottom: Blinks

during ring.

Up Arrow Key

1) Raises Numbers

2) Select a Firing Mode:

From IdLE press START.

Press Up Arrow to select

Single-Speed or Ramp-

Hold.

3) Skips a Segment:

During a Ramp-Hold ring,

skips to next segment.

After pressing the Up

Arrow, SStP will appear. To

skip, press Up Arrow again.

Courtesy of:

Paragon Industries, L.P.

800.545.6566 www.riogrande.com

Sentry Express Digital Temperature Controller 2

Sharing your passion for making jewelry.

Products. Service. Know-how.

Contents

General Guidelines .....................................................3

Time and Temperature Display .....................................................3

Operation Begins from the IdLE Display ....................................3

Thermocouple Inspection ..............................................................3

A Rapid Way to Scroll Numbers ....................................................3

Program Review & Repeat Firing ..................................................3

Delay .......................................................................................................3

Power Failures .....................................................................................4

CPLT Message: Firing Completed .................................................4

Thunder Storms and Power Surges .............................................4

Theory of Operation ...................................................4

Rate .........................................................................................................4

Hold.........................................................................................................5

Two Firing Modes: Single Segment and Ramp-Hold ............5

Single Segment Programming Instructions .............................5

Temperature Over-Shoot ................................................................6

Ramp-Hold Mode .......................................................6

Repeat Firings ......................................................................................6

Programming a Cooling Segment ...............................................6

A Ramp-Hold Practice Program ....................................................7

Skipping a Segment in a Ramp-Hold Program .......................7

Ramp-Hold Programming Instructions......................................7

Lost Wax Burnout .......................................................8

Overview ...............................................................................................8

A Sample Program .............................................................................8

Burnout Instructions .........................................................................8

Error Messages............................................................9

bAdP/Bad Programming .................................................................9

EtH/Electronics Too Hot ...................................................................9

FaIL/Thermocouple Failure .............................................................9

TCR/Thermocouple Reversed ........................................................9

FtL/Firing Too Long ...........................................................................9

PF 1/Power Failure .............................................................................9

PF 2/Power Failure .............................................................................9

tC/Thermocouple Failure ................................................................9

Selecting °F or °C Display ...........................................9

Display Messages .................................................... 10

Trouble Shooter ....................................................... 10

Problem: Controller display is blank. No heat in kiln ......... 10

Problem: Controller display turns on. No heat in kiln ........ 11

Problem: Kiln switch box ½ amp fuses keep blowing ....... 11

Safety

The warranty on your Sentry Xpress controller

does not cover damage from overring, regard-

less of the circumstances. It is the operator’s

responsibility to make sure the kiln turns o at

the proper time.

• When the kiln is not in use, disconnect the

power.

• Do not leave the kiln unattended, especially near

the expected shut-o time.

• Wear ring safety glasses when looking into the

ring chamber of a hot kiln.

• Do not touch hot sides of kiln. Keep unsuper-

vised children away.

• Install your kiln at least 12 inches from any wall

or combustible surface.

• Do not open lid or door until kiln has cooled and

all switches are o.

• Fire only in a well-ventilated, covered and pro-

tected area away from combustible materials.

• Keep cordset away from hot sides of kiln or fur-

nace.

• DANGEROUS VOLTAGE! Do not touch heating

elements with anything. Disconnect before ser-

vicing.

©2004, by Paragon Industries, L.P. IM-221/10-04

General Guidelines

Time and Temperature Display

Center Dot: Time

A center dot appears during

time display. It separates hours

from minutes (i.e. 1 hour, 30

minutes displays as 01.30).

During temperature display, the

dot disappears.

Right-Hand Dot: °C

When temperature is dis-

played in °C, a dot appears in

the lower right. In °F display,

it disappears. You can choose

between Fahrenheit and

Celsius display. See page 9.

Operation Begins from the IdLE Display

IdLE must appear before you can re the kiln

If CPLt, STOP, or other message appears instead of

IdLE when the kiln is rst turned on, press the START/

STOP key (the key with the circular arrow). IdLE will

appear.

If you press the START/STOP during a ring, STOP

will appear. To get back to IdLE, press START/STOP

again.

If the display shows an error message such as FaIL

instead of IdLE, see page 9.

CPLt ( ring completed ) appears at the end of a

ring. To make IdLE appear, press START/STOP.

Thermocouple Inspection

The small rod protruding into the firing chamber is the

temperature sensor, or thermocouple.

CAUTION: Bumping the thermocouple can push it out

of the firing chamber. This could cause an overfire! The

controller does not contain an alarm to detect this type

of failure. Bumping the thermocouple could also cause

inaccurate readings.

A ⅛” thermocouple should extend into the firing

chamber ½” - ⁄”.

A ¼” thermocouple should extend into the firing

chamber ¾” - 1” or more.

Keep shelves, posts and ware 1” - 1½” away from the

thermocouple.

A Rapid Way to Scroll Numbers

During programming, hold an arrow key down several

second, and the numbers will begin to scroll rapidly.

Ordinarily, you would press Up Arrow to raise a number

and Down Arrow to lower it. But sometimes it is faster

to press the opposite key. This is because the numbers

scroll below 0000 to the highest number, and vice versa.

Examples:

To program a 99.59 hour Hold when the display

shows 00.00, press the Down Arrow once.

To program a FULL rate when the display shows 0000,

press the Down Arrow once.

To program a temperature of 200°F when the display

shows 1800°F, press the Up Arrow. That is faster than

pressing the Down Arrow.

Program Review & Repeat Firing

Program Review lets you check that the information

programmed into the controller is correct. It is a good

habit to use Program Review before every firing. Program

Review shows the values for the program in active

memory, which is either—

The program that was fired last.

The program that was selected since the last firing.

Program Review during firing: Press the Down

Arrow key. The rate, temperature, hold, etc. will dis-

play one after the other. Firing will continue.

Program Review from IdLE: Press the Down Arrow

key. After rate, temperature, hold, etc., Strt will

appear. Press START/STOP. -On- will appear, and the

kiln will begin ring the program just reviewed.

Delay

Delay is a count-down timer. The kiln begins firing

when the timer runs out of time. Use Delay to fit a firing

into your schedule.

CAUTION: For safety, do not leave the kiln alone during

the delay or a firing. We cannot guarantee your kiln

against overfiring even though the controller is auto-

matic.

1. After you have entered a program and the controller

is ready to begin firing, Strt will appear.

2. Press the Down Arrow key once. dELA will appear,

alternating with 00.00.

3. Use the arrow keys to enter delay time. (The decimal

separates hours and minutes. Example: 1 hour and

10 minutes = 01.10. Then press START. dELA will

appear, alternating with time left until the firing

begins.

800.545.6566 www.riogrande.com

3 Sentry Express Digital Temperature Controller

Sharing your passion for making jewelry.

Products. Service. Know-how.

°F

°C

The center display dot

indicates time instead of

temperature.

800.545.6566 www.riogrande.com

Sentry Express Digital Temperature Controller 4

Sharing your passion for making jewelry.

Products. Service. Know-how.

Power Failures

After a power failure, the controller will con-

tinue firing provided that:

The kiln temperature is above 212°F/100°C when the

power comes back on.

The temperature dropped no more than 180°F/100°C

while the power was off.

Power Failure Messages

PF 1 The power failed during firing, and tempera-

ture dropped more than 180°F/100°C.

PF 2 The power failed during firing, and kiln tem-

perature was below 212°F/100°C when the power came

back on.

CPLT Message: Firing Completed

When the firing has success-

fully completed, the Sentry

Xpress will shut off power to

the elements. Then three mes-

sages will cycle one after the other:

1. CPLT (complete)

2. Firing time in hours and minutes

3. The current kiln temperature

Thunder Storms and Power Surges

Unplug the kiln or disconnect the power when the

kiln is not in use, especially during thunder storms and

in areas with frequent power surges. If the kiln is part

way through a firing when a storm begins, it is probably

okay to continue the firing with close supervision. Do

no leave the kiln unattended.

Theory of Operation

The temperature you are firing to is called the target

temperature. After the controller reaches the target

temperature, it can also hold that temperature.

The controller fires at a controlled heating rate. The

rate is figured in degrees per hour. If you selected a rate

of 100° per hour, it would take 10 hours for the kiln to

reach 1000°. Rate is similar to “miles per hour.”

In summary, the controller does three basic tasks:

1) It fires at a controlled heating rate, or speed, mea-

sured in degrees of temperature change per hour.

2) It fires to a target temperature.

3) It can hold the target temperature.

The controller fires in segments, or stages. A segment

is a given heating rate to a target temperature. Shown

above is a segment with a rate of 625°, a target tem-

perature of 1250°, and a hold of one hour.

Heating rate is figured in degrees per hour. The rec-

ommended heating rate for the material you are firing

is usually available from your supplier. It also varies

depending on the thickness of the material.

To figure how long a firing segment will take, subtract

the current temperature from the target temperature

and divide the resultant temperature by the heating

rate. In the diagram above, the firing time is 1250° - 80°

(room temperature) = 1170 ÷ 625 = 1.87 hours.

The controller can fire up to 8 segments pre firing.

One segment is often all that is needed, though.

After the controller has finished firing the last seg-

ment, it will turn off power to the elements.

Rate

Each segment must include a rate, which is degrees

of temperature change per hour.

The kiln will fire at full power when the rate is

1799°F/999°C. Full power displays as FULL.

Note: To enter full power from 0000, press the Down

Arrow key once.

CPLT Message: Firing Completed

Parts of a Segment

500°

1500°

2000°

1000°

21 3 4

Ramp

Hold

“Ramp” means to

raise or lower the

temperature.

“Hold” means to

maintain a

temperature.

This segment will reach the target temperature of 1250° in 2 hours, then

hold that temperature for 1 hour.

Rate = Firing Speed

500°

1500°

2000°

1000°

21 3 4

Rate = 1000° per hour

Rate = 500° per hour

Rate = 333° per hour

Hours

Rate is gured in degrees per hour

Hold

Hold maintains a steady temperature for the length of

time you specify. You can use Hold in both heating up or

cooling down segments.

When Hold is set to 99.59 hours, the controller will

remain at that temperature indefinitely, until you press

STOP. To enter 99.59 hour Hold, press the Down Arrow

once from 00.00 during programming.

Note: During firing, the display shows Hold temperature

and time left in Hold.

Two Firing Modes: Single

Segment and Ramp-Hold

To give you greater flexibility, your controller has two

firing modes:

Single Segment Mode (see next column)

Often times, all you will need is one segment that

includes rate (temperature change per hour), a target

temperature, and (if needed) hold time.

In Single Segment mode, you can choose one of five

firing speeds. Then enter the temperature you are firing

to.

Ramp-Hold Mold (see page 7)

Ramp-Hold mode offers much greater flexibility than

Single Segment mode. Use Ramp-Hold to create a cus-

tom firings with up to 8 segments. The controller can

store 4 Ramp-Hold programs in memory. Programs are

numbered 1 - 4.

Type of Firing Suggested Firing Mode

Enameling Single Segment

Silver Clay Single Segment

Glass Bead Annealing Ramp-Hold

Glass Fusing Ramp-Hold

Glass Slumping Ramp-Hold

Lost Wax Ramp-Hold

How to Select a Firing Mode

1. From IdLE display, press START/STOP once.

2. Press the Up Arrow key several times. You will see

the following display messages:

SPd1:

Single Segment 1 / 200°F/111°C rate per hour

SPd2:

Single Segment 2 / 500°F/277°C rate per hour

SPd3:

Single Segment 3 / 1000°F/555°C rate per hour

(List continues on next page.)

Single Segment Programming Instructions

Note: Single Segment firing is all you will ever need

if you are only going to a temperature and holding.

1. From IdLE, press START.

2. Use the Up Arrow key (not the Down Arrow)

to select a firing rate (temperature rise pre

hour) from 1 through 5.

SPd1 / (200°F or 111°C)

SPd2 / (500°F or 277°C)

SPd3 / (1000°F or 555°C)

SPd4 / (1500°F or 833°C)

SPd5 / (Full Power)

Then press START.

3. °F or °C and the target temperature from

the last firing will appear. Use the arrow keys

to change the target temperature. Then press

START.

4. HLd and the hold time from the last firing will

appear (e.g. 1 hour, 10 minutes = 01.10). Use

the arrow keys to change the hold time. Then

press START.

5. Strt will appear. Press START to begin firing.

-On- will appear, the Run indicator light will

begin blinking, and the kiln will begin firing.

To stop a firing before completion, press START/

STOP. StOP will appear, alternating with kiln tem-

perature and total firing time.

Note: Do not be concerned if your kiln makes a

clicking sound during firing. Kilns use relays to

power the elements. The relays click each time their

electrical contacts come together.

Note: The firing speed you select (see step 2) is a

pre-programmed speed. The kiln’s actual firing

speed may be less, depending on the kiln model,

available voltage, and density of the load you are

firing.

When the kiln fires to completion, the controller

will beep for 30 seconds. The display will show the

following:

Firing time

Present temperature

CPLt = Fired to completion

To return to IdLE , press START.

800.545.6566 www.riogrande.com

5 Sentry Express Digital Temperature Controller

Sharing your passion for making jewelry.

Products. Service. Know-how.

800.545.6566 www.riogrande.com

Sentry Express Digital Temperature Controller 6

Sharing your passion for making jewelry.

Products. Service. Know-how.

SPd4:

Single Segment 4 / 1500°F/833°C rate per hour

SPd5:

Single Segment 5 / Maximum rate

PrO1:

Ramp-Hold, Program 1

PrO2:

Ramp-Hold, Program 2

PrO3:

Ramp-Hold, Program 3

PrO4:

Ramp-Hold, Program 4

(To get back to IdLE , press START/STOP several times

until IdLE appears.)

Temperature Over-Shoot

When a kiln is heated too fast, it may over-shoot the

target temperature, especially in small kilns at lower

temperatures. To avoid this, add an extra segment in a

Ramp-Hold program to slow the firing. The segment

with the slower rate should begin approximately 40° -

60° below the target temperature.

Ramp-Hold Mode

You can make your own firing programs and store

them in the controller’s memory. A firing program tells

the kiln how fast to fire, and to what temperature. The

simplest program is one segment. You can use up to

eight segments with your controller in Ramp-Hold

mode.

Each segment includes a firing rate and firing tem-

perature. You can also soak, or hold, the temperature for

a specified period. Each segment stores three details:

rate (temperature change in degrees per hour)

target temperature

hold at the target temperature (not always used)

The controller can retain four programs in memory

even when power is turned off. Programs are numbered

1 - 4.

The first message to appear after you plug in your

Sentry Xpress is IdLE. Press START. Then use the Up

Arrow key to scroll through these messages: PrO1 PrO2

PrO3 PrO4 SPd1 SPd2 SPd3 SPd4 SPd5.

To use Ramp-Hold mode for the rst time, select PrO1.

You do that pressing the START key after PrO1 appears.

Then follow the boxed instructions on page 7 to enter

temperature, heating rate, etc.

PrO1 is Program 1. When you re the kiln again, you

can repeat Program 1 by selecting PrO1. When you are

ready to re a dierent program, select PrO2, which is

Program 2. Then enter temperatures, heating rates, etc.

Select Program 3 and 4 the same way.

A program can have up to 8 segments, but you don’t

have to use all 8 segments. Use only the number needed

per ring. Often one segment is all you will need. Zero

out the unused segments. The instructions on page 7

explain how to do that.

You can over-write a program by selecting it and

entering new rates and temperatures. This automatically

over-writes the previous program. Write down your pro-

grams in a notebook and record ring results for all r-

ings.

Repeat Firings

To repeat the last firing, press ENTER from IdLE.

The kiln will begin firing. But first, make sure you are

repeating the correct firing by using Program

Review (page 3).

Programming a Cooling Segment

For controlled cooling, program a segment to a

lower target temperature than that of the preceding

segment.

Example: You fire at a rate of 500°F per hour to

1450°F with your first segment. You want the kiln to

cool at a rate of 100°F per hour down to 700°F. Here

is how you would program the two segments:

Segment

Rate

°F/°C

Temp.

°F/°C Hold

1 500/277 1450/788 00.00

2 100/55 700/371 00.00

The first segment is the heating segment. The second

one is the cooling segment. The controller does not use

minus numbers for cooling. Just enter a lower target

temperature than that of the previous segment.

If you prop the lid or door for a fast cooling, program

a fast cooling rate for that segment. If you lower the

temperature quickly by propping the lid but program a

slow cooling rate, the controller will just raise the tem-

perature again.

Example: Some glass artists flash-cool the glass just

after it fuses. They open the door a few inches to remove

heat, then close it again. This takes the glass down rap-

idly through the devitrification range. To program a

flash-cool, use maximum rate. This shuts off the heating

elements during that segment, allowing the kiln to cool

rapidly.

Note: During fast cooling, do not open the door all the

way. Do not force-cool the kiln with a fan.

A Ramp-Hold Practice Program

To practice using the controller, we will enter a pro-

gram that includes three segments. The last segment is

a cooling segment.

Using the programming instructions on the next col-

umn, enter this firing schedule. The use Program Review

(page 3) to check for accuracy.

PrO1

rA1 = 250

°F 1 = 750

HLd 1 = 00.00

rA2 = 900

°F 2 = 1425

HLd 2 = 00.30

rA3 = 150

°F 3 = 750

HLd 3 = 00.00

RA4 = 0000 (zeroes cancel segments 4-8)

Skipping a Segment in a Ramp-Hold Program

You can skip a segment in a Ramp-Hold program as

follows:

1. The kiln is firing. Press the Up Arrow key.

2. SStP will appear. Press the Up Arrow key again.

The firing will skip to the next segment.

Skip Segment Example

Skipping to a Cooling Segment: You have pro-

grammed a target temperature of 1425°F for glass

fusing, followed by a segment for controlled cooling.

Watching the glass through the peephole, you notice

that the glass edges have rounded nicely at 1375°F.

Use Skip Segment to end the firing segment and

being one for slow cooling.

Note: Make a note of the temperature at which the

glass fused. Program that temperature for the next

firing of that type of glass.

Ramp-Hold Programming Instructions

Note: You have up to 8 segments available in

Ramp-Hold. If you don’t need all 8, zero out the

unused segments. See step 6 below.

1. From IdLE press START.

2. Press the Up Arrow key (not the Down Arrow).

PrO1 PrO2 PrO3 and PrO4 are Ramp-Hold

programs. When the one you want appears,

press START. (Ignore SPd1 - SPd5.)

3. rA 1 will appear. Enter ring rate (tempera-

ture change per hour) for segment 1. (1° =

slowest rate. 1799°F/999°C = full power.) Then

press START.

4. °F 1 or °C 1 and the target temperature from

the last firing will appear. Use the arrow keys

to change the temperature. Then press START.

5. HLd 1 and the hold time from the last firing

will appear (e.g. 1 hour, 10 minutes = 01.10).

Use the arrow keys to change the hold time.

Then press START.

6. Continue entering values for the segments

needed. When rA_ appears for the next seg-

ment that you don’t need, select 0000. The

press ENTER. This will zero out the remaining

segments. (Example: You need only 1 seg-

ment. When rA 2 appears, enter 0000.

7. Strt will appear. Press START to begin firing.

-On- will appear, the Run indicator light will

begin blinking, and the kiln will begin firing.

To stop a firing before completion, press START/

STOP. StOP will appear, alternating with total firing

time and kiln temperature.

Note: Do not be concerned if your kiln makes a

clicking sound during firing. Kilns use relays to

power the elements. The relays click each time their

electrical contacts come together.

Note: The kiln’s actual firing rate may be less than

the rate you programmed, depending on the kiln

model, available voltage, and density of the load

you are firing.

When the kiln fires to completion, it will beep for 30

seconds. The display will show the following:

Firing time

Present temperature

CPLt = Fired to completion

To return to IdLE , press START.

800.545.6566 www.riogrande.com

7 Sentry Express Digital Temperature Controller

Sharing your passion for making jewelry.

Products. Service. Know-how.

800.545.6566 www.riogrande.com

Sentry Express Digital Temperature Controller 8

Sharing your passion for making jewelry.

Products. Service. Know-how.

Lost Wax Burnout

CAUTION: Only kilns with vent holes are designed for

lost wax burnout. However, you may be able to use a

kiln without the vent hole provided that you open the

door ½” during venting.

CAUTION: Always use a wax tray.

Note: These instructions apply to injection wax that

melts at 200°F, not pattern waxes and plastics that melt

at higher temperatures. If smoke appears during wax

elimination, turn off the kiln. Smoking wax means the

kiln fired hotter than 300°F/148°C.

Overview

Lost wax casting is the process of carving a shape in

wax and then casting that shape in metal. After the wax

has been carved, a mold is made of the wax shape. The

mold is a negative image of the wax. The wax is later

melted out of the mold through hollow channels called

sprues.

Lost wax burnout is the process of preparing a casting

mold for the melted metal that will be poured into it.

The steps in lost wax burnout.

1. Melt the wax from the mold.

2. Remove wax from the kiln before raising the tem-

perature higher than 300°F/148°C.

3. Harden the mold at high temperature.

4. Maintain the mold at the casting temperature rec-

ommended for the type of metal that will be

poured into the mold.

CAUTION: Prevent wax or carbon from contacting the

kiln’s walls and elements. Carbon build-up inside a kiln

ruins the interior. Carbon conducts electricity and

causes elements to short circuit. Damage to elements

from contact will foreign materials is not covered by

warranty.

A Sample Program

See instructions on page 7 to enter this program:

Segment

Rate

°F/°C

Temp.

°F/°C Hold

1 500/277 300/148 01.00

2 500/277 1350/732 01.00

3 450/250 800/426 02.00

Segment 1 heats the wax to 300°F/148°C and holds it

for one hour, allowing it to drip from the mold.

Segment 2 hardens the mold.

Segment 3 lowers the temperatures to 800°F/426°C,

the typical casting temperature for silver. (Most types of

gold cast at 900°F/482C)

Note: Casting temperature depends on the size of the

mold. The temperatures above are only a guide. See

your jewelry supply dealer for temperature recommen-

dations.

Burnout Instructions

1. Place a metal tray inside the kiln on three ½” posts.

Place the mold on a wire mesh screen on top of the

tray. The mold’s sprue hole should be down. The tray

will catch melting wax as it drips from the sprue

hole.

2. Keep the kiln’s vent hole(s), if any, open during wax

elimination. If the kiln has no vent hold, leave the

door open ½”. This allows fumes to escape the kiln.

Heat the kiln to 300°F/148°C and hold it at that tem-

perature for at least one hour.

CAUTION: Do NOT heat the wax above 300°F/148°C.

Hold at 300°F/148°C for at least one hour. During this

hour, the wax will melt from the mold and drip into the

tray. If the kiln gets hotter than 300°F/148°C, the wax

may smoke and deposit carbon inside your kiln, causing

expensive damage.

3. After one hour at 300°F/148°C, open the kiln.

Remove the mold and wax tray. Pour the wax from

the tray and leave the tray out of the kiln until your

next wax elimination. (Do not leave the tray in the

kiln!)

4. Heat the mold to the temperature recommended

by your jewelers’ supply house where you pur-

chased the mold material. This is usually around

1350°F/732°C.

5. Lower the temperature to the casting temperature

of the metal. Hold at that temperature until you are

ready to begin casting. Remove the mold with

tongs. Wear protective gloves and safety glasses.

Saving a Carbon-Damaged Kiln

If you follow the above directions, your kiln should be

safe from wax damage. In some cases, a small amount of

carbon may form on the walls over a period of time. This

is due to the burning of wax residue that was left in the

mold. For this reason we recommend that you periodi-

cally fire the kiln to 1500°F/815°C as follows:

1. Open the vent cover(s) or leave the door ajar ½”.

2. Fire the kiln empty to 1500°F/815°C at a rate of

300°F/166°C with a one hour hold (01.00).

800.545.6566 www.riogrande.com

9 Sentry Express Digital Temperature Controller

Sharing your passion for making jewelry.

Products. Service. Know-how.

Error Messages

bAdP/Bad Programming

The kiln will not fire because the program just entered

has a rate of 0000 in segment 1. Program the firing

again.

EtH/Electronics Too Hot

The temperature of the electronic circuit board is

above 158°F/70°C. This could damage the controller, so

the firing has been stopped. To prevent this, keep the

firing room cooler. Use better ventilation.

FaIL/Thermocouple Failure

The thermocouple, or temperature sensor, failed dur-

ing firing. Causes:

Defective thermocouple or disconnected/loose wires

Defective controller

Electrical noise

Thermocouple Paperclip Test

Check the thermocouple

wire connection. (See your

kiln instruction manual.) If

connections are tight, per-

form this test:

1. UNPLUG the kiln or dis-

connect the power.

Remove the controller. Remove the two thermo-

couple wires from the back of the controller.

2. Cut a thin paperclip in half. Insert a U-shaped paper-

clip piece, or other piece of thin wire, where you

removed the thermocouple wires.

3. Plug in the kiln. If the controller displays room tem-

perature, replace the thermocouple. If it shows FaIL,

replace the controller.

TCR/Thermocouple Reversed

Thermocouple lead wire are reversed.

FtL/Firing Too Long

This message appears when both of the following

conditions are met:

The temperature rise or fall is less than 27°F/15°C per

hour.

The ring is 4 hours longer than programmed.

See “Controller display turn on. No heat in kiln,” page 11.

PF 1/Power Failure

The power failed during firing and temperature

dropped more than 180°F/100°C by the time the power

cam back on.

PF 2/Power Failure

The power failed during firing and kiln temperature

was below 212°F/100°C when the power came back on.

tC/Thermocouple Failure

The thermocouple failed or was disconnected during

the IdLE display. See “FaIL” in the column at left.

Selecting °F or °C Display

The controller can display temperature in either °F or

°C. If your controller shows a small display dot in the

lower right corner of the display, the temperature

shown is °C. No dot means °F. To change temperature

display:

1. UNPLUG kiln or disconnect power.

2. Remove the four screws that hold the controller to

the front kiln. Carefully remove the controller from

the kiln. Leave the wire attached to the controller.

3. Look at the back of the controller. A plastic jumper

on the back of the board determines the type of

temperature display. When the jumper connects

two pin-type terminals, display reads °F. When the

jumper is removed, display reads °C. Remove or

insert the jumper as desired. (You can purchase the

jumper from a computer supply store if necessary.)

4. Install the controller being careful not to jar compo-

nents on the back of the controller against the kiln

case.

800.545.6566 www.riogrande.com

Sentry Express Digital Temperature Controller 10

Sharing your passion for making jewelry.

Products. Service. Know-how.

Display Messages

Abrt The firing was stopped.

CPLt Fired to completion. If the kiln is already hot-

ter that the programmed target temperature when

you begin firing, CPLt will appear immediately after

you begin firing.

dELA (Page 3) Delay is a count-down timer that

start the firing when the time runs out.

°F or °C (and temperature) (Pages 5, 7) The target

temperature (the temperature that the kiln will fire

to). Each segment has a target temperature.

FULL Full power firing rate. At this setting the kiln

will fire at its fastest rate. There are two ways to

select full power:

1. Select SPd5 in Single Segment mode.

2. Select a rate of 1799°F/999°C at the ra _ prompt

in Ramp-Hold mode. A fast way to do this is to

press the Down Arrow key once from 0000.

FULL will appear.

HLd (Pages 4, 5, 7) Hold time of a segment, shown

in hours and minutes. (Example: 2 hours and 15

minutes = 02.15)

IdLE (Pages 3) The controller is ready for you to

enter a program or to begin a repeat firing.

-On- Firing has begun. A moment after -On-

appears, you will hear the relay(s) clicking.

PrO1 PrO2 PrO3 PrO4 (Pages 5, 6, 7) These are

Ramp-Hold programs stored in memory.

ProG (Page 4) These are Ramp-Hold programs

stored in memory.

rA 1 rA 2 etc. (Rate) (Page 7) This appears in Ramp-

Hold programming for each segment. 1, 2, etc. are

segment numbers. Enter the rate of temperature

change for that segment numbers. Enter the rate of

temperature change for that segment. Rate is fig-

ured in degrees of temperature change per hour.

Example:

A temperature rise of 100° in two hours = 50° rate.

A temperature drop of 200° in one hour = 200° rate.

SPd1 SPd2 SPd3 SPd4 SPd5 (Page 5) These are

Ramp-Hold programs stored in memory.

SStP (Skip Step) (Page 7) This message appears

when you press the Up Arrow key during a Ramp-

Hold firing. If you press the Up Arrow again, the fir-

ing will skip out of a segment into the next segment.

STOP The firing was stopped by pressing START/STOP.

Strt The “Ready to Start” message appears after

programming a firing. Press START to begin firing.

Trouble Shooter

Problem: Controller display is blank.

No heat in kiln.

Is the kiln connected to the power?

Has the circuit breaker tripped

or fuse blown?

Is power reaching the wall

receptacle? Test with a volt-

meter or a test light if you are

not sure.

Has the kiln switch box ½

amp fuse blown?

The kiln’s ½ amp fuse is locat-

ed in the kiln switch box. Remove by pressing the fuse

holder and turning counter-clockwise half a turn. Check

the fuse by placing the probes of an ohmmeter on the

ends of the fuse. If the ohmmeter reads less than an

ohm (digital meter) or reads 0 ohms (analog meter), the

fuse is okay. If the reading is OPEN (digital meter) or

infinity/no needle movement (analog meter), the fuse is

bad.

Replacement fuse: AGC ½ A 250V AC

Is the controller receiving power? Test with a power

INPUT connections on the back of the controller with

a voltmeter.

Controller Power Input

Test

Unplug the kiln. Remove the

4 screw holding the controller

faceplate to the switch box. Lift

faceplate out of box and let the

board hang on the box with

the back of the board facing

you. Plug the kiln back in. Touch voltmeter probes (in AC

mode) to both INPUT connections (the white and orange

wires).

CAUTION: Do not let the back of the board touch a

grounded object. Make sure the voltmeter is in the AC

mode when placing the probes on INPUT connections.

Controller Power Input Test Result: No voltage

UNPLUG kiln. Check the switch box for disconnected

wires between the cord, transformer, and controller. If

wiring is okay, replace the transformer.

Controller Power Input Test Result: 20-24 volts AC

Correct current is reaching the board from the trans-

former. But since the board is not lighting up, it is probably

defective. Return the controller for repair or replacement.

800.545.6566 www.riogrande.com

11 Sentry Express Digital Temperature Controller

Sharing your passion for making jewelry.

Products. Service. Know-how.

Controller Power Input Test Result: less than 20 volts

Did you recently replace the transformer? It may be

the wrong voltage. The voltage is below 20, which is not

enough power for the controller. To find out the cause of

low voltage, continue below:

Controller Input Test #2

The back of the board is still

facing you and the kiln is

plugged in. Remove the

INPUT plug, which is the

white, orange, and blue wires,

from the back of the control-

ler. Touch a voltmeter probe to the white wire and the

other probe to the orange wire.

Input Test #2 Result: Less than 20 Volts AC

There are two possible reason: 1) Low voltage at the

wall receptacle; 2) defective transformer. If wall recep-

tacle voltage is correct, replace the transformer.

Input Test #2 Result: 20 - 24 Volts AC

The transformer is sending correct voltage to the con-

troller. Yet when the INPUT plug was connected to the

controller, voltage was less than 20. This means the con-

troller is draining the voltage and is defective. Return

the controller for repair or replacement.

Problem: Controller display turns on.

No heat in kiln.

Is the relay making its normal clicking sound?

Yes, the relay is clicking

Test the elements with an ohmmeter.

Element Resistance Test

1. UNPLUG kiln/disconnect the power. Open the

kiln’s switch box. Make sure the wires connect-

ing the relay to the elements are secure. If con-

nections are okay, continue to step 2:

2. Touch the ohmmeter leads to the two element

connectors of each element. A no-needle-

movement reading on an analog meter, or

OPEN on a digital meter, indicates a broken

element.

If the elements check out okay, replace the relay.

Note: To replace relay, see your kiln’s instruction and

service manual.

No, the relay is not clicking.

We know the controller is receiving voltage, because

the display lit. But the voltage from the transformer may

be too low to power the relays. Perform the “Controller

Power Input Test,” page 10. If your controller passes the

Input Test, perform the “Controller Power Output Test”:

Controller Power Output Test

Is the controller sending voltage to the relay? Test

OUTPUT with a voltmeter:

1. UNPLUG kiln/disconnect the power. Remove the 4

screws holding the controller faceplate to the switch

box. Lift faceplate out of box and let the controller

hang on the outside of the box with the back of the

board facing you. Then plug the kiln back in. Program

the controller to fire to 1000°F at FULL rate in Ramp-

Hold mode. Press START.

2. Put the voltmeter in DC mode. (It must be in DC

mode when testing OUTPUT voltage.) Touch probes

to the red wire and black wire connection. Measure

voltage when the relay clicks on.

Output Test Result: No voltage at red and black wires

The controller is not sending power to the relay.

Return the controller for repair or replacement.

Output Test Result:10-14 v. at red and black wires

The controller is sending correct power to the relay.

Unplug kiln/disconnect power. Remove the kiln switch

box. Look for disconnected wires between the control-

ler, relay and elements. Check the wiring diagram to be

are connected to the correct terminals. Be sure connec-

tions are tight. If the wiring is okay, replace the relay.

Note: To replace relay, see your kiln’s instruction and

service manual.

Problem: Kiln switch box ½ amp

fuse keep blowing.

What size fuse are you using?

Correct fuse: AGC ½ A 250V AC

If the fuse is correct size, perform the following test:

Kiln Switch Box ½ Amp Fuse Test

1. UNPLUG kiln/disconnect the power. Remove the 4

screws holding the controller faceplate to the switch

box. Lift faceplate out of box and let the board hang

on the outside of the box with the back of the board

facing you. Disconnect

both wire plugs form

the back of the control-

ler. Then plug the kiln

back in. Apply power to

kiln. If the ½ amp fuse

blows, replace the

transformer. (If the fuse does not blow, the problem is

the board or relay. Go to step 2.)

2. Connect the INPUT plug (orange, blue, and white

wires) to the board again. Leave off the OUTPUT

wire plug (the one with the red and black wires).

Program the controller to fire at 1000°F at FULL rate

in Ramp-Hold mode. Press START. If the fuse blows,

replace or service the board. (If the fuse does not

blow, the problem is caused by a short in the coil of

the relay. Go to step 3.)

3. UNPLUG kiln/disconnect the power. Reconnect the

OUTPUT wire plug Reinstall the board in the switch

box. Replace the relay.

800.545.6566 www.riogrande.com

Sentry Express Digital Temperature Controller 12

Sharing your passion for making jewelry.

Products. Service. Know-how.

©2011 The Bell Group, Inc. All rights reserved.

Shorthand Instructions

These instructions may be confusing until you have read more detailed instructions on single Single Segment, page 5, or

Ramp-Hold, page 7. Read the safety guidelines, page 2. After pressing the keys in left column, the center message will appear.

Single Segment

Keys to Press Display

IdLE

SPd1 thru PrO4

(Not Down Arrow) Select rate SPd1 (Sample rate)

°F or °C

Enter temperature 1900 (Sample temperature)

HLd

Enter hold time 00.00 (or hold time)

Strt

-O n - The kiln is now ring

Ramp-Hold

Keys to Press Display

IdLE

SPd1 thru Pro4

(Not Down Arrow) Pro1 Select Program #1, 2, 3, or 4

rA 1

Enter Segment 1 rate 500 (Sample rate)

°F 1 or °C 1

Enter temperature 1900 (Sample temperature)

HLd 1

Enter hold time 00.00 (or hold time)

First segment not needed: enter a rate of 0000.

Strt

-O n - The kiln is now ring

Table of contents

Other Rio Grande Temperature Controllers manuals