56

7188

910

Alarm Type Selection Parameter

Sensor Failure Alarm

Process High Alarm

11 12

2.3 Panel Mounting

1

2

1-Before mounting the device in your

panel, make sure that the cut-out is of

the right size.

2-Insert the device through the cut-out.

If the mounting clamps are on the unit,

put out them before inserting the unit to

the panel.

2.4 Installation Fixing Clamp

1

2

The unit is designed for panel mounting.

1-Insert the unit in the panel cut-out from

the front side.

2- Insert the mounting clamps to the

holes that located left and right sides of

the device and make the unit completely

immobile within the panel

2.5 Removing from the Panel

2

1

Loosen the screws

1-Pull mounting clamps from left and

right fixing sockets.

2-Pull the unit through the front side of

the panel

Before starting to remove the unit

from panel, power off the unit and the

related system.

c

Montage of the unit to a system must be

done with it’s own fixing clamps. Do not

do the montage of the device with

inappropriate fixing clamps. Be sure

that device will not fall while doing the

montage.

c

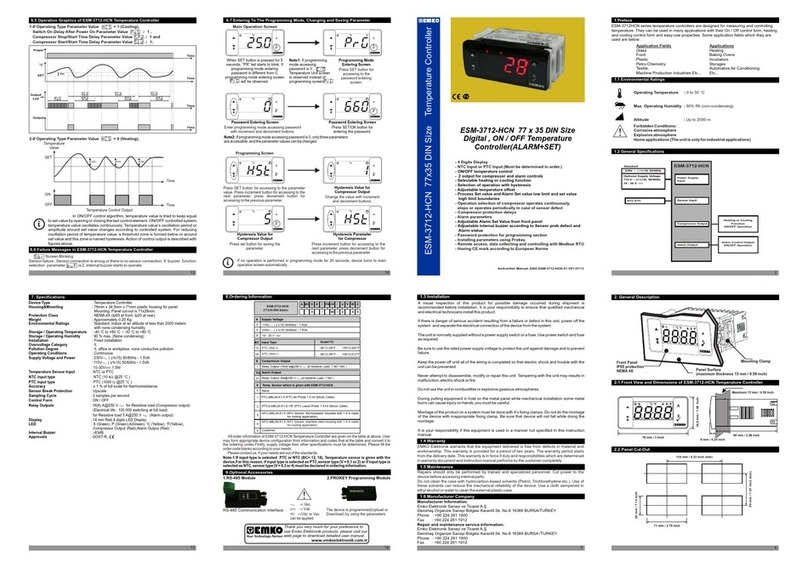

3. Electrical Wiring Diagram

P/N : ESM-3712-HC

PROCESS

OUT

NC CNO

10A@250V V

1 2 3 4 5 6 7 8 9 10 11 12

(-) (+) N L

CAT II

Yc

TC

PTC, PT-100

PT-1000

NTC

a

(-) (+)

CNO

ALARM

OUT

5A@250V V

Process LowAlarm

Deviation High Alarm

Deviation Low Alarm

Deviation Band Alarm

Deviation Range Alarm

Alarm Set Value Low Limit Parameter

, minimum process set value parameter to

alarm set value high limit parameter value.

Alarm set value can not be lower than this value.

This parameter value can be adjusted from

Alarm Set Value High Limit Parameter

alarm set value low limit parameter value

to maximum process set value parameter

Alarm set value can not be greater than this value.

This parameter value can be adjusted from

Alarm On Delay Time Parameter

It can be adjusted from 0 to 99 minutes.

Alarm Off Delay Time Parameter

It can be adjusted from 0 to 99 minutes.

When this parameter is 99, if increment button is pressed, is observed and

alarm latching output is selected. To make the alarm latching output passive,

decrement button must be pressed in main operation screen.

Alarm Delay Parameter After Power On

This parameter defines the delay for the alarm is being active after power on. It can

be adjusted from 0 to 99 minutes.

Alarm Set Value Parameter

Alarm output is controlled according to this value.

For alarm type selection paramater = 1 or 2, this parameter value is can be

adjusted from alarm set value low limit parameter to alarm set value high limit

Parameter, for alarm type selection paramater = 3,4,5 or 6 this parameter

value is can be adjusted from 0 to alarm set value high limit Parameter.

Alarm Hysteresis Parameter

Alarm hysteresis value. This parameter is can be adjusted 0 to %50 of the device

scale

SET

°C

SV

P

SET

°C

SV

P

SET

°C

SV

P

SET

°C

SV

P

4.4 Easy Access Diagram Of Programming Mode Parameters

Hysteresis Parameter Minimum Set Value

Parameter

Password Entering

Screen

Maximum Set Value

Parameter

Process Offset Parameter Alarm Type Selection Parametresi

SET

°C

SV

P

SET

°C

SV

P

SET

°C

SV

P

SET

°C

SV

P

SET

°C

SV

P

Alarm Set Value Low Limit

Parameter

Alarm Set Value High

Limit Parameter

Alarm On Delay Time

Parameter

SET

°C

SV

P

SET

°C

SV

P

SET

°C

SV

P

Alarm Off Delay Time

Parameter

Alarm Delay Parameter

After Power On

Alarm Set Value

Parameter

SET

°C

SV

P

5 sec

Password Entering

Screen

Main Operation Screen

SET

°C

SV

P

SET

°C

SV

P

Programming Mode

Entering Screen

Press SET/OK button for

accessing parameters

If no operation is performed in Programming mode for 20 seconds, device turns to

main operation screen automatically

i

SET

°C

SV

P

SET

°C

SV

P

SET

°C

SV

P

Alarm Hysteresis Parameter Operating Type Parameter Switch On Delay After

Power On Parameter

SET

°C

SV

P

SET

°C

SV

P

SET

°C

SV

P

Compressor Stop/Start Time

Delay Parameter

Compressor Start/Start

Time Delay Parameter

Probe Defect

Parameter

SET

°C

SV

P

SET

°C

SV

P

SET

°C

SV

P

Compressor is active during

this time period in case of

Compressor is inactive

during this time period in

Programming Mode

Accessing Password

Enter password with increment and decrement buttons

3.1 Supply Voltage Input Connection of the Device

6

LN

7

Y

c

a

Make sure that the power supply voltage is same indicated on the instrument. Switch on the power supply

only after that all the electrical connection have been completed. Supply voltage range must be determined

in order. While installing the unit, supply voltage range must be controlled and appropriate supply voltage

must be applied to the unit. Controlling prevents damages in unit and system and possible accidents as a

result of incorrect supply voltage.

There is no power supply switch or fuse on the device. So a power supply switch and a fuse must be added

to the supply voltage input. Power supply switch and fuse must be put to a place where user can reach

easily. Power supply switch must be two poled for seperating phase and neutral. On/Off condition of power

supply switch is very important in electrical connection. On/Off condition of power supply switch must be

signed for preventing the wrong connection.

External fuse must be on phase connection in supply input.

External fuse must be on (+) line connection in supply input.

V

Z

Note-3

Note-2

100...240V (- %15;+%10) 50/60Hz 2VA orV

24V (-%15;+%10) 50/60Hz 2VA orV

24V (-%15;+%10) 2WZ

Note-1

The instrument is protected with an internal fuse (Please refer to Note-1 for information). In

case of failure it is suggested to return the instrument to the manufacturer for repair.

c

Note-2: “L” is (+), “N” is (-) for 24V Supply

Voltage

Z

Supply Voltage

Power

Supply

Switch

External

Fuse

(1 A T)

Note-3: External Fuse is recommended

Note-1 :There is an internal 33R fusible

flameproof resistor in

There is an internal 4R7 fusible flameproof

resistor in

W

W

100-240 V 50/60Hz

24V 50/60Hz

V

W

100...240V (- %15;+%10) 50/60Hz 2VAV

24V (-%15;+%10) 50/60Hz 2VAV

24V (-%15;+%10) 2WZ

Supply Voltage Input

Relay or SSR

Driver Output

For SSr Output

Temperature Sensor Input

(TC, NTC, PTC, PT-100 or

PT-1000)

3.2.2 PTC and NTC Connection

3.2.1 TC (Thermocouple) Connection

3.2 Temperature Sensor Input Connection

1211

TC

i

i

10

PTC

Input resistance is greater than 10M .W

i

1211

10

Pay attention the cable colours of PTC probe while doing the PTC probe

connection.

i

WHITERED

Connect the wires with the polarity as shown in

the figure left.

Always use compensation wire corresponding

to the thermocouple used. If present, the shield

must be connected to a proper ground.

Input resistance is greater than 10M W.

NTC

1211

10

Input resistance is greater than 10M .W

i

1211

10

3.2.3 and PT-1000 ConnectionPT-100

PT-1000

1211

10

PT-100

Displays

Temperature

Value,

Temperature Set

Value

and Parameters

It is used to enter to

the SET value

changing mode,

programming mode

and used as OK

button.

It is used to

increase the value

and access to the

parameter in

programming

mode.

Decrement

Button

Led indication of

Programming Mode is active

Note-1

Note-1: If increment or decrement button is pressed for 5 seconds continuously, increment and

decrement number become 10, if increment or decrement button is pressed for 10 seconds

continuously, increment and decrement number become 100.

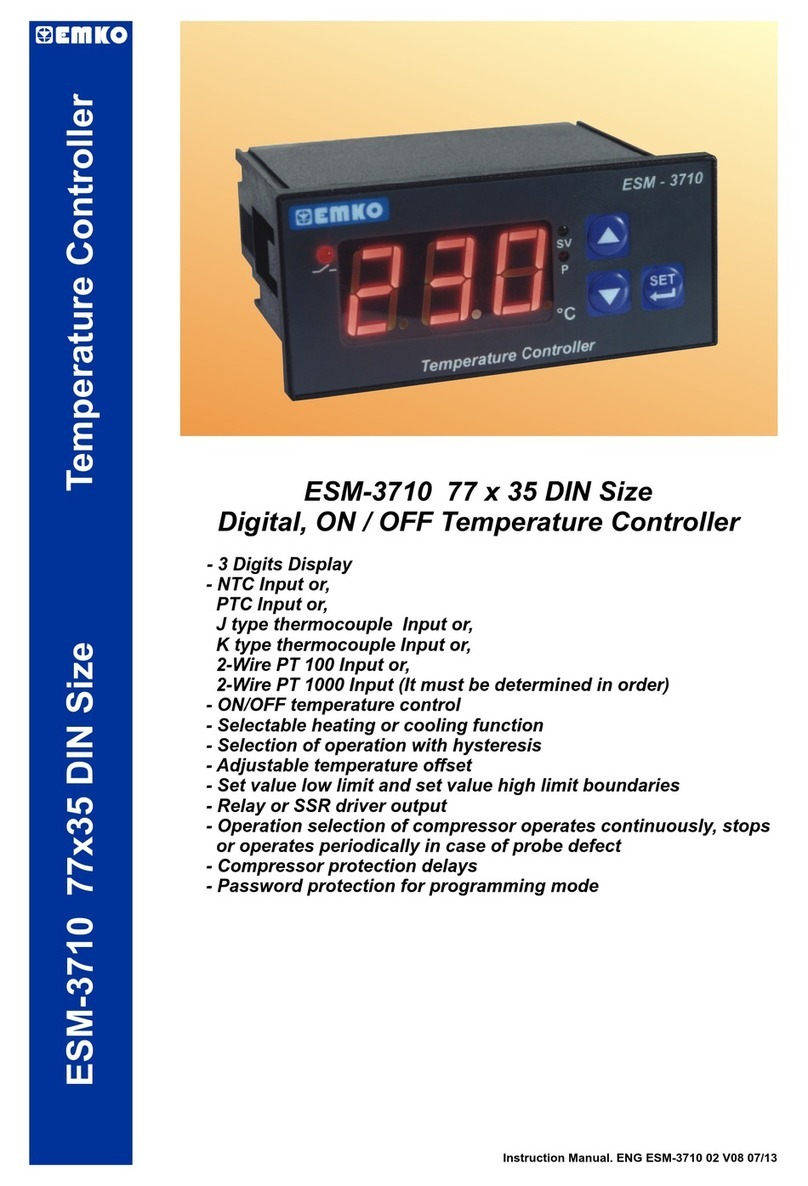

4. Front Panel Definition and Accessing to the Menus

Temperature Controller

ESM - 3712-HC

SET

°C

SV

P

Led indication of

Output is active

(If blinks, Compressor

protection time is active)

Led indication of SET value

changing mode

When power is first applied to the temperature controller, software revision number is shown on

the displays.

4.1 Observation of Software Revision on the Displays

Temperature Controller

ESM - 3712-HC

SET

°C

SV

P

Temperature Controller

ESM - 3712-HC

SET

°C

SV

P

“ r” RevisionÞRevision

Number

Main Operation Screen is shown

If there is an unexpected situation while opening the device, power off the

device and inform a qualified personnel.

c

Note-1

Led indication of

Alarm

Active Led

4.2 Changing and Saving Set Value

SET

°C

SV

P

When SET button is pressed, SV LED

lights on and SET value is shown on

the displays.

SET

°C

SV

P

SET Value Screen

Change the SET value with

increment and decrement

buttons.

SET

°C

SV

P

Press SET button for saving the

SET value

SV LED lights off and main operation

screen is shown.

SET

°C

SV

P

Main Operation Screen SET Value Screen

iIf no operation is performed in Set value mode for 20 seconds, device turns to main

operation screen automatically.

SET value is can be adjusted from minimum set value parameter to maximum set value

parameter , Which can be accessed from programming parameters.

Main Operation Screen

4.3 Program Parameters

i, , , , and parameters are observed if

Operating type is selected “ Cooling ”. If operating type is selected “ Heating ”

beginning of the parameters list is shown.

Hysteresis Parameter for Output ( Default = 1 )

1 to 100 °C for TC Type Devices,

1 to 100 °C for PT-100 (-50°C, 400°C) and PT-1000 (-50°C, 400°C),

0.1 to 10.0 °C for PT-100 (-19.9°C, 99.9°C) and PT-1000 (-19.9°C, 99.9°C),

1 to 20 °C for PTC (-50°C, 150°C) and NTC (-50°C, 100°C),

0.1 to 10.0 °C for PTC (-19.9°C, 99.9°C) and NTC (-19.9°C, 99.9°C)

Minimum Set Value Parameter ( Default =Minimum value of device scale )

Set value can not be lower than this value. This parameter value can be adjusted

from minimum value of device scale to maximum set value parameter

Maximum Set Value Parameter ( Default = Maximum value of device scale )

Set value can not be greater than this value. This parameter value can be adjusted

from minimum set value to maximum value of the device scale

Process Offset Parameter ( Default = 0 )

-100 to 100 °C for TC Type Devices,

-100 to 100 °C for PT-100 (-50°C , 400°C) and PT-1000 (-50°C , 400°C),

-10.0 to 10.0 °C for PT-100 (-19.9°C, 99.9°C) and PT-1000 (-19.9°C, 99.9°C),

-20 to 20 °C for PTC (-50°C, 150°C) and NTC (-50°C, 100°C),

-10.0 to 10.0 °C for PTC (-19.9°C, 99.9°C) and NTC (-19.9°C, 99.9°C)

Switch On Delay After Power On Parameter

When power is first applied to the device, this time delay must be expired for

activation of the compressor. It can be adjusted from 0 to 20 minutes

Compressor Stop/Start Time Delay Parameter

When compressor is inactive, this time delay must be expired for activation of the

compressor. It can be adjusted from 0 to 20 minutes.

Probe Defect Parameter

Compressor is active during this time period in case of probe defect

If Probe Defect Parameter is , then this parameter can be

observed. It can be adjusted from 0 to 99.

Compressor is OFF in case of probe defect

Compressor is ON in case of probe defect

Compressor operates periodically according to and time

periods in case of probe defect.

Compressor Start/Start Time Delay Parameter

This time delay must be expired between two activation of the compressor.

It can be adjusted from 0 to 20 minutes.

Operating Type Parameter

Heating

Cooling

Compressor is inactive during this time period in case of probe defect

If Probe Defect Parameter is , then this parameter can be

observed. It can be adjusted from 0 to 99.

Programming Mode Accessing Password

It is used for accessing to the programming mode. It can be adjusted from 0 to 999.

If it is selected 0, password is not entered for accessing to the parameters.

Max. 24mA,Max.16V Z