Riverside FFA-14003 User manual

MODEL NUMBER

FF

A -

14003

RWiiside

I

OWNER'S

GUIDE

ASSEMBLY

AND

ADJUSTMENT

carefully

and

com:Jactly

crated

Your

Sport

Bike

has

been

condition

.

Carefui

assembly

familiar

with

the

workings

assembly

and

adjustment

are

assembly

.

of

your

Riverside

will give

you

and

minor

adjustments

packed

with

your

mach

ine.

1.

After

removing

the

lid

of

the

crate

you

,,,ill

observe

that

packing

braces

are

located

at

the

handlebars

and

seat

post.

Pernove

the

bolts

fastening

the

packing

braces

to

the

side

of

the

crate

and

remove

rE'ar

brace

.

(Fig

. 1).

2.

Remove

seat

and

handlbar

s

from

crate

.

(

Fi

q. 2).

3.

Re

mov

~

ma

chin

e

and

s

et

on stand a

nd

rear

w

hee

l.

(F

ig.

3)

.

Re

m

ove

large

box

containing

front

wheel

and

fe n

der

.

4.

Dur

ing

shipment

the

suspension

spring

inside-

each

fork

tube

might

have

become

jurrecl

loose

on

the

s

pr

ing-olock

onto

which

the

spring

is

spiraled

.

Both

the

spri

ng

and

block

ar

e

insid

e

the

fork

and

canri0t

be

s

ee

n.

The

spring

can

be

snugged

onto

the

spring-bl

ock

by

simply

t

urni

ng

each

lower

fork

tube

clockwise

(to

the

right)

1/8

to

1/2

turn.

You will feel

the

sprin

g

spiral

onto

the

spring

block

and

then

butt

against

it.

Further

turning

only

twists

the

spring

and

you

will

sense

the

"springy

feel"

as

the

spring

resists

the

twist.

5.

Remove

the

tools

from

the

tool

box

.

of

th'i:!

Fol l

ow

to

br

ing it

t'.J

0 in circelle

nt

an

excellent

oppor

tuni

· -

'='

?eCOmG

co

nt

rols.

The

too

ls r

ec

'::-ssor

for

the

steps

.

below

for

q

u·ck

and

easy

fig. 1 e 2

fig. 3

6.

Installat

i

on

of

front

fender

. The

enr

J of

the

fender

with

the

longer

curve

is

m

ounted

at

the

front.

(Fig

. 4 ).

v. Th

ere

are

two

bo

lts

on

the

l

ower

tulJe

of

each

fork

about

midway

dow

n.

Slip

one

vertical

fender

brace

over

these

bo

lts,

then

the

flat

wa

she

rs

,

lock

washers

and

nut

. Leave nuts

loose.

b.

Twist

opposite

lo

wer

for

k

so

that

the

bolts

swing

into

th

e

ot

h

er

brace

as

shown

in

photograph.

Put

on

washers

a

nd

nuts

as on

other

si

de

and

tight

en

nuts

on

bot

h sides.

7. Pe

mov

e

the

front

wheel

from

its

pack

ing

box

and

examine

.

(F

ig. 5 ). On

right

side

i

rider's

view)

of

the

wheel

are

the

brn

k

~

cctuc;t

in

g l

ever

and

the

torque

arm

.

The

sp

ee

dom

eter

drive

is

on

the

left

side

.

On

the

spe

edometer

drive

there

is

an

"L

" sh

aped

drive

arm

which fits into

<J

hole

in

the

brake

drum.

Be

sure

this

ar

m

is in

the

drum

hole

and

remain

s

there

as

the

wh

ee

l is

mounted.

8. MOUNTIG

OF

FRONT WHEEL.

;

i.

Loosen

outer

nut»

on

eoch

si

de

;f

axle suff

ici

ently

to

<1ccept

the

for

;-

.

Do

not

remove.

b.

Sl

ip

the

axle

snugly

into the

forl<

ke

ep

ing

the

flat

washers

bet

we

en

thf!

fork

and

the

outer

ax le nuts. 'Nhile

moun

ting

the

wheel

on

the

fork,

sl

i

r,

the

to

rque

arm

over

the pi n lornte:

cl

about

two inches

above

the

bo•t

om

0f

the

right

(r

i

der

's

view)

fork.

l"

ec:r

the flat

portion

of

the

s

peedo

rne~

-::

r

dr

ive hori

zontal

as

shown

.

(F

ig

.

6)

c. O

il

the

speedometer

dr

ive

throug

h t

h.;,

hall

-;

ealed

hole

at

the

hottom

of it.

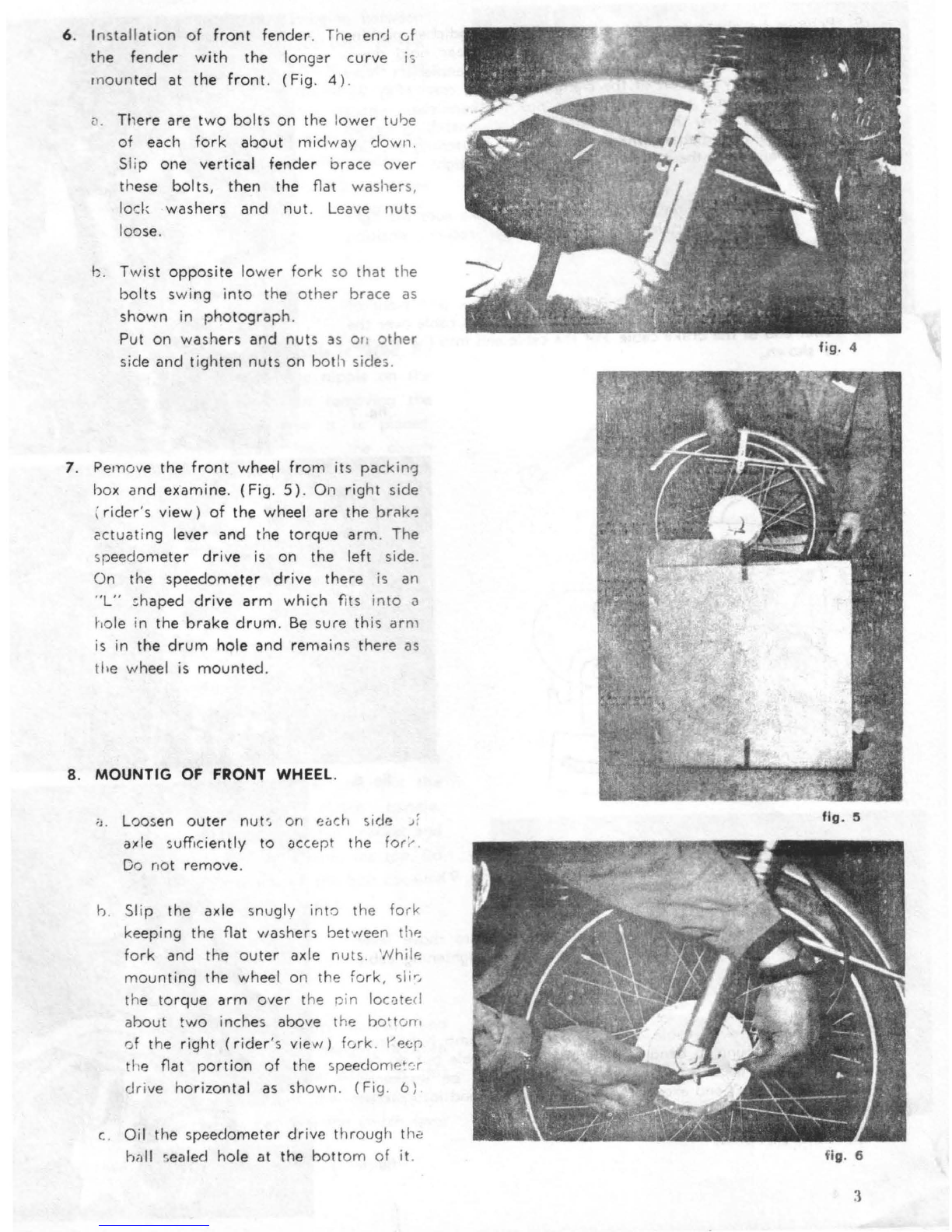

fig. 4

fig. 5

fig. 6

9. Remove

headlight

to

make

removal

of

the

handle

bar

packing

bar

easier

. (Fig.

7)

. Remove

the

two

handleba

r hold

down

clamps

and

replace

the

packing

bar

with

the

hand

lebars.

Note

that

the

heavy

portion

of

the

clamps

is

to

·

the

rear.

(Fig

.

8).

Put

on

OM

clamp

without

tightening,

pos

iti

on

hand

l

ebars

where

desired

,

and

allow

them

to

swing

down

while

in

sta

lling

second

clamp

.

Hold

handlebars

where

desired

while

tighten

ing

one

side

a

littre

and

then

the

other

until

both

sides

are

t

i

gh

~

.

10.

Put

headlight

back

on

without

tightening.

Make

sure

the

light

will

make

good

electrical

contact

with

the

bracke

ts,

position

properly

and

tighten.

11. Uncoil

brake

cable

and

put

between

right

fo

rk

a

nd

front

of

frame.

Slip

the

plastic

sleeve

for

retaining

excess cable

over

the

lower

end

of

the

brake

cable

.

Put

the

cable

end

into

the

bracket

as

shown.

fig.

7

12. Draw

cable

down

.to

brake

actuatin

g lev

er

. (Fig.

9)

.

13. Use

wrench

on

large

nut

of

actuating

lever

to

move lever

upward

. Hold in

this

upward

position

while

tighten

ing

cable

clamp

.

14. Slip

cable

through

cable

clamp

and

tigh

te

n

clamp

nut.

Draw

nut

tight

enough

to

bend

and slightly flatten

cable

but

do

!lOt

Q>.Jttr

·ti9htttn because the

damp

or

cable

mqy

be

weakened

~

"d

f~

f

b~k

,

Bend excess

cable

back and

sl

ip end into

plastic

sl~

vc

tor

excess

.

fig. 9

4

15. There

are

two cables hanging between

the

front

forks. One leads back to the

carburetor

and

is

the

throttle

cable.

Th~

other

leads back to the transmission

and

is

the clutch cable. Bring

the

throttle

cable up to

the

right

grip

. Open the

plate on the twist grip. See sketch

A.

Insert the nipple

end

of

the

inn

er

cable

in

to

the

slotted

retainer

as illustrated.

(Fig.

10).

16.

Th

e end of the clutch cable is taped.

Be

careful no o loose

the

nipple on the

end of the cable when removing

the

tape

and

observe how it

is

placed.

Remove

the

screw from the clutch

handle and remove handle. Put

the

end

of the cable through

the

bracket

on

the

handleb

ar

as illustrated. (Fig.

11)

.

Tighten the knurled

nut

to

compress

spring.

17. Push

the

clutch lever,

on

the top

of

the

transmission, to

ward

the

center

of

machine

and

block

in

this position. Do

not remqve the

end

of

the

cable

at

the

engine.

At

the

handlebar

end,

put

the

nipple

through

the clutch handle.

Mount Handle

on

handlebar

bracket

and

slip bolt

through

hole from the top.

Do

not over-tighten

nut

on

the

bol t because

otherwise

handle

wi

ll

bind.

18. The light switch, horn

button

, and

engine

stop

assembly

is

hanging between

the forks. Remove the

strap

on this

assembly

and

mount

the

assembly

on

the handlebars between

the

dutch

lever

and

the

left grip.

fig.

10

Sketch A

fig.

11

5

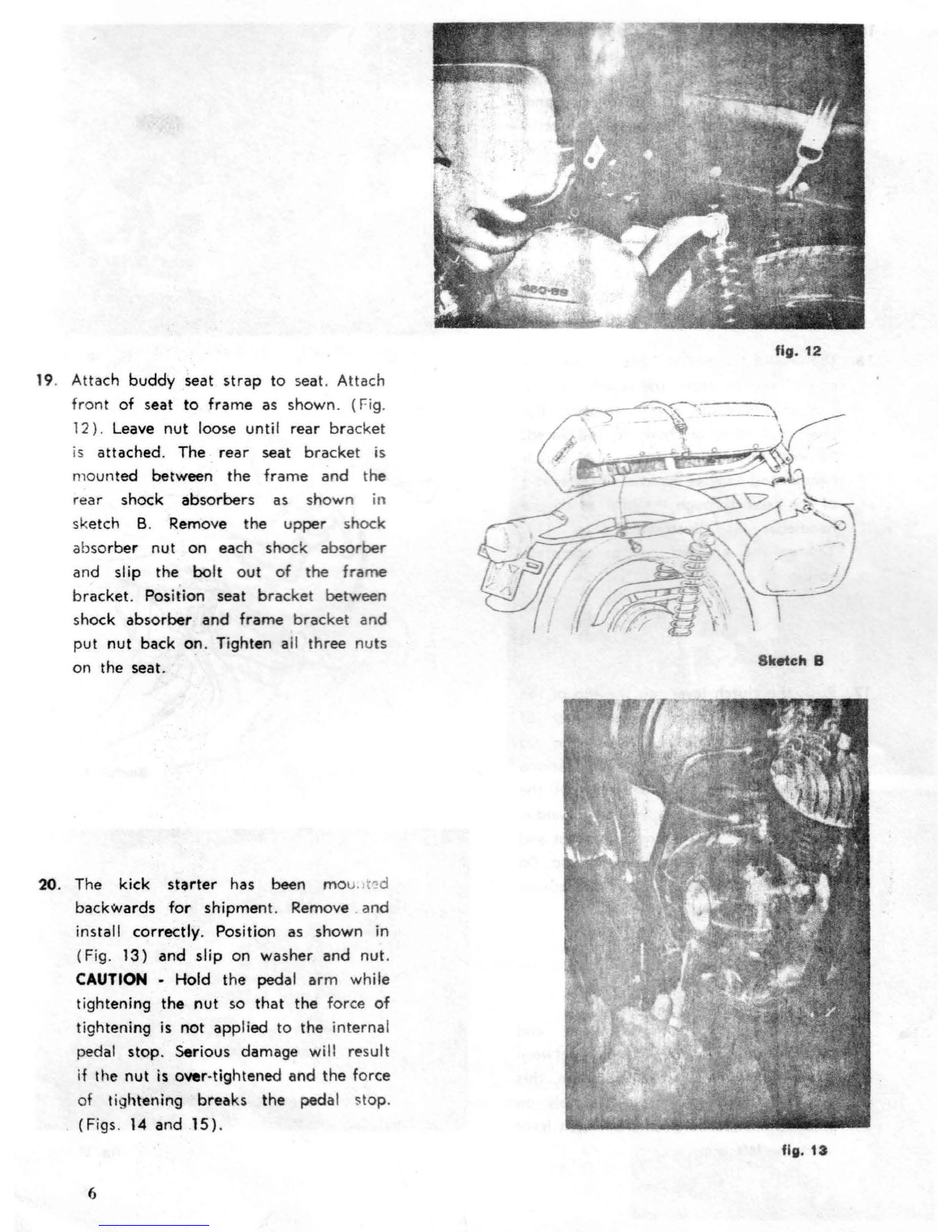

19. Attach

buddy

seat

strap

to

seat. Attach

front

of

seat to

frame

as shown. (Fig.

12)

. Leave

nut

loose until rear

bracket

is attached. The

rear

seat

bracket

is

mounted between

the

frame

and

the

rear shock

absorbe

rs

as

shown

in

sketch B. Remove the

upper

shock

absor

ber

nut

on

each shock

absorber

and slip the

bolt

out

of

the

frame

brack

et. Position seat

bracke

t between

sh

ock

absorber

and

frame

bracket

and

put

nut

back on. Tighten a

ll

three

nuts

on the seat.

20. The kick

starter

has been

mo

u.

1t-:

d

backwards

for

shipmen

t. Remove . and

install

correctly

. Position as shown in

(Fig.

13)

and

sl

ip

on

washer

and

nut.

CAUTION -Hold the pedal

arm

while

tightening

the

nut

so

that

the force

of

tightening

is

not

app

lied to the internal

pedal stop.

Ser

i

ou

s damage will result

if

the

nut

is over-tightened

and

the

force

of

tightening

breaks

the pedal stop.

(Figs. 14 and .

15)

.

6

Hg.

12

Sketch B

fig.

13

' I

:1

t

'I)

21

. The

brake

pedal was also mo

unted

b

ackwards

for

shipmen

t.

Re

move

the

pedal with the

attached

cable.

Sl

ip

the

i

nner

and

outer

cable

s

into

brack

et

on

frame as shown in

the

sketch

C.

Run

the cable up

over

the

foot

r

ets

. Re

mount

pedc11

(Fig.

16),

slip on

washer

and

not,

and tighten

nut

.

If

rear

wheel d

oe

s not

spin freely, ad

ju

st cable

at

rear

wh

ee

l.

22. The shift pedal ls also mou

nte

d

back

-

wards

fo

r shi

pment

. Remove

bolt

and

ni

ount c

orrect

ly.

I

I

Sketch C

fig. 15

fig. 1

45

7

TIRES

ire

pr

ess

ur

es

are

i

mportant

to

the

safe

h

and

ling

o·

your

·versicle. C you

tires

at

regular intervals

and

be

sure

to keep

them

at

the

following

pr

es

sures

(co

ld

after

i g):

Front

Tire: 22 l

bs

. Rear Tire:

32

l

bs

.

LUBRICATION -

Your R

iv

erside

Sport

B

ik

e two-cycle engine never needs

an

"oil

change";

a

fresh

supply

of

oil is

continu

ou

sly

carr

i

ed

to

the

vital

inner

parts

of

the

engine

with

the fuel.

There

is

never a y waiting

for a

warm

-

up

of

the oil

for

p

roper

lubrication.

BREAK-IN PERIOD

Important -During

the

break-in

period

( 1,000

miles)

the

amount

of

oil mixed

with

the

gasoline

is

increased

from

5%

to

7%.

Use

the

following

chart

in

prepar

ing

the

proper

mixture

.

Gallons

of

Regular Gasoline

5

2

1

1/ 2

(2

qts.)

Add

this amount

of

oil

42

oz.

17 O'Z.

9 oz.

3 capfuls

Us

e

Wards

Riverside 2 cycle engine oil No. 61-8311

winter

and

sum

mer.

Be

sure

gasoline

and

oil

are

thoroughly

mixed in

the

gas

tank

befor

e

starting

engine.

AFTER BREAK-IN PERIOD

After 1,000 miles

and

for

th

e life

of

your

Riverside

use

a 5% mixt

ure

of

oil

and

regular gas

oline

.

There

is a

meas

uring

cap

built

Into

the

filler

bn

your

gas

tank.

For

eac

h qua

rt

of gas

put

into

your

tank

add

one

capful

of

oil.

For mixing

in

larger

quan

t

1.1

es

fellow

the

following

chart.

Gallons

of

Regu

lar Gasoli.,.

5

2

1

1/ 2 (2 qts.)

Add

this amount

of

oil

32 0%, ( 1

qt.)

12

oz.

6

oz.

2

c;1pful1

OPERATION

STARTING

THE

ENGINE

1. Open the petcock

at

the

bottom

of

the

gasoline

tank

by

putting

the lever

in

a vertical position. This petcock should be kept closed

(lever

horizontal)

whenever the vehicle

is

not in use.

2.

Check to see

if

the

transmission

is

in

neutral by rolling

the

bike

forward

slightly.

If

the

bike rolls wit

hout

turning

the

engine over,

te

transmiss

ion

is

in

neutra

l.

If

the

engine

turns

over, see section

on Changing Gears for

instructions

.

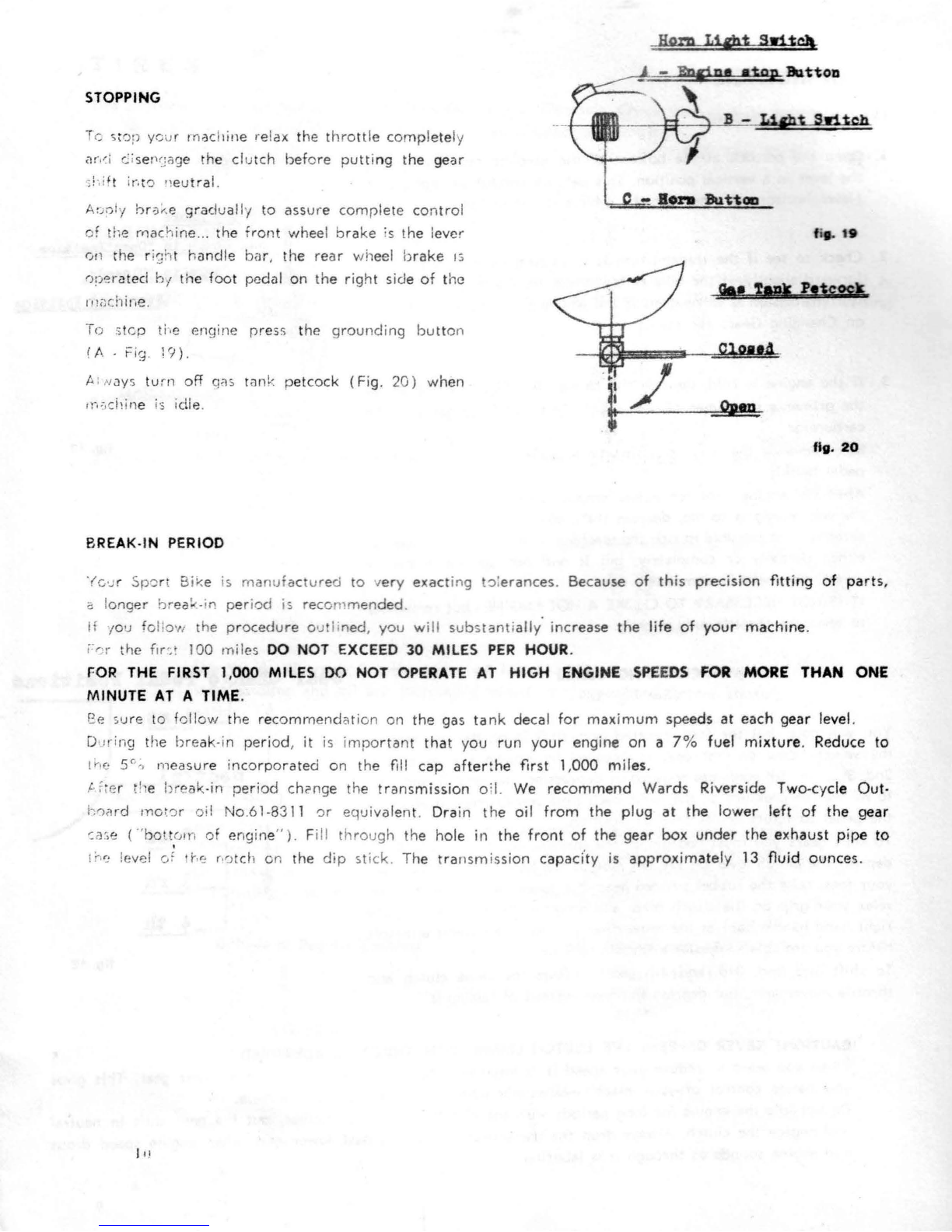

3.

If

the

engine is cold,

depress

the

choke

(A -Fig.

17)

and

pump

the

primer

a few times (B -Fig.

17)

. This will

force

~as

into

the

carburetor

.

Next, advance

the

twist

grip

throttle

slightly

and

kick.

the

starter

pedal briskly.

After the engine runs for a few seconds, lift

the

choke

lever.

If

the

engine begins to die,

depress

the

choke

again

for

a few

more

seconds.

It

is

possible

to

ride the

machine

with

the

choke

depressed

either

partially

or

completely,

but

it will not

operate

efficiently

unless the

choke

is

completely

out

.

IT

IS

NOT

NECESSARY

TO CHOKE A

HOT

ENGINE -

but

remember

to

open

the

throttle

only slightly.

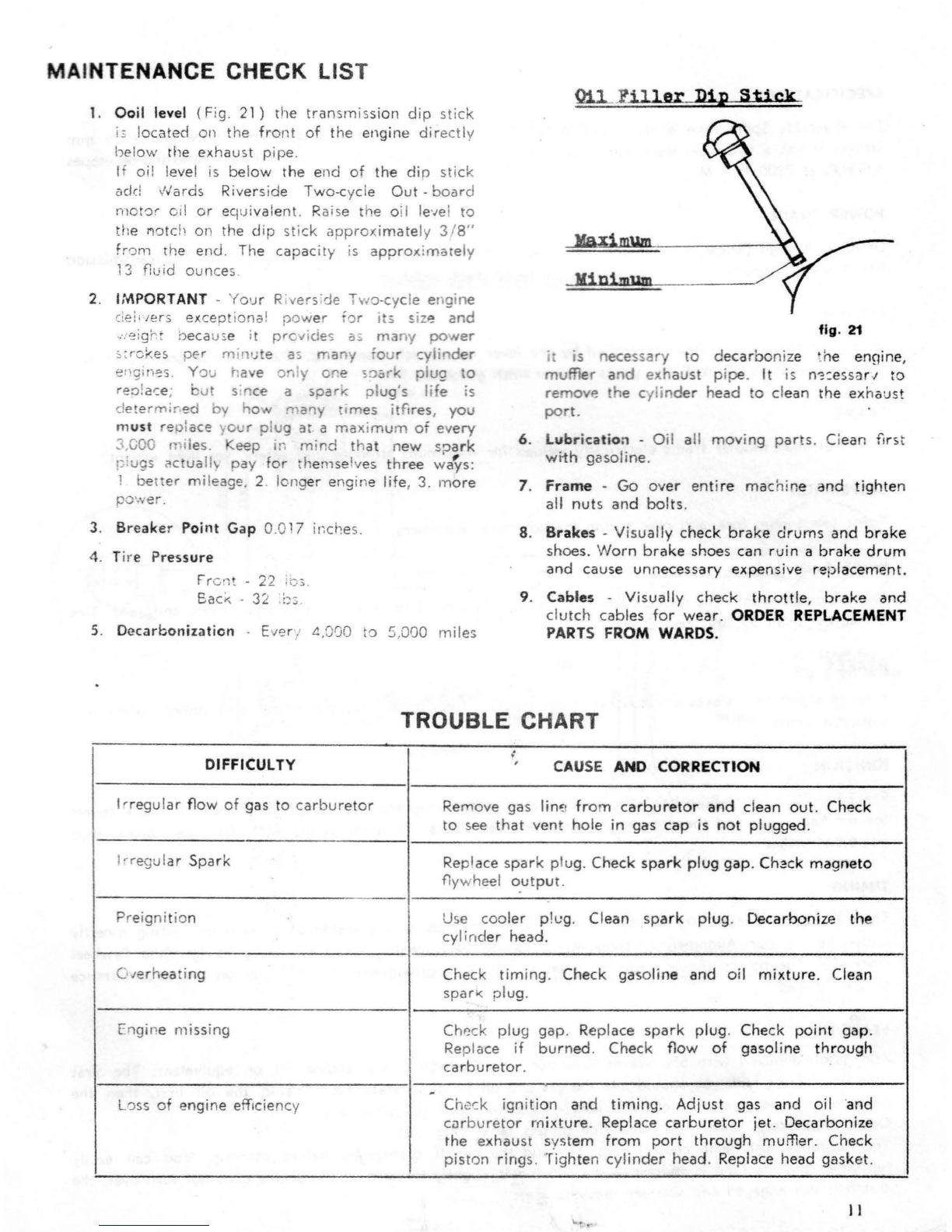

CHANGING

GEARS

(See

Fig

.

18)

You will n

ote

that

the foot-operated gear shift

is

on

the -

~ide

of

the v

eh

icl

e. Low

or

first

gear

is

engaged by raising

the

pedal

and

2nd,

3rd,

and

4th

gears

are

engaged by depressing

the

pedal. Remember

to re

li

eve the

pressure

on the pedal each

time

you depress, it allowing

the pedal to

return

to its

or

iginal position.

To shift gears you must

coordinate

the

throttle

and

the

clutc

h. First,

depr

ess the clutch lever on

the

left side of

the

handlebar

... Next,

with

your toes, raise

the

rubber

padded

ge

ar

<hift lever

into

l

ow

gear

. Now,

relax your

grip

on the clutch lever and advance the

throttl

e,

(on

the

ri

ght

hand

h

and

le

bar)

at the

same

time. It may

take

several

attempts

before you

are

ab

le to

master

a

smooth

take

o

ff.

To

shift in

to

2nd

,

3rd

,

and

4th

gears

follows

the

same

clutch

and

throttle

movements,

but

depr

ess the lever

in

stead

of

raising it...

(HwUv)

lotitipp

fig.

17

Gear

Chane• Pedal

Positions

r--1

•t

fig.

18

CAUTION:

NEVER

DEPRESS

THE

CLUT

CH

LEVER

WITH

THROTTLE

ADVANCED.

When you w

ant

to reduce

your

speed it

is

import

ant

to

remember

to

shift

to a lower gear. This gives

you

better

control of

your

machine-especially when you

want

to

re-accelerate.

Do

not idle the engine for long periods with

the

clutch

disengaged.

Ra

the

r,

put

the

gear

shift

In

neutral

·

and

engage the clutch. Always

drop

the

transmission

into

the

next lower .gear when engine speed

drops

and

engine sounds as

through

it

is

laboring.

9

STOPPING

Tc >t

or

your machi ne relax

the

t

hr

ottle

comp

l

ete

ly

M1' i

C:is

eP

ry

ige

the

cl

utch

be

fo

re

putt

ing

the

gear

:!

·.i

ft i

r.

t0

•i

eutra

l.

Armly

b

r

;;i~.

e

grad

ually to

assu

re comf)lete

co

n

tro

l

of

the

ma

chine

..

.

the

front

whee

l brake is t

he

l

ever

0 n the r

ish

t h

andle

bar,

the

re

ar

wh

ee

l b

rake

1~

ope

rated

h:1

the

foot pedal

on

the right side

of

the

rn;;chine.

To

:;

tcp the engine

r:>res

s the

grounding

but

t

on

( A ·

Fi

g. 1? ) .

A: Nays turn off

qas

tank p

et

cock

(Fig

.

20)

when

Horn Li&ht

SwHg

---~==

~

~~~·~t~o

~p~~tton

GI•

;.,..

P•tsos'

1n,,chine

is

i

dle

.

~

fig.

20

BREAK-IN PERIOD

'(c,·J

r Sp'.::rt Bike is

manufa

c

tur

ed

to

very exacting

t~:eranc

e

s

.

Be

cau

se

of

th

is

precision

fitting

of

pa

rts,

a l

ong

er

br

e

a

~-

i

n

peri

od

is

reco

m

men

de

d.

If 1ou fo

lio>"

the

pr

oc

edur

e

out

ii

ne

d,

you will

substant

ially i

ncrea

se

the

life

of

your

machin

e.

r:rJr the

fir

~.

100 miles

DO

NOT EXCEED 30 MILES

PER

HOUR.

FOR

THE FIRST 1,000 MILES

DO

NOT

OPERATE

AT

HIGH ENGINE

SPE

E

DS

FOR

MORE THAN ONE

MINUTE

AT

A TIME.

f:e s

ur

e to fo llo

v.

1

the

re

comm

en

dation

on

the

gas

tank

decal

for

max

i

mum

spee

ds

at

each

ge

ar

leve

l.

During the

bre

ak

-i

n period, it

is

impo

rtant

that

you

run

your

eng

ine

on

a

7%

fuel

mixtu

re

. Reduce

to

Jrie

5"

;,

meas

ure

in

corp

o

rated

on the

fl

ll

cap

aft

er

~he

first 1,

000

miles.

t. f;er t! e break.

-i

n

per

i

od

ch2nge the

tr

a

nsmission

o i

l.

We

recommend

Wards

Riverside Two-cycle

Out

·

h

0or

d

mo~0

r

oil No.61-83

11

0r

equiv

alent. Drain the oil

from

the

plug

at

the

low

er

l

eft

of

the

gear

::a:,e (

"'

bott

0

0m

of engine" ). F

ill

through

the hole in

the

front

of

the

gear

box

under

the exh

aust

pipe

to

i

r•

'! level

c,i

hr::

r·

cJt

<:

h on

the

dip

stick

. The tra

nsmis

sion

capadty

is

approximately

13 fluid

ounce

s.

MAINTENANCE CHECK LIST

1. Ooil level

(Fig

. 21) rhe

transmissi

on dip

stick

i;;

located

011

the

front

of

the

eng

i

ne

directly

below the

exhaust

pipe.

If

oi! level

is

below

the

e

nd

of

the

dip

stick

add

Nards

Ri

vers

ide Two-cycle

Out

-

board

moto

r oil

or

eq

ui

val

ent.

Raise

the

oil level

to

the ri0tc

'1

on

the

dip

stick

approxim

ate

ly

3 / 8"

fr'Jm the

end

. The

capac

ity is

approx

i

marely

13

fluid

oun

ces

2. IMPORTANT - Y

ou

r Riv

ers

:

de

Two-cycle engine

ci

el; 1ers ex

cept

i

onal

power

'or

i

ts

size

and

.

.-

..

eigr t b

eca

use it

prc

v1

de

s as

ma

ny

oower

;,:

rc~es

per

min

i.,te a

:>

many

'our cylin

der

e P

g

in

~s

.

Yo

u have on

'y

O"e

s

:Jesrk

plug

to

reo

!

ai::e

; but s'n

ce

a

spark

plug

's Ii e is

d

etermi

r.ed by

ho"

m

a11

rm

es

itflr

es

,

you

m

us

t

rep

l

ace

y

our

plug

at

a

max

i

mum

of

every

3 GOO 1

nil

es.

eep

1n

mind

that

n

ew

sp

ark

plugs .c ua

ll

1 pay

for

th

e

mselves

three

wc{!ys:

! ber

ter

mileage, 2. longer

eng

in

e life, 3.

more

po

•.ver.

3. Bre

ake

r

Point

Gap 0.

01

7 ii;ches.

4.

Tire P

ressure

Fr

ont -

22

:c

5_

Ea

c;.;

-

32

!::;;

5. De

carbonization

· Ever/ 4,000

to

5,000

miles

Oil._

_

l'

ill

er

D

ip

Stick

fig.

21

i is

eces

s

ary

to

dec

a

rbon

ize tne

ennine

,

muffler a

nd

exh

a

ust

pipe.

It is

n-;

:e

ssa

r

.;

to

remove

the

cy

li

nd

er

h

ead

to

cl

ea

n the exhaust

port.

6. L

ub

ric

at

ion - O

il

a

ll

moving

parts

. Ci

ea

n

fi

r

st

with

gasoline

.

7.

Frame

-

Go

ov

er

enti

re

macni

ne

and

tighten

all

nut

s

an

d

bolts

.

8.

Brakes

- Visually

check

brake

drums

and

brake

sh

oes

. W

orn

brake

shoes

can

ruin

a

brake

drum

and

ca

use un

necessary

expensive

re

p

lacement.

9.

Cables

-Visual

ly

check

throttle,

brake

and

clutch

cabl

es

for

wear

. O

RD

ER REPLACEMENT

PARTS FROM WARDS.

TROUBLE CHART

t

DIFFICULTY ,

CAUSE

AND

CORRECTION

Ir

regular

fl

ow

of

ga

s

to

carburetor

Remove

gas

lim

i

from

c

arburetor

and

cl

ean

out.

Check

to

see

th

at

vent

hole

in

gas

cap

is

not

plugged

.

!

•regul

ar

S

park

Repl

ace

spark

plug. Ch

eck

spark

plug

gap

.

Ch~ck

magneto

flywheel o.

utput

.

Preignition

Use cooler

ph:

g.

Cl

ea

n sp

ark

plug

.

Decarbonize

the

cylind

er head.

C

1e

rh

eat

ing Check

tim

ing. Che

ck

ga

so

li

ne

and

oil

mixtu

re

. Clean

spar'<

plug.

Engine

missing

Ch

~ck

plug

gap

. R

eplac

e

sp

a

rk

plug.

Check

point

gap

.

Re

pla

ce

if

burn

ed

. Che

ck

flow

of

gasol

i

ne

through

carburetor

.

.

L0ss

of

engin

e

effkie

ncy Ch

eck

ignition

an

d

ti

ming.

Adjust

gas

and

oil ·

and

curburetor

mixtu

re

. Replace

car

b

uretor

jet.

Decarbonize

the

exhaust

s

vst

em

from

port

through

muffler.

Check

piston

rings. T.ighten

cylinder

h

ead

. Replace

head

gasket.

11

SPECIFICATIONS

The P

iv

er

si

cJe

Sport

Bike Model No.

FFA

-

14003

has a

49cc

engine

with

a

40

mm

bore

and a

39

mm

stro e. It has a two-cycle

loop

scavanged

engine

.

The

engine

has

a 9.8 to 1

compres

sion ra io and devel

opes

L!

,5 H.P. at

7800

R. P. M.

POWER TRAIN

Drive is

through

helical g

ea

rs

in

the

tran

sn-.i

ss

i

on

. Final

drive

to

the

rear

whee

l is

by

chain

.

The

ra

nsmi

ss

io

has 4 s

peeds

forward

and

is

operated

by

the

left

foot

pedal.

CLUTCH

illu

ltiple

disc in

an

oil

bath

controlled

by

the

lever

on

the

left

hand

lebar.

The

Riversi

de

Sport

B

ike

will

develop

speeds

to

50

M. P. H., yet

is

a

miser

with

g::isoline.

FRAME

Husky a

ll

-s

teel

tuhular

frame

electrically

welded

for

max

i

mu

m st

rength

and

saf

ety

, y

et

li

ght

weight.

SUSPENSION

Front t

ele

s

C')f)

ing fo rk an

cJ

re

ar sp

ring

lo

aded

:;

h

ock

abs

orbe

rs

.

WHEELS

Ch

rom

e-

pl

ated s

ee

l ri

ms

prov

ide

st

rength

and

add

bea

uty

. T

ir

e size 2.25 x

18

both

front

and

rear

.

Tire

press

ure

s:

front

22 lbs.,

rear

32

l

bs

.

BRAKES

Internal ex pand ing

brakes

on

fro

nt

a

nd

re

ar

wheel

s.

Two

shoes

on

each

wheel

give

added

safety

and

s

moo

ther

sto

ps

.

IGNITION

The F

FA-

14

003

S

po

rt Bike

ha

s a 6 volt

28

watt

flywheel

mag

neto

which

suppli

es

mor

e

than

ample

power

for the hea

cJ

li

ght

and

t

he

co

mb

inati

on

stop

and

tail

lights.

Platinum

points

with

.

017

gap

.

Spark

plug

gap 0.

024

inches

.

TIMING

Th

ere

is

a ti

ming

m

ark

(0

) o n

the

flywheel

an

d

on

the

top

of

the

inside

of

the

eng

ine

casting

directly

und

er

the cyl

inder

. A

lignment

of

these

marks

locates d

ead

center

.

From

th

is

position

turn

the

flywheel

clo

ckwis

e. The p

oin

ts s

hould

begin

to

open

at

33

~

30

' ,

approx

im

ately

1-1

/ 8

inches

on

the

circumference

·

'J

f t

he

fl

yw

he

el .

STARTING

.t..

d

cl

gas

oline m

ix

ed wi

th

5%

War

ds

Riv

er

side T

wo

Cycle-Outbo11rd engine oil

or

equivalent.

The

first

time you

fi

ll

the

t

ank

you s

hou

ld mix

the

gas

a!"ld

oil in a s

eparate

can.

Put

in

the

oil

first

,

then

the

gasol i

ne

. Use

the

measuring

cap

prov

i

ded

- 1

cap

for

each

V

2

gallon

gas

.

Open

the

petcock

u

nder

left

hand

si

de

of

gas

tank

.

(Fi

g.

20)

.

T

he

mach

i

ne

must

be

in

neut

ral

(Fig

.

18)

and

the

clutch

disengaged

before

starting

.

You

can

easily

tel l

when

the

machine

is in

neutra

l

by

moving

it

slightly

forward.

If

the

engine

does

not

turn

over

,

th

e

clutch

is

not

eng

aged

and

you

are

rea

dy

to

start

.

I~

!!JUD LIGHT

HORII

NOT

E

SPORT BIKE WIRING DIAGRAM

g

....

....

•

,,.

u

•

...

p

J

.!

Gll'l' S'llITCH

ROBJI

BUT'l'Oll

UGllll!

STOP

STOPLIGll"'

SWITCH

llACIETO

TAILLIGHT

Allll

STOP

LIGlf!

llITCB

Stop

lamp

is

wired

in

circuit.

If

bulb

is defective, the engine

may

kill

when rear

brake

is

applied

while

eng

in

e is

running.

Table of contents