5

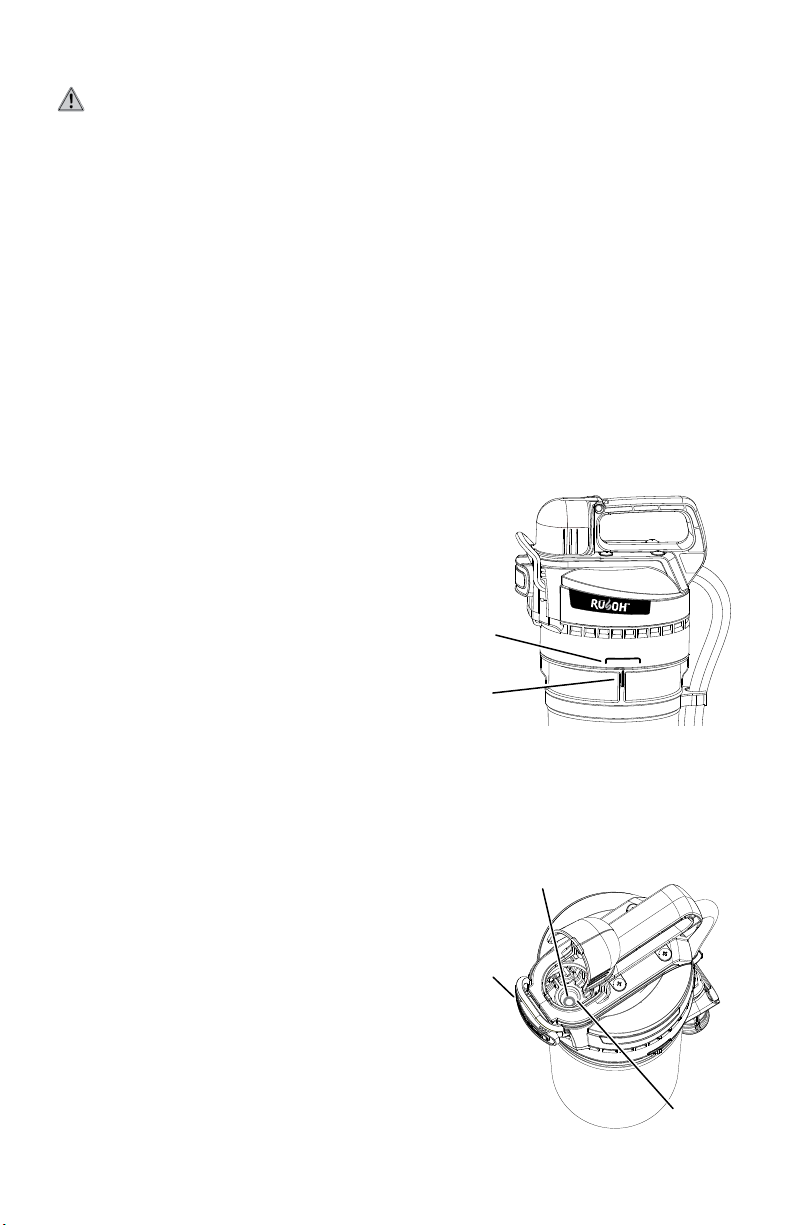

Two smaller

O-rings

Mixing tube

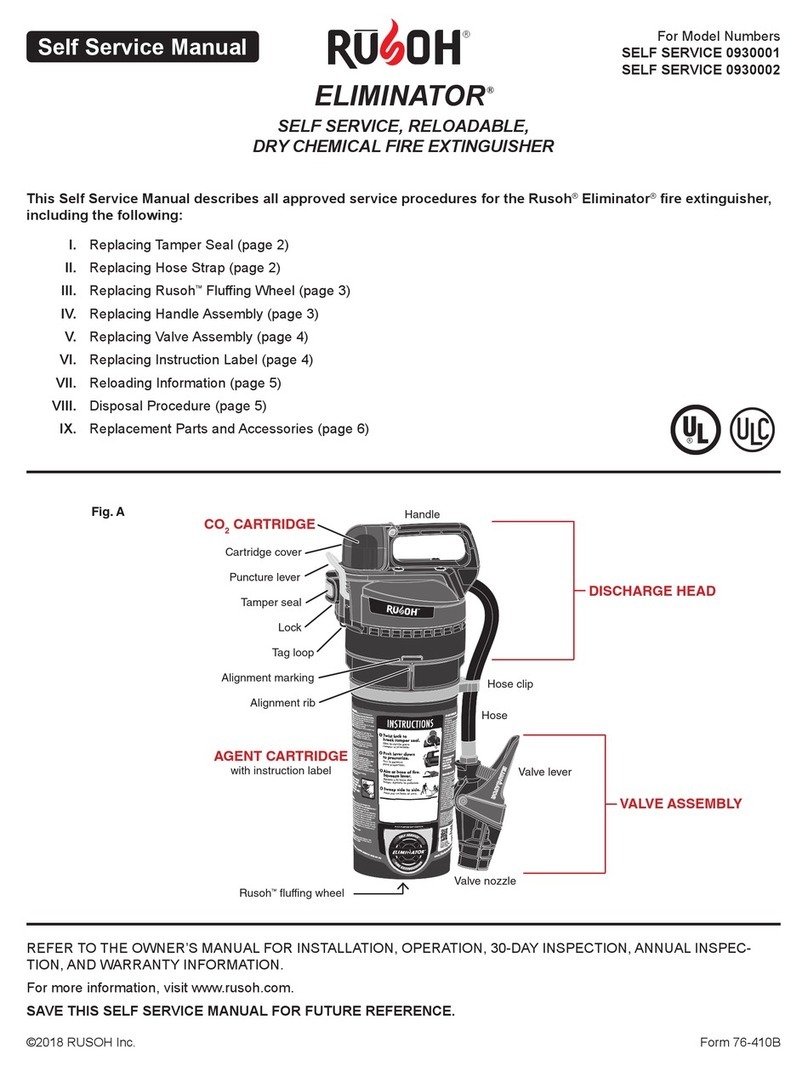

Fig. H

Handle

recess

Fig. I

Reload

kit cap

Replacement

agent cartridge

Replacement

agent cartridge

Outer

threads

Large

O-ring

Mixing tube

cover

Black band

STEP 8

Remove reload kit cap from replacement agent cartridge.

Use the Eliminator™wrenchset(soldseparately)toloosenthereloadkitcap,

perthemethoddescribedbelow.

IMPORTANT:Alwayskeeptheagent

cartridgeonalevelsurfacetoprevent

extinguishingagentfromspilling.

1. Placethecartridgewrenchwiththe

texturedfootrestfacingup.Setthe

bottomofthereplacementagent

cartridgeontothecircularportionof

thewrench.

2. Insertthebarwrenchinthehandle

recessonthereloadkitcap(Fig.H).

3. Graspbothendsofthebarwrench

and place one foot on the footrest.

Turnthebarwrenchcounterclockwise

untilthecapbeginstoloosen.Once

itturnseasily,thebarwrenchisno

longernecessary.Continueturning

thecap,byhand,untilitiscompletely

detachedfromtheagentcartridge.

Discardthecapinaplasticrecycling

receptacle.

4.Oncethereloadkitcapisremoved,

useasmallbrushandcleanoffany

drychemicalonthegraymixingtube

cover(Fig.I).Thencuttheblackband

onthebottomofthecover.Slowly

removethegraycoveranddiscard.

5.VerifythetwosmallerredO-rings

onthemixingtubeandthelargered

O-ringontheouterthreadsonthereplacementagentcartridge(Fig.I)are

clean,welllubricated,andfreeofdrychemical.

6. IftheO-ringshaveanydrychemicalonthem,removeeachoftheO-rings

andwipethemoffwithadrycloth.OncetheO-ringsareremoved,clean

theO-ringgroovesontheagentcartridgeandmixingtubewithadrycloth

orsmallbrush.

7. Ifneeded,relubricatetheO-ringsandO-ringgrooveswithagenerous

amountofpetroleumjelly.ReinstalltheO-ringsintheirgroovesonthe

agentcartridge.IMPORTANT: Toensureaworkingreextinguisher,the

O-ringsmustbeproperlyseatedintheirgrooves.Wipeawayexcess

lubricationontheagentcartridgeandmixingtube.