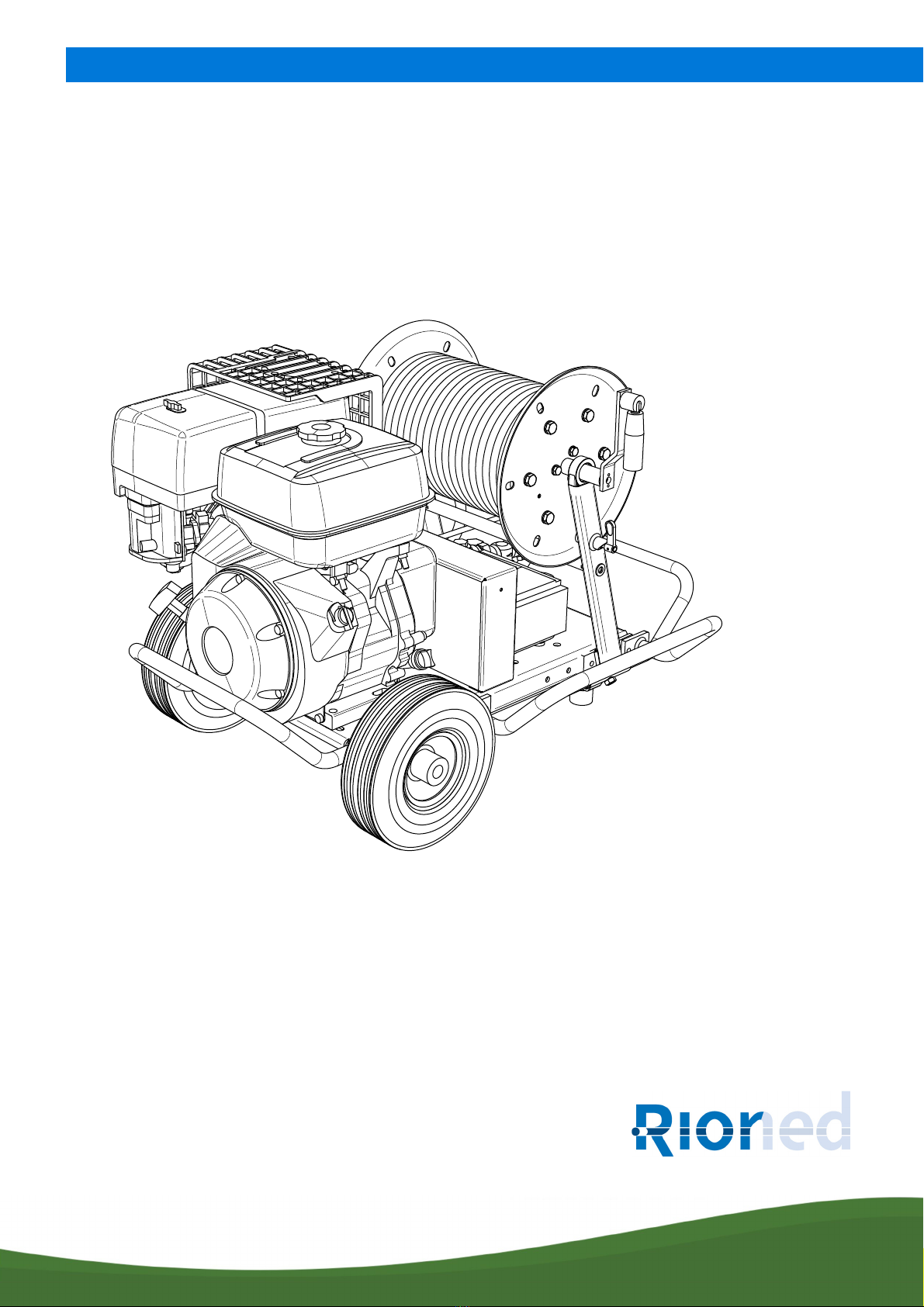

Rioned HD30 User manual

1

HD30

user manual

2

Operating and maintenance manual

Identification number: vo . . . . .

Serial number: . . . . . . . . . . . . .

Type HD30

Year of manufacture: . . . .

Manufacturer:

Rioned

Centaurusweg 45

5015 TC Tilburg

P.O. Box 5070

NL-5004 EB Tilburg

Tel. no.: +31 13-5479100

E-mail: [email protected]

Internet: www.rioned.com

For information about adjustments, maintenance or repairs not contained in this user

manual, contact Rioned.

Original user manual

Publication date: 14-01-2019

Version: 07

All rights reserved. No part of this publication may be reproduced and/or made public

by means of printing, photocopying, microfilm or any other means whatsoever without

the prior written permission of Rioned.

Rioned reserves the right to make changes to parts at any time, without providing prior

or direct notification to the buyer. The content of this user manual may also be changed

without prior notification.

3

Preface

This user manual is intended for the professional user. It is intended

to enable the user to operate the machine and must always be kept

with the machine.

The photographs and drawings in the manual are intended to support

the text.

In this user manual you will first find an introduction that describes,

among other things, the intended purpose of the machine. Then there

is an explanation of how the machine is constructed and how it works

in general. This is followed by an overview of the most important

safety aspects.

Then the best way to start up and operate the machine is explained.

The standard functions and additional functions are described

separately. The information in the Maintenance section allows you to

perform simple maintenance work yourself. Troubleshooting tips to

help you correct minor malfunctions yourself are also provided.

Finally, at the end of this user manual you will find an index to help

you quickly find information and a number of annexes containing,

among other things, Rioned's contact details.

4

5

Table of contents

Preface ......................................................... 3

Table of contents......................................... 5

1 Introduction ....................................... 7

2 Description and principle of

operation.............................................9

2.1 Introduction...................................................................9

2.2 Machine.........................................................................9

2.2.1 Design and principle of operation................................9

2.2.2 Symbols on pressure gauge, pressure regulator and

valve controls ...............................................................13

2.2.3 Accessories...................................................................13

3 Safety..................................................15

3.1 Introduction..................................................................15

3.2 General danger symbol ................................................ 15

3.3 Working safely ..............................................................15

3.4 Dangers of non-compliance with safety

instructions ..................................................................15

3.5 Use only by authorized personnel .............................. 16

3.6 Bystanders ................................................................... 16

3.7 Restrictions on use...................................................... 16

3.8 Thunderstorm ............................................................. 16

3.9 Spraying....................................................................... 16

3.10 Spray break ...................................................................17

3.11 Sewer gases ..................................................................17

3.12 Engine stop...................................................................17

3.13 Levers and valves .........................................................17

3.14 Personal protective equipment....................................17

3.15 Water discharge............................................................18

3.16 Other machine safety provisions.................................18

3.16.1 Pressure regulator ........................................................18

3.16.2 Non-return valve...........................................................18

3.16.3 Temperature protection valve......................................18

3.16.4 Protective covers ..........................................................18

3.17 Supplied documentation..............................................18

3.18 Safety sticker................................................................ 19

4 Operation: standard functions.........21

4.1 Introduction..................................................................21

4.2 Checks before departure ..............................................21

4.3 Preparations at the workplace .................................... 22

4.3.1 Preparing the machine................................................ 22

4.3.2 Before starting............................................................. 22

4.3.3 Workstations ............................................................... 23

4.4 Starting the engine...................................................... 24

4.4.1 Starting Honda GX340................................................ 24

4.4.2 Stopping the engine .....................................................25

4.4.3 Stopping Honda GX340...............................................25

4.4.4 Unblocking a sewer.....................................................26

4.4.5 Spray nozzle warning ..................................................26

4.4.6 Preparations for spraying............................................26

4.4.7 Starting spraying .........................................................26

4.4.8 Stopping spraying ....................................................... 27

4.4.9 Handling the high pressure hose ............................... 27

4.5 Cleaning a wall, terrace or floor...................................28

4.5.1 Warnings for spray gun ...............................................28

4.5.2 Preparations for spraying ............................................28

4.5.3 Pressurizing the system...............................................28

4.5.4 Starting spraying..........................................................28

4.5.5 Depressurizing the system......................................... 29

4.6 Ending the work .......................................................... 29

4.6.1 Cleaning up and securing........................................... 29

4.6.2 Additional steps during freezing temperatures ......... 29

5 Operation: extra functions ...............31

5.1 Introduction ................................................................. 31

5.2 Reel............................................................................... 31

5.2.1 Safety ............................................................................ 31

5.2.2 Manually reeling high pressure hose out.................... 31

5.3 Suction hose ................................................................ 31

6 Maintenance......................................33

6.1 Safety instructions ....................................................... 33

6.2 Making changes to the machine ................................. 33

6.3 Maintenance schedule.................................................34

6.4 Maintenance before the work...................................... 35

6.4.1 Check oil levels............................................................. 35

6.4.2 Clean water filter .......................................................... 35

6.4.3 Check high pressure hose and other hoses................ 35

6.5 Weekly maintenance....................................................36

6.6 Maintenance every 50 hours of operation ..................36

6.7 Maintenance every 250 hours of operation or

at least once every six months ....................................36

6.7.1 Lubricate moving parts................................................36

6.7.2 Clean pressure regulator .............................................36

6.8 Maintenance every 1000 hours of operation or

at least once a year ......................................................37

6.8.1 Clean suction valves of high pressure pump..............37

6.8.2 Clean pressure valves of high pressure pump............37

6.8.3 Major scheduled maintenance....................................37

7 Malfunctions .................................... 39

7.1 Troubleshooting...........................................................39

8 Index ................................................. 41

9 Attachments ..................................... 43

Annex 1 EC declaration of conformity......................................... 44

Annex 2 Type plate .......................................................................45

Annex 3 Dimensions ................................................................... 46

Annex 4 Technical specifications.................................................47

Annex 5 Contact details............................................................... 49

10 Exploded views ..................................51

10.1 Table of machines........................................................52

10.2 900000088 Frame....................................................... 53

10.4 900000155 Frame with protective brackets................ 55

10.5 900000405 Accessories 100 bar 40 lpm....................56

10.6 900000456 Accessories 120 bar 22 lpm.....................57

10.7 900000647 High pressure reel NW10 - 40 m............58

10.8 900000648 Motor/pump group P30 .........................59

6

10.9 900000649 Pressure regulator 160 bar.....................60

10.10 900000650 High pressure reel NW8 - 40 m............. 61

10.11 900000651 Motor/pump group P21 protective

cap blue excl. dirt trap.................................................62

10.12 900000652 Pressure regulator 250 bar...................... 63

10.13 900000653 High pressure reel NW10 - 30 m............ 64

10.14 900000654 Pressure regulator 250 bar incl. temp.

protection.....................................................................65

10.15 900000655 Protective cap yellow incl. dirt trap ........ 66

INTRODUCTION

7

1 Introduction

Congratulations on the purchase of the HD30! The HD30 is suitable for cleaning house

connections, rainwater drains and grease-blocked and industrial pipes. The HD30 is

also suitable for cleaning street furniture, terraces etc. The HD30 is directly connected

to a water supply, so a tank is not necessary.

Read this user manual carefully before putting the machine in service, and always use

the machine in accordance with the instructions. If problems occur, consult Rioned.

This user manual contains all the information about operation and maintenance. If the

machine is set up and operated correctly and regularly maintained, we provide the

warranty specified in the general terms and conditions of delivery. The warranty is void

and your safety and that of people in the vicinity cannot be guaranteed if the operating

and maintenance instructions are not followed or are not followed correctly.

The following requirements must be met when working with the machine:

Use in enclosed spaces:

> When working in an enclosed space, the space must be well ventilated.

> Make sure the combustion gases are properly discharged. Prevent CO poisoning!

Spray site:

ALWAYS follow the instructions below for the spray site:

> Demarcate the site clearly. The minimum distance between the spray site and the

demarcation is six metres.

> Remove anything within the demarcation that is not firmly anchored.

> NEVER spray from an unstable location. Examples: ladder, boat, or hanging

scaffolding.

> If it is necessary to use artificial lighting, ALWAYS use waterproof light fixtures.

INTRODUCTION

8

DESCRIPTION AND PRINCIPLE OF OPERATION

9

2 Description and principle of operation

2.1 Introduction

In this chapter we briefly describe the operation, the main components and the

symbols used for the machine and the accompanying accessories.

2.2 Machine

2.2.1 Design and principle of operation

The engine drives the high-pressure pump via a V-belt The high pressure pump draws

water from the water supply network via the non-return valve and pressurizes it. The

water then exits the machine at high pressure via the high pressure hose on the reel.

The machine consists of the following parts:

1. High pressure hose on reel

2. Connection, filling hose

3. Water filter

4. Non-return valve

5. High pressure valve

6. Pressure regulator

7. Pressure gauge

8. Engine Honda GX340

9. Starter handle

10. On/off switch, engine

11. Dipstick and oil filler opening

12. High pressure pump

13. Reel latch

14. Handle, reel

15. Fuel tank

16. Carrying handle

17. Wheels

DESCRIPTION AND PRINCIPLE OF OPERATION

11

The following is a brief explanation of parts from the illustrations above that are not

discussed further in the manual.

Non-return valve (4)

The valve ensures that the contaminated water used by the HD30 cannot get back into

the water supply network.

High pressure valve (5)

This valve regulates the supply of water to the high pressure hose.

The high pressure valve acts as a safety valve in an emergency: this allows you to

immediately interrupt the supply of water to the high pressure hose.

Reel latch (13)

This latch prevents the reel from turning. It is operated by twisting the wings.

Handle, reel (14)

Fold out to reel up the high pressure hose.

Fold the handle in when storing or moving the HD30.

Carrying handle (16)

The HD30 can be moved by extending and lifting this handle.

Loosen the wing bolt to extend the carrying handle. Then tighten the wing bolt again

to secure the carrying handle in place.

Push the carrying handle in when using or storing the HD30.

16 17

DESCRIPTION AND PRINCIPLE OF OPERATION

13

2.2.2 Symbols on pressure gauge, pressure regulator and valve controls

2.2.3 Accessories

Pressure gauge (7)

The maximum operating pressure is indicated on a sticker near the

pressure gauge.

Reduce the operating pressure with the handwheel of the pressure

regulator until the indicator of the pressure gauge is halfway

between 0and the maximum operating pressure.

The following are included as standard with the machine:

1. Three nozzles for unblocking sewers: ‘Open nozzle’ and ‘Blind

nozzle’ 1/4" and one 1/8" nozzle, which are fitted on the end of

the high pressure hose.

2. One spray gun with lance for cleaning façades, terraces and

floors.

The spray gun is attached to the end of the high pressure hose

using the open-end spanners. These open-end spanners are

also supplied as standard.

3. Two open-end spanners for tightening and loosening the spray

gun.

4. This user manual

5. Engine documentation

6. One suction hose with strainer.

7. Attachment: high pressure pump

8. Attachment: exploded view drawings and diagrams.

NOTE

Set of accessories may differ between models!

Operating

range

Danger zone

Maximum allowable

pressure

Spray nozzle,

open

Spray nozzle, blind

Spray gun with lance

Open-end spanners

DESCRIPTION AND PRINCIPLE OF OPERATION

14

SAFETY

15

3Safety

3.1 Introduction

This user manual contains very important safety instructions. In this chapter we

provide general instructions. ALWAYS follow these instructions for use and

maintenance. In other chapters we provide specific safety instructions for each action

or situation. ALWAYS follow these instructions too.

Also observe the following safety instructions:

> internal work, operating and safety instructions

> national accident prevention regulations

3.2 General danger symbol

3.3 Working safely

ALWAYS take these three important points into account when working and maintaining

the machine:

> You must NEVER remove protection from moving parts while the machine is in

operation.

> You must dispose of leaked hazardous substances in such a way that there is no

danger to yourself, your colleagues or the environment. Observe the environmental

regulations.

> Prevent all electrical hazards.

3.4 Dangers of non-compliance with safety instructions

Possible consequences of non-compliance with safety regulations:

Dangers to persons

This concerns the exposure of persons to electrical, mechanical or chemical hazards.

Dangers to environment

This includes, for example, the danger to the environment due to leakage of hazardous

substances.

Dangers to the machine

This concerns:

> failure of important functions of the machine

> failure of prescribed maintenance and repair methods

In this user manual we provide various safety instructions. If these

instructions are not followed, there is a danger to persons. Such a

safety instruction is indicated by this general danger symbol (in

accordance with DIN 4844-W9):

NOTE

Failure to comply with the instructions may result in the loss

of any right to compensation.

SAFETY

16

3.5 Use only by authorized personnel

Your employer must carefully document the following:

> the level of responsibility

> the authorizations of the personnel

> the supervision of personnel

You may ONLY operate, service and inspect the machine if you are authorized by your

employer and have the necessary qualifications. Rioned can provide training if

necessary.

You must have read and understood these operating instructions completely before

you start working with the machine. You must keep the manual with the machine.

3.6 Bystanders

> ALWAYS consider your responsibility to other people when working with this

machine.

> Keep unauthorized persons, especially children or animals, out of range of the

machine.

3.7 Restrictions on use

The machine may ONLY be used for:

> unblocking sewers

> for cleaning façades, terraces and floors

NEVER suck up the following substances (option filling hose with strainer):

> combustible liquids

> chemical substances

> substances subject to special rules

Do NOT use the machine in an explosive environment.

Rioned ONLY guarantees the safety when working with the machine if the machine is

used as described in this user manual.

NEVER exceed the following limit values (EN IEC 60204-1):

> ambient temperature: +5 to +40 °C

> storage temperature: -25 to +55 °C

> humidity: 50% at +40 °C (higher at lower temperatures, e.g. 90% at +20 °C)

> elevation of operation: the machine works up to a maximum elevation of 1000 m

without any problems. Above this elevation the machine may not function as well

due to the lower air pressure.

If the machine is not functioning or displays faults, DO NOT continue working. In that

case, contact Rioned by phone (tel. no. +31 13-5479100.

3.8 Thunderstorm

We ADVISE AGAINST working with the machine when the weather conditions or

forecasts are unfavourable. Consider thunder and lightning in particular!

3.9 Spraying

ALWAYS follow the instructions below when spraying:

> NEVER point the jet at people or animals.

> If skin penetration occurs, consult a DOCTOR immediately.

> NEVER spray on live parts, such as electrical equipment.

> NEVER spray the machine itself.

> Prevent damage from splashing or flying parts.

SAFETY

17

3.10 Spray break

If you leave the spraying area for a short time, do the following:

1. Stop the machine (see section ‘Stopping spraying’ in ‘Unblocking a sewer’

and section ‘Stopping spraying’ in ‘Cleaning a wall, terrace or floor’).

2. Depressurize the high pressure hose. Do this as follows:

• Open the high pressure valve.

• Squeeze the trigger of the spray gun.

3.11 Sewer gases

If you use the machine for sewer cleaning, you may be exposed to bacteria and sewer

gases. This is your own responsibility.

3.12 Engine stop

The machine is equipped with an engine stop in the form of a twist knob.

If you need to switch off the engine quickly in an emergency, follow this procedure:

> Ensure that the engine stop is ALWAYS easily accessible.

> Use the engine stop in the event of a dangerous situation or one that is likely to

become dangerous.

> Set the engine stop in the OFF position. The engine stops immediately.

> Under normal circumstances, use the procedure described in section ‘.

After use of the engine stop:

1. First make sure that the danger is no longer present.

2. Turn the engine stop to the ON position.

You can now continue working.

3.13 Levers and valves

> NEVER fasten the levers in position in any way whatsoever, unless otherwise

instructed.

3.14 Personal protective equipment

ALWAYS use the following personal protective equipment when working with the

machine:

> hearing protection

> safety glasses or face shield

> waterproof work gloves

> waterproof workwear

>helmet

> spray boots with steel toes

This safety sticker shows you what you should not spray on:

Recommendation: do not use spray lances shorter than 75 cm.

SAFETY

18

3.15 Water discharge

Ensure that the water is drained off properly.

Clean the discharge water before discharging it into the sewer system in the following

two cases:

> when cleaning with harmful chemicals, or

> when the object to be cleaned is contaminated with environmentally harmful

substances.

3.16 Other machine safety provisions

3.16.1 Pressure regulator

The pressure regulator ensures that the operating pressure never becomes too high

and thus acts as a safety valve.

3.16.2 Non-return valve

The valve ensures that the contaminated water used by the machine cannot get back

into the water supply network.

3.16.3 Temperature protection valve

The temperature protection valve ensures that the temperature of the water in the

pump never gets too high and thus acts as a safety valve.

When the water exceeds the set temperature, the water flows out of the connected

hose.

3.16.4 Protective covers

Your machine is fitted with various protective covers and panels. It is forbidden to

remove these protective covers unless maintenance is to be carried out on the

machine. You should then stop the machine and let it cool down if necessary.

3.17 Supplied documentation

SUPPLIED DOCUMENTATION!

Read the safety chapters of the documentation supplied with

this machine!

It contains information that is not included in this manual.

You can see which documentation is supplied in the

‘Description and operation’ chapter, section ‘accessories’.

SAFETY

19

3.18 Safety sticker

The safety sticker is located on the back of the vehicle. The symbols used have the

following meaning:

1. Hearing, head and eye protection must be worn

2. Safety shoes with extra protection required

3. Reading the manual is mandatory

4. Safety gloves with wrist protection required

5. Protective workwear required

6. Not potable water

7. Risk of slipping

8. Beware of hand injury

9. Rotating machine

10.Warning for automatically starting machine

SAFETY

20

Table of contents

Other Rioned Pressure Washer manuals