PAGE 10

TESTING AND REASSEMBLY

TESTING

1. RECONNECT NEGATIVE BATTERY CABLE AND TORQUE TO 3 FT*LBS. RE-ENTER

ANY THEFT DETERRENT INFORMATION, IF APPLICABLE.

2. TURN THE IGNITION SWITCH ON. PRESS THE MENU BUTTON TO SWITCH FROM

VIDEO 1 TO VIDEO2. VERIFY THAT THE REARSIGHT MONITOR IS ON AND THE

CAMERA’S PICTURE APPEARS. PRESS THE POWER BUTTON. PUT THE VEHICLE

IN REVERSE. VERIFY THAT THE CAMERA’S PICTURE APPEARS.

3. IF THERE IS NO PICTURE, VERIFY ALL CONNECTIONS ARE SECURE.

REASSEMBLY

1. REINSTALL ALL TRIM PIECES TAKING SPECIAL CARE TO ENSURE HARNESSES

AND WIRING CONNECTIONS ARE PROPERLY SECURED.

2. BE SURE HARNESS IS NOT PINCHED OR BOUND BY TRIM PIECES.

3. PLACE THE OWNER’S CARD IN THE GLOVE BOX.

4. RECONNECT ALL DISCONNECTED BULBS AND CHECK FOR FUNCTION.

INSTALLATION TIPS

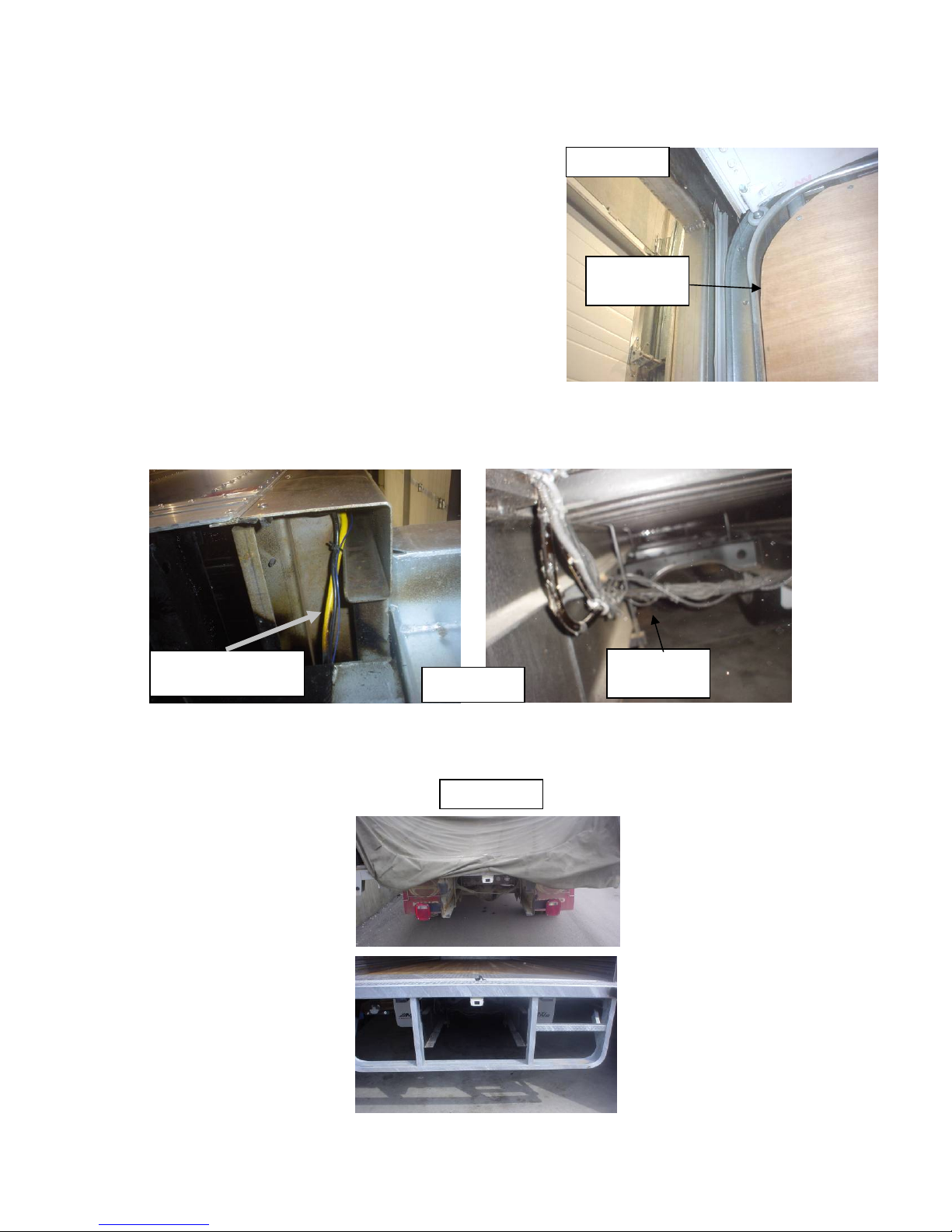

CONFIRM PROPER CABLE EXTENTION CONNECTOR ORIENTATION AND

ALWAYS VERIFY PROPER ENDS ARE ROUTED IN PROPER DIRECTION.

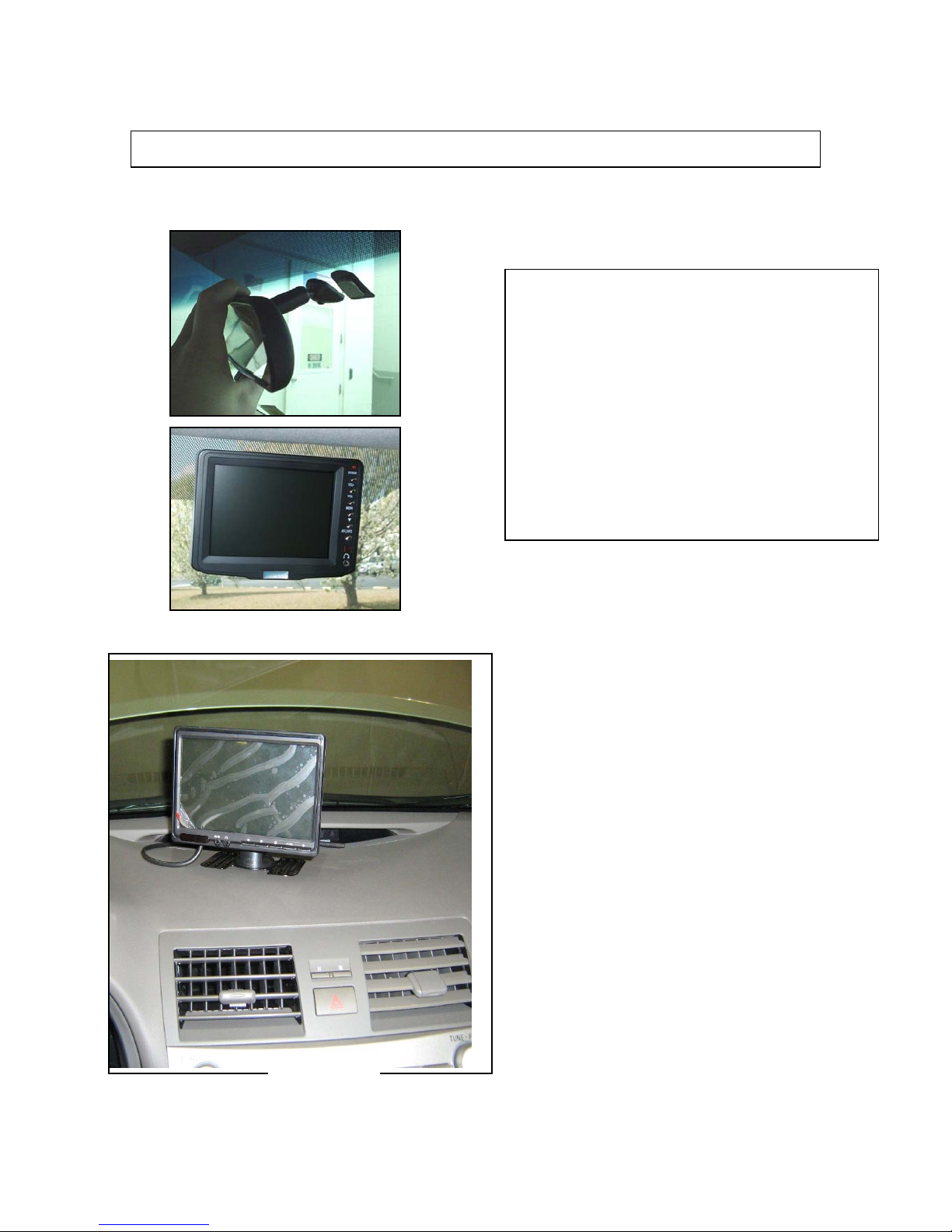

IT IS A GOOD IDEA TO DRY FIT THE KIT BEFORE PERMANENTLY ATTACHING

THE UNIT TO INSURE PROPER ORIENTATION AND OPERATION BEFORE

BEGINNING INSTALLATION FOR FAMILIARIZATION OF COMPONENTS.

READ ALL INSTRUCTIONS AND WARNINGS BEFORE BEGINNING THE

INSTALLATION OF THIS KIT.

ALWAYS TREAT ANY METAL EXPOSED DURING INSTALLATION WITH RUST

PREVENTATIVE COMPOUND TO PREVENT RUST AND OR CORROSION

FAILURE.

ALWAYS SEAL ANY HOLES DRILLED WITH PROVIDED SEALING PUTTY TO

PREVENT WATER INFILTRATION INTO UNPROTECTED OR AREAS OF

CONCERN.

CONFIRM INTEGRITY OF MECHANICAL AND ELECTRICAL CONNECTIONS

BEFORE MOVING TO NEXT INSTALLATION SEQUENCE.