ROJEK a.s.

8

PF 300L_PF 350_PF 400S

Sliding table

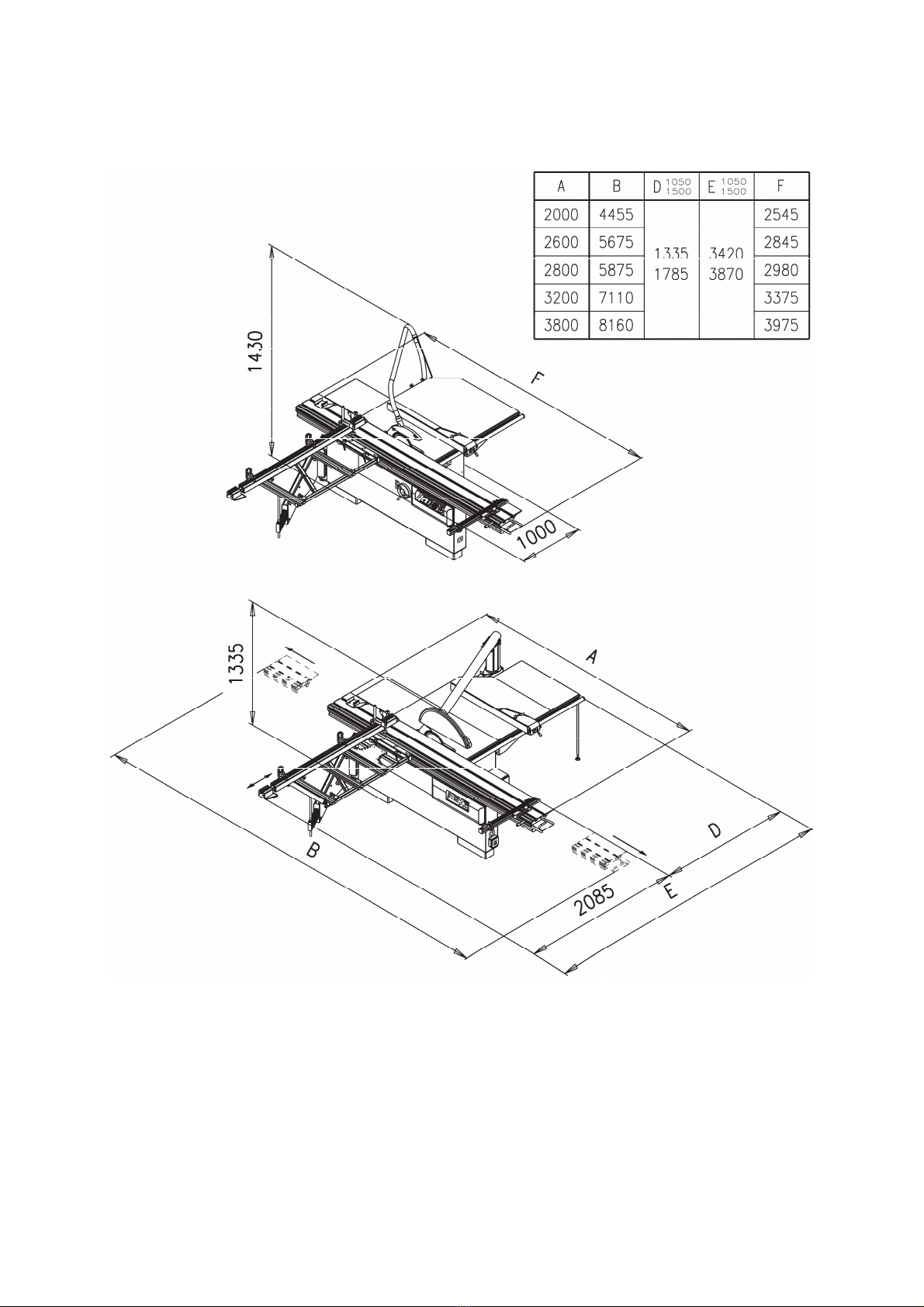

Table dimensions mm 2000 (2600 | 2800 | 3200 | 3800) x 360

Supporting frame dimensions mm 1 290 x 650

Length of sawing cut mm 2000 (2600 | 2800 | 3200 | 3800)

Other parameters

Voltage / frequency V / Hz 3f + PE + N ; 400 (230) V/ 50(60) Hz

Electric lead safeguarding A 16 (25).

3.1 Possible machine variants

electric motor power - 3 | 4 | 5,5 | 7,5 or 5,5/ 4 ( 2-speeds motor) kW

saw blade revolutions - 4 450 | 3 500/ 5 000 ( 2 speeds motor)

saw blade spindle diameter - 30 mm | 1“ | 5/8“ (“~ inch)

scorer spindle diameter - 20 mm | 3/4“

saw blades tilting - by hand wheel | by an electric motor

tilting indication - on indicator in hand wheel | on electronic display

offcut height setting - by hand wheel | by electric motor

sawing height indication - without indication | on electronic display

max. width of sawing - 1050 | 1500 mm

sliding table length - 2000 | 2600 | 2800 | 3200 | 3800 mm

operation voltage - 3 x 400 V | 3 x 230 V

frequency of mains - 50 | 60 Hz

control pannel - lower | upper.

3.2 data of machine operation nois value (EN 1870-1: 2013)

PF 300L PF 350 PF 400S

idle run Lpf = 81,8 dB Lpf = 81,8 dB Lpf = 81,8 dB

Value of acoustic pressure L

pf

sawing Lpf = 85,3 dB Lpf = 85,3 dB Lpf = 85,3 dB

idle run L

WA

= 98,6 dB L

WA

= 98,6 dB L

WA

= 98,6 dB

value of acoustic power L

WA

ISO 3744 K

2A

= 0 dB

sawing L

WA

= 102,1 dB L

WA

= 102,1dB L

WA

= 102,1dB

Above stated values are those of emissions and need not represent the safe working

values. Although there exists a correlation between emissions values and levels of exposition, these

values cannot be used for a reliable statement whether other precautions are necessary or not. Agents,

influencing a real exposure of workers, include other working space attributes, other sources of nois,

etc., e.g. the number of machines and other from neigh-bourhood influencing processes. The most

permissible exposition levels can differ accord-ing to country in question, too. This information will

serve for machine user to a better astimation of risks.