ritm RDD2 User manual

Magnetic wireless sensor

RDD2

Data sheet

Device identification number

2

1. General Information

The RDD2 radio channel magnetic contact sensor (hereinafter referred to as the

device) is designed to be used as an opening sensor (reed relay). The device generates

alarm signals for sensors, additional ribbon cables, enclosure break-in, and transmits

them to the control panel.

2. Manufacturer:

195248,

Energetikov avenue, building 30, block 8,

St Petersburg, Russia

Tel.: +7 911 795 02 02

3. Package Contents

Magnetic wireless sensor RDD2

1 pc

N35-6-25 magnet in enclosure

1 pc

Magnet backing plate

3 pcs

2 mm jumper

2 pcs

Enclosure tear-off tamper1

1 pc

Enclosure break-in tamper

1 pc

АА ER14505 3.6В battery

1 pc

Kit for fastening enclosure and magnet to surface

1 pc

Data sheet

1 pc

Packaging

1 pc

1Installed by default

3

4. Technical Specifications

Parameter

Value

Communication channels band, MHz

433.075–434.775

Number of communication channels

7

Maximum distance for strong signal, line-of-sight, m

600

Transmitter radiated power, mW

not exceeding 10

Reed relay gap (in between magnet), not exceeding, mm

10

Monitoring period of device operation in radio system, min

4

Enclosure break-in tamper

Yes

Surface tear-off tamper

Yes

Normal state setup for additional wire loop

Yes

Radio system configuration w/o personal computer

Yes

Battery type, 3.6 V

Li battery

Standalone operation time from one battery, yrs

up to 32

Dimensions, mm

29×101×38

Weight, g

63

Operating temperature range, °С

−30…+55

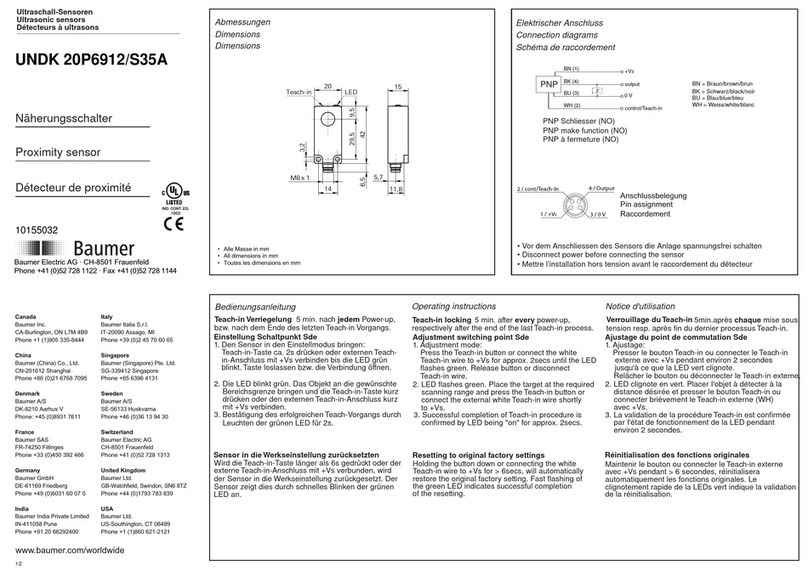

5. Arrangement of Elements on the Device Board

2The stand alone operation time is directly related to the operating conditions.

4

Part

Designation

XT1

Connector for alarm additional wire loop.

This connector may be connected to auxiliary ribbon cable of ‘dry

contact’ alarm. Ribbon cables allows its normal state setup (NC or

NO).

SA1

Reed relay

SA2

Tamper button

XР1

Not used

JMP1

JMP2

JMP3

Jumpers for changing operating modes.

Jumpers should be installed with the battery removed.

Designation of jumpers is described in Paragraph 6.

Red and green LEDs are located on the back of the RDD2 board.

The operating modes of these LEDs are described in Paragraphs 7.

6. Designation of Jumpers

To change a device’s operating mode, remove its battery, install (remove) necessary

jumpers, and place the battery back respecting its polarity.

Installed Jumpers

Operating Mode

JMP1

Mode of addition to radio system

JMP2

Not used

JMP3

Radio channel test mode

JMP1 + JMP3

Configuration hardware reset mode

All jumpers removed

Operating mode

7. Visual Indication3

Operating Mode

Red Blinks once

Device received acknowledgment

signal indicating that transmitted

alarm signal was received by control

panel

Red/Green

Alternating once per second

Tamper open

Red

Blinks 2 times after 5 s

Battery depleted

3Battery and radio channel test modes are described in Paragraph 8.

5

Configuration Mode

Red + Green

Always on

Device ready to be connected to PC

Red

Blinks 5 times

Getting ready for configuration reset

Red

On

Configuration reset to factory settings

Red

Blinks faster than once

per second

Device not added to radio system

Red

Blinks 5 times after 3 s

Faulty device

8. Device: Getting Ready for Operation and Adding to Radio System

8.1. Place a device on a fixed surface of a door or window opening at least 1 m from

the receiving radio channel device. Install the mating piece to the window frame

or door.

Do not place the device in the vicinity of EMI sources, large

metal objects and structures, power cable runs!

8.2. Open the enclosure.

8.3. Install a battery and close the cover.

8.4. After closing the device cover or installing the battery, the device switches to

battery test mode, signaled by the red indicator turning on for 2 seconds. If the

battery had not been in use for a long time, it depassivates. The red indicator

lights up in series of flashes illustrated in the figure below up until the moment

the battery goes into the normal operating mode. If a battery remains in this

mode for longer than 15 minutes, it is recommended to replace it.

t

Red

2 s

1 s

4 s

1 s

1 s

After testing a battery (the battery now operates at its normal voltage), the red

indicator will light up for 4 seconds, and then the green indicator lights up for 1

second.

If the depassivation has not been performed, the red indicator lights up for 2

seconds, after which the green indicator lights up for 1 second.

6

t

Red

Green

t

2 s

1 s

The battery is tested each time the device cover is closed!

8.5. If the red indicator emits short flashes twice in 5 seconds (not to be confused

with the battery test mode), this means the battery is depleted and needs to be

replaced.

8.6. Switch the device to the mode of addition to a radio system (see Paragraph 6).

Add the device to the control panel radio system according to the radio system

instruction. The distance between the device and the receiver should be at least

1 m. The device then receives settings from the control panel. The addition

process is illustrated in the diagram:

t

Device

successfully added to

radio system

Adding to radio

system is in

progress

Red

The active device

has been found

Green

The device

switched to

adding mode

8.7. Switch the device to the radio channel test mode (see Paragraph 6).

8.8. Make sure the message exchange quality is strong in the supposed installation

location by referring to LED indicators. 2–3 missed responses are OK for 10

transmitted messages:

7

Green

Red

Got the answer

Send test message

8.9. If an additional alarm wire loop is used, insert the ribbon cable and connect it to

the XT1.

8.10. Put corresponding wires in slots and secure the enclosure base on the surface.

An enclosure tear-off tamper is installed by default.

8.11. Switch the device to the standby mode (see Paragraph 5).

8.12. Verify the signal path for alarm signals of the sensor, tamper, and, if necessary,

additional alarm wire loop by referring to LED indicators.

8.13. Install the mating piece (magnet) not further than 10 mm away from the SA1 reed

relay. If necessary, use backing plates.

8.14. The device is ready for operation.

9. Hardware Reset to Factory Settings

Remove the battery from its holder, install the JMP1+JMP3 jumpers, and place the

battery back. This procedure is shown in the diagram:

t

5 times

The device reset settings

Red

The settings have been reset

to factory settings

The radio signal strength between the device and the control panel is

determined by the level of signal attenuation, which can be seen in the radio

channel security and control panel configuration software, page Radio Device

Map. For more information please refer to the control panel user manual.

8

10. Replacing Battery

If necessary, clean the bonding pads and replace the battery. When replacing a

battery, close the battery contacts for 2 seconds and then install the new battery.

11. Transportation and Storage

The device should be transported in packaging in closed vehicles. Storage premises

should be free of current-conducting dust, acid and alkaline fumes, corrosive gases and

gases harmful to insulation.

12. Maintenance and Safety Measures

All setup and maintenance activities applied to the device should be performed by

duly qualified personnel.

13. Manufacturer’s Warranties

The manufacturer guarantees that the device complies to requirements of the

technical specifications, provided the client ensures compliances to conditions of

transportation, storage, installation and operation.

Although the warranty period is 12 months from the commissioning date, it may not

exceed 18 months from the production date.

The warranty storage period is 6 months from the production date.

The warranty does not cover the battery.

The manufacturer reserves the right for modification of the device in any way that

does not degrade its functional characteristics without prior notice.

14. Information on Claims

In case of a device failure or defect during the warranty period, please fill in a

malfunction report specifying the dates of issue and commissioning of the device and

nature of the defect and submit it to the manufacturer.

Table of contents

Popular Accessories manuals by other brands

AECO

AECO SMC-12 NO SS BC HF AGD1 Series operating instructions

Endress+Hauser

Endress+Hauser Oxymax COS61D operating instructions

NuTone

NuTone LB-55 Wiring instructions

McIntosh

McIntosh MCINTOSH R649 installation guide

Lufft

Lufft CHM 15k Nimbus manual

Wieland

Wieland sensorPRO STS installation instructions