5.7. OPERATION WITH DETERGENT

5.7.1. Detergent can only be added when the device is operated in low pressure mode.

▲DANGER When using detergents, the material data safety sheet issued by the detergent

manufacturer must be adhered to, especially the instructions regarding personal protective

equipment.

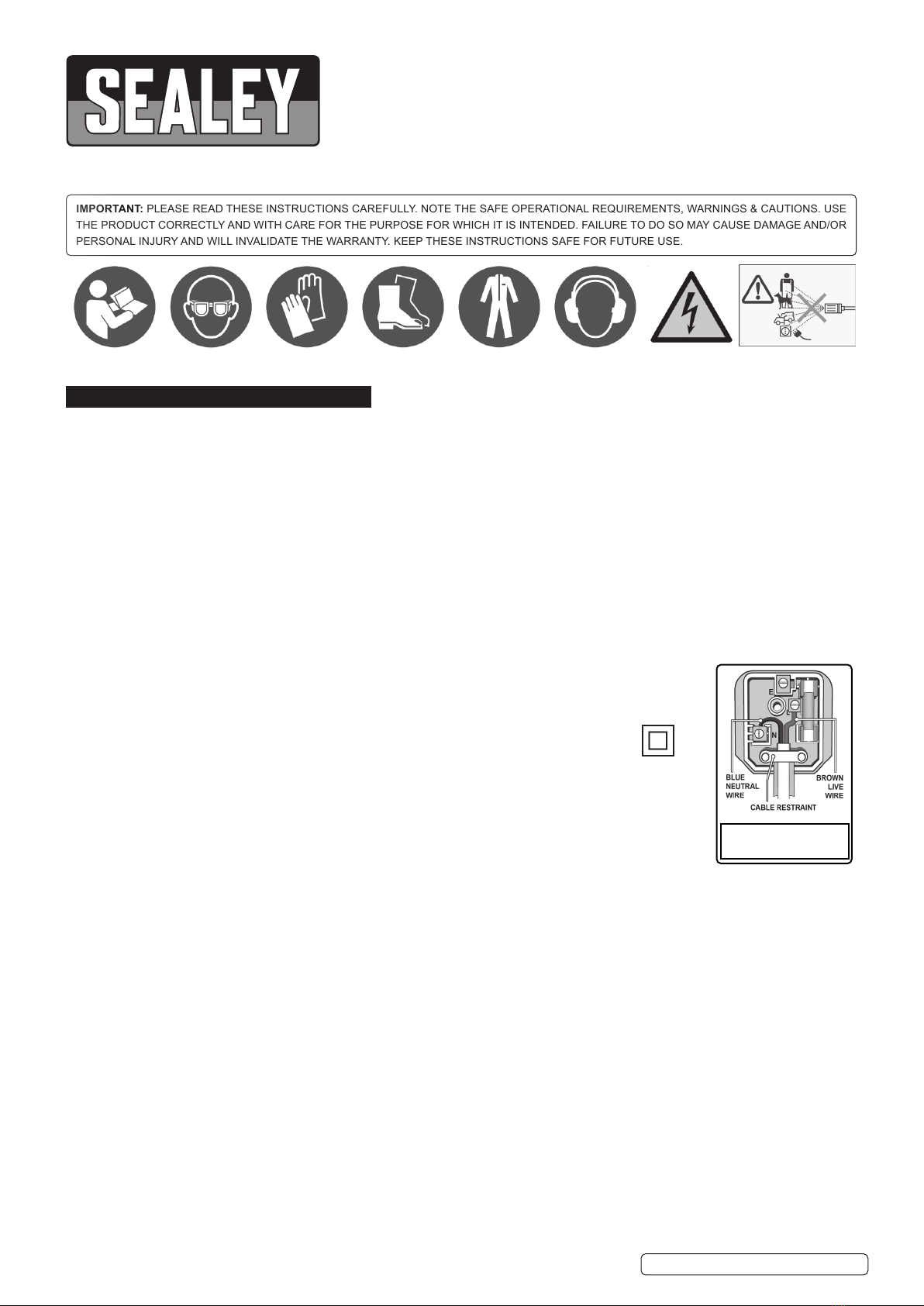

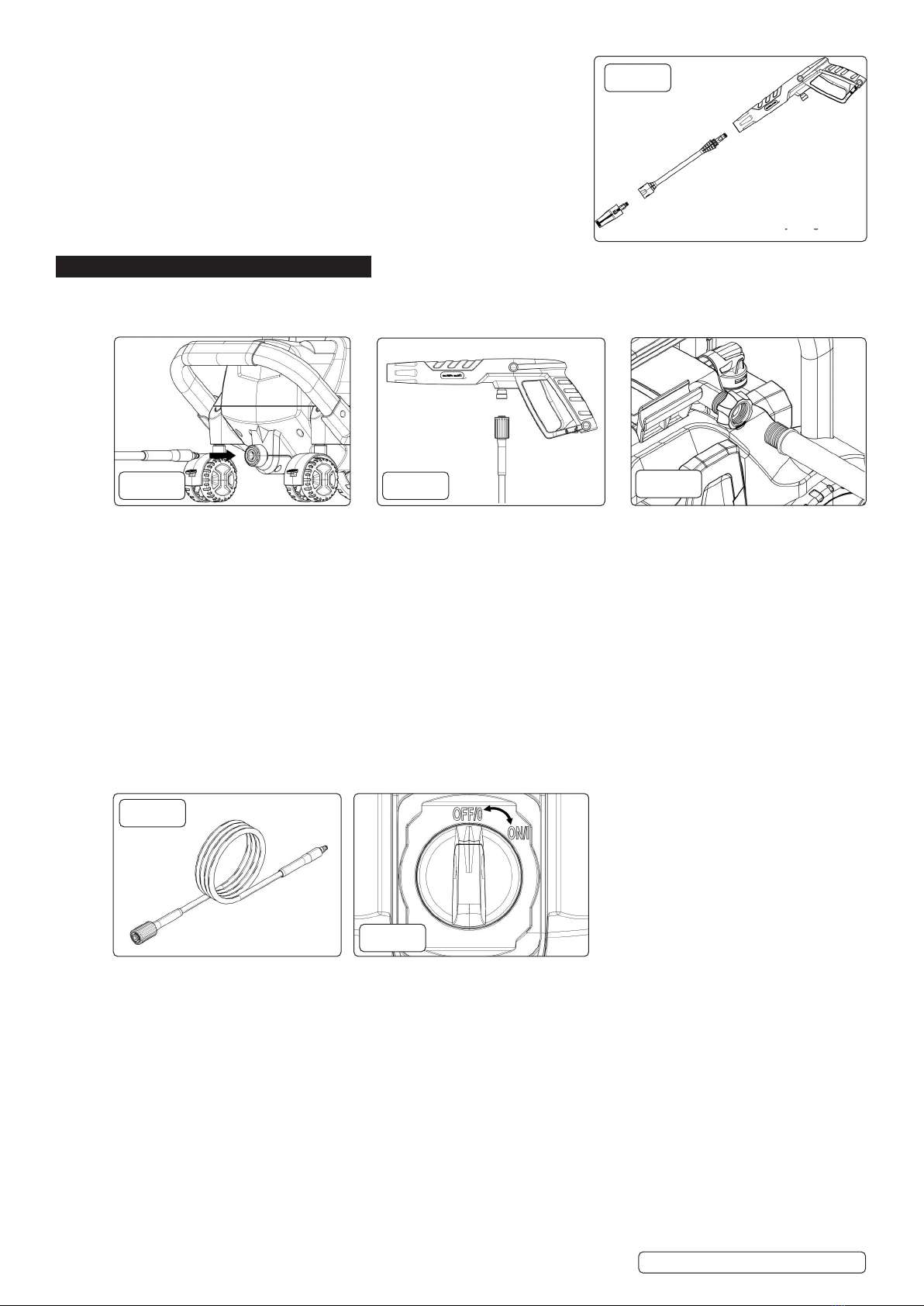

5.7.2. Remove the cap of the clean detergent bottle. Gently pull the on board detergent tank out of its

storage position.

5.7.3. Fill the tank with detergent designed specically for use with pressure washers.

5.7.4. Push the detergent bottle with the opening pointing downwards into the connection for the hose

clean detergent. Make sure you connect the detergent hose to the detergent pipe (g.8).

5.8. RECOMMENDED CLEANING METHOD

5.8.1. Spray the detergent sparingly on the dry surface and allow it to react, but not to dry.

5.8.2. Spray o loosened dirt with the high pressure Met.

5.8.3. After operation with detergent

5.8.4. Remove the hose clean detergent bottle from the intake and close it with the lid.

5.8.5. For storage, put the detergent bottle into the retainer with the cap pointing up.

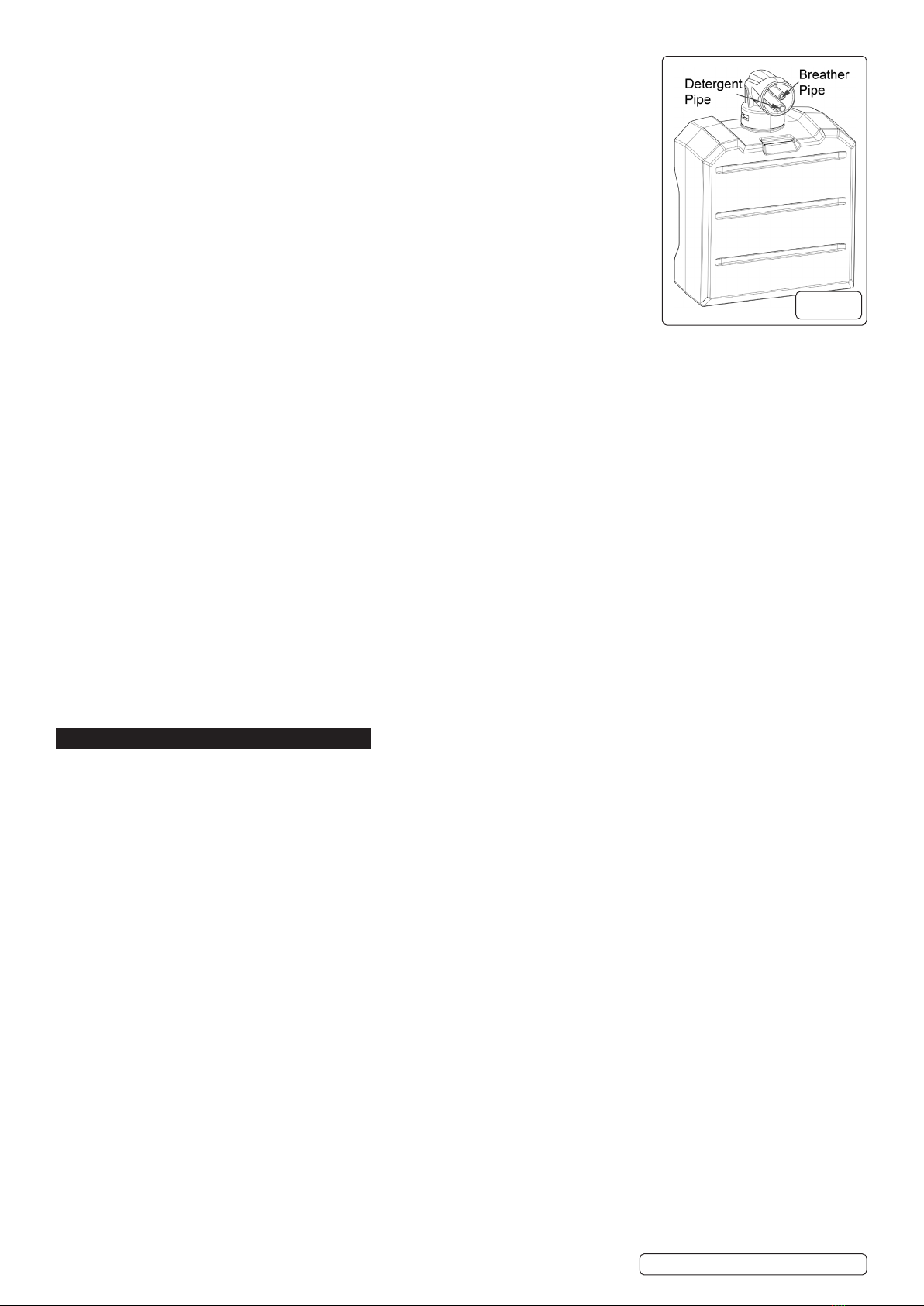

5.9. INTERRUPTING OPERATION

5.9.1. Release the lever of the trigger gun.

5.9.2. Lock the lever of the trigger gun.

5.9.3. Put the trigger gun with the spray lance into the parking position.

5.9.4. During longer breaks(more than 5 minutes), also turn the appliance o using the “OFF/ON” switch.

5.10. FINISH OPERATION

5.10.1. Release the lever of the trigger gun.

5.10.2. Turn o the appliance “ OFF/ON”.

5.10.3. Disconnect the mains plug from the socket.

5.10.4. Only separate the high-pressure hose from the trigger gun or the device when there is no pressure in the system.

5.11. TURN OFF TAP

5.11.1. Pressure the lever of the trigger gun to release any remaining pressure in the system.

5.11.2. Release the lever of the trigger gun.

5.11.3. Lock the lever of the trigger gun.

WARNING! When disconnecting the supply or high pressure hose, warm water may leak from the connection after operation.

5.11.4. Detach the appliance from the water supply.

5.12. WHEN TRANSPORTING BY HAND

5.12.1. Switch the product o and disconnect it from the water and power supply.

5.12.2. Pull out the transport handle until it audibly snaps into place. Attach transportation guards, if applicable.

5.12.3. Pull the appliance by its transport handle.

5.13. WHEN TRANSPORTING IN VEHICLES

5.13.1. Prior to horizontal transport: close the cap of clean detergent bottle.

5.13.2. Tilt the product towards you until it balances on the wheels. Then move it by its transportation handle.

5.13.3. Protect the product from any heavy impact or strong vibrations which may occur during transportation in vehicles.

5.13.4. Secure the appliance against shifting and tipping over

6. MAINTENANCE

6.1. Consider the weight of the appliance when storing it.

6.2. STORING THE APPLIANCE

6.2.1. Park the machine on an even surface.

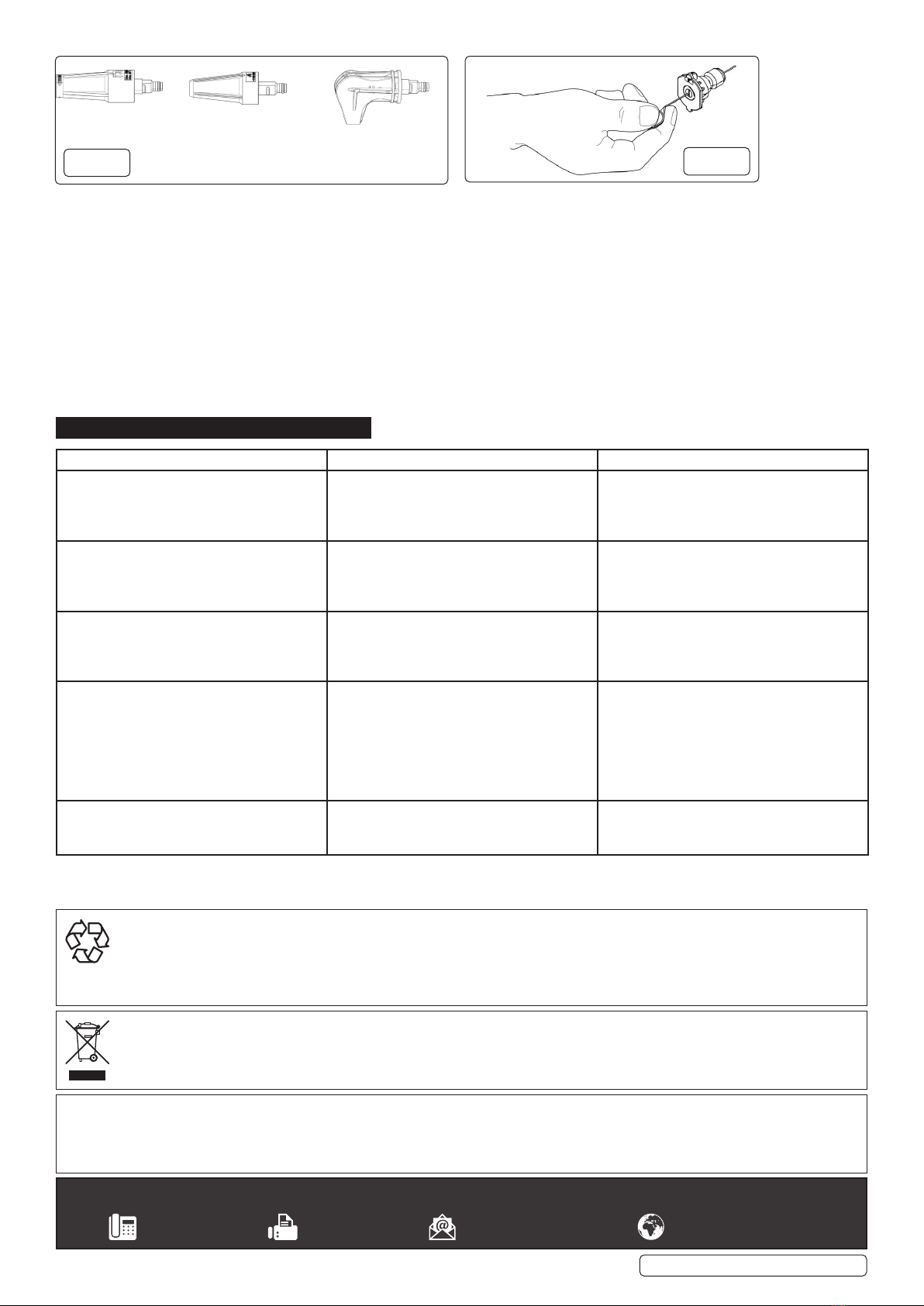

6.2.2. Detach spray lance from the trigger gun.

6.2.3. Push the disconnect button on the trigger gun and pull the high-pressure hose out of the trigger gun.

6.2.4. Place the trigger gun into the storage for the trigger gun.

6.2.5. Put both spray lances into the storage for the spray lance.

6.2.6. Dirt grinder spray lance: Nozzle towards the bottom.

6.2.7. Coil the high-pressure hose and hang it over the hose storage.

6.2.8. Store the mains connection in the accessory compartment.

6.2.9. Prior to extended storage periods, as during the winter, also observe the instructions in the care section.

6.2.10. Always store the pressure cleaner, parts, and accessories in a place that is inaccessible to children. The ideal storage temperature is

between 10 °C and 30 °C. Store the power washer indoors to prevent the water in the unit from expanding under freezing conditions.

6.2.11. We recommend using the original package for storage or covering the product with a suitable cloth or enclosure to protect it against

dust.

6.3. FROST PROTECTION

WARNING! Appliance and accessories that are not completely drained can be destroyed by frost.

6.3.1. Completely drain appliance and accessories and protect them against frost. To avoid damage:

6.3.2. Detach the appliance from the water supply.

6.3.3. Detach spray lance from the trigger gun.

6.3.4. Turn on the appliance “ON/OFF”.

6.3.5. Push the lever of the trigger gun until no more water is escaping .

6.3.6. Release the lever of the trigger gun.

6.3.7. Lock the lever of the trigger gun.

6.3.8. Turn o the appliance “ON/OFF”.

6.3.9. Store the appliance and the entire accessories in a frost free room.

6.3.10. The high pressure hose is specially constructed with reinforced walls it can be easily damaged and should be stored carefully.

8DO NOT kink the hose.

8DO NOT drive vehicles over the hose.

8DO NOT expose the hose to sharp edges or corners. Misuse will lead to ballooning or premature failure and will invalidate warranty.

g.8

Original Language Version

© Jack Sealey Limited PW2000PA Issue 2 (2) 10/02/21