4

A. GENERAL:

Be sure that all pipes and fittings used are clean, free of chips,

dirt and moisture. If pipe compound or shellac is used, apply a

small amount above the second or third male thread only.

DO NOT GET PIPE COMPOUND OR SHELLAC INSIDE

RELAY.

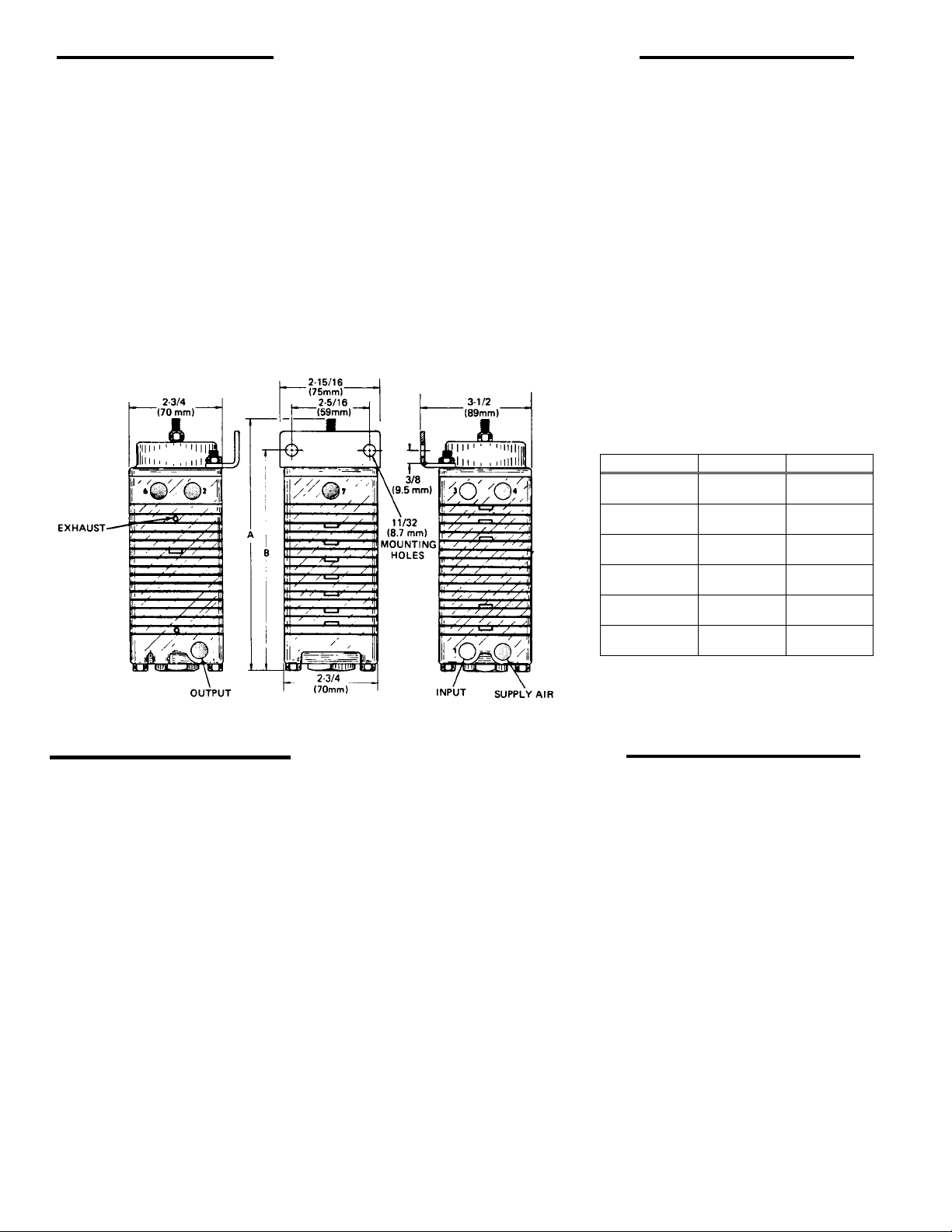

B. MOUNTING:

When installing the relay, do not remove the plastic plugs from

the connections until ready to install fittings. Do not remove

any metal pipe plugs.

The relay may be mounted in any position. Due to its size and

OPERATION:

The illustration (Figure 2) shows a relay for averaging 7 input

pressure signals. The operation of the smaller units is similar.

With zero input pressure at all input ports and the biasing

spring adjusted so that it is not exerting any force in either

direction, the unit is in a balanced position. In this balanced

position, both the supply and exhaust seats of the valve are

closed and there is no air flow. The diaphragm areas are

related in such a manner that the effected force of any input

pressure is downward. Therefore, with the unit in a balanced

position, introduction of any input pressure will create a

downward force which will move the center assembly down,

opening the supply seat of the valve and permitting supply air

pressure to flow into the output chamber. This output pressure

is channeled into all of the balancing chambers. The

diaphragms of the balancing chambers are related so that this

output air pressure creates an upward force. As the output

pressure approaches the average input pressure, the center

weight, it may be supported by the air lines. If more secure

mounting is desired, use the mounting bracket furnished as

shown in Figure 1. Use two 1/4" bolts, toggle bolts or wood

screws as required by the installation. Bracket may be

removed or inverted by removing two lock nuts.

C. CONNECTIONS:

The input, supply and output ports are 1/4" female NPT.

Make the air connections to the proper ports as shown in

Figure 1. The air supply must be clean, dry and regulated

(use filter-regulator #97478) and must not exceed 60 psig (4.2

bar).

assembly will be returned to the balanced position, permitting

the supply seat of the valve to close, throttling the flow of

supply air.

Should any or all of the input pressure decrease, the upward

force of the output pressure would be greater than the

downward force of the input pressures. Then the center

assembly would move upward, opening the exhaust seat and

thereby exhausting the output air until the decreased output

pressure again balances the input pressures.

The spring assembly permits biasing the output pressure to a

maximum of ±18 psig (1.2 bar) divided by the number of

inputs. In the 6 input signal relay, this means that the output

pressure may be biased ±3 psig (0.21 bar). In the 2 input

signal relay, it may be biased ±9 psig (0.62 bar). This is

accomplished by turning the adjusting screw in the top of the

assembly to either extend or compress the spring.

SECTION II - INSTALLATION

SECTION III - OPERATION

Figure 1

NUMBERED PORTS ARE INPUT SIGNAL

CONNECTIONS

DIMENSIONS

MODEL NO. A B

CR103-A2 4-7/8″

(124 mm) 4″

(102 mm)

CR103-A3 5-3/8″

(137 mm) 4-1/2″

(114 mm)

CR103-A4 5-7/8″

(149 mm) 5″

(127 mm)

CR103-A5 6-3/8″

(162 mm) 5-1/2

(140 mm)

CR103-A6 6-7/8″

(175 mm) 6″

(152 mm)

CR103-A7 7-3/8″

(187 mm) 6-1/2″

(165 mm)

SIGNAL PORT 5 IS ON THE FACE OPPOSITE

PORT 7

DIMENSIONS