RMS 1S25 Series Service manual

Visit www.rmspl.com.au for the latest product information.

Due to RMS continuous product improvement policy this information is subject to change without notice. 1S25/Issue F/07/03/2011 - 1/9

Features

Four independent arc fault

tripping zones

1 or 2 arc fault sensors per

zone allowing up to 8 arc fault

sensors per 1S25 module

Trip indication LED for each arc

fault monitoring zone

Non volatile memory ensures

last recorded alarm states are

restored on power up

Nine (9) high speed arc fault

tripping duty output contacts

(Set for latching or self reset)

Zone segregated or common

tripping output configuration

Continuous arc sensor

supervision with sensor fail

LED for each zone

Wide range status input to

block arc fault monitoring

Front panel reset button &

status input

Self supervision watchdog with

healthy LED & alarm contact

Built in test sequence

Wide range auxiliary supply

Introduction

Medium voltage switchgear is a key

element in the power supply chain.

Existing protection systems operate

effectively under most circumstances, but

they are too slow to handle arcing short

circuits.

Arcing faults can occur as a result of

insulation breakdown due to equipment

age & / or poor maintenance.

The degree of damage caused by arcing

depends principally on the duration of the

arc. If an arc lasts only 100ms, the

switchgear needs to be checked & the

insulation resistance measured before

power can be re-established. With a

200ms arc, the power supply will be

interrupted; the switchgear must be

checked; power is re-established only

after minor repairs. In the event of a

500ms arc the supply is interrupted, metal

parts of the switchgear are destroyed &

poisonous gases are emitted. A 1s arc

destroys most of the switchgear & may

cause a fire, injury to personnel & damage

to property.

Technical Bulletin 1S25

Arc Fault Monitor – 4 Zones, 8 Sensors

1S25 depicted in a 2M28-S draw out case

with custom alarm text engraving

ARC Fault Protection Made in Australia

Arc fault protection is a relatively new technique employed for the fast clearance of arcing

faults on low voltage panels, MCC’s, BUS bars & within metal clad switchgear &

associated cable boxes. The arc is detected using an optical sensor & the signal input to a

protection device which also monitors the load current on the system. A trip signal can be

achieved in less than 10ms using arc detection only or within 15ms when using

overcurrent check. This is considerably faster than a traditional IDMT overcurrent relay &

provides additional protection from the onset of arcing faults with relatively low fault

currents.

Arguably the greatest risk of arc fault damage exists at the CB cable termination & in the

CB chamber itself due to the slow clearance times of the IDMT feeder protection. The CB

cable termination is particularly at risk to ingress of moisture & rodent damage.

The problem of arc faults is most prevalent in older metal clad switchgear which already

has operational protection systems. The 1S25 Arc Fault Monitor has therefore been

designed for the following applications:

EXISTING SWITCHGEAR

Where a requirement exists to retrofit arc fault protection to metal clad switchgear utilizing

the existing overcurrent protection relay;

NEW SWITCHGEAR

Where a requirement exists to install arc fault protection to new switchgear for integration

with the customer preferred overcurrent feeder protection relay;

LOW VOLTAGE PANELS

Arc fault protection may also be applied on low voltage panel control boards & motor

control centers (MCC’s).

Visit www.rmspl.com.au for the latest product information.

Due to RMS continuous product improvement policy this information is subject to change without notice. 1S25/Issue F/07/03/2011 - 2/9

ARC FAULT PROTECTION

The over-current caused by an arc is, due to its resistance, lower

than the over-current caused by a “metallic” short circuit. The

over-current caused by the arc may also be lower than the

protection start current when energising circuits or starting large

motors. The consequence of these conditions is that a protection

system based solely on over-current detection cannot effectively

discriminate between normal system currents & an arc fault

condition:

For moderate arc fault currents the trip time of the over-current

IDMT stage will be too slow;

For very low arc fault currents the instantaneous trip stage of a

standard over-current relay cannot be set low enough.

SWITCHGEAR ARC PROTECTION

The risk of arc fault damage exists at the CB cable termination &

in the CB chamber itself. The CB cable termination is particularly

at risk to ingress of moisture & rodent damage.

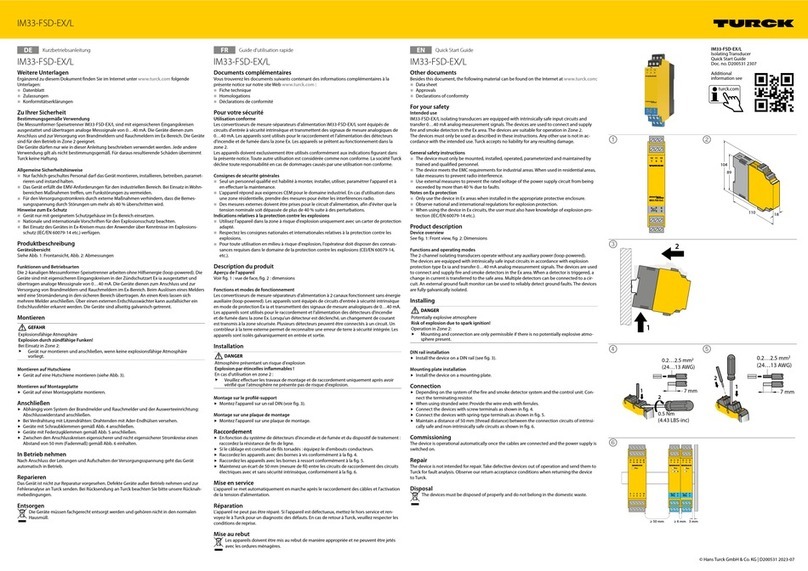

The 1S25 Arc Fault Monitor provides four (4) independent

tripping zones with one or two arc sensors per zone as depicted

in the single line application diagrams at right.

Figures 1 & 2 depict arc protection of up to four feeder circuits

with a single 1S25 as independent zones. A trip signal will be

initiated to the circuit breaker in the event of an arc fault occurring

at the sensor(s) within its zone provided the overcurrent relay

starter contact is picked up. In these applications the overcurrent

check stage is optional as the consequence of a single feeder

outage is less than the loss of an entire BUS.

Figure 3 shows an application where a 1S25 is applied for the

protection of the Cable box, CT chamber & CB chamber across

two feeder circuits (Zones). In this configuration one arc trip zone

is used to trip the feeder circuit breaker in the event of an arc

fault in the cable box or CT chamber. The second zone trip

output is wired to trip the upstream BUS breaker (BUS

overcurrent check not shown), in the event of an arc fault in the

CB chamber.

EXISTING SWITCHGEAR APPLICATIONS

The existing overcurrent relay protecting the feeder will normally

provide an independent output contact associated with the start

current setting of the relay. That is an output contact that will

close when a phase or earth fault current is detected above the

threshold which starts the internal relay timers. This starter

element should be set for instantaneous operation so that it will

pick up in the order of 15ms.

An Arc Fault Monitor relay 1S25 is installed on the switchgear

panel adjacent to the protection relay.

1S30 optical arc sensors are fitted in the cable termination box &

CT chamber as depicted in figure 2.

The overcurrent relay starter contact may optionally be wired in

series with the arc fault detection trip output contact as depicted

in figure 8. The resulting “AND” function trip output is wired to trip

the breaker in ~15ms in the event that an arc fault is detected

while the overcurrent start element is picked up.

The common arc trip & fail alarm contacts may be employed for

interface to a SCADA system for fault reporting.

NEW SWITCHGEAR APPLICATIONS

For new switchgear installations a modern numeric feeder

protection relay is likely to be employed which will have

numerous programming & configuration options.

The basic concept is the same as for the existing switchgear

application described above except that the additional features &

flexibility of modern feeder protection relay allows improved

system integration.

This may be achieved by using the common arc trip output

contact to interface to a programmable status input on the feeder

protection relay. Depending on the model of protection relay

being used this input may be programmed to provide an alarm

message on the HMI, time stamped event record available via its

communications link.

Switchgear Applications

ZONE 1

ARC PROTECTION

COMMON

ALARM

OUTPUT

1S2550/51

Figure 1: Single arc sensor per zone 1 - Cable box

ZONE 1

ARC PROTECTION

COMMON

ALARM

OUTPUT

1S2550/51

HEALTH Y

ZONE 2

ZONE 3

ZONE 4

ZONE 1

Custom text

Custom text

Custom text

Custom text

FAIL

FAIL

FAIL

FAIL

TRIP

TRIP

TRIP

TRIP

RESET

/TES T

Figure 2: Two arc sensors per zone - Cable box & CT chamber

ZONE 1

ARC PROTECTION

COMMON

ALARM

OUTPUT

1S2550/51

HEALTH Y

ZONE 2

ZONE 3

ZONE 4

ZONE 1

Custom text

Custom text

Custom text

Custom text

FAIL

FAIL

FAIL

FAIL

TRIP

TRIP

TRIP

TRIP

RESET

/TES T

ZONE 2 TRIP

UP STREAM

BREAKER

ZONE 2

ARC PROTECTION

ZONE 1 TRIP

Figure 3: Two arc sensors in zone 1 - Cable box & CT chamber

One or two arc sensors in zone 2 for CB chamber

Visit www.rmspl.com.au for the latest product information.

Due to RMS continuous product improvement policy this information is subject to change without notice. 1S25/Issue F/07/03/2011 - 3/9

COMBINED BUS BAR & SWITCHGEAR ARC PROTECTION

Figure 4 shows an application where a single 1S25 is applied for

the protection of a feeder Cable box & CT chamber plus the CB

chamber & BUS chamber using up to eight arc sensors over four

zones. In this configuration one arc trip output is used to trip the

feeder circuit breaker in the event of an arc fault in the cable box

/ CT chamber. Zone 2, 3 & 4 trip outputs are used to trip the BUS

breaker (BUS overcurrent check stage not shown), in the event of

an arc fault in the CB chamber or BUS chamber.

ZONE 1

ZONE 2

ARC PROTECTION

ZONE 3

ARC PROTECTION

ZONE 2, 3 & 4 TRIP

UP STREAM BREAKER

ZONE 4

ARC PROTECTION

COMMON ALARM OUTPUT

1S25

HEALTH Y

ZONE 2

ZONE 3

ZONE 4

ZONE 1

Custom text

Custom text

Custom text

Custom text

FAIL

FAIL

FAIL

FAIL

TRIP

TRIP

TRIP

TRIP

RESET

/TES T

50/51

Figure 4: Two arc sensors in zone 1 - Cable box & CT chamber

One or two arc sensors in zone 2 for CB chamber

One or two arc sensors in zone 3 for BUS chamber

One or two arc sensors in zone 4 for BUS chamber

BUS Bar Applications

BUS BAR ARC PROTECTION

Figure 5 depicts how the 1S25 may also be applied for the

protection of bus bars. The number of sensors in the bus

chamber is dictated by the switchgear design and the length of

switchboard.

In most indoor metal clad switchgear the bus bar chamber is a

continuous chamber between panels only broken into segregated

sections at a bus section breaker & as such the strategic

placement of one or two arc sensors in each bus bar chamber

run is normally adequate.

Some indoor metal clad switchgear may segregate the bus

chamber of each panel from the next via insulated bus chamber

side barriers per panel, if this is the case then each bus chamber

per panel would need to be monitored by at least one arc sensor.

Isolating switches between BUS bar sections need also be

considered & appropriate tripping zones created to ensure

isolation of the faulted section.

In large enclosures the arc sensors should be placed at

approximately 5m intervals. 1S30 arc sensors are also available

with dual optical detectors to allow detection of arc in both

directions.

ZONE 1 & 3

TRIP COMMON

ALARM

OUTPUT

50/51 1S25

HEALTH Y

ZONE 2

ZONE 3

ZONE 4

ZONE 1

Custom text

Custom text

Custom text

Custom text

FAIL

FAIL

FAIL

FAIL

TRIP

TRIP

TRIP

TRIP

RESET

/TES T

ZONE 2 & 3

TRIP

50/51

ZONE 1

TRIP

ZONE 3

TRIP

ZONE 2

TRIP

ZONE 3

TRIP

ZONE 1 ZONE 3 ZONE 2

ZONE 1

TRIP

ZONE 2

TRIP

Figure 5: One to eight arc sensors located in the BUS chamber in up to four tripping zones

Visit www.rmspl.com.au for the latest product information.

Due to RMS continuous product improvement policy this information is subject to change without notice. 1S25/Issue F/07/03/2011 - 4/9

ZONE 1

ARC PROTECTION

COMMON

ALARM

OUTPUT

1S2550/51

HEALTH Y

ZONE 2

ZONE 3

ZONE 4

ZONE 1

Custom text

Custom text

Custom text

Custom text

FAIL

FAIL

FAIL

FAIL

TRIP

TRIP

TRIP

TRIP

RESET

/TES T

TRIP

Figure 6:

Up to eight arc sensors distributed in low voltage switchgear.

Over current check stage depicted.

Low Voltage Applications

LOW VOLTAGE ARC PROTECTION

Figures 6 & 7 depict how the 1S25 may also be applied for low

voltage panels & MCC switchgear.

Figure 6 depicts an arrangement where over current check stage

is employed while the protection application depicted in figure 7

is a system based solely on arc detection.

1S25

HEALTH Y

ZONE 2

ZONE 3

ZONE 4

ZONE 1

Custom text

Custom text

Custom text

Custom text

FAIL

FAIL

FAIL

FAIL

TRIP

TRIP

TRIP

TRIP

RESET

/TES T

COMMON

TRIP ALARM

OUTPUTS

Figure 7:

Up to eight arc sensors distributed in low voltage switchgear or

MCC compartments without over current check

Visit www.rmspl.com.au for the latest product information.

Due to RMS continuous product improvement policy this information is subject to change without notice. 1S25/Issue F/07/03/2011 - 5/9

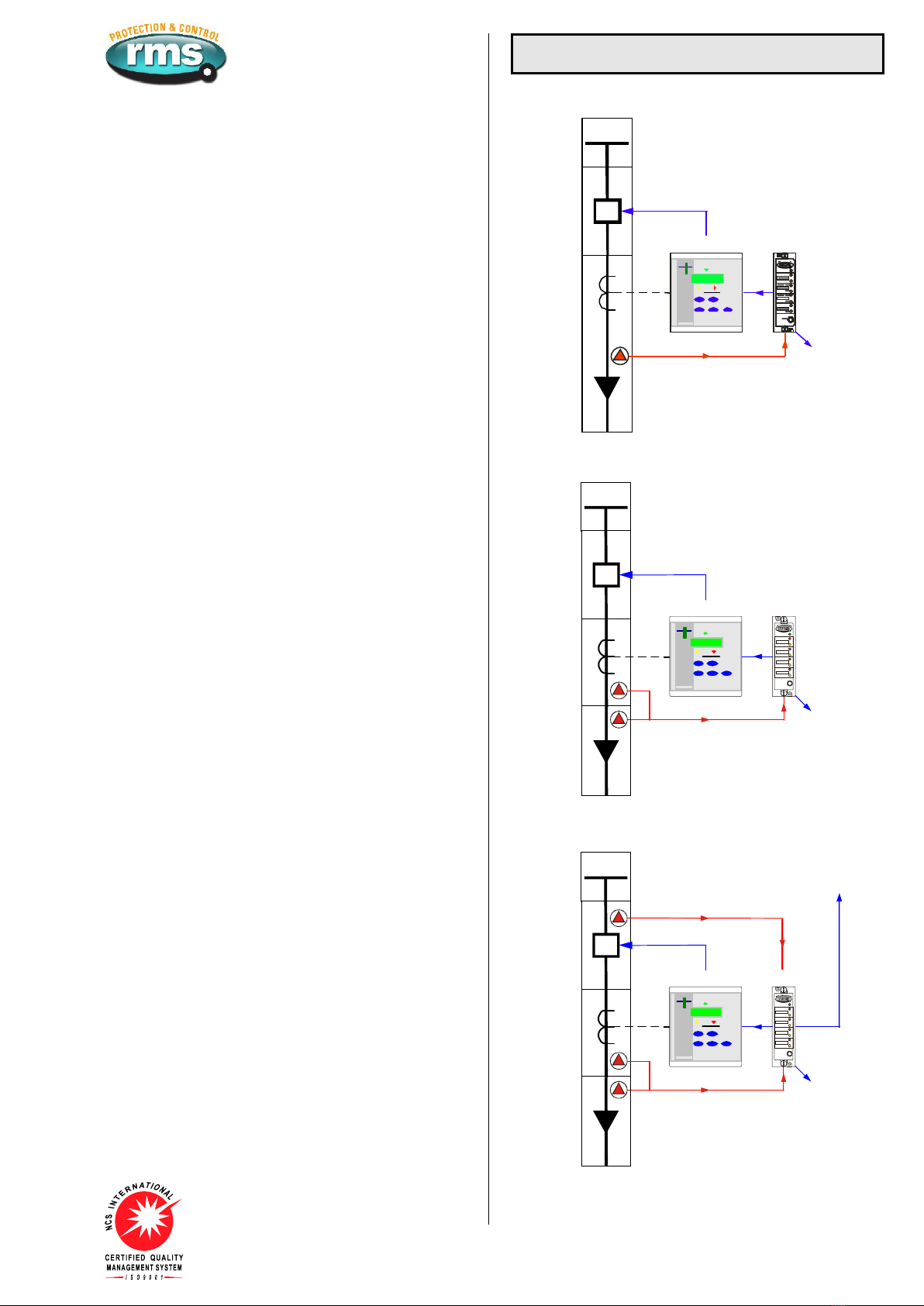

OPERATION INDICATOR

Two (2) LED’s are provided for each tripping zone to provide the

following status indications:

Trip: Flashes for 2s on detection of arc fault in zone & then solid

Resets when front panel reset button pressed or voltage

pulse applied to remote status input.

Fail: Flashes to indicate failure of 1S30 Arc Fault Sensor in zone.

CONFIGURATION SWITCHES

Three banks (A, B & C), of four (4) configuration switches are

accessible to the user by first withdrawing the relay module from

the outer case.

CONFIGURATION SWITCH SETTINGS

The internal wiring label identifies the position of the following

switch functions as follows:

Switch

ON

OFF

A1

Zone 1 Arc sensor fitted

Zone 1 Arc sensor not fitted

A2

Zone 2 Arc sensor fitted

Zone 2 Arc sensor not fitted

A3

Zone 3 Arc sensor fitted

Zone 3 Arc sensor not fitted

A4

Zone 4 Arc sensor fitted

Zone 4 Arc sensor not fitted

Switch

ON

OFF

B1

Zone 1 – 2 Arc sensors

Zone 1 – 1 Arc sensor

B2

Zone 2 – 2 Arc sensors

Zone 2 – 1 Arc sensor

B3

Zone 3 – 2 Arc sensors

Zone 3 -1 Arc sensor

B4

Zone 4 – 2 Arc sensors

Zone 4 – 1 Arc sensor

Switch

ON

OFF

C1

Latching trip contacts

Self reset trip contacts

C2

Independent trip outputs

Common trip outputs

C3

Apply volts to BLOCK

Remove volts to BLOCK

C4

DC only status inputs

AC/DC status inputs

ARC SENSOR CIRCUIT SUPERVISION

The 1S30 Arc Sensor is the heart of the system & supervision of

circuit continuity is critical for correct operation. To monitor the

integrity of the wiring between the 1S30 arc sensor & 1S25 Arc

Monitor, a continuous 2mA supervision current flows between the

units.

The 1S25 alarm contact will drop out after a 1s time delay if it

fails to detect this current.

The failed zone will be indicated by the front panel ‘Sensor fail’

LED.

Operation

ARC SENSOR FUNCTION

The 1S30 is an optical sensor that responds to the flash of light

emitted during the incidence of an arcing fault. Onset of the light

flash & detection by the 1S30 occurs in a few ms.

When an arc is detected, the resistance presented by the 1S30

drops to a level where the current flow increases to approximately

20mA. This increased current flow is instantaneously detected by

the 1S25 & its trip output contacts closed. Refer to the 1S30

Technical Bulletin for further details.

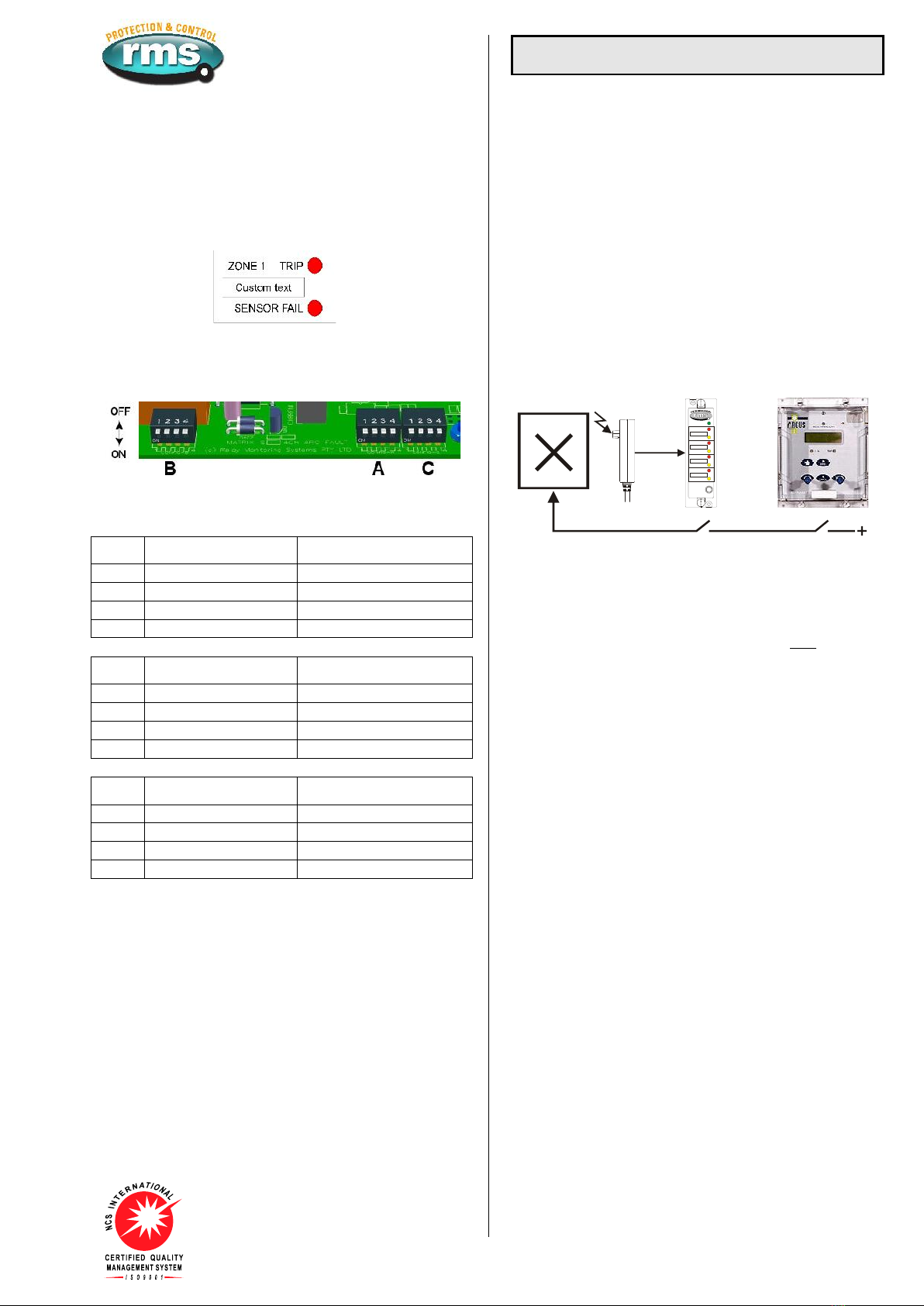

ARC FAULT TRIPPING USING CURRENT CHECK

Fast operation of a tripping scheme usually results in reduced

system security. The arc detection method can however,

combine the 1S25 optical detection technique with a traditional

overcurrent method to maximize system security particularly for

BUS bar protection schemes. Both conditions must coexist for

the trip condition to be met as depicted in figure 8.

ARC FAULT TRIP INITIATE

CB ARC FAULT

MONITORSENSOR

OVER-CURRENT RELAY

3 Pole OC + EF

HEALTHY

ZONE 2

ZONE 3

ZONE 4

ZONE 1

Custom text

Custom text

Custom text

Custom text

FAIL

FAIL

FAIL

FAIL

TRIP

TRIP

TRIP

TRIP

RESET

/TEST

Figure 8:

Key components required to implement an Arc Fault Protection

scheme with an overcurrent check stage

to enhance system security

The application examples in figures 1 to 5 utilize this concept for

enhanced system security in that both the 1S25 AND the OC 50

starter contact must be picked up for a CB trip signal to be

initiated. As the arc fault trip contact picks up considerably faster

than the overcurrent relay starter element, the CB trip time will be

dictated by the overcurrent relay performance.

LOW CURRENT ARCING FAULTS

Arcing faults can occur at low current levels & it is possible for

the over-current starter element to be set above this level. To

avoid this problem & obtain very fast clearance (<10ms), of an

arc fault, the 1S25 arc fault trip contact may be wired directly to

the breaker operate coil. It should be noted that this method may

lead to reduced system security.

ARC DETECTION RESET TIME (Effect of multiple arc trips)

A delay of 2s is required to reset the 1S25 after an initial arc

sensor trip. Subsequent arc detection will cause the trip output

contacts to re-operate.

INDEPENDENT TRIP OUTPUT CONTACTS

The 1S25 provides up to four (4) tripping zones each with an

independent tripping output. Alternatively configuration switch C2

can be set to OFF so that all trip outputs will operate in the event

of an arc being detected by any sensor.

ARC SENSOR CONTINUOSLY PICKED UP

High ambient light levels may cause a 1S30 to be continuously

picked up. This condition could occur for example if the CB cable

box cover was left open in very high ambient light level

conditions. A non arc fault over-current pick up would then result

in an arc fault trip operation.

To avoid possible mal operation due to this condition, the 1S25 is

designed to automatically disable the arc fault tripping function if

the 1S30 sensor is picked up for >10s. The 1S25 alarm contact

will be set & the front sensor fail LED will flash until the ambient

light level problem is corrected. The 1S25 will then perform an

arc sensor test function & automatically reset.

The failed zone will be indicated by the front panel ‘Sensor fail’

LED.

Visit www.rmspl.com.au for the latest product information.

Due to RMS continuous product improvement policy this information is subject to change without notice. 1S25/Issue F/07/03/2011 - 6/9

AUXILIARY SUPPLY

A high efficiency switchmode power supply is incorporated which

provides a low burden to the auxiliary supply.

Low range model: 20-70V DC

High range model: 40-300V DC & 40-275V AC

AUXILIARY SUPPLY BURDEN (At 110V DC)

Quiescent: Less than 4W

Maximum: Less than 10W

OPERATING TIME OF ARC FAULT DETECTION

Arc fault trip contacts guaranteed to pick up in less than 10ms

including bounce. Typical operate time is 7ms.

Reset time of the arc fault element is 2s.

CRO trace showing nominal operation time of the trip contacts at

7ms. First contact touch at 6.25ms and fully closed by 7.25ms.

Operation in <10ms is considered acceptable as current check

relay operate time is ~15ms.

FRONT PANEL LED’s

Green system healthy LED

Arc Trip - One red LED per zone – off, flashing or on solid

Sensor Alarm – One red LED per zone – off, flashing or solid

ARC FAULT BLOCK STATUS INPUT DELAY

AC Rejection Filter

Initiate input

Minimum

ON

OFF

P/U

<16ms

<4ms

DC

D/O

<4ms

<16ms

P/U

<23ms

AC

D/O

N/A

<33ms

Table 1

STATUS INPUT OPERATING VOLTAGE

An internal configuration switch is provided to select status input

operation for DC only or AC/DC. This setting may be pre defined

when ordering.

18 - 300V DC Set Configuration Switch to ON

In this mode the universal status input will reject AC signals that

may be induced on the control wiring. Suitable for high security

applications where a DC battery supply is available.

18 - 300V DC & 18 – 275V AC Set Configuration Switch to OFF

In this mode the universal status input is designed to operate on

both AC & DC input voltages. Suitable for applications where an

AC auxiliary voltage is available such as transformer or generator

control panels.

STATUS INPUT MINIMUM OPERATING CURRENT

10mA P/U for 1ms then reducing to1.5mA after 4ms.

RESET

Press the front reset button or pulse the reset status input.

Technical Data

OUTPUT CONTACTS

Tripping contacts: 8 - 2 N/O per tripping zone

Common tripping contact: 1 N/O

Fail alarm: 1 C/O contact for the power supply /

CPU fail / arc fault sensor.

Normally picked up & drops out to

signal an alarm condition.

OUTPUT CONTACT RATINGS IEC60255-0-2

Carry continuously

5A AC or DC

0.5s 20A AC or DC

Make & carry

L/R ≤ 40ms & V ≤ 300V

0.2s 30A AC or DC

AC resistive

AC inductive

1,250VA

250VA @ PF ≤ 0.4

DC resistive

75W

Break capacity

I ≤ 5A & V ≤ 300V

30W @ L/R ≤ 40ms

DC inductive

50W @ L/R ≤ 10ms

Minimum number of operations

106 at maximum load

Minimum recommended load

0.5W limit 10mA / 5V

TRANSIENT OVERVOLTAGE IEC60255-5

Between all terminals & earth

5kV 1.2/50us 0.5J

Between circuit groups:

Status/Reset Inputs, Auxiliary Supply,

Sensor Inputs, Trip Outputs

Without damage or flashover

5kV 1.2/50us 0.5J

INSULATION COORDINATION IEC60255-5

Between all terminals & earth

2.0kV RMS for 1 minute

Between circuit groups:

Status/Reset Inputs, Auxiliary Supply,

Sensor Inputs, Trip Outputs

2.0kV RMS for 1 minute

Across normally open contacts

1.0kV RMS for 1 minute

AUXILIARY SUPPLY IEC60255-11

Allowable breaks / dips in supply

Collapse to zero from nominal voltage

≤ 20ms

HIGH FREQUENCY DISTURBANCE IEC60255-22-1 CLASS III

2.5kV 1MHz common mode

1.0kV 1MHz differential mode

No mal operation

ELECTROSTATIC DISCHARGE IEC60255-22-2 CLASS III

6kV contact discharge

No mal operation

RADIO FREQUENCY INTERFERENCE IEC60255-22-3

10V/m, 80 TO 2,700MHz

No mal operation

FAST TRANSIENT IEC60255-22-4

4kV, 5/50ns, 100KHz repetitive

No mal operation

CONDUCTED RFI IEC60255-22-6

10V, 0.15 to 80MHz

No mal operation

CUSTOM ALARM TEXT - Refer ordering information page.

Maximum characters: 2 lines x 15 characters / tripping zone.

Maximum font size: 1 line x 10 characters / tripping zone.

TEMPERATURE RANGE IEC68-2-1/2

Operating: -5 to +55oC

Storage: -25 to +75oC

HUMIDITY IEC68-2-78

40 oC & 95% RH non condensing

Visit www.rmspl.com.au for the latest product information.

Due to RMS continuous product improvement policy this information is subject to change without notice. 1S25/Issue F/07/03/2011 - 7/9

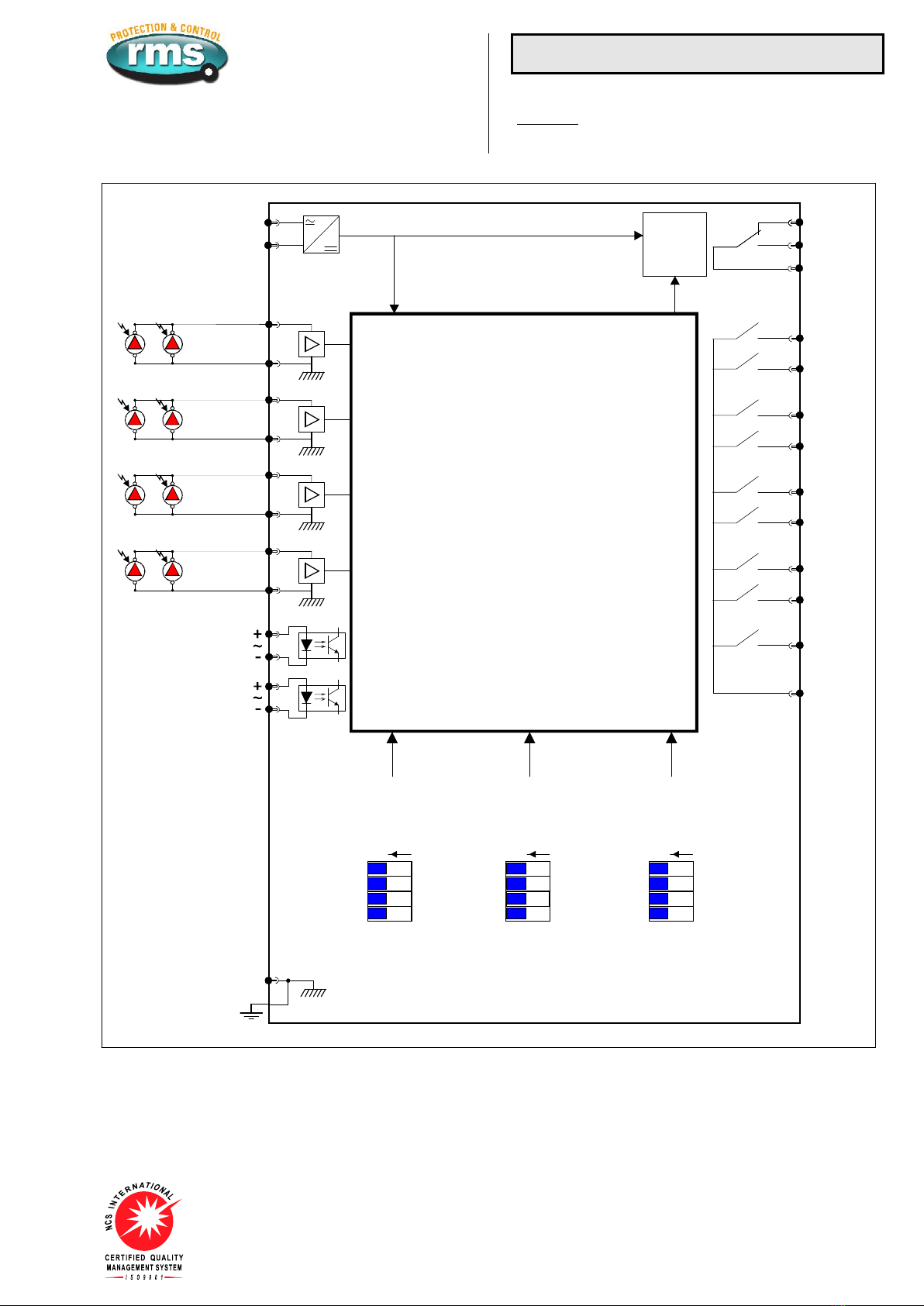

Wiring

TERMINATION SCREWS

M4 Screws

An M4 screw kit is supplied as standard with each 1S25.

Additional M4 screw kits may be purchased separately.

1

24

5

26

28

3

Vx Power supply,

CPU & sensor

fail alarm

Remote reset

Arc fault BLOCK input

Configuration switches

(Primary PCB)

7

9

11

13

15

17

19

21

Zone 1

Arc sensor input

1S30

Arc Fault Sensors

Zone 2

Arc sensor input

Zone 3

Arc sensor input

Zone 4

Arc sensor input

6

8

Zone 1 Trip

Zone 1 Trip

Zone 2 Trip

Zone 2 Trip

4Common Trip

Switch 1

Switch 2

Switch 3

Switch 4

BANK

A

BANK

B

BANK

C

27

25

23

Fail

Healthy

Alarm common

Signal processing

and logic

functions

ON ON ON

Arc sensor fault signal

Zone 3 Trip

Zone 3 Trip

Zone 4 Trip

Zone 4 Trip

12

10

16

14

20

18

22 Common

2

Case & module

earth connection

Figure 9: Wiring diagram for 1S25 four zone arc fault monitor - Relays shown in de-energized condition

Visit www.rmspl.com.au for the latest product information.

Due to RMS continuous product improvement policy this information is subject to change without notice. 1S25/Issue F/07/03/2011 - 8/9

HEALTHY

ZONE 2

ZONE 3

ZONE 4

ZONE 1

Custom text 1

Custom text 2

Custom text 3

Custom text 4

SENSOR FAIL

SENSOR FAIL

SENSOR FAIL

SENSOR FAIL

TRIP

TRIP

TRIP

TRIP

RESET

/TEST

P

R

O

T

E

C

T

I

O

N

&

C

O

N

T

R

O

L

Figure 10: Alarm text position layout

Case Mounting

CASE

2M28-S draw out case

ACCESSORIES SUPPLIED WITH EACH RELAY

1 x M4 self threading mounting screw kit P/N 290-406-151

2 x M4 terminal screw kit (28 per kit) P/N 290-407-153

1 x Product Test Manual

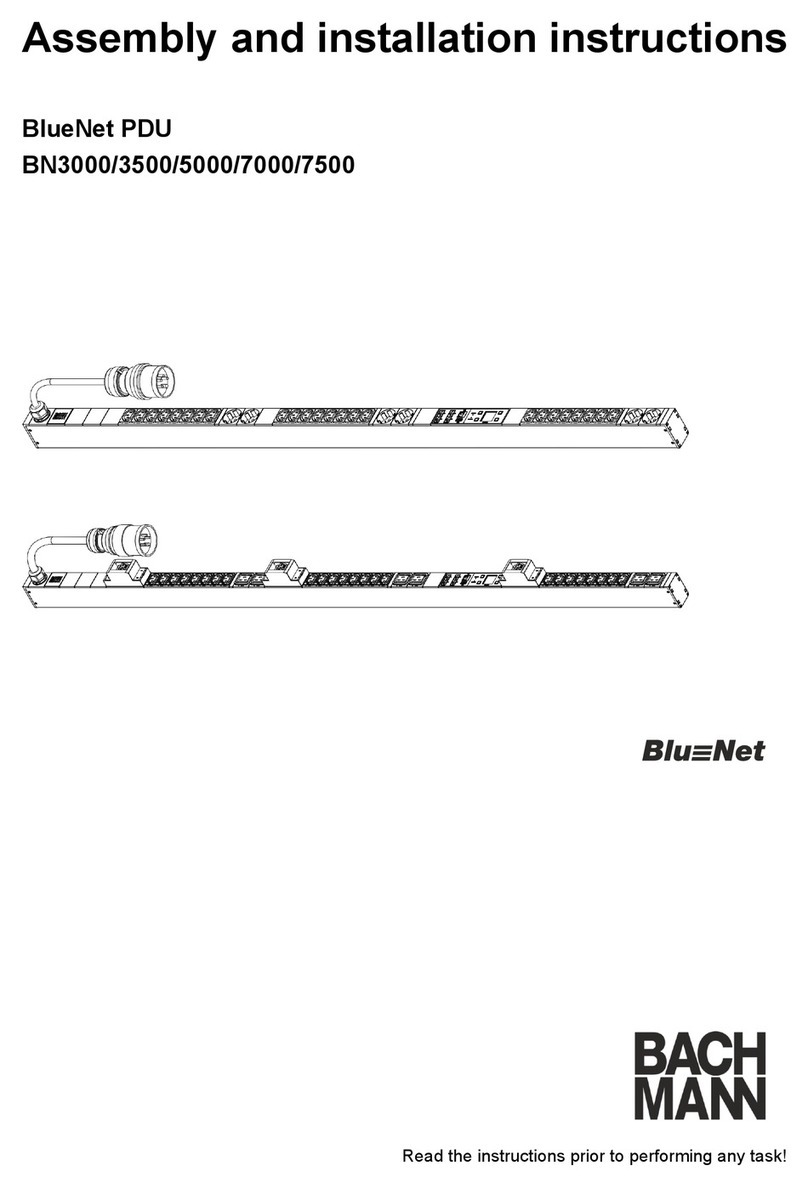

1S30 ARC FAULT SENSORS

Refer to the 1S30 Technical Bulletin for details.

Figure 11: 1S30 Arc Fault Sensors

Through panel mounting detector version depicted at left

Front panel view of dual detector version depicted at right

Front view

15 2 holes of 3.7

Indicative

position

Side view

Size 2M28-S

draw out case

Drawing units: mm

Terminal layout Panel cut out

Suits flush panel mounting &

4U high 19 inch rack frame

14

1 2

27 28

Figure 12: Case mounting details 8 point alarm version

Visit www.rmspl.com.au for the latest product information.

Due to RMS continuous product improvement policy this information is subject to change without notice. 1S25/Issue F/07/03/2011 - 9/9

ALARM TEXT LABELS

The 1S25 front panel has provision for custom text to identify the

sensor location for each arc fault tripping zone. The required text

may be engraved on the front panel by the factory if specified at

time of order. Alternatively the front panel may be removed for

engraving by the user or contractor. The RMS web site provides

an ACAD file for this purpose.

The front panel is fabricated from flexible plastic sheet with a

white surface & black substrate to provide high contrast black

text when engraved.

Removal of the front label is achieved by drawing out the 1S25

module from the outer case & pulling the label from the edges at

the mid point between the top & bottom draw out handles. This

will cause the label to bend & disengage from the top & bottom

handle retention points. Once free from the 1S25 module the

front label can be placed on an engraving table. Additional factory

engraved labels may be sourced from RMS for later field

installation.

While an engraved label provides the most permanent record

other methods such as laser printed stick on labels or indelible

marker pen may be satisfactorily employed.

CUSTOM ENGRAVED TEXT DEFINITION

Complete the following tables with one character per box. Refer

to the front panel layout depicted in figure 10. Submit completed

labeling information with the 1S25 product ordering code. For

maximum font size limit text for each alarm point to 1 line x 10

characters.

Text will be left justified.

Zone 1

Zone 2

Zone 3

Zone 4

Ordering Information

ORDER CODE

The order code determines the production build in the factory &

cannot be changed in the field.

Generate the required order code as follows: e.g. 1S25 BA

Order

Code

General

Type

1

2

1S25

-

1

AUXILIARY SUPPLY RANGE

A 20 - 70V DC

B 40 - 300V DC & 40 – 275V AC

2

CUSTOM ENGRAVED TEXT

A Not required No engraving - factory default

B Required Complete the custom text details at left

CONFIGURATION CODE (Optional specification)

The configuration code can be set in the field by withdrawing the

relay module & following the instructions on the side plate label.

The configuration code may be specified at time of order so that

the relay will be shipped from the factory pre-set to meet

customer requirements. e.g. CONFIG-0101-0101-1111

If a configuration code is not specified the factory default will be

set as indicated below. i.e. CONFIG-1111-1111-1111

Configuration

Switches

Specify

Factory

Configuration

A1

A2

A3

A4

CONFIG

-

B1

B2

B3

B4

-

C1

C2

C3

C4

-

A1-4

ZONE 1 - 4 SENSOR INPUTS

1 ON Arc sensor(s) connected (Default)

0 OFF No sensor connected

B1-4

ZONE 1 - 4 SECOND SENSOR

1 ON Second sensor connected (Default)

0 OFF Single sensor only

C1

OUTPUT CONTACTS FUNCTION

1 ON Latching (Default)

0 OFF Self reset

C2

OUTPUT CONTACTS GROUPING

1 ON Segregated zone tripping outputs (Default)

0 OFF Common outputs

C3

ARC FAULT INITIATE INPUT FUNCTION

1 ON Apply volts to BLOCK arc detection (Default)

0 OFF Remove volts to BLOCK arc detection

C4

STATUS INPUT AC REJECTION

1 ON DC operation only - AC rejection ON (Default)

0 OFF AC / DC operation - AC rejection OFF

© 2011 Relay Monitoring Systems Pty Ltd

Due to RMS continuous product improvement policy this information is subject to change without notice.

Australian Content

Unless otherwise stated the product(s) quoted

are manufactured by RMS at our production

facility in Melbourne Australia. Approximately

60% of our sales volume is derived from

equipment manufactured in house with a local

content close to 80%. Imported components

such as semi-conductors are sourced from local

suppliers & preference is given for reasonable

stock holding to support our build requirements.

Quality Assurance

RMS holds NCSI (NATA Certification Services

International), registration number 6869 for the

certification of a quality assurance system to

AS/NZS ISO9001-2008. Quality plans for all

products involve 100% inspection and testing

carried out before despatch. Further details on

specific test plans, quality policy & procedures

may be found in section A4 of the RMS product

catalogue.

Product Packaging

Protection relays are supplied in secure

individual packing cardboard boxes with moulded

styrene inserts suitable for recycling. Each

product & packing box is labeled with the product

part number, customer name & order details.

Design References

The products & components produced by RMS

are based on many years of field experience

since Relays Pty Ltd was formed in 1955. A large

population of equipment is in service throughout

Australia, New Zealand, South Africa & South

East Asia attesting to this fact. Specific product &

customer reference sites may be provided on

application.

Product Warranty

All utility grade protection & auxiliary relay

products, unless otherwise stated, are warranted

for a period of 24 months from shipment for

materials & labour on a return to factory basis.

Repair of products damaged through poor

application or circumstances outside the product

ratings will be carried out at the customer’s

expense.

Standard Conditions of Sale

Unless otherwise agreed RMS Standard Terms &

Conditions (QF 907) shall apply to all sales.

These are available on request or from our web

site.

Relay Monitoring Systems Pty Ltd

6 Anzed Court, Mulgrave, Victoria 3170, AUSTRALIA

Table of contents