Contents

SAFETY INFORMATION..............................................................................................................................................5

EMERGENCY CASE.....................................................................................................................................................6

ENVIRONMENTAL PROTECTION..............................................................................................................................6

PRODUCT WARRANTY ..............................................................................................................................................6

I. ABOUT THE PRINTER..........................................................................................................................................7

1. TECHNICAL SPECIFICATIONS ........................................................................................................................................8

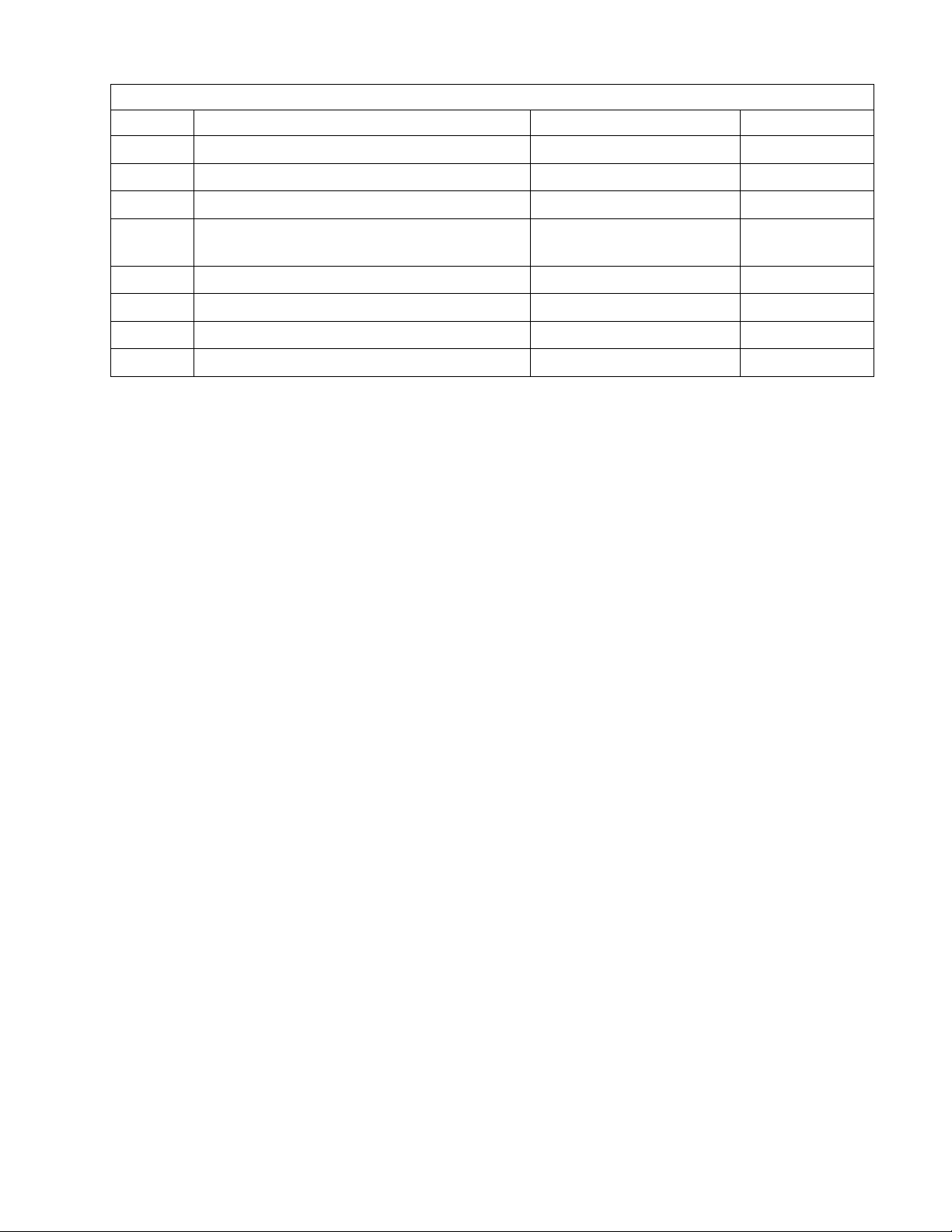

2. PRINTING SPEED TABLE .................................................................................................................................................8

3. PRINTER OVERVIEW......................................................................................................................................................9

3.1. Controller front side .....................................................................................................................................9

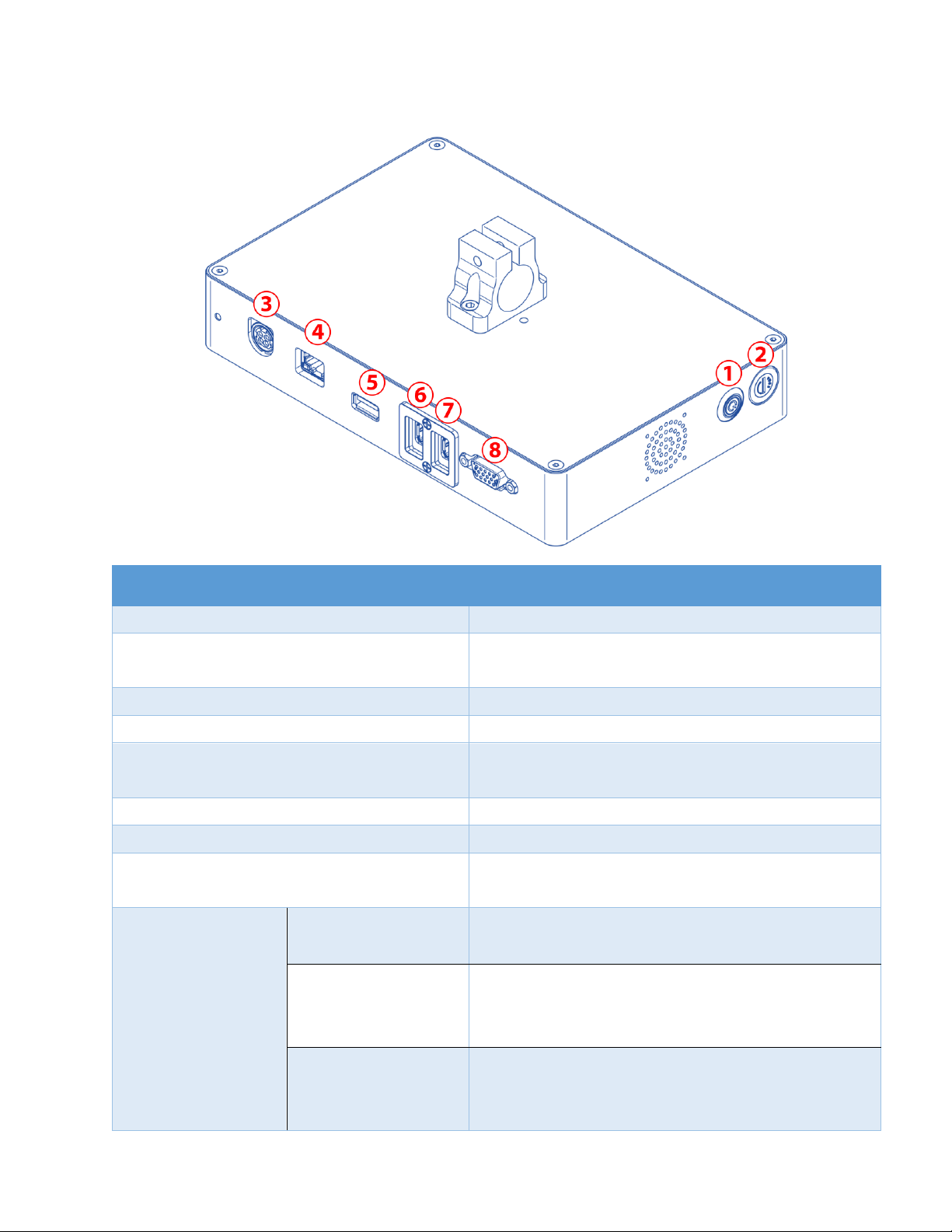

3.2. Controller back side ..................................................................................................................................10

3.3. Printhead ......................................................................................................................................................11

II. INSTALLATION...................................................................................................................................................14

1. COMPONENT LIST......................................................................................................................................................14

2. PRINTHEAD SETUP.......................................................................................................................................................15

3. CONTROLLER SETUP...................................................................................................................................................15

4. PRINTHEAD CABLE SETUP............................................................................................................................................16

4.1. Use 1 printhead R20 PRO .........................................................................................................................16

4.2. Use 2 printheads R20 PRO........................................................................................................................16

4.3. Use printhead R20 PRO Stitching ...........................................................................................................17

5. EXTERNAL DEVICES CONNECTIONS ............................................................................................................................18

5.1. External Sensor ............................................................................................................................................18

5.2. External Encoder ........................................................................................................................................18

5.3. Alarm beacon.............................................................................................................................................19

6. SOFTWARE USING ................................................................................................................................................21

6.1. Main interface ............................................................................................................................................21

6.2. DesignJet......................................................................................................................................................24

6.3. Printing parameters ...................................................................................................................................27

6.4. Advanced Settings....................................................................................................................................36

6.5. POD Settings ................................................................................................................................................37

III. GETTING STARTED........................................................................................................................................40

IV. OPERATION...................................................................................................................................................40

1. HOW TO DESIGN A TEMPLATE!...................................................................................................................................40

1.1. New template.............................................................................................................................................40

1.2. Open template...........................................................................................................................................41

1.3. Save template ............................................................................................................................................42

1.4. Delete template.........................................................................................................................................42

1.5. Save As template.......................................................................................................................................43