2

CONTENTS

Contents

1.0 IMPORTANT SAFETY INFORMATION ............................................................3

2.0 GENERAL INFORMATION ...............................................................................4

2.1 Introduction ....................................................................................................4

2.2 Importance of Quality Installation .................................................................4

2.3 System Sizing and Selection.........................................................................4

2.4 Importance of Proper Indoor/Outdoor Match-Ups........................................5

2.5 Checking Product Received ..........................................................................5

2.6 Efficiency Testing Notice ...............................................................................5

2.7 Compressor Break-In Notice .......................................................................5

3.0 UNIT SPECIFICATIONS ....................................................................................6

3.1 Model Number Nomenclature........................................................................6

3.2 Available Models............................................................................................6

3.3 Electrical and Physical Data..........................................................................6

4.0 INSTALLATION..................................................................................................8

4.1.1 Tools Required for Installing and Servicing R-410A Models.................8

4.1.2 Specications of R-410A .......................................................................8

4.1.3 Quick-Reference Guide for R-410A ......................................................8

4.1 Tools and Refrigerant.....................................................................................8

4.2.1 Allowable Clearances............................................................................9

4.2.2 Operational Issues Related to Unit Location........................................9

4.2 Choosing a Location......................................................................................9

4.2.3 Corrosive Environment........................................................................10

4.2.4 Customer Satisfaction Issues .............................................................10

4.3.1 Unit Mounting Methods .......................................................................10

4.3.2 High Wind and Seismic Tie-Down Methods.......................................10

4.2 Choosing a Location (cont.).........................................................................10

4.3 Mounting Unit...............................................................................................10

4.3.3 Elevating Unit ......................................................................................11

4.4.1 Replacing Existing Systems................................................................12

4.4.2 Line Set Length and Fitting Losses ....................................................12

4.4.3 Liquid Line Selection...........................................................................12

4.4 Refrigerant Line Set Selection.....................................................................12

4.4.4 Suction Line Selection.........................................................................14

4.4.5 Long Line Set Considerations.............................................................14

4.4.5.1 Determining if Long Line Set Length Requirements Apply ..........14

4.4.5.2 Oil Return to Compressor.............................................................14

4.4.5.3 Refrigerant Migration During Off Cycle........................................14

4.4.5.4 Maximum Liquid Pressure Drop ...................................................15

4.4.5.5 Liquid Line Refrigerant Flashing...................................................15

4.4.5.6 Oil Level Adjustment for Long Line Set Applications ...................15

4.4.5.7 Capacity Losses............................................................................15

4.5 Line Set Installation .....................................................................................15

4.5.1 Important Tubing Installation Practices...............................................15

4.5.2 Relative Location of Indoor and Outdoor Units ..................................16

4.5.2.1 Indoor and Outdoor Unit Near Same Level......................................16

4.5 Line Set Installation (cont.) ..........................................................................16

4.5.2.2 Outdoor Unit Below Indoor Unit.......................................................17

4.5 Line Set Installation (cont.) ..........................................................................17

4.5.2.3 Outdoor Unit Above Indoor Unit ...................................................18

4.5 Line Set Installation (cont.) ..........................................................................18

4.5.3 Tubing Connections ............................................................................19

4.5 Line Set Installation (cont.) ..........................................................................19

4.6 Initial Leak Testing ......................................................................................20

4.7 Evacuation ...................................................................................................20

4.8 Final Leak Testing........................................................................................20

4.9 Control Wiring ..............................................................................................21

4.10 Typical Control Wiring Connections...........................................................21

4.11 Power Wiring ..............................................................................................22

4.12 Grounding...................................................................................................22

4.10 Typical Control Wiring Connections (cont.) ...............................................22

5.0 SYSTEM START-UP & REFRIGERANT CHARGING....................................23

5.1 System Start-Up Overview ..........................................................................23

5.2 Initial System Power-Up ..............................................................................23

5.4 Refrigerant Charging ...................................................................................24

5.4.1 Measurement Device Set-Up..............................................................24

5.4.2 Preliminary Charging by Weight .........................................................24

5.4.3 Preliminary Charging by Pressures ....................................................25

5.4.4 Final Charging by Liquid Subcooling ..................................................25

5.4.5 R-410A Temperature Pressure Chart .................................................26

5.5 Completing Installation................................................................................26

6.0 SEQUENCE OF OPERATION.........................................................................26

7.0 COMPONENTS & CONTROLS .......................................................................27

7.1 Compressor ..................................................................................................27

7.2 Fan Motor .....................................................................................................27

7.3 Outdoor Fan .................................................................................................27

7.4 Compressor Contractor................................................................................27

7.5 Compressor/Fan Motor Capacitor ...............................................................27

7.6 Compressor Crankcase Heat (CCH) ...........................................................27

7.7 High- and Low-Pressure Controls (HPC and LPC) .....................................27

7.8 Compressor Hard Start Components..........................................................27

8.0 ACCESSORIES................................................................................................28

8.1 Compressor Time Delay ..............................................................................28

8.2 High Pressure Control .................................................................................28

8.3 Low Pressure Control ..................................................................................28

8.4 Low Ambient Control ...................................................................................28

8.5 Compressor Hard Start Kit ..........................................................................28

8.6 Compressor Crankcase Heater...................................................................28

8.7 Compressor Sound Enclosure.....................................................................28

9.0 DIAGNOSTICS & TROUBLESHOOTING.......................................................29

9.1 Cooling Mechanical Checks Flowchart .......................................................29

9.0 DIAGNOSTICS & TROUBLESHOOTING.......................................................30

9.2 General Troubleshooting Guide ..................................................................30

9.0 DIAGNOSTICS & TROUBLESHOOTING.......................................................31

9.3 Service Analyzer Charts..............................................................................31

9.4 Troubleshooting Tips ...................................................................................35

10.0 OUTDOOR UNIT MAINTENANCE................................................................36

10.1 Outdoor Coil Cleaning................................................................................36

10.2 Cabinet Cleaning and Care .......................................................................36

10.3 Motor Lubrication .......................................................................................36

10.4 Replacement Parts ....................................................................................36

11.0 WIRING DIAGRAMS......................................................................................37

12.0 INSTALLATION NOTES ................................................................................38

List of Tables

Table 1: Available Models......................................................................................6

Table 2: Electrical Data and Physical Data..........................................................6

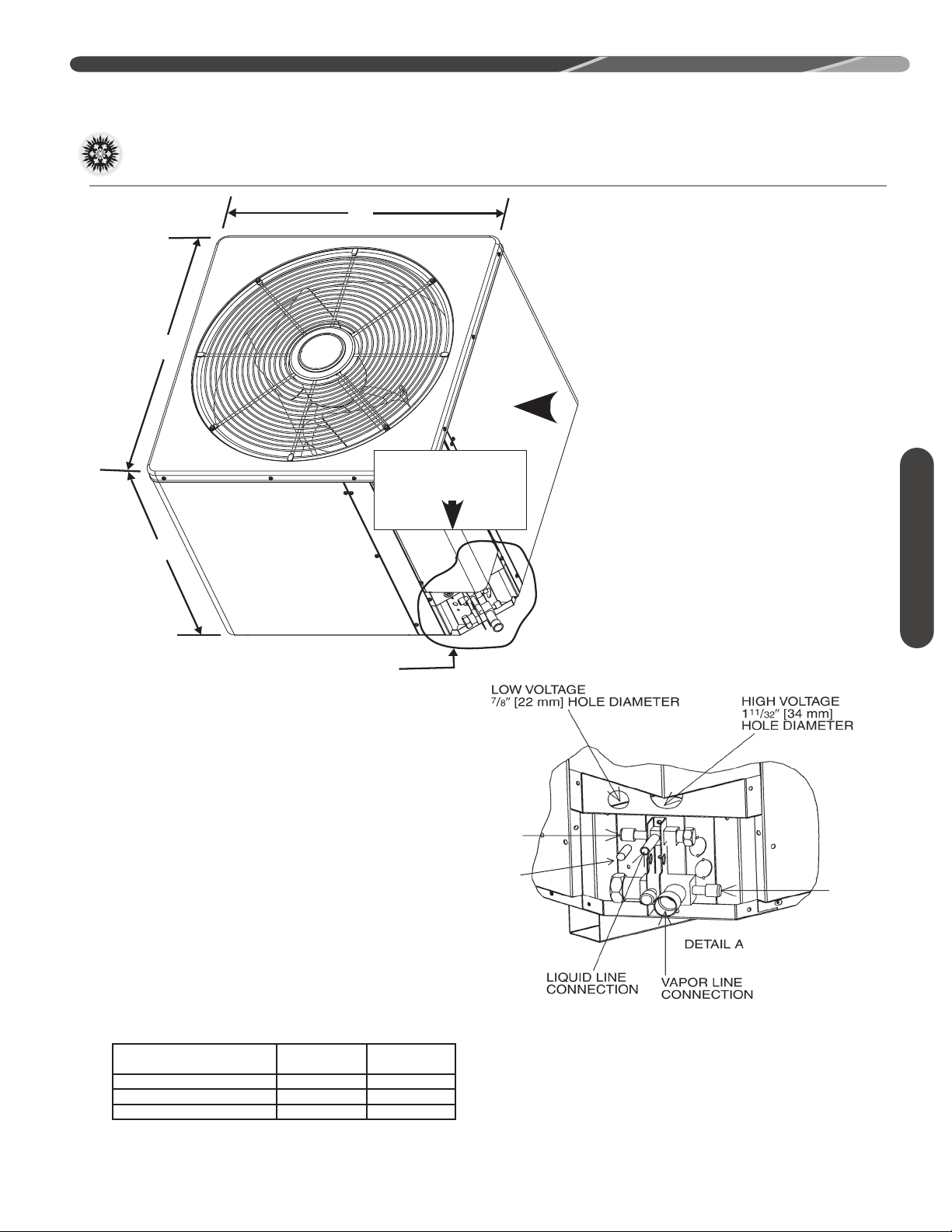

Table 3: Dimensions...............................................................................................7

Table 4: Equivalent Length for Fittings: ft [m] .................................................12

Table 5A: Refrigerant Line Sizing Chart (English Units).................................13

Table 5B: Refrigerant Line Sizing Chart (Metric Units) ...................................13

Table 6: Example Table .......................................................................................14

Table 7: Factory Installed Crank Case Heaters.................................................14

Table 8: Voltage Ranges ......................................................................................22

Table 9: Altitude Temperature Rise Ranges .....................................................24

Table 10: R-410A Temperature Pressure Chart.................................................26

Table 11: Maximum System Charge Values ......................................................27

Table 12: Troubleshooting Guide .......................................................................30

Table 13: Service Analyzer Chart .......................................................................31

Table 14: Cooling Mode Trouble Shooting Tips................................................35