Tigris 850 en English

4

1. Symbols .........................................................................4

2. Safety Instructions ....................................................4

3. Intended Use ................................................................4

4. Technical Specifications .......................................... 5

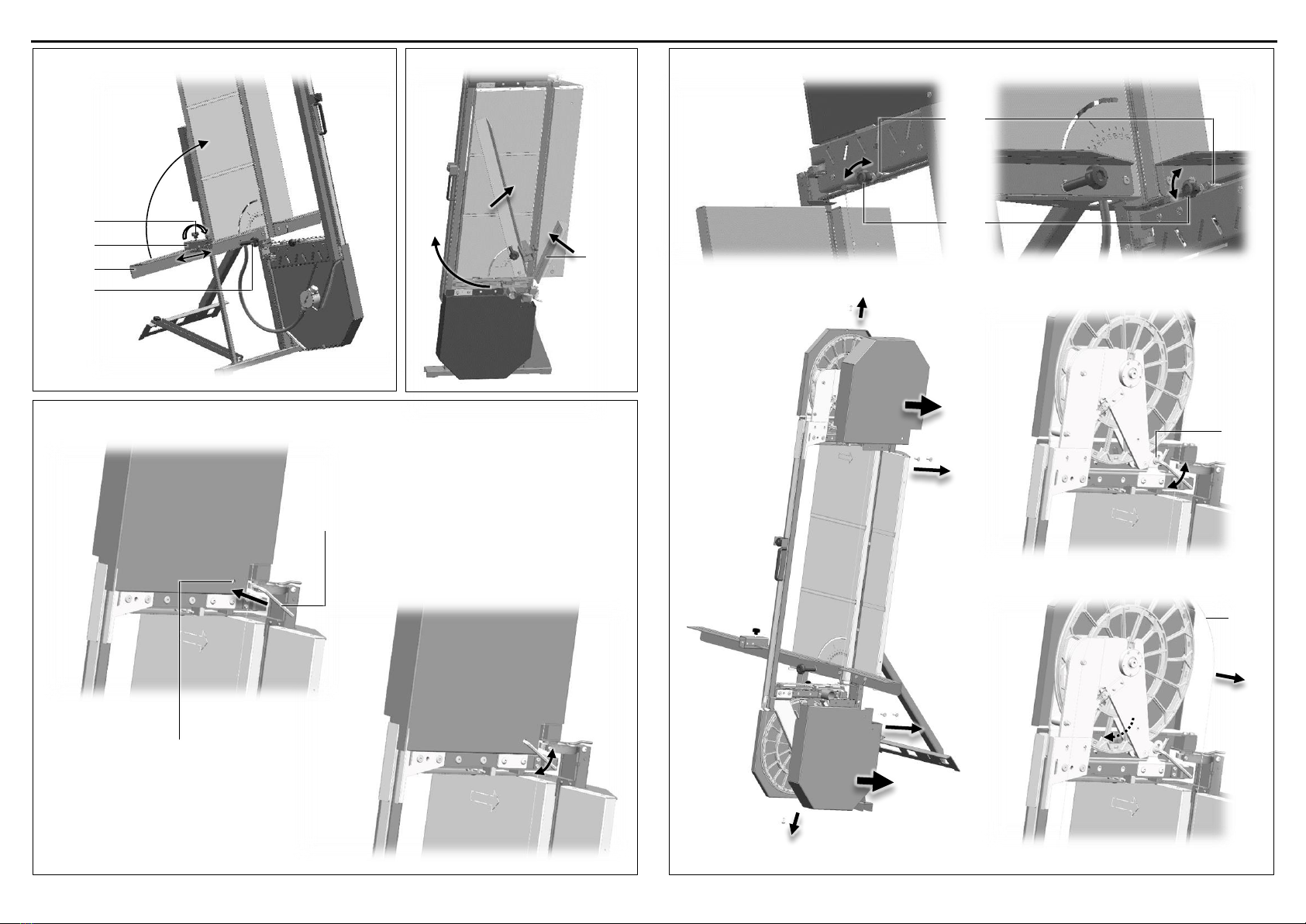

5. Device Components................................................... 5

6. Commissioning............................................................ 5

7. Instructions for Use................................................... 5

8. Maintenance and Care.............................................. 6

9. Spare Parts and Accessories.................................. 6

10. Environmental Protection....................................... 6

11. Declaration of Conformity....................................... 6

12. Troubleshooting ......................................................... 6

For your own protection and for the protec-

tion of your power tool, pay attention to all

parts of the text that are marked with this

symbol!

Risk of electric shock!

Warning of hand injuries! *)

Read operating instructions and safety no-

tices! *)

Wear protective goggles!

Wear ear protection!

Wear hand protection!

Wear a dust mask! *)

CAS Li-Ion battery pack

Removing battery pack!

Do not dispose of as domestic waste! *)

Important advice/information

Direct Current (DC) *)

Confirms the conformity of the power tool

with the directives of the European Com-

munity. *)

Confirms the conformity of the power tool

with UK legislation. *)

*)These symbols are (also) on the device.

For your safety

Read all safety warnings and instructions.

Failure to follow all safety warnings and in-

structions may result in electric shock, fire

and/or serious injury.

Do not use this power tool before you have

thoroughly read and completely understood

this Instruction Manual, the enclosed “Gen-

eral Safety Instructions”, instructions for bat-

tery packs and chargers.

Keep all safety instructions and information for

future reference. Pass on your power tool only to-

gether with these documents.

Please also observe the relevant national indus-

trial safety regulations.

Safety instructions for wire saws

Do not reach into the area of the saw wire when the

tool is switched on.

Only make the saw cuts using the handle provided

for this purpose and at the same time secure the

workpiece (insulation material) by hand.

Only use suitable materials.

If the impeller tensioner is already at the end stop,

the impellers must be switched.

If the cutting speed decreases, the saw wire should

be replaced.

A damaged or worn saw wire must not be used.

If the saw wire jams in the workpiece (insulation

material), switch off the motor immediately. Before

switching on again, the saw wire must be able to

rotate freely again.

Before operating the wire saw, check that it is sta-

ble and that all machine parts are assembled cor-

rectly, especially all protective devices. Also check

that the saw wire and impellers are in good condi-

tion and that the saw wire is sufficiently tensioned.

Additional safety instructions

Particles generated when working with this ma-

chine may contain substances that can cause can-

cer, allergic reactions, respiratory diseases, birth

defects or other propagation defects. Some of

these substances include: mineral dust (from min-

eral wool, aerated concrete or similar), styrene, etc.

The risk depends on for how long the user or near-

by persons are exposed to the substance.

This dust must not be allowed to enter your body.

Do the following to reduce exposure to these sub-

stances:

- Ensure good ventilation of the workplace

- To protect your health, wear a suitable

protective mask.

- Always wear protective goggles to protect

against sanding hazards.

- Connect the electric power tool to a suitable ex-

traction system.

- Sweeping or blowing stirs up dust.

- Vacuum or wash the protective clothing. Do not

blow, beat or brush.

Collect the generated particles at the source, avoid

deposits in the surrounding area.

Always use an antistatic suction hose with the

power tool. A slight electric shock may cause you to

panic briefly and become distracted, which may re-

sult in an accident.

switch off the machine immediately when the

safety clutch responds and if the saw wire breaks!

Do not overload the motor for a long period. Engine

noise should be regular (not wave-like). Unsteady

engine performance can be perceived acoustically.

Take a break when the machine is heated up

strongly and let it cool down again. To that let the

motor idle at top speed for some time.

Don’t bend the flexible drive shaft!

Only use original Rokamat saw wire. Foreign mate-

rials are not suitable for the saw wire speed and

applications of the wire saw and could tear.

Emission levels

NOTE! Values for the A-weighted sound pressure

level and for the total vibration values can be found

in the “Technical specifications” table at page 5.

The vibration emission level given in this infor-

mation sheet has been measured in accordance

with a standardized test and may be used to com-

pare one tool with another. It may be used for a

preliminary assessment of exposure.

CAUTION! The indicated measurements refer to

new power tools. Daily use causes the noise and vi-

bration values to change.

The declared vibration emission level represents

the main applications of the tool. However, if the

tool is used for different applications, with differ-

ent accessories or poorly maintained, the vibration

emission may differ. This may significantly in-

crease the exposure level over the total working

period. However, if the tool is used for different ap-

plications, with different accessories or poorly

maintained, the vibration emission may differ. This

may significantly decrease the exposure level over

the total working period.

CAUTION! The noise produced during work

may damage your hearing.

Wear ear protection!

Environmental conditions

Operation

Temperature range: +5° C to +50° C

Humidity: ≤ 85 %, non-condensing

Climate: dry

Transport and storage

Temperature range: -5° C to +55° C

Humidity: 0 % to 70 %

Climate: dry, roofed, dew protected

The portable Rokamat Tigris 850 cordless wire

saw is intended exclusively for cutting insulation

materials and plasterboard at angles of 30°-90°.

Insulation materials up to a max. thickness (cutting

depth) of 320 mm, a max. width (cutting length) of

1200 mm and a max. density of 650 kg/m³ can be

cut using only the Rokamat special saw wire. and

may only be operated with an external dust extrac-

tion device.

The transportable wire saw must be set up on a

level and solid surface and may only be operated

with an external dust extraction device.

Only sufficiently qualified and trained personnel

may carry out activities with the Tigris.

The intended use includes the observance of the

operating instructions, in particular the safety in-

structions and the observance of generally recog-

nized accident prevention regulations.

The manufacturer is not liable for damage caused

by non-intended use of the tool.