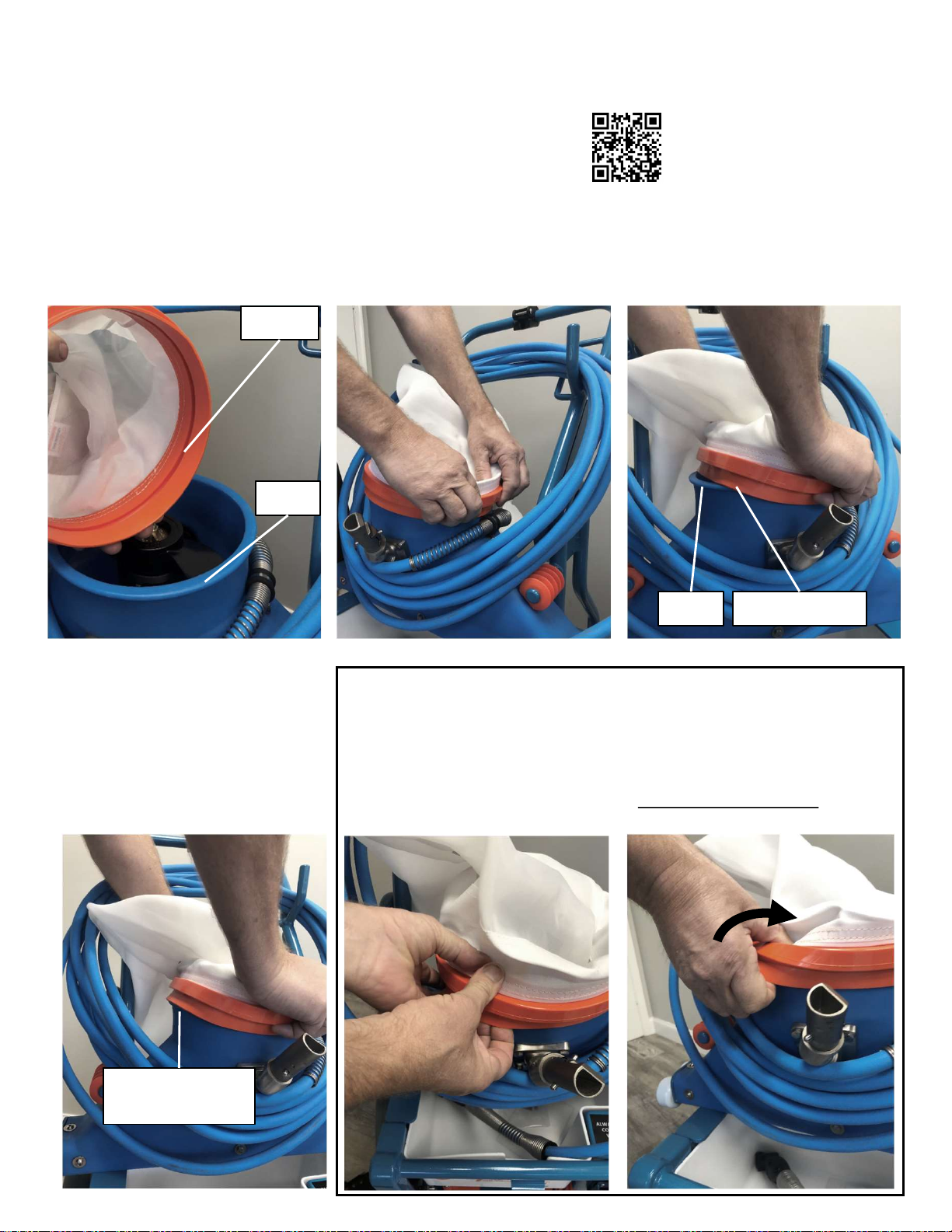

Understanding Filter Bag Options

There are several different bags available, the hole size in the cloth is measured in microns, the higher the

number the larger the hole that is in the filtering cloth. Bags are available in 25,60,75,100,200 and 400

micron. There is also a heavy net bag available, the heavy net bag is the only one that will work for a pool

with algae. It will be necessary to experiment with different bags to find the best one for your situation.

•A finer bag will vacuum slower and plug easier.

•A plugged bag can’t vacuum at all and will push debris away from the vacuum.

•Algae will plug all bags except the heavy duty net bag.

•Algae will need to be vacuumed to waste (with a pump) after removing the

large debris with the heavy duty net bag.

Available Bags:

GRAY RING Heavy Duty Net Bag (no filter cloth) (3/16 inch holes) This is the only bag that will work with

algae, it removes the large debris and allows the algae and fine debris to pass through so it can easily be

vacuumed to waste without clogging your vacuum hose with the leaves and large debris.

BLACK RING Coarse (400 Micron) Leaves and large debris.

YELLOW RING Medium (200 Micron) Leaves and general debris

ORANGE RING Standard (100 Micron) General debris and sand.

RED RING Fountain bag (100 Micron) This bag uses the same filter cloth as the standard bag but it is short

enough that it won’t drag on the floor of the pool when vacuuming in shallow water or when vacuuming

large amounts of debris like sand.

GREEN RING Ultra Fine (75 Micron) Fine sand and granular particles.

BLUE RING Extreme Fine (60 Micron) Very fine particles, some pollen.

PURPLE RING (25 Micron) This is a true dust bag it will remove most pollen, black dirt, cement and other

small particles. It may plug and need to be emptied even though it looks like there is very little debris in

the bag.

Plugged Bag/Reduced Suction

Reduced suction occurs when a bag becomes clogged, in this scenario the bag will have a lot of pressure

and appear hard. When the bag is clogged water can’t pass through it so water moving into the vacuum

head is reduced, when a bag becomes totally clogged water will be forced backward out through the

intake so debris will be pushed away from the vacuum, when this occurs you either need to empty the

bag and/or switch to a coarser bag.