Ripmax Hellcat Slim User manual

Other Ripmax Toy manuals

Ripmax

Ripmax Wots Wot FOAM-E User manual

Ripmax

Ripmax WOT trainer User manual

Ripmax

Ripmax Wot4 EP/GP User manual

Ripmax

Ripmax WOT4-E User manual

Ripmax

Ripmax EF - 2000 TYPHOON Owner's manual

Ripmax

Ripmax Acro Wot mk2 User manual

Ripmax

Ripmax J!VE Fun Fly User manual

Ripmax

Ripmax Hawker Hunter User manual

Ripmax

Ripmax Polar Violence Cross-Country User manual

Ripmax

Ripmax WOT 4 Pro Mk2 User manual

Ripmax

Ripmax Trainer 40 User manual

Ripmax

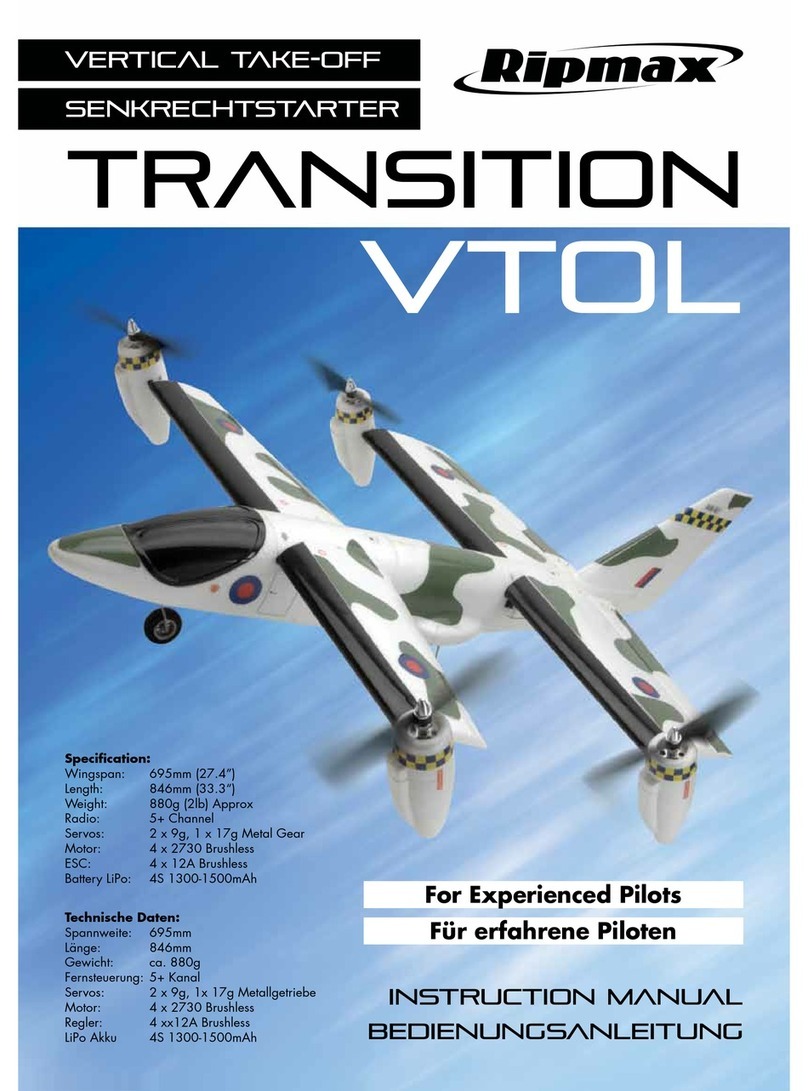

Ripmax Transition Vtol User manual

Ripmax

Ripmax Phase 5 E User manual

Ripmax

Ripmax Acro Wot MK2 XL User manual

Ripmax

Ripmax WOT 4 FOAM-E User manual

Ripmax

Ripmax MINI BOLERO User manual

Ripmax

Ripmax WOT4-E User manual

Ripmax

Ripmax Super X-Blaze RTR User manual

Ripmax

Ripmax NANO Boomerang User manual

Ripmax

Ripmax mini Bossanova User manual

Popular Toy manuals by other brands

FUTABA

FUTABA GY470 instruction manual

LEGO

LEGO 41116 manual

Fisher-Price

Fisher-Price ColorMe Flowerz Bouquet Maker P9692 instruction sheet

Little Tikes

Little Tikes LITTLE HANDIWORKER 0920 Assembly instructions

Eduard

Eduard EF-2000 Two-seater exterior Assembly instructions

USA Trains

USA Trains EXTENDED VISION CABOOSE instructions