7

GB

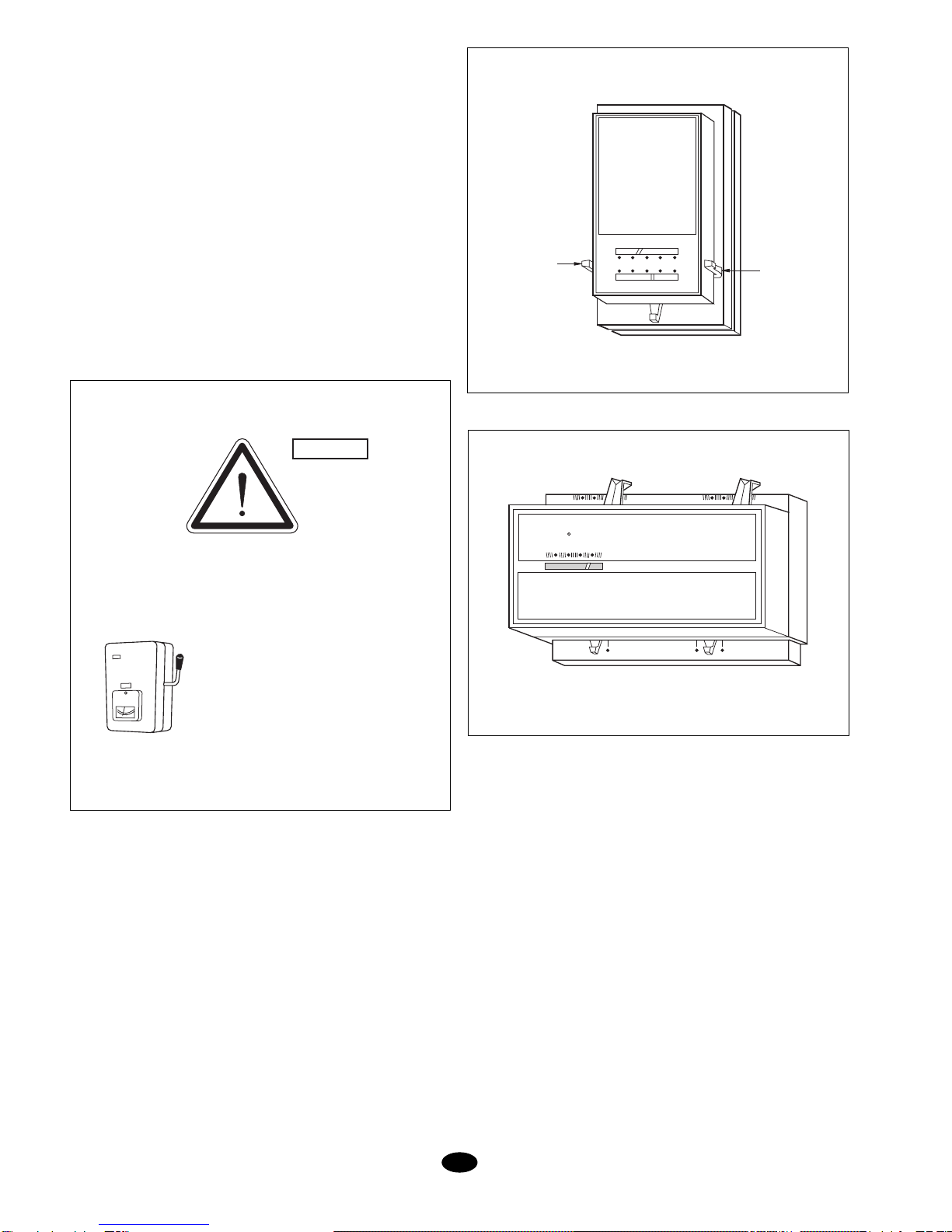

Compact installation of the units

The units are supplied prepared for connection of their

cooling circuits and electrically.

To install the units as a compact system, the outdoor ASAO

unit and the indoor ASAI one have to be joined through the

holesprovidedinthembythescrewsprovided.Thesewillbe

found in a bag inside the electrical box in the ASAO-60 and

in the indoor unit in the ASAI-25, 30 & 45.

The indoor and outdoor units are supplied with the cooling

circuit connections ready for soldering and to be intercon-

nected on the outside of the casing.

The ASAO/I-25 and ASAO/I-30 units have one sole circuit.

The ASAO/I-45 and ASAO/I-60 units has two circuits.

And the refrigerant load should be applied onsite.

Charge process

1 - Depressurise the units.

2 - Drain the refrigerant.

3 - Clean out with dry nitrogen.

4 - Solder the tubing under dry nitrogen inside the tubes.

5 - Forsolderinguselowmelting-pointrodswithaminimum

silver content of 5%.

6 - Fill with 2 kg. R-22 refrigerant to detect leaks.

7 - Drain off the refrigerant.

8 - Clean out with dry nitrogen.

9 - Create a vacuum down to 200 microns.

10- Put in the refrigerant, using scales or a calibrated

cylinder. Charge accuracy should be within 30 grams.

Theoutdoor unitisfittedwithplug-in pointsattheconnection

outlets for verification of pressure and temperature, Super-

heat and Sub-cooling. Check that these values are in the

order of 5°C.

Installation with separated units

Separation between the units

The length of connecting tubing should be kept down to the

minimum possible.

Maximumadmissibledistanceswiththecircuitandstandard

diameter tubes are:

Total length

of tubes

m

Maximum level

difference between units

m

1020

For greater lengths the installation must be made after a

previous project approved by our technical service.

This project may require modification of any of the following

elements:

- Tube dimensions.

- Refrigerant charge.

- Suction traps.

- Suction accumulator.

- Liquid solenoid valve.

In such cases the maximum lengths which can be recom-

mended are:

Cooling interconnections

When forming the tubing to join the two units special care

shouldbe takentokeepthetubes cleananddryevenbefore

installation. The following recommendations should be ob-

served:

1 - Use only copper tubing of refrigerant quality.

2 - Do not carry out outdoor work if it is raining.

3 - The ends of the tubes should be kept closed during the

installation.

4 -The dryer filters and compressor should not be left

exposed to the elements for more than one or two

minutes.

5 - For soldering use low melting-point rods with a minimum

silver content of 5%.

6 -During soldering and for as long as the tube stays hot, a

current of dry nitrogen should be kept up to avoid the

formationofoxideswhichcouldcausecontaminationand

blockage.

7 - For copper-copper unions stripper should not be used.

Units at same level, maximum length

Installation type

50m

Outdoor unit higher than indoor. Maximum

length and level difference. 50

m

Outdoor unit lower than indoor. Maximum

length and level difference. 15

m

PANEL

LOCKSCREW UPPER AND LOWER

UNITS LOCKSCREWS

(TWO ON EACH SIDE)

UPPER UNIT

(INDOOR)

LOWER UNIT

(OUTDOOR)