TAPMATE™XL 424 OPERATING MANUAL

2

TABLE OF CONTENTS

Specication .......................................................................................................... 3

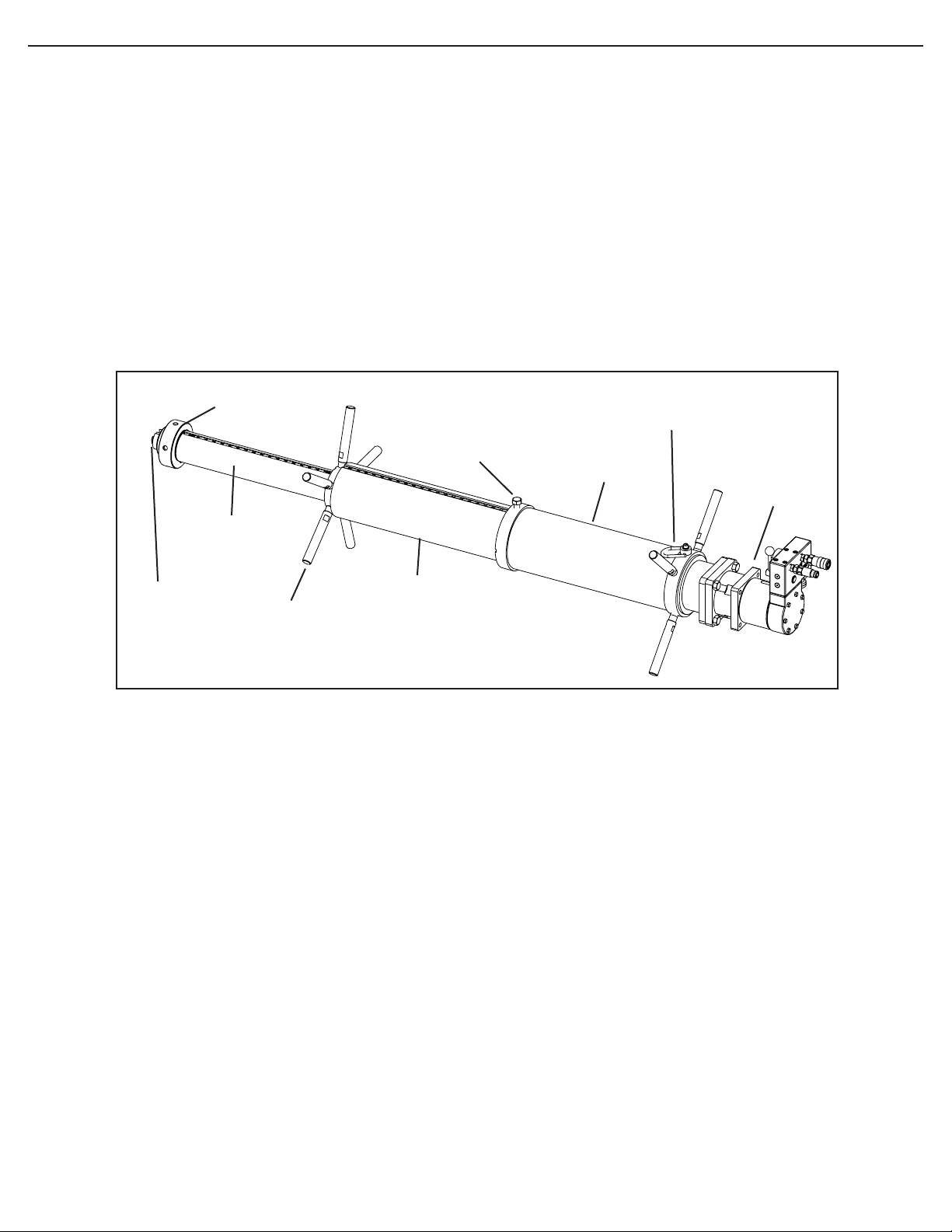

Machine Overview ................................................................................................. 4

ASSEMBLY

Open the Shipping Crate ...................................................................................... 5

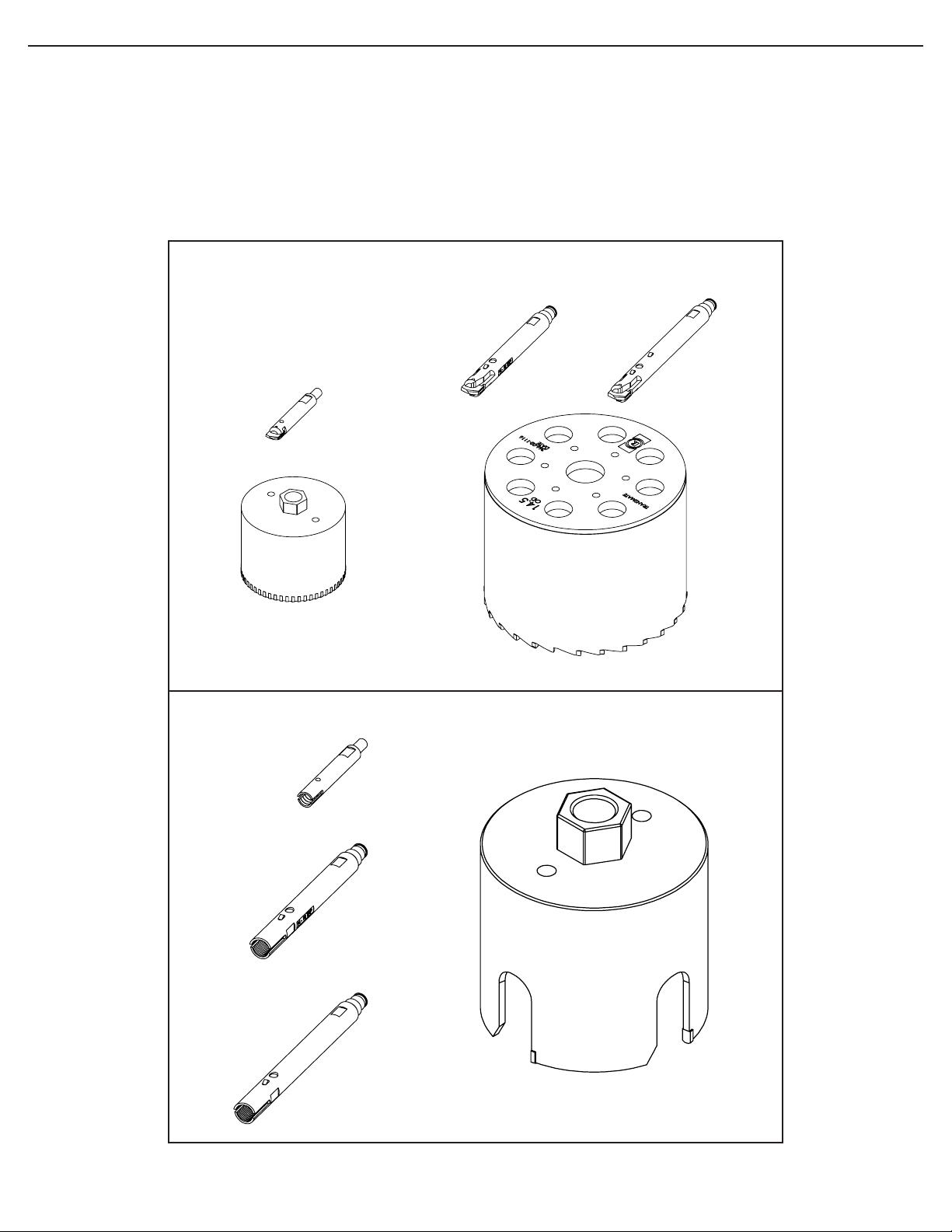

CutterandPilotIdentication................................................................................ 6

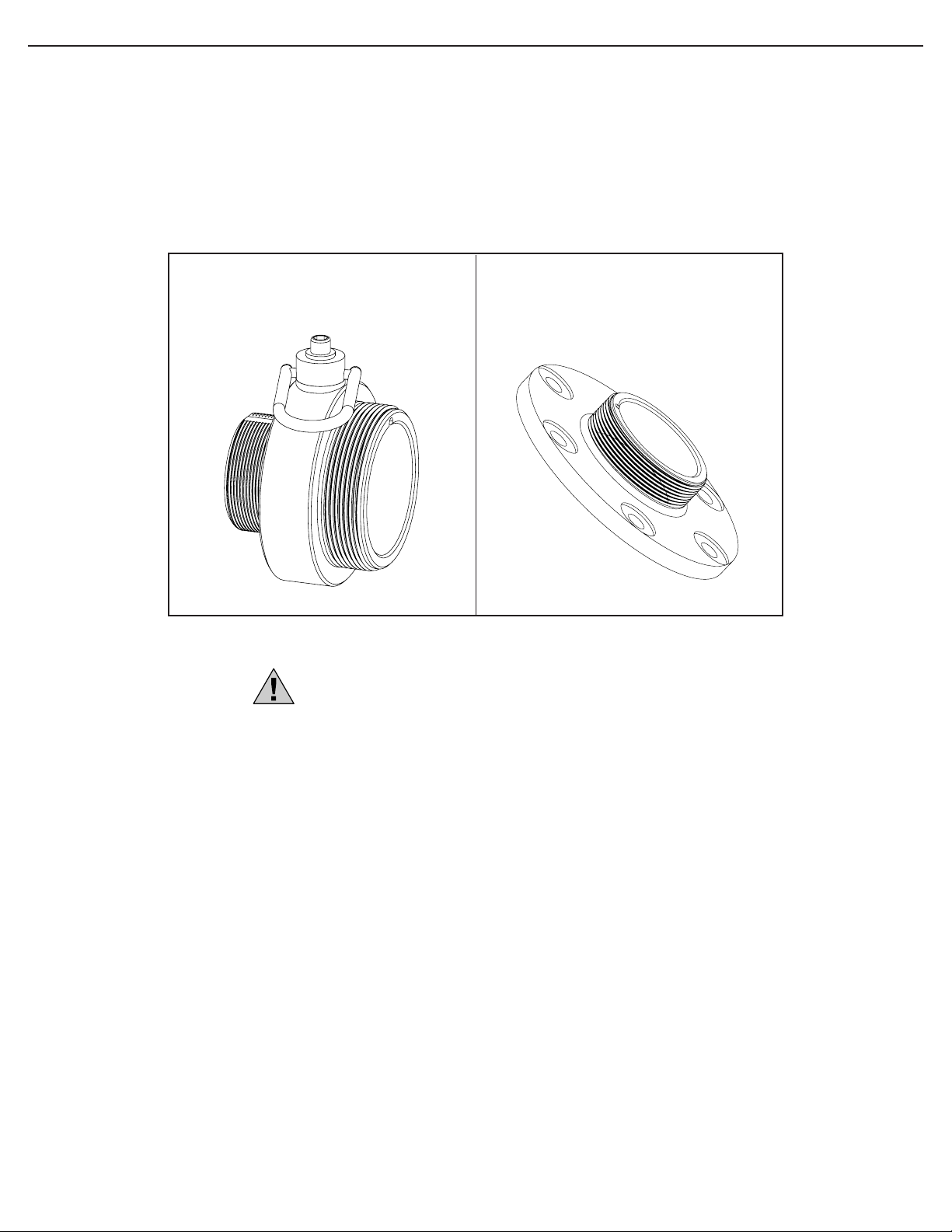

About Adapter Hub Sizes ...................................................................................... 7

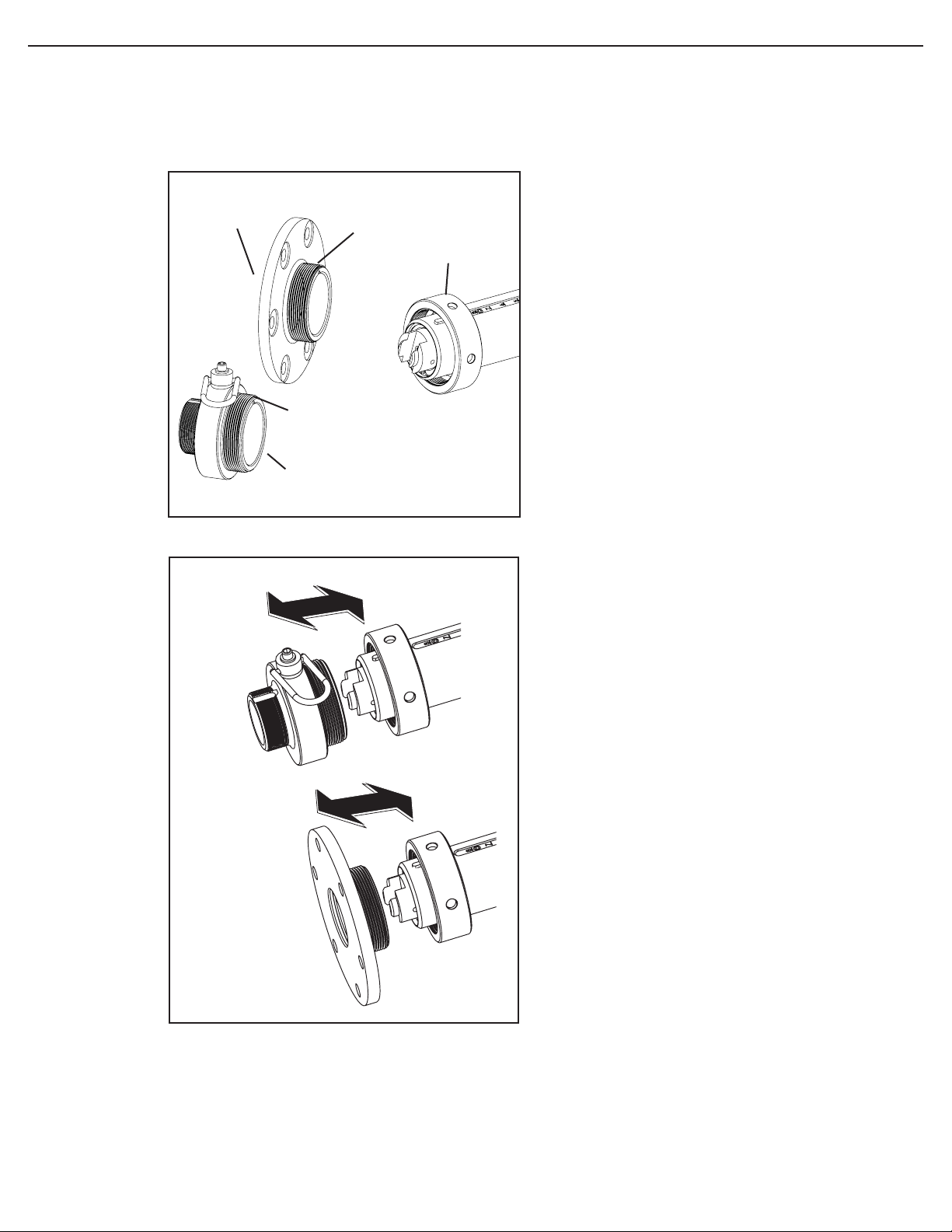

Adapter Hub Installation and Removal.................................................................. 8

TapMate XL‑424 Set‑Up for 4"‑12" Taps ............................................................. 10

TapMate XL‑424 Set‑Up for 14"‑24" Taps ........................................................... 14

Attaching the TapMate XL‑424 to the Valve ........................................................ 18

OPERATION

Performing the Tap .............................................................................................. 21

Disassembly and Removal of the Coupon........................................................... 26

Care and Maintenance......................................................................................... 27

PARTS IDENTIFICATION DRAWINGS

TapMate XL‑424 (included items) ........................................................................ 28

TapMate XL‑424 (base machine).......................................................................... 29

Adapter Bells (4" ‑ 12")........................................................................................ 30

Adapter Bells (14" ‑ 24")...................................................................................... 31

Adapter Hubs ...................................................................................................... 31

Small Shaft Head Assembly ................................................................................. 32

Large Shaft Head Assembly................................................................................. 32

Jam Nut ............................................................................................................... 32

TM‑XL, PVC Pilot.................................................................................................. 33

TM, PVC Pilot....................................................................................................... 33

TM‑XL, Shaft Nose............................................................................................... 34

TM, Shaft Nose .................................................................................................... 34

Hydraulic Motor Assembly................................................................................... 35

Shipping Crate / Workstation .............................................................................. 35