7

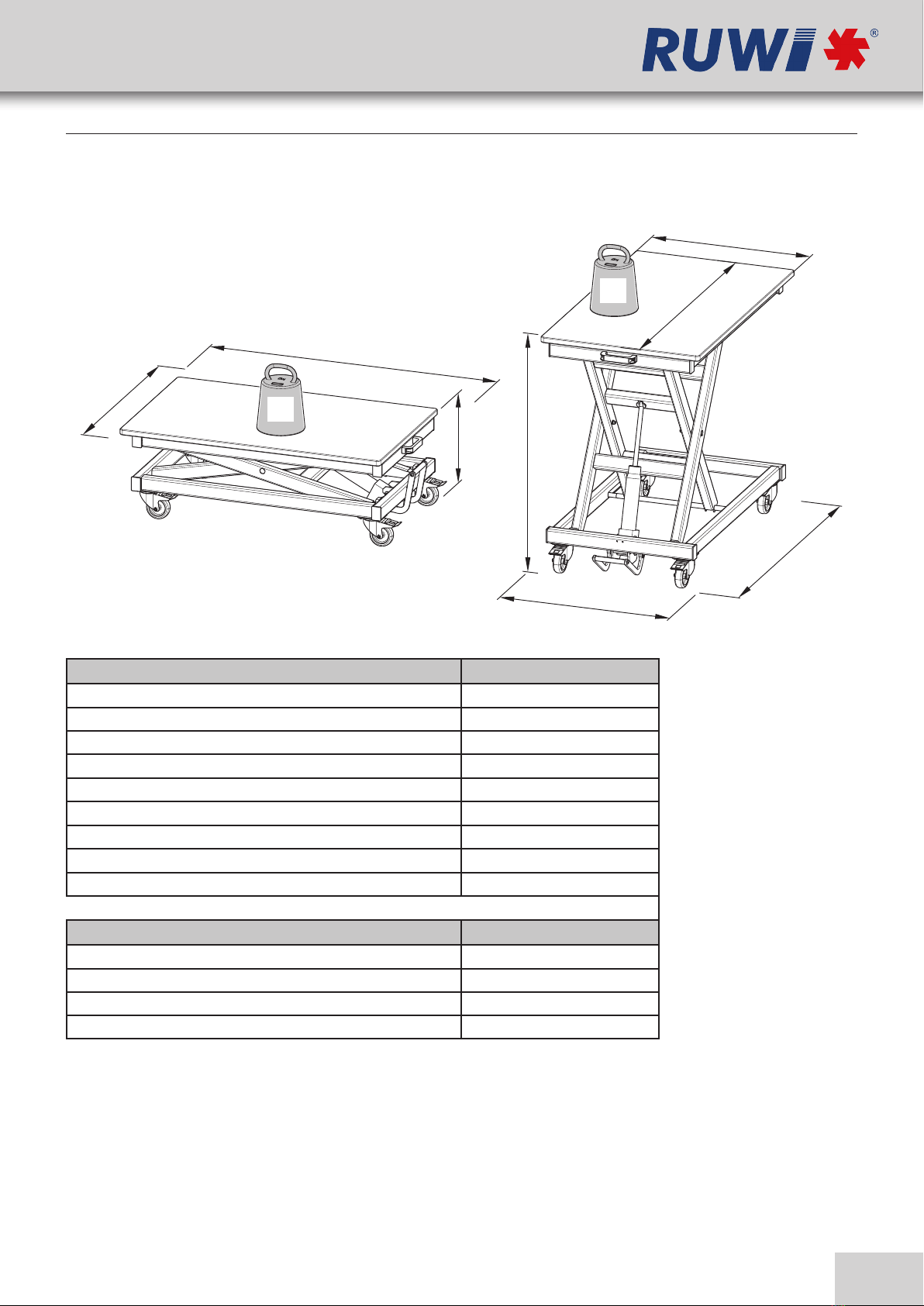

Height adjustable RUWI working table

AT 300

2.4 Responsibilities of the operator

This manual must be kept in the immediate vicinity of

the machine and be accessible at all times to all persons

working on or with the machine. The machine may only

be operated if it is in proper working order and in safe

condition. The general condition of the machine must be

checked and the machine must be inspected for visible

defects every time before it is switched on. All instructions

in this manual must be strictly followed without exception.

Besides the safety advice and instructions stated in this

manual, it is necessary to consider and observe local

accident prevention regulations, general safety regula-

tions as well as current environmental stipulations that

apply to the operational range of the machine.

The operator and designated personnel are responsible

for the trouble-free operation of the machine as well as

for clearly establishing responsibilities for installing, servi-

cing, maintaining and cleaning the machine. Machines,

tools and accessories must be kept out of the reach of

children.

2.5 Personnel requirements

Only authorised and trained personnel may work on and

with the machine. Personnel must be briefed about all

functions and potential dangers of the machine. "Quali-

fied personnel" is a term that refers to those who – due

to their professional training, know-how, experience,

and knowledge of relevant regulations – are in a posi-

tion to assess delegated tasks and recognise potential

risks. If the personnel lack the necessary knowledge for

working on or with the machine, they must be trained.

Responsibility for working with the machine (installation,

service, maintenance, overhaul) must be clearly defined

and strictly observed. Only those people who can be

expected to carry out their work reliably may be given

permission to work on or with the machine. Personnel

must refrain from working in ways that could harm

others, the environment or the machine itself. It is absolu-

tely forbidden for anyone who is under the influence of

drugs, alcohol or reaction-impairing medication to work

on or with the machine. When appointing personnel to

work on the machine, it is necessary to observe all local

regulations regarding age and professional status. The

user is also responsible for ensuring that unauthorised

persons remain at a safe distance from the machine.

Personnel are obliged to immediately report any irregu-

larities with the machine that might compromise safety to

the operator.

2.6 Work safety

Following the safety advice and instructions given in this

manual can prevent bodily injury and material dama-

ge while working on and with the machine. Failure to

observe these instructions can lead to bodily injury and

damage to or destruction of the machine. Disregard of

the safety advice and instructions given in this manual as

well as the accident prevention regulations and general

safety regulations applicable to the operative range of

the machine shall release the manufacturer and their

authorised representatives from any liability and from

any compensation claims.

Safety