HYDRAULIC WORKHOLDING ▪ MACHINE VISES ▪ ZERO POINT MOUNTING

QUICK DIE CHANGE ▪ QUICK MOLD CHANGE ▪ MAGNETIC CLAMPING

PRODUCTS FOR ASSEMBLING

CARR LANE ROEMHELD MFG. CO.

7 | H I L M A

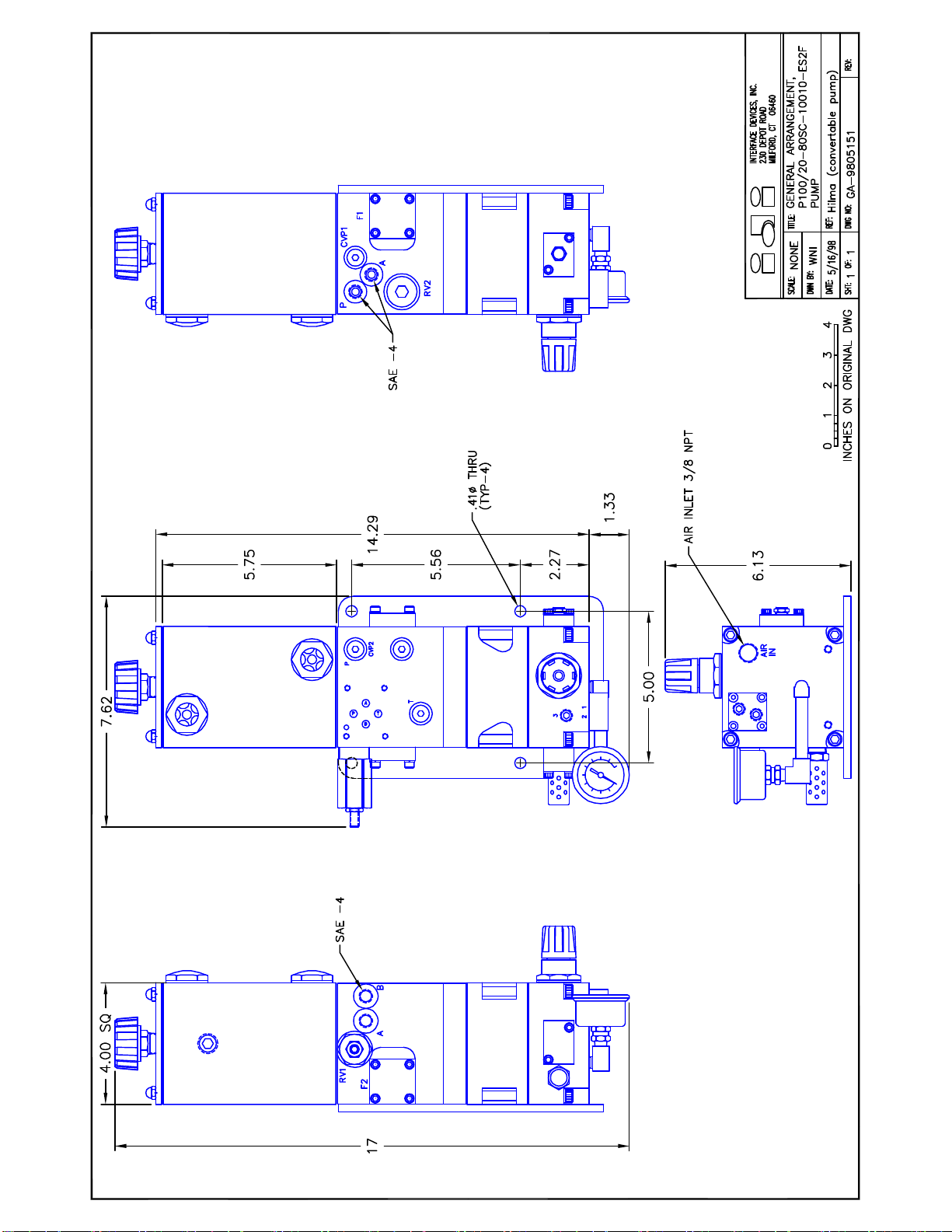

SECTION 4.0: GENERAL ASSEMBLY

This section is provided to a general overview for all the service needs of the HCR-PA-

11X10 line of pumps. An exploded view with Bill of Materials of all parts is included at

the back of this manual.

The general assembly of the HCR-PA-11X10 line of pumps consists of three major sub-

assemblies: AIR CAP, AIR BODY, and HYDRAULIC BODY. It is most efficient if each of

these three components is entirely sub-assembled prior to final assembly.

A. MOUNTING THE RATIO PLATE TO THE HYDRAULIC BODY

Make sure that all components are clean and dry. Spread a thin film of

waterproof grease on the rod, hydraulic piston and bore. Place static seals (O-

rings) in the appropriate counterbores in the Hydraulic Body.

While holding the Ratio Plate sub-assembly by the air-end piston, align the

actuator to its counterbore and gently rock the hydraulic piston into the bore.

Slide the Ratio plate down the shaft until contact is made with the Body. Next,

install the four mounting bolts (1/4-20 x 1”) and lock-washers into the center

pattern and snug to just compress the lockwashers. If there are two more bolt

holes along the bottom edge, install these bolts now, without lock-washers, and

snug.

Lastly, tighten all bolts in small increments using a cross-type pattern to a final

torque of approx. 15 ft/lb.

B. MOUNTING THE AIR BODY TO THE RATIO PLATE

Slip one air body gasket over the air piston and align to the edges with the

hydraulic body. Apply a thin film of waterproof grease to the bore of the Air Body

and lay atop the piston with chamfered bore edge down. Holding the Air Body

and piston with both hands, “squeeze” the body over the air piston seal and

wiggle down until contact is made with the body gasket.

Make sure that the serialized face of the Air Body is facing up. On later models,

body pins assure proper alignment. At this point, tie down the Air Body through

the Ratio Plate to the Hydraulic Body with the four mounting bolts (5/16-18 x 1

¾'') and lock washers. Snug the bolts until the lock-washers are compressed,

NOT torqued.