Roach Conveyors 725TB User manual

Installing and Maintaining Your Roach Conveyor

WARNING LABELS

ABOVE: Label attached to all protective guards (drives, roller guards, etc.) ABOVE: Label placed near all pulleys (center drives, end drives, tail pulleys)

ABOVE: Label placed near all drive assemblies and at 30’ intervals

-Warning Labels.............................................. 2

CAUTIONS, WARNINGS AND HAZARDS............ 3

-Important Safety Guidelines............................. 3

RECEIVING AND INSPECTION............................ 4

-Shortages, Damages & Return Auth................. 4

-Uncrating and Storage.................................... 4

-Safety Popout Roller Standard ......................... 4

GENERAL INSTALLATION INFORMATION ........... 5

-Attaching Bed Sections.................................... 5

-Couplings and Unit Squareness ....................... 5

-Safety Connector Brackets (How to Order) ....... 5

INSTALLATION OF SUPPORTS ............................

-Identifying/Installing Perm. Floor Supports.......... 6

-Installing Knee braces and Casters................... 6

POLYTIER SUPPORTS,CEILING HANGERS

AND UNDERTRUSSING...................................... 7

-Installation of Polytier Supports ....................... 7

-Installation of Ceiling Hangers ........................ 7

-Installation of Undertrussing ............................ 7

INSTALLATION OF BELTING .............................. 8

-Belt Connections ............................................. 8

-Maintaining Proper Belt Tension ...................... 8

-Nose-Over & Snub Roller Guard Adj............... 8

START-UP PROCEDURES..................................... 9

-Drive Chain and Sprocket Alignment ............... 9

-Drive Chain and Sprocket Tension ................... 9

-Gear Reducer .with Posivent Plug..................... 9

-Preparing for Initial Start-Up ........................... 9

BELT TRACKING............................................... 10

-General Information ..................................... 10

-Skewing Return Rollers.................................. 10

-Erratic Tracking at Start-Up ........................... 10

-Advanced Tracking Adjustments .................... 10

MAINTENANCE SAFETY PRECAUTIONS ............ 11

-Before Performing Maintenance..................... 11

-Maintenance and Follow-Up Details............... 11

-Periodic Maintenance Schedule ..................... 11

-Misc. Lubricants............................................ 11

-Report on Miscellaneous Maint Performed...... 11

BELT PATH....................................................... 12

-Illustrations for Units with End Drive............... 12

-Illustrations for Units with Center Drive........... 12

BELT PATH....................................................... 13

-Illustrations for Incline Units with End Drive..... 13

-Illustrations for Incline Units with Center Drive. 13

MAINTENANCE AND LUBRICATION ................. 14

TROUBLE SHOOTING & REPLACEMENT PARTS.. 15

-Trouble Shooting / Serial Plate...................... 15

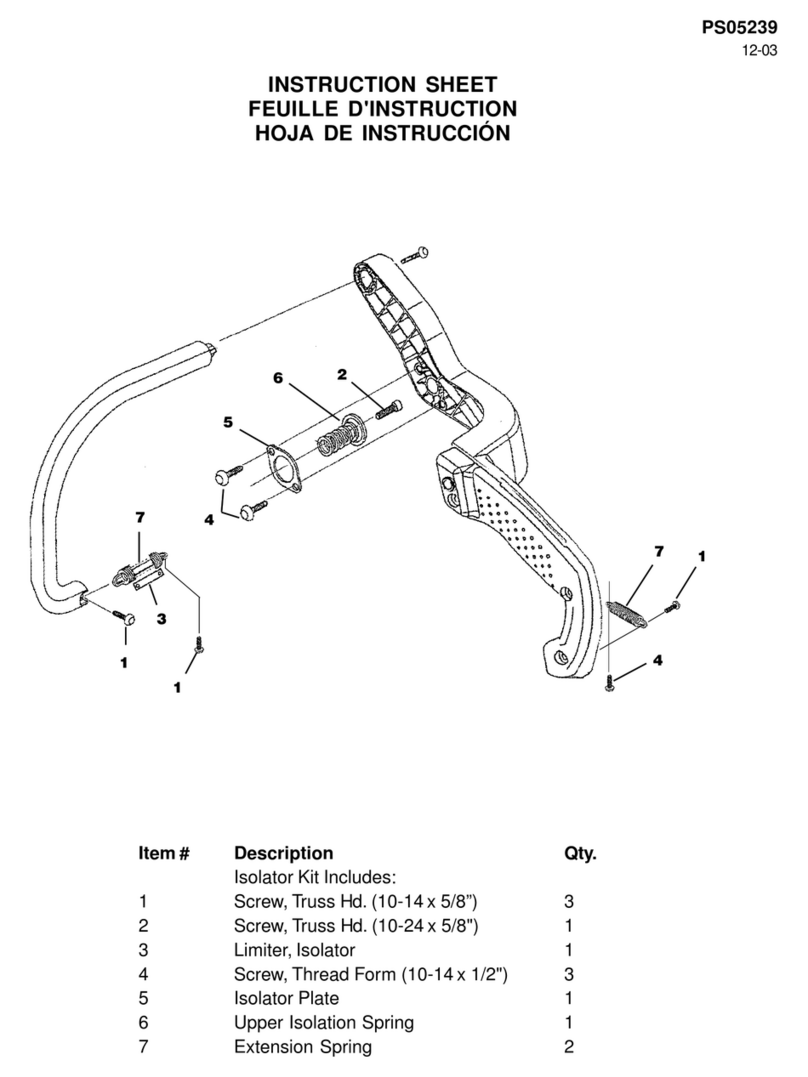

PARTS LISTS FOR 725TB................................... 16

-Parts List....................................................... 16

-Drawings ..................................................... 17

PARTS LISTS FOR 700SB .................................. 18

-Parts List....................................................... 18

-Drawings ..................................................... 19

PARTS LISTS FOR 700BSB ................................ 20

-Parts List....................................................... 20

-Drawings ..................................................... 21

PARTS LISTS FOR 450BOS................................ 22

-Parts List....................................................... 22

-Drawings ..................................................... 23

PARTS LISTS FOR 796RB .................................. 24

-Parts List.................................................. 24-25

-Drawings ..................................................... 26

PARTS LISTS FOR 751RB .................................. 27

-Parts List.................................................. 27-28

-Drawings ..................................................... 29

PARTS LISTS FOR 796RBF................................. 30

-Parts List.................................................. 30-31

-Drawings ..................................................... 32

PARTS LISTS FOR 700SBF................................. 33

-Parts List.................................................. 33-34

-Drawings ..................................................... 35

PARTS LISTS FOR INTEGRAL FEEDERS ............... 36

-Parts List ..................................................... 36

-Drawings ..................................................... 37

PARTS LISTS FOR CHAIN DRIVEN FEEDERS ....... 38

-Parts List ..................................................... 38

-Drawings ...................................................... 39

WARRANTY .................................................... 40

TECH HANDBOOK FOR 725TB/700SB/700BSB/450BOS

796RB/751RB/796RBF/700SBF

DO NOT OPERATE BEFORE READING THIS MANUAL!

KEEP IN SAFE PLACE--DO NOT DISCARD!

This manual was prepared as a “how-to-guide” for installers, end-users and maintenance personnel. It is also intended to educate both owner

(purchaser) and all individuals working around the unit, of potential hazards.

Conveyors contain many moving parts--pulleys, belting, chains, sprockets, shafts, rollers, etc. Therefore, it is imperative to become familiar with

basic unit operation and know all points of potential hazards.

This manual must be read by all new users before operating or working near this unit.

CAUTIONS, WARNINGS AND HAZARDS

NEVER connect belt conveyors directly to gravity conveyors, machinery

or fixtures without using connector brackets & pop out roller.

ALWAYS anchor permanent supports to floor (or mounting

surface). Use 3/8” x 2-1/2” (or longer) wedge anchors for

permanent installation in concrete flooring.

It is the responsibility of the customer and installation personnel to

supply and install net or mesh guarding on overhead mounted

conveyors to prevent product and/or debris from falling to floor in

areas where required.

If belt conveyor pulleys are adjusted during installation or

maintenance, nip point guard (at drive end on end drive unit) must

be readjusted. Nip point guard (take-up end) is automatically

adjusted when take-up pulley is adjusted. Nip point guards at both

ends of conveyor (center drive) must be readjusted. Center drive

guards MUST be replaced after installation or maintenance.

Before unit is ready for operation, snub roller guard (cover) must be

adjusted to ensure safe unit operation.

Belt lacing must be kept in good condition for safe work

environment.

To check drive sprocket alignment, shut “OFF” and lock out power

source before attempting any adjustments.

Electrical controls must be designed by a qualified electrical

engineer to ensure that appropriate safety features (emergency

stops, pull cords, switches, etc.) are installed on unit for safe

operation. Before conveyor start-up, all operators and other

personnel coming in contact with unit must be properly trained and

must have read accompanying Tech Handbook.

Upon start-up, if belt tracks to one side, turn unit “OFF”, lock

out power source and confirm that conveyor is square and that

all prime tracking components are square with bed. Belt tracking

adjustments should be performed by trained personnel ONLY. Read

section on “Belt Tracking” completely before attempting belt tracking

adjustments.

Only trained personnel shall perform maintenance functions. Before

maintenance operations are performed, shut conveyor “OFF” and

lock out power source to prevent unauthorized start-up. When

maintenance is completed, only authorized personnel shall be permitted to

start conveyor following maintenance or other emergency shut-off.

Do not operate conveyor with protective guards removed. This

includes chain guards, belt guards, snub roller guards, center drive

guards and any other safety guard.

Do not walk, ride, climb, or touch moving parts on a conveyor in

operation.

Do not wear loose clothing or uncovered hair around conveyor.

Do not work near conveyor without knowing how & where to shut

power “OFF” and lock out power source.

Do not remove jammed product with conveyor running.

Do not replace parts or perform

maintenance on conveyor, or moving conveyor parts, without first

shutting “OFF” power to conveyor and locking out power source.

Do not connect gravity to powered conveyor without safety gravity

connector brackets.

To prevent electrical shock, conveyor must be grounded, and have

proper electrical connections in accordance with federal, state, and

local codes.

Safety pop out rollers in conveyors installed above 7’-0” elevation

must be retained by guard rail, clips, etc. Safety pop out rollers must

be allowed to pop out when conveyors are installed at or below

7’-0” elevation.

It is the responsibility of conveyor end-user to comply with all safety

standards including OSHA and other federal, state, and local codes

or regulations. Install protective guarding and other related safety

precautionary equipment to eliminate hazardous operating condi-

tions which may exist when two or more vendors supply

machinery for related use.

Any violation of above safety instructions hereby removes all product

liability claims from Roach Manufacturing Corporation®.

Warning: All personnel coming in contact with this conveyor should be

aware of the following safety guidelines BEFORE USING OR WORKING

AROUND CONVEYOR. Note: always notify Roach Manufacturing®

whenever any conveyor is used in an application or condition other

than was originally intended. Failure to notify Roach® may allow

conveyor to be operated in a hazardous operating condition. Injuries

resulting from negligence or violation of safety instructions hereby

removes responsibility of product liability claims from Roach®.

IMPORTANT SAFETY GUIDELINES

Before uncrating, check the quantity of items received against bill

of lading to confirm that all material has been received. Examine the

condition of the equipment to determine if any damage has occurred.

It is possible that some items may become separated from the

original shipment. Therefore, when receiving goods, it is imperative that

the bill of lading (or, accompanying freight documentation) be checked to

ensure receipt of ALL units ordered including ALL accessories.

Damage and/or shortage in shipment should be reported immedi-

ately to both vendor and carrier. Obtain a signed

damage report from carrier agent and send copy to vendor.

Do not repair any damage before obtaining this report.

For damaged shipments, consult factory to determine if entire ship-

ment must be returned to factory for repair or if an immediate order

should enter production to produce a new, replacement shipment.

Note: Do not return goods to factory without prior, written return

authorization. Unauthorized returns are subject to refusal at factory.

RECEIVING AND INSPECTION

SHORTAGES, DAMAGES AND RETURN AUTHORIZATIONS

UNCRATING AND STORAGE

Carefully remove crating and look for essential components and

specific accessories that may have been boxed and attached (or

‘banded’) to crating material. Safety pop out rollers, guard rails and

hardware are often packaged and shipped in this manner. Save all

hardware for subsequent use by installation personnel.

The drive section will be shipped mounted to its actual operat-

ing bed section (see illustration above). Intermediate bed sections are

shipped mounted on top of drive bed section with formed steel stiffener

(spacer) brackets.

In illustration to the left, a model 700SB is shown palletized with

belting and return rollers for all bed sections mounted to top of crate

which is prepared for shipment.

Some items (electric motors, gearbox, etc.) may be shipped direct

from their manufacturer to final destination. Thus,

the conveyor may consist of two or more separate shipments.

Belting must be housed in dry quarters. Do not store belt on edge

(see illustration below).

Never Store belt placed directly on floor. Elevate to prevent contact

with floor moisture.

4

SAFETY POPOUT ROLLER STANDARD

Always leave popout roller (see illustration at left) in place when

permanently attaching any gravity conveyor to power conveyor.

Never connect powered belt conveyors directly to gravity convey-

ors without using the pop out roller.

Never connect power belt conveyors to any other conveyor or equip-

ment with out the safety popout roller in place as shown at left.

5

SAFETY CONNECTOR BRACKETS (450BOS ONLY)

Always use gravity connector bracket with pop out roller (see illustration)

to permanently attach any gravity conveyor to 450 BOS conveyor.

Never connect powered conveyors directly to gravity conveyors without

using connector brackets with pop out roller.

This simple connection eliminates hazardous pinch points that would oth-

erwise exist by attaching a gravity conveyor directly to a powered belt unit.

Connector Brackets are supplied as an optional component for the

450BOS.

Connector brackets may not have been originally required for unit appli-

cation, but they are readily available.

GENERAL INSTALLATION INFORMATION

ATTACHING BED SECTIONS

Use mechanical hoist (fork truck or other available means) to raise

bed sections to approximate installed elevation. Mate intermediate sec-

tions with either butt couplings or splice plates to join bed sections (see

illustration).

One of the most critical elements of proper installation is unit

squareness. Check drive pulley, tail pulley, snub roller (if used in

drive assembly) and return roller assemblies to ensure these com-

ponents are square with unit bed (see ‘Belt Tracking’ section later in

handbook for detailed information).

The unit must be installed at level elevation across the width to pre-

vent erratic belt tracking.

When preparing to install conveyor:

Locate all component sections in the actual installation area.

After uncrating, place unit bed sections conveying side up. Each

bed section is marked to indicate proper sequence for mating (see illus-

tration for typical bed section labels).

It is critical for bed sections to be field assembled in proper

sequence following bed section labels. Refer to bed section drawing

for location of supports and assemble as shown.

Conveyors are set up at the factory, bed section labels are applied, unit

is test run and receives rigorous quality assurance inspection. At this time the

unit becomes field-ready. Therefore, it is critical that field installation person-

nel re-assemble unit by mating beds in accordance with bed section labels

(and bed section drawing).

Create a reference base line on floor by marking a chalk line along the

center line of conveyor. Follow base line when installing unit.

COUPLINGS AND UNIT SQUARENESS

WARNING

Never connect belt conveyors directly to gravity conveyors, machinery or fixtures without using connector brackets with pop out roller.

Splice Plate (MODEL 700SB/700BSB/450BOS/700SBF) Splice Plate (MODEL 796RB/751RB/796RBF)

Knee braces add strength to permanent supports and stability to units

in portable applications. Install knee brace (when supplied) after

final permanent support installation and elevation adjustment. Its

pivot bracket is bolted to underneath side of lower conveyor flange

and slotted end is attached to outer side of support.

Knee braces are most commonly used at the terminal ends of

long runs of conveyor lines and are recommended on inclined (or

declined) floor-to-floor belt conveyors for added stability.

INSTALLING KNEE BRACES AND CASTERS

INSTALLATION OF SUPPORTS

IDENTIFYING/INSTALLING PERMANENT FLOOR SUPPORTS

Permanent supports may be installed on conveyors at various loca-

tions. However, it is most common to use single tier permanent

floor supports at each end of a powered section (see illustration A)

and where intermediate bed sections are adjoined (see illustration

B). Notice intermediate supports have two lag bolts in a diagonal

pattern while end (terminal) supports have four lag bolts, one in

each of the four foot plate mounting holes.

When two (or more) powered conveyors are placed end-to-end,

a single tier permanent support may be used at the end junction

commonly supporting both units. Check load rating of support

before using this method of installation.

Adjust elevation to top of conveyor by loosening bolts in support

uprights, raising or lowering conveyor and fully tightening bolts at

desired elevation. Tighten all bolts in supports before unit opera-

tion. Complete support installation by lagging support attachment

plates to floor. Confirm that unit is level across width of conveyor

before completing final support height adjustment.

Always anchor permanent supports to floor (or mounting surface).

Use 3/8” x 2-1/2” (or longer) wedge anchors for permanent

installation in concrete flooring.

Supports are normally shipped at minimum support height.

6

*MINIMUM/MAXIMUM SUPPORT HEIGHT

SM-1................... 7-1/4”-10-1/4” SM-7 ...............34-1/4”-46-1/4”

SM-2...................10-1/4”-13-1/4” SM-8 ...............46-1/4”-58-1/4”

SM-3...................13-1/4”-16-1/4” SM-9 ...............58-1/4”-70-1/4”

SM-4...................16-1/4”-22-1/4” SM-10 .............70-1/4”-82-1/4”

SM-5...................20-1/4”-26-1/4” SM-11 .............80-1/4”-92-1/4”

SM-6...................24-1/4”-36-1/4” SM-12 .............92-1/4”-104-1/4”

For a complete drawing and parts list log onto http://roachconveyors.com/belt-conveyor.htm

WARNING

Always anchor permanent supports to floor (or mounting surface).

Use 3/8” x 2-1/2” (or longer) wedge anchors for permanent installation in concrete flooring.

Polytier supports provide convenient installation method for two or

more tiers of conveyor.

To install, raise conveyor to desired eleva-

tion (approximate). Place 1” inside diameter cross pipe underneath

lower conveyor flange. Attach cross pipe to upright legs. Use

U-shaped retainer (“hat”) bracket to connect cross pipe to lower con-

veyor flange. Do not tighten

fully at this time.

There are two styles of attachment brackets available for use with

polytier supports. Minimum elevation style (see TYPE “0”, illustra-

tion above) offers lowest unit elevation, 0” + frame depth utilizing

L-shaped mounting bracket. Standard elevation style offers unit

elevation of 3-1/2” + frame depth and includes bracket welded to

cross pipe which is bolted to upright legs during installation.

When unit is at operating elevation and unit has been checked

across width for level, tighten locking bolts in U-shaped bracket.

Add knee braces for unit rigidity.

7

INSTALLATION OF CEILING HANGERS

Ceiling hangers are frequently used in high-elevation applications for suspension

from ceiling. The 5/8” diameter (#11 UNC) all threaded rod is supplied to allow

infinite vertical adjustment along the length of the suspension rod (see illustration

above).

Attach and firmly tighten U-shaped retainer (“hat”) bracket to underneath side of

lower conveyor flange with hardware provided

to hold cross pipe (1” inside diameter) against underneath side of conveyor.

Do not tighten cross pipe locking bolts (these attach in the bottom of the U-shaped

retainer bracket) until threaded suspension rods have been firmly secured to ceiling

structure.

To adjust conveyor elevation, tighten or loosen lower nut and jam nut on threaded

suspension rods to desired elevation. A lock washer must be used on suspension

rods to maintain unit at desired elevation.

When unit is at operating elevation and unit has been leveled across bed width,

tighten locking bolts in U-shaped bracket to secure position of cross pipe.

It is the responsibility of the customer and installation personnel to supply

and install net or mesh guarding on conveyors mounted overhead to pre-

vent product and/or debris from falling to floor in areas where required.

POLYTIER SUPPORTS, CEILING HANGERS AND UNDERTRUSSING

INSTALLATION OF POLYTIER SUPPORTS

When installing some conveyors, using a permanent support or ceiling hanger is sim-

ply not practical. In this situation, three bed sections (maximum) may be joined togeth-

er utilizing truss assembly, mounted underneath conveyor (see illustration at right).

Adjoin beds on floor using both connector rod support assemblies and connector rods

(5/8” diameter-11UNC threaded rod). The diagonal connector rod is used not only to

support the intermediate bed section joint but it is instrumental for setting and maintain-

ing proper tension across intermediate spanned beds.

Use mechanical hoist (fork truck or other means) to raise pre-assembled bed sections

(with undertrussing) to desired elevation for final installation.

Use diagonal connector rods to level the undertrussed beds both along and across

the conveyor. Remember that the tension must provide adequate for both dead load

(conveyor weight) and product load during unit operation.

It is the responsibility of the customer and installation personnel to supply and

install net or mesh guarding on conveyors mounted overhead to prevent prod-

uct and/or debris from falling to floor in areas where required.

INSTALLATION OF UNDERTRUSSING

8

INSTALLATION OF BELTING

BELT CONNECTIONS

MAINTAINING PROPER BELT TENSION

Maintaining proper belt tension is vital to unit operation. Enough tension should be

maintained so that drive pulley does not slip under unit fully loaded conditions.

It is perfectly normal for a belt to stretch (in varying climatic conditions) under rated

loading. Therefore, a short belt insert or “belt patch” (or patches) is provided for

future removal when belting has stretched beyond means of conveyor take-up

assembly. For yet additional belt take-up, the belt should be cut and re-laced to

maintain proper belt tension.

To adjust conveyor take-up, adjust position of take-up rod (see illustration above)

as required. Remember to equally adjust both sides to hold take-up pulley square

(to maintain unit squareness for belt tracking). Operating unit with slipping belt will

decrease life of both belting and pulley lagging.

Also, do not operate unit with too much tension on belt. This will

decrease belt life and may harm unit drive and take-up bearings.

Over tensioning belt requires additional horsepower from unit drive

and can cause belt mistracking.

Conveyor belting is cut to proper length, laced and assembled on

conveyor at the factory. It is test run and inspected before it is shipped to

its final destination.

Before field installation of belting, it is critical to determine the correct

side to be placed down. One of the most common problems associated

with belt installation involves placing the incorrect side down.

PVC belting is most commonly supplied as “COS” (cover one side).

The opposite side, or side to be placed down, is a friction surface for

decreased friction and improved conveyability. The friction side appears

dull and grainy. ALWAYS place this side down against the conveyor bed.

The cover side is darker and shiny.

If unit is shipped “knocked down,” belt must be re-threaded on unit

during installation. (See page 13-14 for proper belt paths.)

Join ends of belt as shown with lacing pin. Loosen threaded take-up

rods (if necessary) at take-up pulley equal amount on both sides and re-

adjust when belt is installed keeping pulley square with conveyor bed. A

belt puller can also be used to join belting.

Belt lacing must be kept in good condition for safe work environment.

MAKE ADJUSTMENTS HERE

NOSE-OVER AND SNUB ROLLER GUARD ADJUSTMENT

Nose-over assemblies may be supplied (optional) when slider/roller belt conveyors are

inclined or declined to ease the transition from inclined to horizontal. A single nose-over

assembly consists of one set of nose-over brackets with carrier roller, one snub roller with

snub roller guard and attachment bracket. A double nose-over assembly includes one

additional set of nose-over brackets and carrier roller.

Beds are cut and nose-over brackets and rollers are installed at the factory. Before unit

is ready for operation, final adjustment of snub roller assembly is required to ensure safe

unit operation. Snub roller guard (cover) should be set (see illustration above) with 1/4”

belt clearance between bottom of belt and top of guard, both sides of guard, during final

installation.

caution: Before unit is ready for operation, snub roller guard (cover) must be

adjusted to ensure safe unit operation.

Warn all personnel to keep clear of CONVEYOR during unit start-up

9

START-UP PROCEDURES

DRIVE CHAIN AND SPROCKET ALIGNMENT

DRIVE CHAIN AND SPROCKET TENSION

Maintaining proper chain tension is especially important. Again, a peri-

odic visual inspection is recommended to ensure chain tension within a

pre-determined operating range.

Remember, before any adjustments are attempted, conveyor must be

shut “OFF” and power source locked out.

Before replacing chain guard cover, check to see if drive chain is operat-

ing within 1/2” range (see illustration). If unit is out of tolerance, adjust-

ment is necessary.

To adjust drive chain tension, tensioner bolt located on reducer push

plate should be tightened (rotate clockwise) if chain tension

is loose. Tighten until proper operating range is achieved. If chain

tension is too tight, loosen tensioner bolt (rotate counterclockwise) as

required. When adjustment is complete replace chain guard cover.

WARNING: Do not operate unit until chain guard cover is replaced.

Serious operator or other personal injury could result if protective

guarding is not replaced.

Set up and maintenance of drive sprocket and drive chain alignment is

critical. A periodic visual inspection is recommended to confirm align-

ment of drive components (which includes both drive sprockets and drive

chain). Should set screws become loose, drive sprockets are subject to

excessive wear and ultimately, to untimely replacement.

To check drive sprocket alignment, it is imperative that conveyor is

shut “OFF” and power source is locked out before any adjustments are

attempted.

Remove chain guard cover and place straight-edge (see illus-

tration) across face of both drive sprockets. If re-alignment is necessary,

loosen set screws and adjust drive sprockets as required. Remember to

securely tighten set screws when alignment is complete. Before replacing

chain guard cover, check drive chain tension as described in following

section, “Drive Chain and Sprocket Tension.”

Do not operate without guards in place.

GEAR REDUCER WITH POSIVENT

PosiVent Unique design incorporates

a single seam construction. Factory

filled with synthetic lubrication for

universal mounting. Lubed for life, no

oil changes are required.

No vent plug required.

PREPARING FOR INITIAL START-UP

Provisions must be in order to instruct all personnel coming in contact

with conveyor on the location of emergency stops,

pull cords, etc.

A routine maintenance program should be implemented before unit is

placed into operation so that fundamental unit components are attended

to. This maintenance program should include an inspection to ensure

that any dangerous or hazardous operating conditions are noted and

IMMEDIATELY corrected, as well as including electrical and mechanical

unit inspections and corrections.

Finally, when conveyor is initially started, an immediate visual inspection

should include motor, gear reducer, belt tracking (discussed in following

section under “Belt Tracking”) and related adjustments noted in handbook

ELECTRICAL CONTROLS

Electrical controls must be designed by

a qualified electrical engineer to ensure

that appropriate safety features (emer-

gency stops, pull cords, switches, etc.)

are installed on unit for safe operation.

One of the most common and productive

means to track conveyor belting is to skew roll-

ers. Excess skewing of rollers, which may cause

belt to bow and may force belt to rub on side

frame causing belt damage, usually will not

completely solve belt tracking problems

ONLY trained personnel should make belt

tracking adjustments. Shut unit “OFF” and

lock out power source before attempting

adjustments in belt tracking.

To adjust return rollers, simply loosen attach-

ment bolt that secures bracket to the side of

the conveyor (see illustration above). Move

bracket to skew return roller assemblies (as

noted in Advanced Tracking Adjustments later

in manual). Remember to make adjustments in

SMALL increments.

When adjustment is complete, tighten bolt

firmly securing return roller bracket to the side

of the conveyor.

When adjustments noted in section above

have been completed and belt continues to

track erratically, a second series of tracking

adjustments are necessary.

First, determine the infeed and discharge ends

of the conveyor. The following adjustments

will be made with the infeed end as the refer-

ence point.

If belt tracks toward side “R” (see illustration

above), skew return rollers in direction “B” to

shift belting toward side “L”. If belt tracks

toward side “L”, skew return rollers in direc-

tion “A” to shift belting toward side “R”.

Skewing head pulley (pulley at unit discharge)

in direction “A” moves belt toward side “L”.

Skewing head pulley in direction “B” moves

belt toward side “R”.

As a rule of thumb, do not use drive and

take-up pulley for belt tracking since this will

overly increase belt tension. When adjusting

take-up pulley, adjust both sides an equal

amount.

As a last resort, shift the tail pulley in

direction “B” to move belting toward side “L”;

shift head pulley in direction “A” to move

belting toward side “L”.

Improper tracking of conveyor belting should

be considered a “systems” problem rather than

solely a deficiency in the belt. To explain, a belt

is tracked with adjustments made in the system or

entire conveyor rather than just the belting.

Upon start-up, if belt tracks to one side of

unit, turn unit “OFF”, lock out power source

and confirm that conveyor is square. All

prime tracking components must be square

with bed including drive pulley, tail pulley,

snub roller and return rollers.

Both sides of

take-up should be adjusted exactly the same

amount. The conveyor should be level across

the width of the unit. Confirm that the belt has

been properly threaded (see “Belt Path” section)

and that belt lacing is square with the belt edges.

Make adjustments as necessary; however, all

adjustments should be made in small increments.

Start conveyor again and operate for at least

ten minutes once initial phase of adjustments are

complete. If belt continues to track erratically, turn

unit “OFF” before belt is allowed to run so far off

center that it rubs side of conveyor.

BELT TRACKING

GENERAL INFORMATION 10

Upon initial use the belting will stretch after

a few days of operation. Remember that

maintaining proper belt tension is a crucial

element in belt tracking.

Therefore, this stretch-

ing of a belt when placed into operation may affect

its ability to track. Adjustment of the take-up pulley

will likely adequately compensate for initial stretch.

However, depending on the overall unit length,

removal of a belt patch may be necessary to correct.

ONLY trained personnel should make belt

tracking adjustments.

Belt must be tracked in both unloaded and loaded

situations. The return direction of the belt must

clear supports, ceiling hangers, floor openings,

etc. Dragging on such components will contribute

to belt tracking problems and is certain to damage

belting at extended intervals.

In a reversible application, a belt that runs off to

one side in one direction will likely run off to the

other side when operated in the opposite direc-

tion. Do not allow belt to rub against side of con-

veyor frame, which will surely damage belt.

SKEWING RETURN ROLLERS

ERRATIC TRACKING AT START-UP

ADVANCED TRACKING ADJUSTMENTS

MAINTENANCE AND FOLLOW-UP DETAILS

11

MAINTENANCE SAFETY PRECAUTIONS

BEFORE PERFORMING MAINTENANCE

While performing maintenance do not wear loose clothing. Immediately

report any hazardous conditions--sharp edges, pinch (or nip) points or other

conditions that may result when several manufacturers supply machinery

which may create operating hazards.

When using mechanical aids such as hoists, cables, or cranes exercise

extreme caution to prevent damage to conveyors or other integrated machin-

ery which may create a working hazard when maintenance is completed and

units are in operation.

Clean up any spilled lubricants or other materials used in the main-

tenance process or those which may be deposited during unit operation.

Eliminating poor housekeeping practices increases unit efficiency while creat-

ing safer personnel working conditions.

After maintenance, conduct visual inspection to ensure that all safety

devices and guards have been replaced. Confirm that all units are clear

of tools, debris or other items. Before starting conveyor, check condition of

conveyor warning labels (see “WARNING LABELS” at front of handbook). If

labels have been destroyed or are not clearly legible, call 870.483.7631 to

receive replacement labels. Placement of warning labels is critical to avoid

unauthorized unit operation which may result in hazardous working condi-

tions for all related personnel coming in contact with conveyor.

Warn personnel that conveyor is being prepared for start-up and to stay

clear of unit. Do not start conveyor until all personnel are clear. When main-

tenance is completed, only authorized personnel shall be permitted to start

conveyor following maintenance or other emergency shut-off.

One of the most important guidelines for maximizing conveyor operation

and personnel safety is to implement a regular maintenance schedule and

train personnel on the appropriate needs of the specific unit.

Only trained personnel shall perform maintenance functions.

Before maintenance operations are performed, conveyor must

be shut “OFF” and disconnects locked in the “OFF” position to prevent

unit from unauthorized start-up during maintenance. All personnel

should be informed of the safety procedures associated with unit main-

tenance and performance.

Do not perform any work on conveyors or conveyor system while in

operation unless it is impossible to otherwise conduct adjustment, lubrication

or other maintenance function.

Only experienced, trained personnel possessing advanced hazards-train-

ing should attempt such critical operations.

MAINTENANCE PERIODIC MAINTENANCE SCHEDULE AND LUBRICATION

**NOTE: Temperatures listed indicate the nominal operational temperature for the specific lubricant listed. This does not imply that the bearing housing, seals or any other conveyor unit

component is rated to operate in this specific temperature range or environment. 250°F is the maximum operating temperature for standard bearing lubricants and bearing components.

Although various lubricants may enhance bearing operation, special-order bearings may be required to achieve optimal bearing performance. For additional information, consult factory.

WEEKLY RECOMMENDED MAINTENANCE SCHEDULE*

COMPONENT

BELTING

PILLOW BLOCK /

FLANGE BEARINGS

UNIT

SAFETY

CHECK

DETAIL OF MAINTENANCE

Inspect belt tracking

Lubricate in dirty, dusty, or

moist/wet conditions

Confirm placement of all guards, pop-out

rollers, warning labels & check for loose

bolts, nip points & other hazards

MONTHLY RECOMMENDED MAINTENANCE SCHEDULE*

COMPONENT

GEAR REDUCER

BELTING

PILLOW BLOCK /

FLANGE BEARINGS

DRIVE CHAIN

DRIVE SPROCKETS

DETAIL OF MAINTENANCE

Check for leaks

Inspect belt tracking

Lubricate in dirty, dusty, or

moist/wet conditions

Check for proper operating tension &

overall wear & lubricate

Check for overall wear & re-tighten set screws

PERIODIC RECOMMENDED MAINTENANCE SCHEDULE*

COMPONENT

GEAR REDUCER

DRIVE CHAIN

MOTOR

DETAIL OF MAINTENANCE

Check for leaks

Clean (brush in solvent) & re-lubricate by ap-

plying lubricant to inside of chain with brush

or spout can at 2000 hour intervals

Check & clear motor ventilation openings

at 500 hour intervals. Check miscellaneous

operating conditions (normal heat & noise)

MISC. LUBRICANTS**

General Purpose Grease

(For -30°F to 300°F operation)*

For Extreme Temperature Operation

(-90°F to 350°F operation)*

Washdown Application*

(-30°F to 225°F operation)

(May require special consideration

consult factory)

General Purpose Oil

Shell Dolium R (Shell Oil Co.)

(or suitable equivalent)

Mobiltemp SHC-32 (Mobil Oil Corp.)

(or suitable equivalent)

Shell Alvania No. 3 (Shell Oil Co.)

(or suitable equivalent)

SAE 10; SAE 20 OR SAE 30

*All charts are for guidelines in normal operating or ‘as noted’ conditions. Severe applications warrant additional maintenance.

**

BELT PATH

ILLUSTRATION FOR UNITS WITH END DRIVE

ILLUSTRATION FOR UNITS WITH CENTER DRIVE

If pulleys are adjusted during installation or mainte-

nance, it is crucial that nip point guard (at drive end)

is readjusted. See detail “A” above. Note: Nip point

guard on take-up end is automatically adjusted when

take-up pulley is adjusted.

If pulleys are adjusted during installation or mainte-

nance, it is crucial that nip point guards (at both ends

of conveyor) are readjusted. See detail “B” above.

Center drive guards MUST be replaced after installa-

tion or maintenance.

FLOW

FLOW

12

BELT PATH

ILLUSTRATION FOR INCLINE UNIT

FIXED END

PULLEY

BELT

RETURN

ROLLER

TAKE-UP PULLEY

TAKE-UP

PULLEY

DRIVE

PULLEY SNUB

ROLLER

NOSE-OVER

SNUB ROLLER

CAUTION: If pulleys are adjusted during installation or maintenance, it is crucial that nip point guards (at both ends of conveyor) are readjusted. See

DETAIL“A” at left. Center drive guards MUST be replaced after installation or maintenance. If optional feeder is used, nip point guards in end assem-

blies (including drive or fixed end pulley) must be adjusted when feeder pulleys are adjusted.

DETAIL “A”

Unit shown with optional

Chain Feeder

CHAIN DRIVEN AND INTEGRAL FEEDERS

Two types of feeders (both optional) are commonly supplied on floor-to-floor

belt conveyors. Horizontal chain driven feeders (see above illustration) are

powered from the inclined (or declined) conveyor section via slave drive con-

nection. This feeder requires one support at each end of the feeder and an

additional support at each intermediate feeder bed section when installing.

Integral feeders (see illustration at right) use a 3-pulley device to transfer the

belt from its inclined section to the horizontal feeder for loading or unloading

from the floor-to-floor conveyor. Here, the same type of belting, generally

supplied as 2-ply ruff-top, is used on both feeder and inclined section due to

the continuous travel of the belt. Note that the support at the terminal feeder

end must be 7” taller to top of support than the support assembly placed

under the 3-pulley device, which commonly supports both intermediate feeder

and inclined section.

NOTE: Optional integral feeders and chain driven feeders are often used

to transfer product from horizontal position to inclined or declined con-

veyor section. Always use feeder when transferring to or from gravity

conveyors.

CHAIN DRIVEN FEEDER INTEGRAL FEEDER

FLOW

13

MOTOR ALWAYS MOUNTED

ON HIGH SIDE

14

MAINTENANCE AND LUBRICATION

REPORT ON MISCELLANEOUS MAINTENANCE PERFORMED

REPORT ON MAINTENANCE

CONVEYOR REPAIRED INSPECTION DETAIL OF MAINTENANCE COMPLETED (OR INSPECTION)

MARK NO. BY DATE LIST PARTS REPLACED OR REPAIRS

TROUBLE SHOOTING AND REPLACEMENT PARTS

TROUBLE SHOOTING / SERIAL PLATE

ORDERING REPLACEMENT PARTS

To order any replacement parts or when calling for assistance with

any powered conveyor, ALWAYS provide the unit serial number.

Shown at actual size, this aluminum plate is placed on the con-

veyor frame near the location of the drive assembly.

To order replacement parts or add-on components, contact the

Roach distributor who originally furnished the unit if possible. If

this is not possible, contact the National Sales Office at 870-

483-7631 for the name of the authorized Roach distributor in

your area. Have unit model number and serial number BEFORE

calling. Refer to unit drawings on the Roach Conveyors website

( http://roachconveyors.com/belt-conveyor.htm ) for part numbers

if ordering replacement parts.

TROUBLE SHOOTING

TROUBLE PROBABLE CAUSE REMEDY

Motor & gear

reducer running ex-

cessively hot, or hard

to start

A. Drag on conveyor

B. Lack of lubricant

C. Frozen sprocket

D. Frozen roller

E. Overload

F. Electrical

A. Inspect entire conveyor for obstruction causing drag

on chain.

B. Check for leaks.

C. Check and inspect all sprockets and bearings. Replace

sprockets failing to rotate or that are difficult to rotate.

D. Check all rollers for rotation.

E. Reduce cause and/or increase motor horsepower.

F. Check wiring and circuits, take ampere reading, replace

motor if necessary.

Motor & gear re-

ducer makes exces-

sive noise

A. Lack of lubrication

B. Damaged Gears

C. Faulty Bearing

A. Check for leaks.

B. Replace unit.

C. Replace bearing.

Drive chain, con-

veying chain or

sprockets experience

excessive wear

A. Excessive chain tension

B. Sprockets misaligned

C. Chain not lubricated

D. Damaged sprocket or chain

E. Misalignment of chain guard

F. Dirty chain

A. Reduce chain tension.

B. Realign with straight edge across sprocket faces.

C. Lubricated chain with approved lubricant, wipe away

excess lubricant.

D. Replace Damaged Component.

E. Adjust chain guard assembly as necessary.

F. Clean thoroughly and lubricate with approved lubricant.

Drive chain,

conveying chain

or sprockets make

excessive noise

A. Insufficient chain tension

B. Chain not adequately

lubricated

C. Sprockets misaligned

A. Adjust chain tension.

B. Lubricate chain with approved lubricant, wipe away excess

lubricant.

C. Realign sprockets with straight edge across sprocket faces.

Pulsating chain

A. Insufficient chain tension

B. Misalignment of chain guard

C. Overload

A. Adjust chain tension.

B. Adjust chain guard assembly as necessary.

C. Inspect for obstruction to or drag on conveyor.

Broken chain

A. Frozen bearing or sprocket

shaft

B. Worn or damaged chain

C. Obstructed or jam

A. Inspect for damaged bearings, replace if necessary. Re

place links as required.

B. Replace chain as required.

C. Remove obstruction to clear jam.

Sprocket loose on

shaft

A. Loose set screws

B. Worn or damaged key

A. Realign sprockets with straight edge and tighten set screws.

B. Replace with new key.

Excessive slack in

chain

A. Normal wear A. Expect rapid chain growth in first two weeks of operation.

B. Adjust chain tension as specified in the manual.

15

MODEL 725TB

PARTS LIST

Specify Unit Serial Number when ordering replacement parts to ensure proper

allocation of components (See Ordering Replacement Parts on page 15).

Recommended Spare Parts are shown in red. Charted are item numbers and

part descriptions. When ordering use example below.

Example: Need a replacement End Take-up Assembly for a 725TB.

Part No: SN 123456 - 15 - End Take-up Assembly

ITEM # DESCRIPTION

1 725TB End Bed Section

2 Guard Rail Fastener Strap

3 Return Roller Bracket

4 Splice Plate

5 Bed Pan Brace Channel

6196S Roller Assembly

7 End Trough Bed

8 Intermediate Trough Bed

9 Box Type Bed

10 725TB Full Length Bed Assembly

11 End Trough Bed

12 725TB Full Length Center Drive Bed Assembly

13 725TB Intermediate Bed Assembly

14 Intermediate Bed

15 End Take-up Assembly

16 5/8” Diameter Take-up Rod

17 1-3/16” Milled Take-up Bearing RH

18 1-3/16” Milled Take-up Bearing LH

19 5/16” - 18 x 2” Hex Flange HCS

20 5/16” - 18 Nylon Insert Locknut

21 1/4” Flat Washers

22 5/8” - 11 Hex Nut

23 Safety Pop-out Roller Assembly

24 Take-up Bearing Guide

25 Bolt-in Butt Coupling

26 Take-up Bed Joint Mounting Angle

27 Idler Pulley Assembly

28 Take-up Plate

29 Bearing Guide Spacer

30 Top Take-up Bearing Guide

31 5/16” Flat Washer

32 Fixed End Assembly

33 Safety Pop-out Roller Assembly

34 Bolt-in Butt Coupling

35 Bearing Take-up Mounting Angle

36 Bearing Push Plate

37 Bed Joint Mounting Angle

38 Idler Pulley Assembly

39 Fixed End & Drive Plate Assembly

40 2-Hole Flange Bearing w/ 1-3/16” Bore

ITEM # DESCRIPTION

43 Bolt-in Butt Coupling

44 Bearing Take-up Mounting Angle

45 Bearing Push Plate

46 Bed Joint Mounting Angle

47 Drive Pulley Assembly

48 Fixed End & Drive Plate Assembly

49 4 Hole Flanged Bearing w/ 1-7/16” Bore

50 2.5 Roller Keeper

51 251S Roller Assembly

52 Belt Guards

53 Snub Roller Belt Guard

54 Center Drive Assembly

55 2.5 Roller Keeper

56 Center Drive Take-up Bearing Guide

57 (Milled) Take-up Bearing Assembly

58 251S Roller Assembly

59 Center Drive Plate Weld Assembly

60 Drive Pulley

61 Idler Pulley Assembly

62 Center Drive Belt Guard

63 Center Drive Belt Guard

64 Frame Crossbrace

65 4 Hole Flange Bearing w/ 1-15/16” Bore

66 3 Hole Flange Bearing w/ 1-3/16” Bore

67 Belting Assembly

68 Sidemount Drive Kit

69 Motorbase Stiffener Assembly (1HP+)

70 Reducer Push Plate Assembly

71 Sidemount Motorbase Plate

72 Sidemount Chain Guard Assembly

73 End Drive Kit

74 Motorbase Stiffener Assembly

75 Chain Guard Mounting Angle

76 Reducer Push Plate Assembly

77 Underneath Motorbase Plate

78 Chain Guard Assembly

79 Center Drive Kit

80 Motorbase Stiffener Assembly (1HP+)

81 Reducer Push Plate Assembly

16

MODEL 725TB

END DRIVE, END SIDE MOUNT DRIVE & CENTER DRIVE DRAWINGS 17

MODEL 700SB

PARTS LIST

Specify Unit Serial Number when ordering replacement parts to ensure proper

allocation of components (See Ordering Replacement Parts on page 15).

Recommended Spare Parts are shown in red. Charted are item numbers and

part descriptions. When ordering use example below.

Example: Need a replacement Drive Pulley Assembly for a 700SB.

Part No: SN 123456 - 51 - Drive Puller Assembly

ITEM # DESCRIPTION

1 700SB Intermediate Bed Assembly

2 1.9 Roller Keeper

3 Splice Plate

4 Bed Pan Brace Channel

5196S Roller Assembly

6 Slider Bed Pan

7 Medium Duty Side Channel

8 Frame Crossbrace

9 End Take-up Assembly

10 5/8” Diameter Take-up Rod

11 Safety Pop-out Roller Assembly

12 Take-up Bearing Guide

13 Bolt-in Butt Coupling

14 Take-up Bed Joint Mounting Angle

15 Take-up Filler Pan

16 Idler Pulley Assembly

17 196S Roller Assembly

18 Take-up Plate

19 Bearing Guide Spacer

20 Top Take-up Bearing Guide

21 Fixed End Assembly

22 Safety Pop-out Roller Assembly

23 Bearing Take-up Mounting Angle

24 Bed Pan Brace Channel

25 Bearing Push Plate

26 Bed Joint Mounting Angle

27 Idler Pulley Assembly

28 Fixed End & Drive Plate Assembly

29 Filler Pan

30 4 Hole Flanged Bearing w/ 1-7/16” Bore

31 End Drive Assembly

32 Safety Pop-out Roller Assembly

33 Bearing Take-up Mounting Angle

34 Bed Pan Brace Channel

35 Bearing Push Plate

36 Bed Joint Mounting Angle

ITEM # DESCRIPTION

38 Fixed End & Drive Plate Assembly

39 Filler Pan

40 4 Hole Flange Bearing w/1-7/16” Bore

41 2.5 Roller Keeper

42 Belt Guard

43 Snub Roller Belt Guard

44 251S Roller Assembly

45 Center Drive Assembly

46 2.5 Roller Keeper

47 Center Drive Take-up Bearing Guide

48 (Milled) Take-up Bearing Assembly LH/RH

49 251S Roller Assembly

50 Center Drive Plate Weld Assembly

51 Drive Pulley Assembly

52 Idler Pulley Assembly

53 Center Drive Belt Guard

54 Center Drive Belt Guard

55 Frame Crossbrace

56 4 Hole Flanged Bearing w/1-7/16” Bore

57 3 Hole Flanged Bearing w/1-3/16” Bore

58 Belting Assembly

59 Sidemount Drive Kit

60 Motorbase Stiffener Assembly (1HP+)

61 Reducer Push Plate Assembly

62 Sidemount Motorbase Plate

63 Sidemount Chain Guard Assembly

64 End Drive Kit

65 Motorbase Stiffener Assembly (1HP+)

66 Chain Guard Angle Mount

67 Reducer Push Plate Assembly

68 Underneath Motorbase Plate

69 Chain Guard Assembly

70 Center Drive Kit

71 Motorbase Stiffener Assembly (1HP+)

72 Reducer Push Plate Assembly

73 Underneath Motorbase Plate

18

MODEL 700SB

END DRIVE, END SIDE MOUNT DRIVE & CENTER DRIVE DRAWINGS

GUIDE

BUSHING

DETAIL

TAKE-UP

FILLER

PAN DETAIL

"X"

"X"

VIEW "X" - "X"

SIDEMOUNT VIEWS

SEE

DETAIL

DETAIL

SPLICE PLATE CONNECTION

FOR CONNECTING ALL FRAMES

TAKE-UP FILLER

PAN DETAIL

NOTE: DO NOT OVER TIGHTEN 1/4"

HHCS AS THIS COULD CRUSH

SHOULDER OF GUIDE BUSHING.

GUIDE BUSHING DETAIL

1 1/2 1 1/2

12

BED LENGTH

12

BED LENGTH

4" & 6" END DRIVE 12" LG

8" END DRIVE 24" LG.

7”

OVERALL LENGTH (OAL)

"A"

OVERALL WIDTH (OAW)

BETWEEN FRAME (BF)

BELT WIDTH

32 58 39 38

69

66

67

68

64

43

42

37

40

58

63 59

62 61

38

32

31 40 35 33 39 41

37 42 43 44 63 62 61 59

36

3

1

38

32

42 37

43

44

66

40 35 33 39 41 31 36 58 6

1

64

67

68

69

8

5

7

2

17 15

11 10

16

14 13

17 15 9

11

10

12

19

18

8

29

27

28

22

30 21 25 23 26

29 24

149 52 6 5258

46

49

55 53 50 45 48 47 51 54 56 73 74 72 70

26 23 25 21

30

22

28

29 27

19

MODEL 700BSB

PARTS LIST

Specify Unit Serial Number when ordering replacement parts to ensure proper

allocation of components (See Ordering Replacement Parts on page 15).

Recommended Spare Parts are shown in red. Charted are item numbers and

part descriptions. When ordering use example below.

Example: Need a replacement Center Drive Chain Guard

Assembly for a 700BSB.

Part No: SN 123456 - 77 - C/D Chain Guard Assembly

ITEM # DESCRIPTION

1 700BSB Intermediate Bed Assembly

2 Return Roller Bracket

3 Splice Plate

4196S Roller Assembly

5 700 Box Type Bed Section

6 Bed Pan Brace Channel

7 700 Box Side Channel

8 Bed Pan

9 Frame Crossbrace

10 End Take-up Assembly

11 5/8” Diameter Take-up Rod

12 Safety Pop-out Roller Assembly

13 Take-up Bearing Guide

14 Bolt-in Butt Coupling

15 Take-up Bed Joint Mounting Angle

16 Take-up Filler Pan

17 Idler Pulley Assembly

18 196S Roller Assembly

19 Take-up Plate

20 Bearing Guide Spacer

21 -

22 Fixed End Assembly

23 Safety Pop-out Roller

24 Bolt-in Butt Coupling

25 Bearing Take-up Mounting Angle

26 Bed Pan Brace

27 Bearing Push Plate

28 Bed Joint Mounting Angle

29 Idler Pulley Assembly

30 Fixed End & Drive Plate Assembly

31 Filler Pan

32 4 Hole Flanged Bearing w/ 1-7/16” Bore

33 End Drive Assembly

34 Safety Pop-out Roller Assembly

35 Bolt-in Butt Coupling

36 Bearing Take-up Mounting Angle

37 Bed Pan Brace

38 Bearing Push Plate

ITEM # DESCRIPTION

40 Drive Pulley Assembly

41 Fixed End & Drive Plate Assembly

42 Filler Pan

43 4 Hole Flanged Bearing w/ 1-7/16” Bore

44 2.5 Roller Keeper

45 Belt Guard

46 Snub Roller Belt Guard

47 251S Roller Assembly

48 Center Drive Assembly

49 2.5 Roller Keeper

50 Center Drive Take-up Bearing Guide

51 (Milled) Take-up Bearing Assembly LH/RH

52 251S Roller Assembly

53 Center Drive Plate Weld Assembly

54 Drive Pulley Assembly

55 Idler Pulley Assembly

56 Center Drive Belt Guard

57 Center Drive Belt Guard

58 Frame Crossbrace

59 4 Hole Flanged Bearing w/ 1-7/16” Bore

60 3 Hole Flanged Bearing w/ 1-3/16” Bore

61 Belting Assembly

62 Sidemount Drive Kit

63 Motorbase Stiffener Assembly (1HP+)

64 Reducer Push Plate Assembly

65 Sidemount Motorbase Plate

66 Sidemount Chain Guard Assembly

67 End Drive Kit

68 Motorbase Stiffener Assembly (1HP+)

69 Chain Guard Angle Mount

70 Reducer Push Plate Assembly

71 Underneath Motorbase Plate

72 Chain Guard Assembly

73 Center Drive Kit

74 Motorbase Stiffener Assembly (1HP+)

75 Reducer Push Plate Assembly

20

This manual suits for next models

7

Table of contents

Other Roach Conveyors Accessories manuals

Popular Accessories manuals by other brands

Rain Bird

Rain Bird RSD-BEx Installation & operating instructions

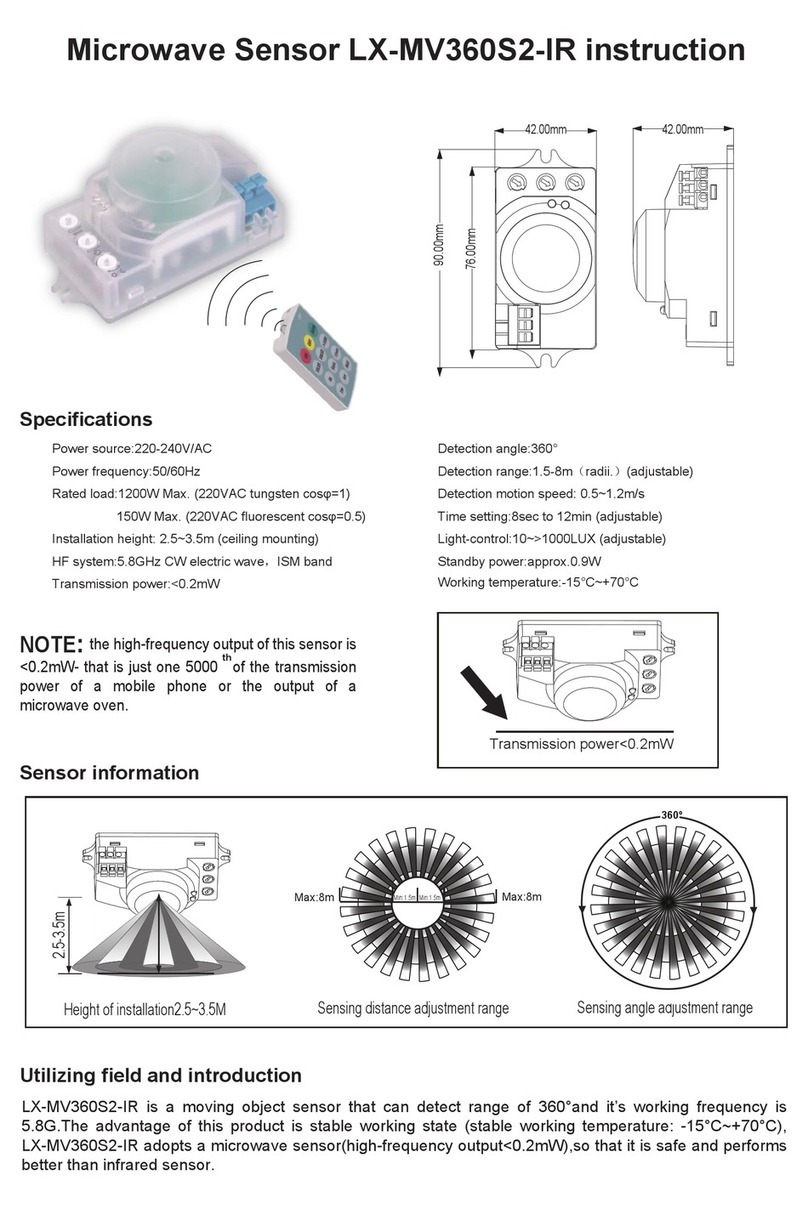

Lexing

Lexing LX-MV360S2-IR Series Instruction

PCB Piezotronics

PCB Piezotronics 113B21 Installation and operating manual

Banner

Banner Q4X Series user guide

Elenco Electronics

Elenco Electronics AK-100/SP-1A Assembly and instruction manual

ATEN

ATEN VS-0116 user manual