10 PRECISION TOOLS

GB I english

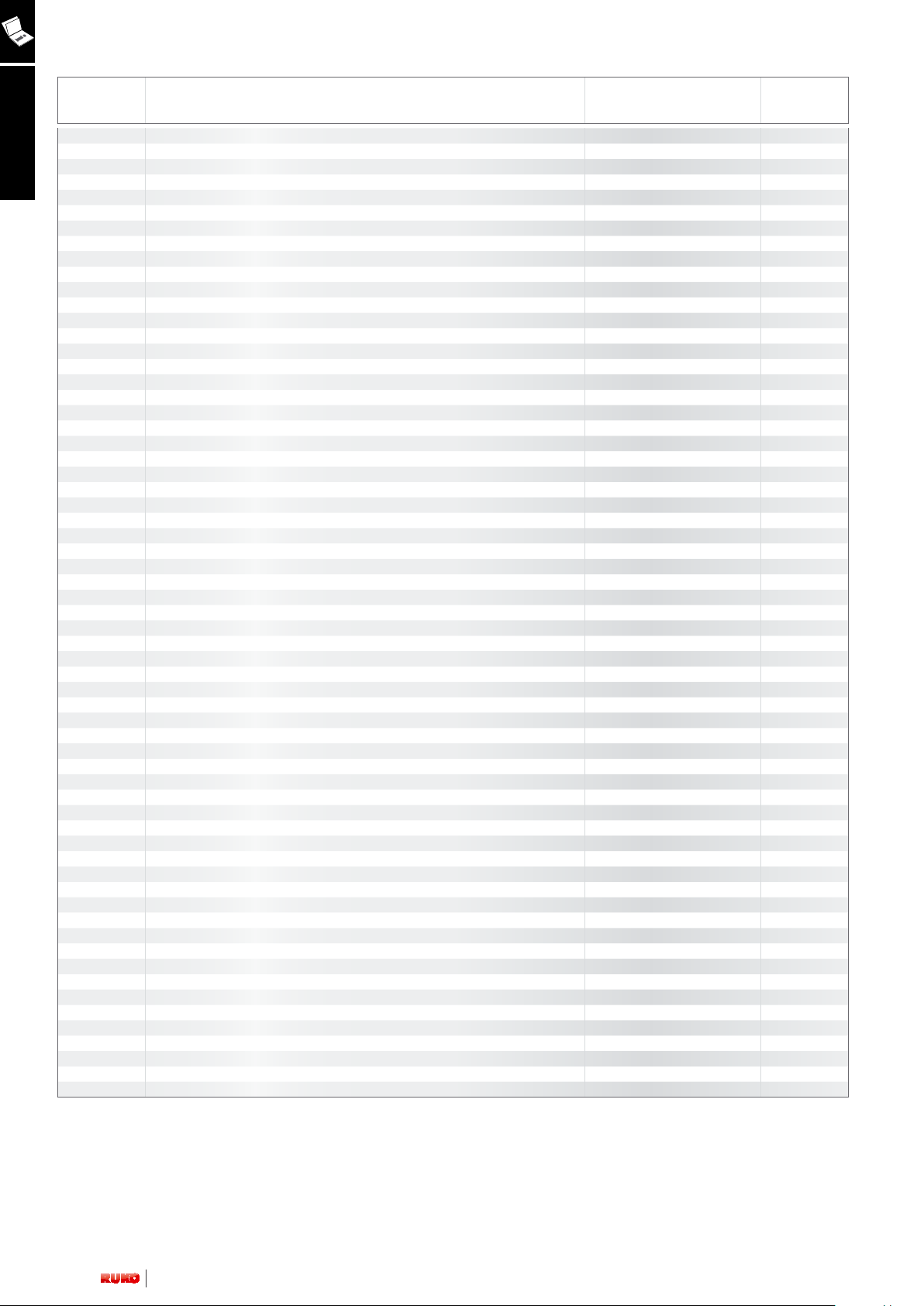

Spare parts list

Pos. Description Article no. Quantity

1 Connecting cable 2 x 1 mm² 6115001 1

2 Filler piece 6115002 1

3 Suppression capacitor 6115003 1

4 Handle halves, mach. 6115004 1

5 Cable version sleeve 6115005 1

6 Built-in switch 6115006 1

7 Tapping screw HC 4.2 x 22 6115007 3

8 Strain relief clamp 6115008 1

9 Tapping screw HC 4.2 x 13 6115009 2

10 Tapping screw HC 4.8 x 45 6115010 8

11 Gearbox seal 6115011 1

12 Grooved ball bearing 608 2Z 6115012 1

13 O-ring 22 x 2.5 6115013 1

14 Pocket brush holder, cpl. 6111528 2

15 Carbon brush, complete 6.3 x 10 x 18 L85F13 7112503 2

16 Cold-forming tapping screw ZM4 x 12 6115014 4

17 Corrugated spring washer B4 6115015 4

18 Motor housing 6115016 1

19 Tapping screw C 3.9 x 70 6115017 2

20 Air guide ring 6115018 1

21 Circlip 28/1.2 6111524 1

22 Grooved ball bearing 6001 2RS 7112017 1

23 Sealing ring 6115019 1

24 Spindle wheel 6115020 1

25 Adjusting washer 15/22 x 0.2 6115021 1

26 Grooved ball bearing 6003 2RS 6115022 1

27 Gear housing 6115023 1

28 Grooved ball bearing 6203 2RS 6115024 1

29 Work spindle 6115025 1

30 Axial bearing AX 513 6115026 1

31 Coupling shaft 6115027 1

32 Needle sleeve HK 1210 6115028 1

34 Disc spring 28/12.2 x 1.25 6115029 6

35 Brass disc 6115030 1

36 Driving plate 6115031 1

37 Grooved dowel pin 4 x 12 6113215 1

38 Coupling wheel 6115032 1

39 Cylinder bearing Getro type 1210 T 6115033 1

40 Disc spring 25/12.2 x 0.9 6115034 1

41 Hexagon nut BM10 x 1 6115035 1

42 Coupling, cpl. 6115036 1

43 Needle sleeve HK 0810 6111521 1

44 Gear bearing plate 6115037 1

45 Runners, cpl. 6115038 1

46 Pole ring, cpl. 6115039 1

47 Connecting strand 1 6115040 1

48 Connecting strand 2 6115041 1

49 Switching strand 6115042 2

50 Changeover switch 6115043 1

51 Disc 10 x 4.8 x 1,7 6115044 4

52 O-ring 4.9 x 1.9 6115045 4

53 Support handle, complete 6115046 1