4

SAFETY INFORMATION

IMPORTANT SAFETY GUIDELINES

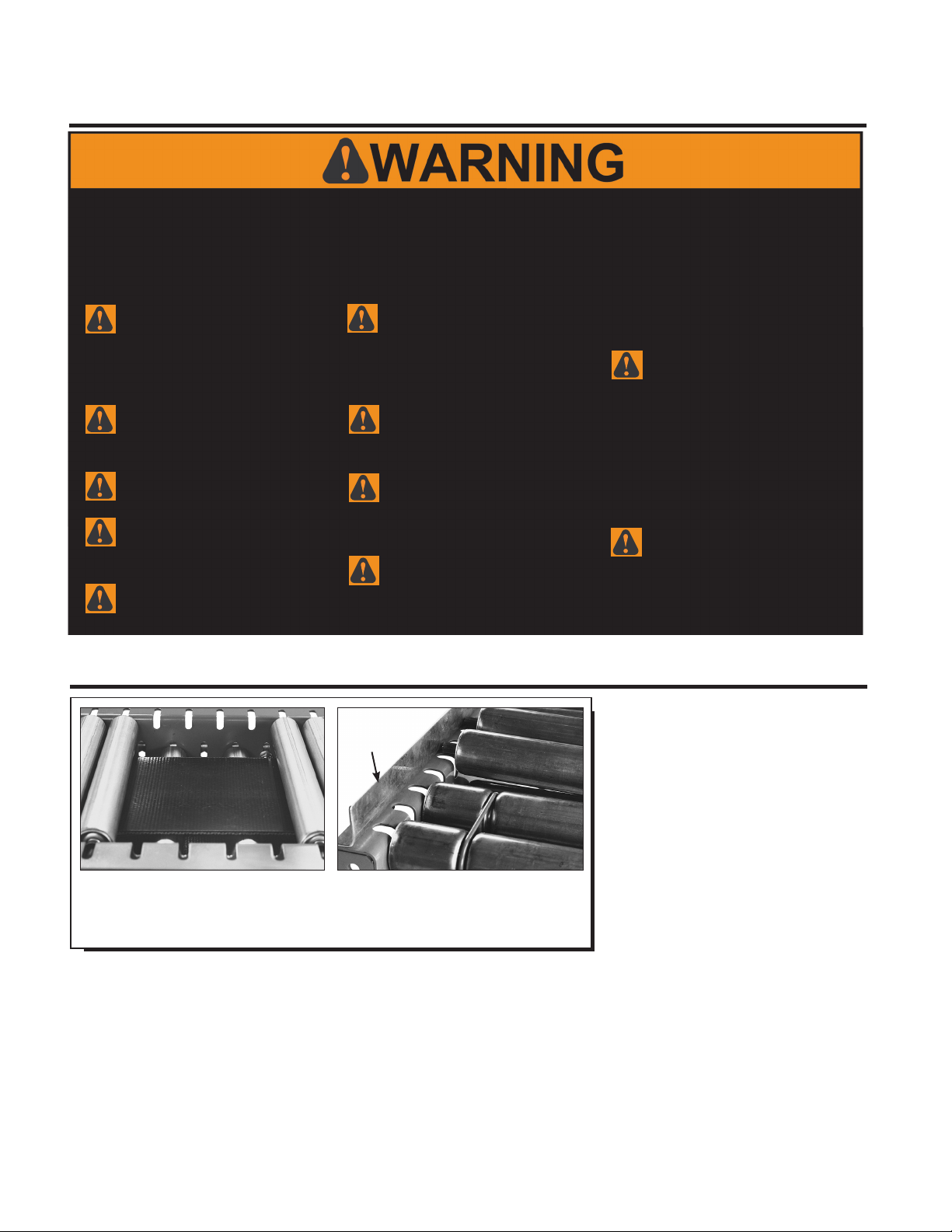

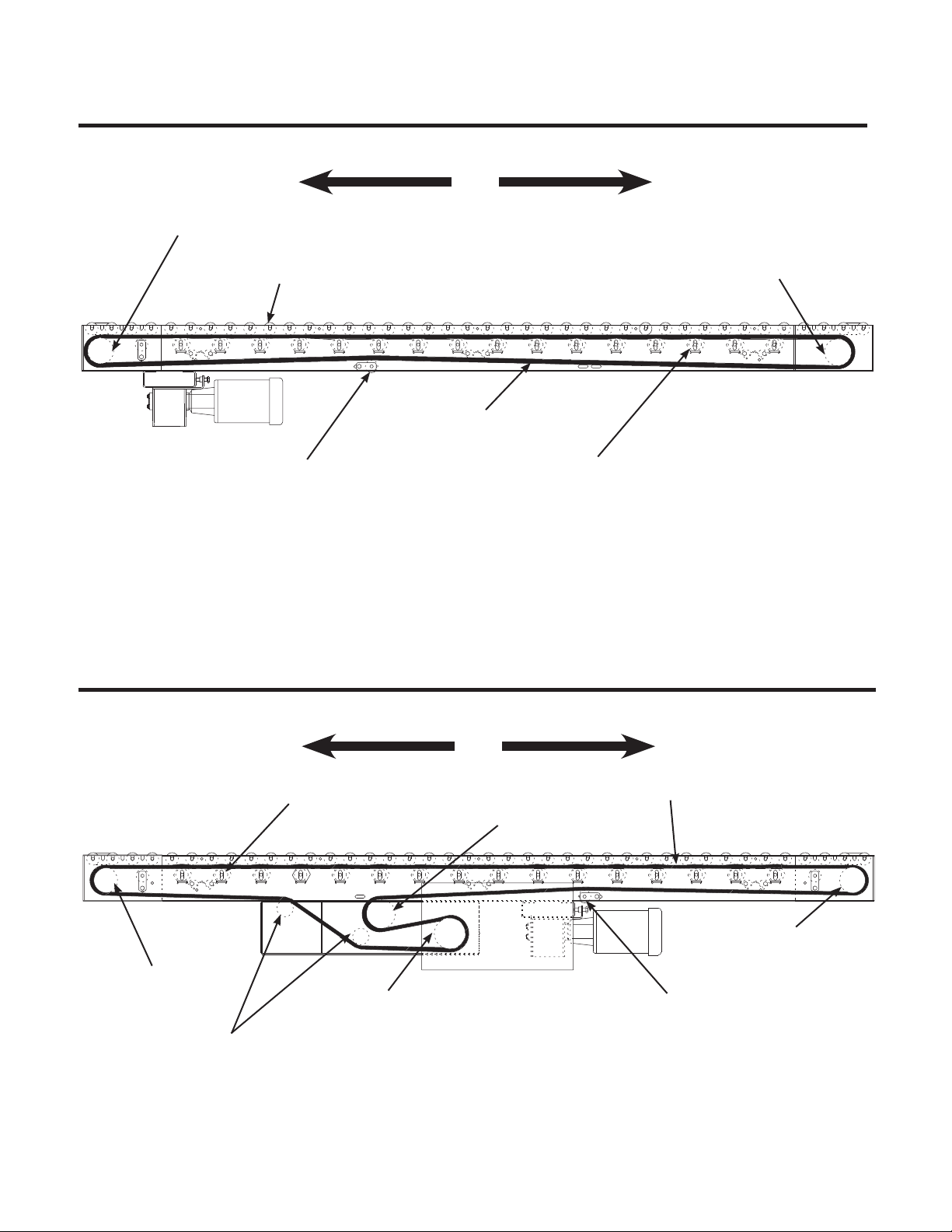

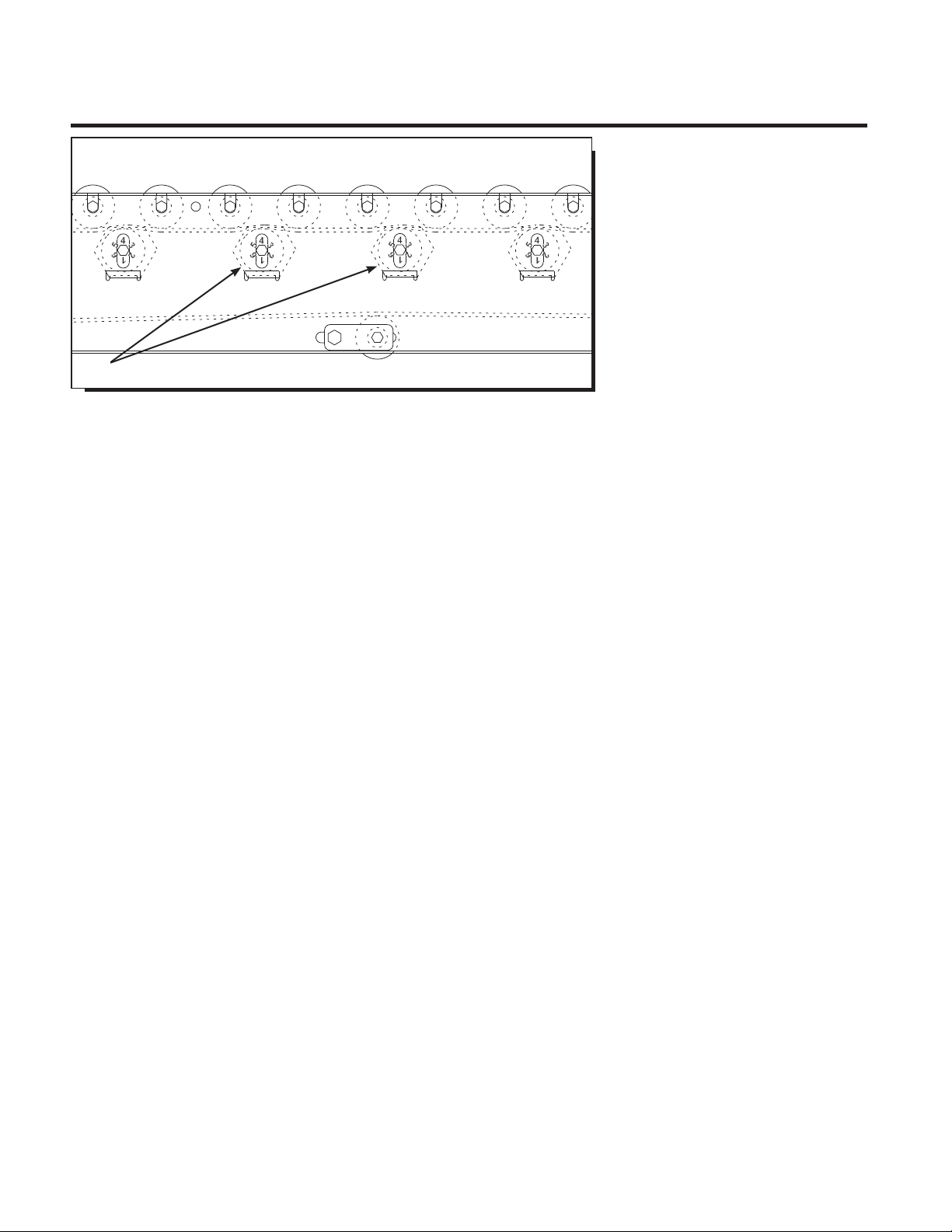

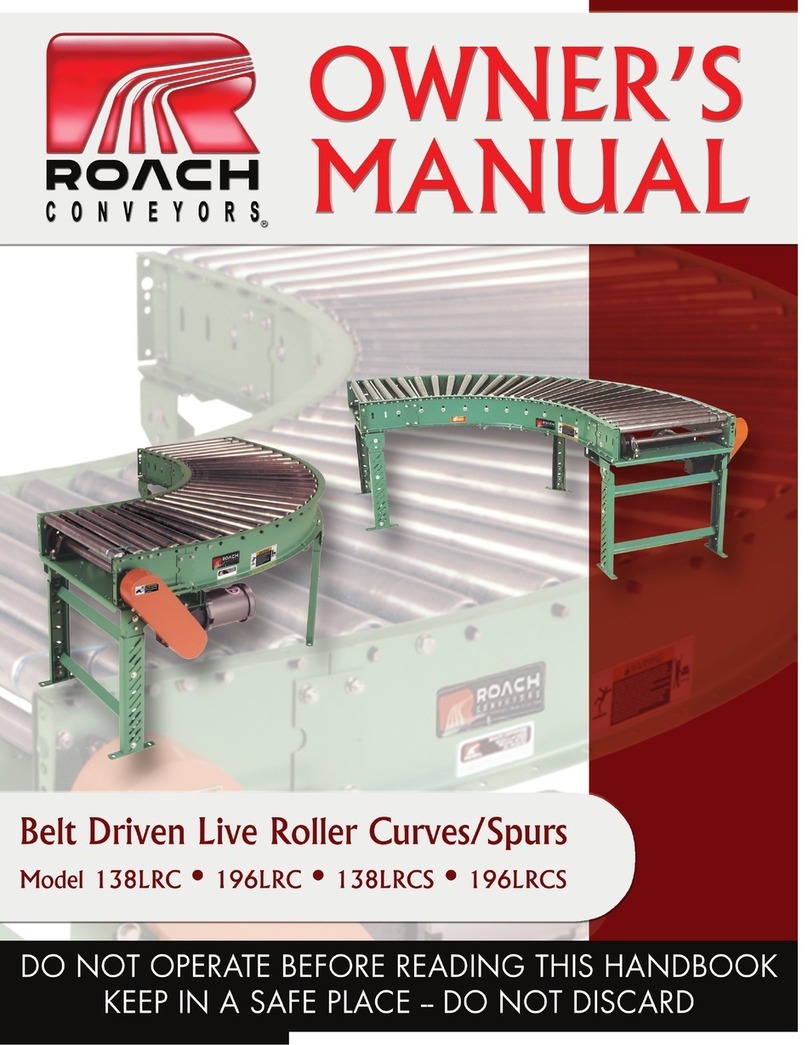

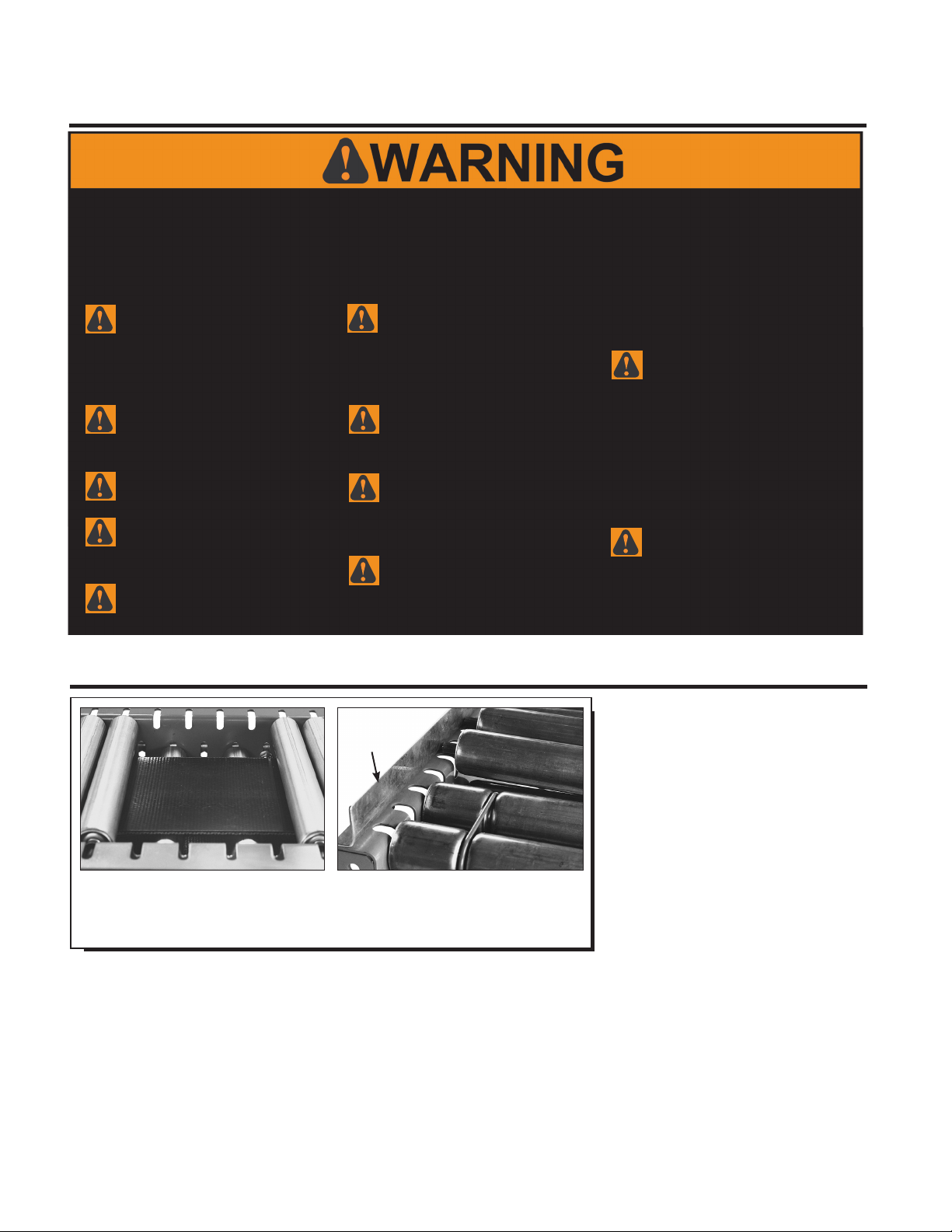

UNDERSTANDING POP OUT ROLLERS

In most instances, live roller conveyor

frames are equipped with slots in the frame

for tread rollers. Why is this necessary?

When installed below 7’-0” elevation,

tread rollers must be designed to pop out

of the frame to prevent injury to operator

or individuals coming in contact with tread

rollers. However, when installed at 7’-0”

and greater elevation, tread rollers must

NOT be allowed to pop out. Individuals

stationed below the conveyor could be

injured by rollers that inadvertently become

free from conveyor frame. Therefore, a

belt driven live roller originally supplied

with slotted frame and pop out rollers, must

be modified if it is moved to 7’-0” or high-

er elevation. A special hold-down angle

must be installed to eliminate pop out roll-

ers. Also, when a live roller conveyor that

does not feature pop out rollers,

is used in an application below 7’-0”

elevation, conveyor MUST be modified to

include safety pop out rollers.

Contact Roach national sales at

870-483-7631 with conveyor serial

number for additional information.

WARNING: Belt driven live roller con-

veyors must have safety pop out tread

rollers when installed below 7’-0” eleva-

tion. Conversely, when installed at 7’-0”

or greater elevation, tread rollers must

NOT be allowed to pop out of frame.

Shut conveyor OFF and lock out power

source until above safety considerations

are completely adhered to.

*NOTE: Guard rail may be used to hold

rollers in frame when installed at 7’-0” or

higher elevations.

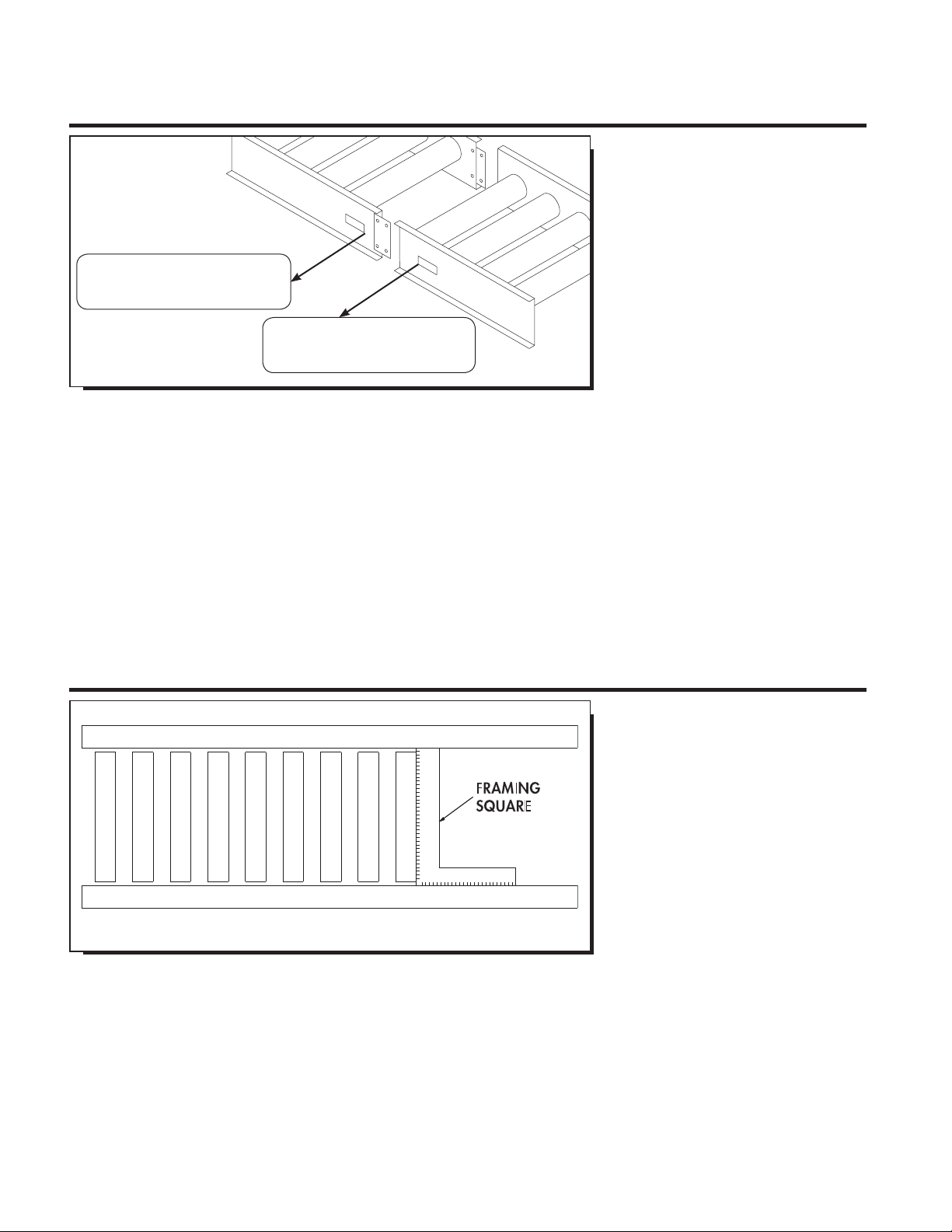

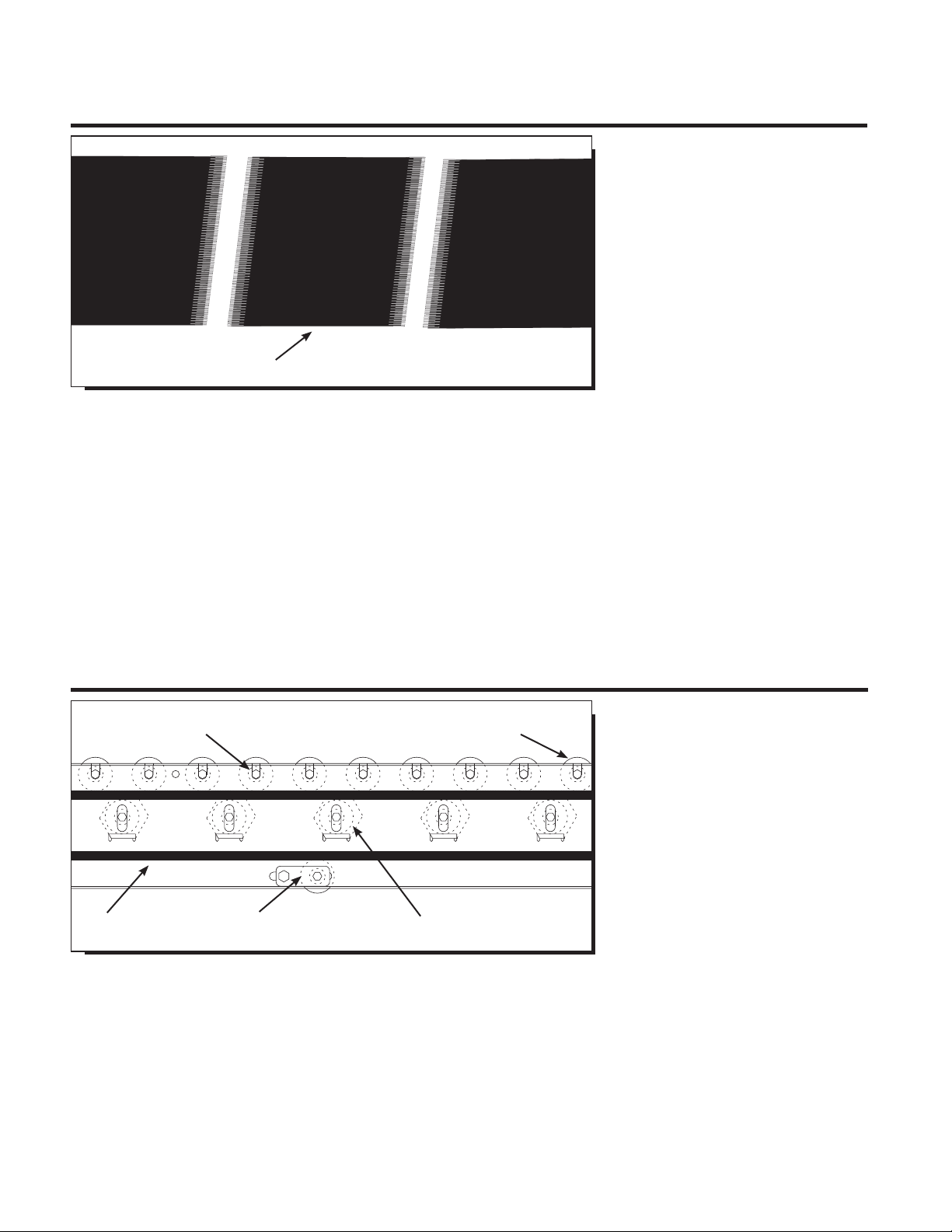

SLOTTED FRAME ALLOWS

ROLLERS TO EASILY POP OUT

(rollers removed for clarity)

WHEN GUARD RAIL IS ADDED,

DO NOT COVER POP OUT SLOTS

IN CONVEYOR FRAME*

GUARD

RAIL

WARNING: All personnel coming in contact with this conveyor should be aware of the following safety guidelines

BEFORE USING OR WORKING AROUND CONVEYOR. NOTE: ALWAYS notify Roach Manufacturing

®

whenever any

conveyor is used in an application or condition other than was originally intended. Failure to notify Roach

®

may

allow conveyor to be operated in a hazardous operating condition. Injuries resulting from negligence or violation of

safety instructions hereby removes responsibility of product liability claims from Roach

®

.

Do not operate conveyor with

protective guards removed. This

includes chain guards, belt guards, snub

roller guards, center drive guards and

any other safety guard.

Do not walk, ride, climb, or touch

moving parts on a conveyor in

operation.

Do not wear loose clothing or

uncovered hair around conveyor.

Do not work near conveyor with-

out knowing how & where to shut

power “OFF” and lock out power source.

Do not remove jammed product

with conveyor running.

Do not replace parts or perform

maintenance on conveyor, or mov-

ing conveyor parts, without first shutting

“OFF” power to conveyor and locking out

power source.

Do not connect gravity to powered

conveyor without safety gravity

connector brackets.

To prevent electrical shock, conveyor

must be grounded, and have proper

electrical connections in accordance with

federal, state, and local codes.

Safety pop out rollers in conveyors

installed above 7’-0” elevation must

be retained by guard rail, clips, etc. Safety

pop out rollers must be allowed to pop out

when conveyors are installed at or below

7’-0” elevation.

It is the responsibility of conveyor

end-user to comply with all safety

standards including OSHA and other fed-

eral, state, and local codes or regulations.

Install protective guarding and other relat-

ed safety precautionary equipment to elimi-

nate hazardous operating conditions which

may exist when two or more vendors sup-

ply machinery for related use.

Any violation of above safety

instructions hereby removes all

product liability claims from Roach

Manufacturing Corporation

®

.