s-rack Sigma S1 User manual

Sigma S1

Installation Manual

Sigma S1 Installation Manual

Contents:

1

Introduction

1.1

Description

1

1.2

About the Manual

1

1.3

Warnings

2

1.4

Safety

2

2

Technical Description

2.1

System Overview

3

2.2

Component Details

4

2.3

Module Clamps

5

3

Project Drawing and Bill of Materials

6

4

Basic Installation Requirements

4.1

System Units

6

4.2

Required Tools

6

4.3

Tightening Torques

6

5

Foundation

7

6

Support Assembly

8

7

Purlin Installation

9

7.1

Purlin Placing and Alignment

9

7.2

Purlin Connector

9

8

Module Clamp Installation

10

9

Module Installation

9.1

Framed Modules –Portrait

11

9.2

Framed Modules –Landscape

12

9.3

Frameless Modules –Portrait

13

9.4

Frameless Modules –Landscape

13

10

Maintenance

10.1

Inspection

14

10.2

Testing

14

1Sigma S1 Installation Manual

Sigma S1 Installation Manual

1. Introduction

1.1. Description

The Sigma S1 is a single post PV ground mount system

that allows for flexible arrangement of modules in either

portrait or landscape orientation and can be installed by

means of driven piles.

1.2. About the Manual

Content

These instructions provide important information

regarding system, components, planning and safety

warnings when handling the Sigma S1.

Sections 1, 2 and 3 show an overview as well as detailed

information about the Sigma S1 and its components.

Section 4 provides the basic planning information. The

remaining sections provide detailed system assembly and

installation instructions.

Installation Manual Validity

This installation manual is only valid in conjunction with:

•S-Rack Australia Pty Ltd’s Terms and Conditions. This

document applies to all contracts and agreements

for all products and services offered by S-Rack

Australia Pty Ltd.

•The Project Specific Drawings. These documents

show all the project specific installation details,

choice of components, dimensions and any

deviation from the standard material/assembly.

Therefore, these drawings take precedence over the

installation manual in case of discrepancies between

the two documents.

•The supplied material for the Sigma S1 according to

the Bill of Materials (BOM).

The content of these documents must be followed during

installation for the S-Rack Australia Pty Ltd warranty to

apply.

Please read and check the Installation Manual, Project

Drawings and Bill of Materials carefully prior to any

installation, maintenance, and disassembly work.

All necessary information regarding installation,

maintenance and disassembly will be provided. If you

have any questions after having read these documents,

please contact S-Rack Australia Pty Ltd.

Target Group

Skilled and trained personnel.

Skilled/Trained Personnel

An individual who has acquired professional training and

as such, capable of executing installation, maintenance

and disassembly work properly.

Guidance Notes

Please see below installation guidance notes.

Symbols:

Important information and useful tips

Additional information and hints to make

the installation process easier

2Sigma S1 Installation Manual

Sigma S1 Installation Manual

1.3. Warnings

The following are used in the installation manual to

indicate safety-related information. These include:

•Warning Symbols

•Signal words which identify the hazard level

•Information about the type and source of the hazard

•Information about the potential consequences if the

hazard is disregarded

•Measures to prevent injuries and damage to

property

The signal words of the warnings respectively indicate

one of the following hazard levels:

DANGER

Indicates a potentially fatal danger

which may result in death or serious

injury if ignored.

WARNING

Indicates a potentially dangerous

situation which may result in serious

injury or damage to property if

ignored.

CAUTION

Indicates a potentially dangerous

situation which may result in injuries

or damage to property if ignored.

ATTENTION

Indicates potential danger which can

result in damage to property if

ignored

1.4. Safety

Safety instructions for S-Rack Australia Pty Ltd products

are included in the documents. Do not use the products

in a manner other than its intended function.

It is the responsibility of the customer to ensure that all

general and specific safety instructions are followed.

In addition, please observe the specific safety instructions

provided in this Installation Manual for all installation

work. The specific safety instructions are positioned in

each case directly with the respective installation steps.

3Sigma S1 Installation Manual

Sigma S1 Installation Manual

2. Technical Description

This section provides a breakdown of the Sigma S1 and its components. Upon delivery of the system, check to ensure

that all parts and components adhere to the BOM and project specific drawings. Any items missing or damaged must

be notified to S-Rack Australia Pty Ltd immediately.

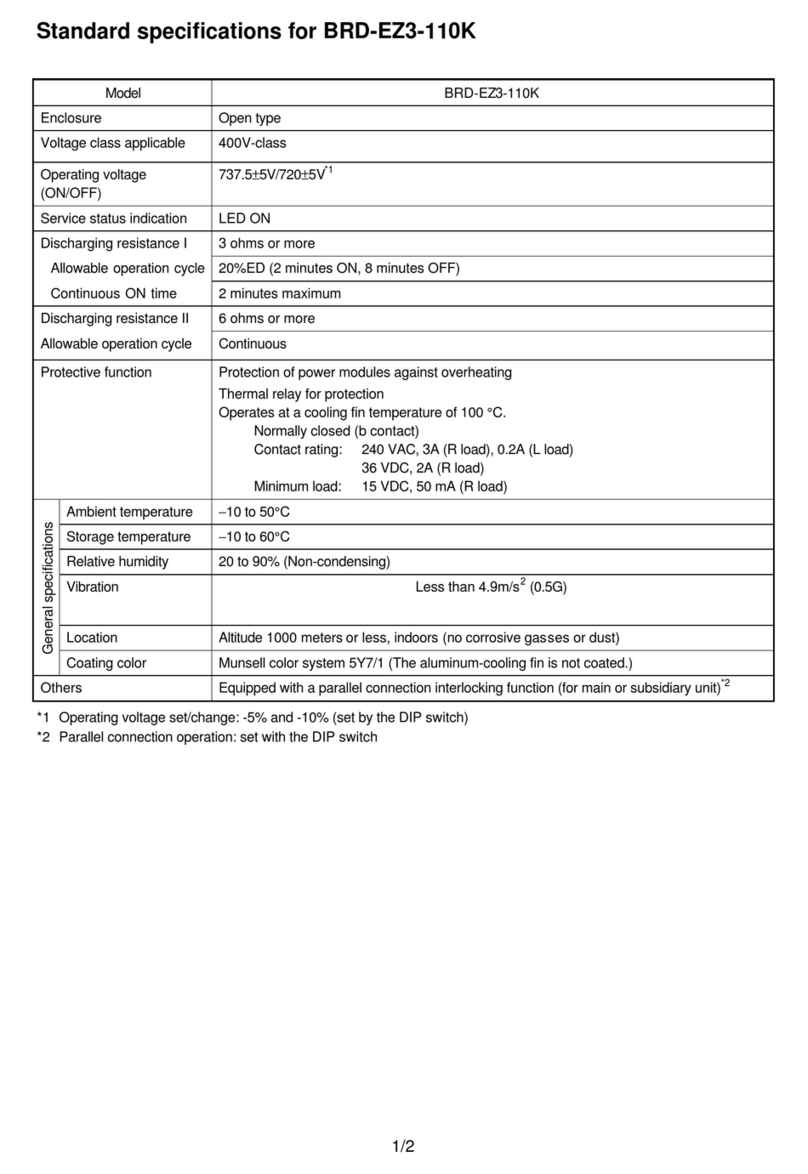

2.1. System Overview

An overview of the Sigma S1 system can be seen below (Image 2.1-1). Please note that some components can vary

depending on project-specific requirements.

Image 2.1-1 - System Overview of the Sigma S1 System

Driven Pile

Girder

Strut

Purlin Clamps

Module Clamps

Purlin

4Sigma S1 Installation Manual

Sigma S1 Installation Manual

2.2. Component Details

Overview of System Components

Foundation

Girder

Strut

Purlin

Purlin Connector

Purlin Clamp with Cage Nut

5Sigma S1 Installation Manual

Sigma S1 Installation Manual

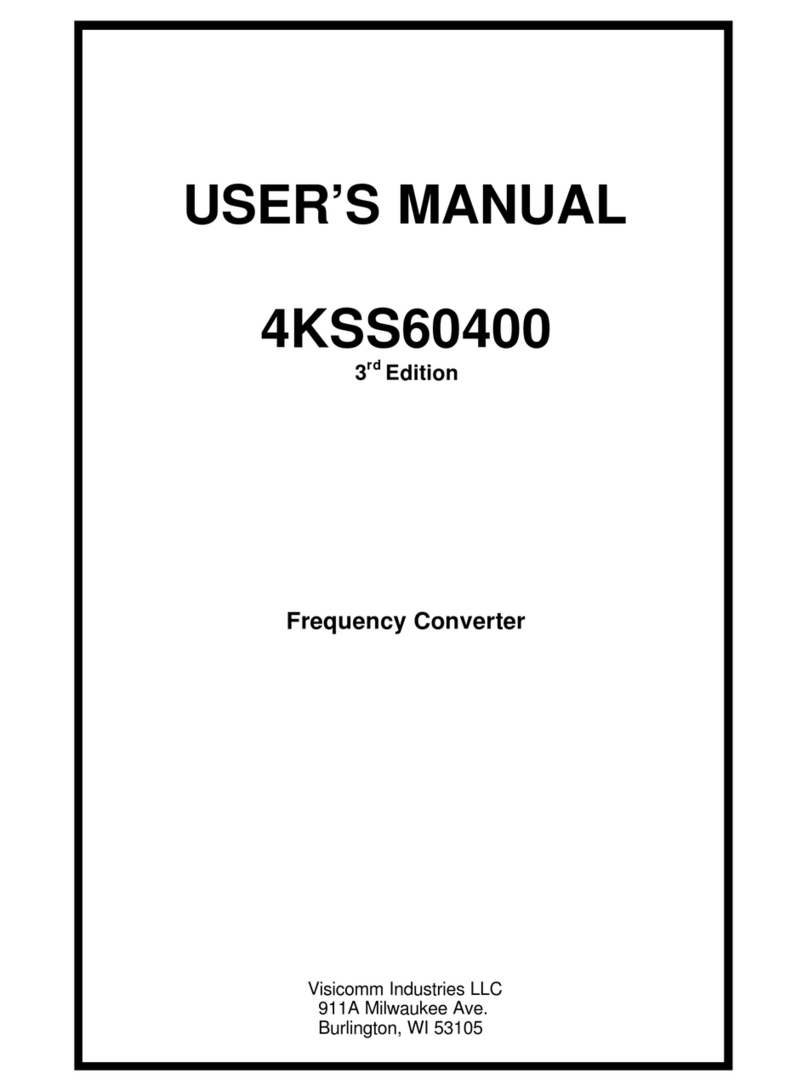

2.3. Module Clamps

Module Clamps are used to secure the PV modules

to the Sigma S1 purlins. Module clamps are

equipped with a clickstone, while laminate clamps

use a T-head bolt to install the module clamps into

the Sigma S1 purlins.

Module End Clamp

These clamps are installed at the start and end of a

PV module row. These clamps are available in

discrete sizes allowing it to precisely match the

required PV module thickness.

Module Mid Clamp

These clamps are installed in-between PV modules

along a PV module row and can be integrated with

grounding pins.

Laminate Mid/End Clamps

Laminate module clamps allow frameless modules

to be mounted without applying too much pressure

on the modules.

Image 2.3 –2 Module End Clamp

Image 2.3 –1 Module Clamps

Image 2.3 –3 Module Mid Clamp with Grounding Pins

Image 2.3 –4 Laminate Mid Clamp

Image 2.3 –5 Laminate End Clamp

6Sigma S1 Installation Manual

Sigma S1 Installation Manual

3. Project Drawings and Bill of Materials

Project-specific documentation is supplied as part

of the Sigma S1. These documents contain all the

information necessary to install the system.

The documentation includes:

•Bill of Materials

•Project Drawings (s) which show:

oExact module configuration for

the project

oSpecific foundation information

for the project

oDimensions and tolerances

4. Basic Installation Requirements

4.1. System Units

The Sigma S1 is designed in separate system units

which can be up to 30m long (without expansion

gaps). Please refer to the BOM and Project

Drawings for the dimensions of a specific system

unit.

4.2. Required Tools

In order to mount the Sigma S1, the following tools

are required:

•Power drill/electric screwdriver

•Folding rule/measuring tape

•Angle measuring tool (protractor)

•Spirit level or laser level tool

•M6 Allen key for module clamps

•M8 Allen key for laminate module clamps

•Wrenches for M10 and M12 bolts

4.3. Tightening Torques

A good quality torque wrench should be used to

tighten bolted connections to the torque

requirements below.

Connection

Size

Nm

Piles, girder, and struts

M12

40

Purlin clamps and cage nut

M10

30

Laminate module clamps

M8

15

Module clamps

M6

10

7Sigma S1 Installation Manual

Sigma S1 Installation Manual

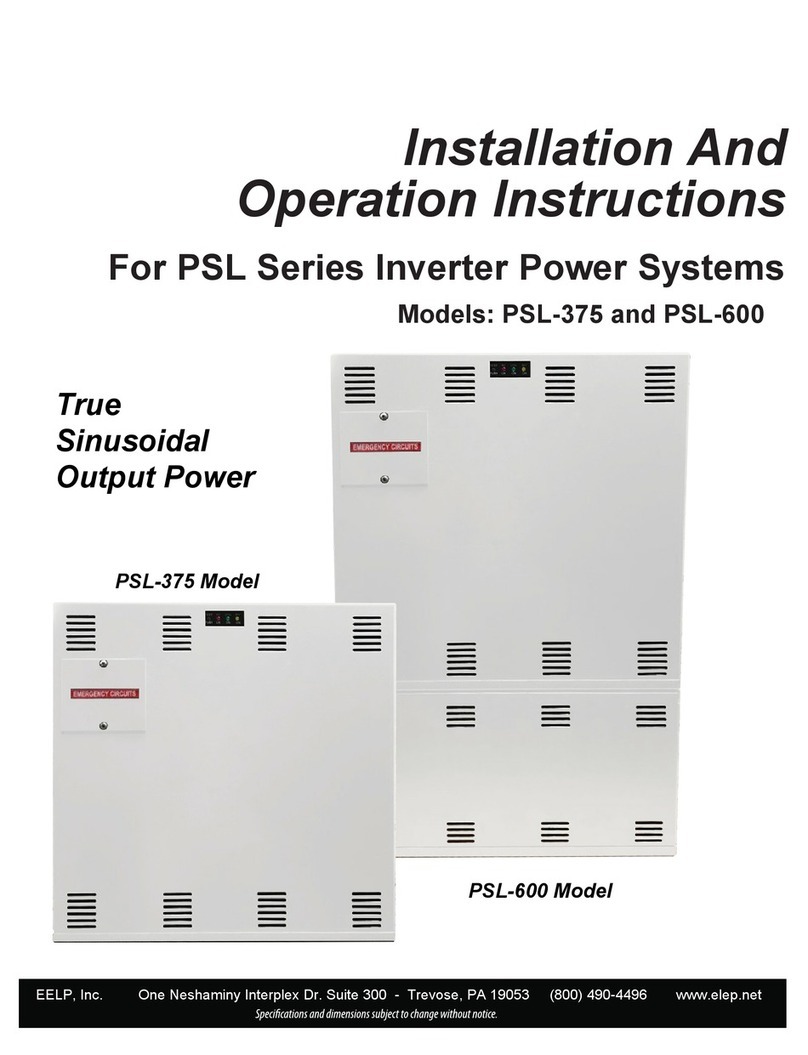

5. Foundation

Driven piles should be oriented as shown in Image 5.1 -1. Make sure that the posts are positioned and installed within

the tolerances. The corresponding tolerances will be specified in the project drawings.

Note:

As an alternative to ramming, piles can also be encased in concrete / stabilised sand.

Refer to project documentations for specific dimensions and requirements.

Tolerances

Image 5.1 –1 Orientation of Driven Piles

In the absence of specific information in the drawings, the following guidelines apply:

1. Post height max. ± 2 cm based on planned height

2. Position E-W max. ± 5 cm, Position N-S max. ± 2 cm

3. Inclination tolerance E-W max. 2° (1° ≈ 2cm/m)

4. Inclination tolerance N-S max. 2°

5. Torsion max. 2°

6. Axis tolerance E-W max. ± 2cm based on the post top

Hint!

After the ramming posts have been set, the pile head (about 3cm) should be treated with a zinc dust primer.

This prevents premature corrosion and thus support the longevity of the system.

8Sigma S1 Installation Manual

Sigma S1 Installation Manual

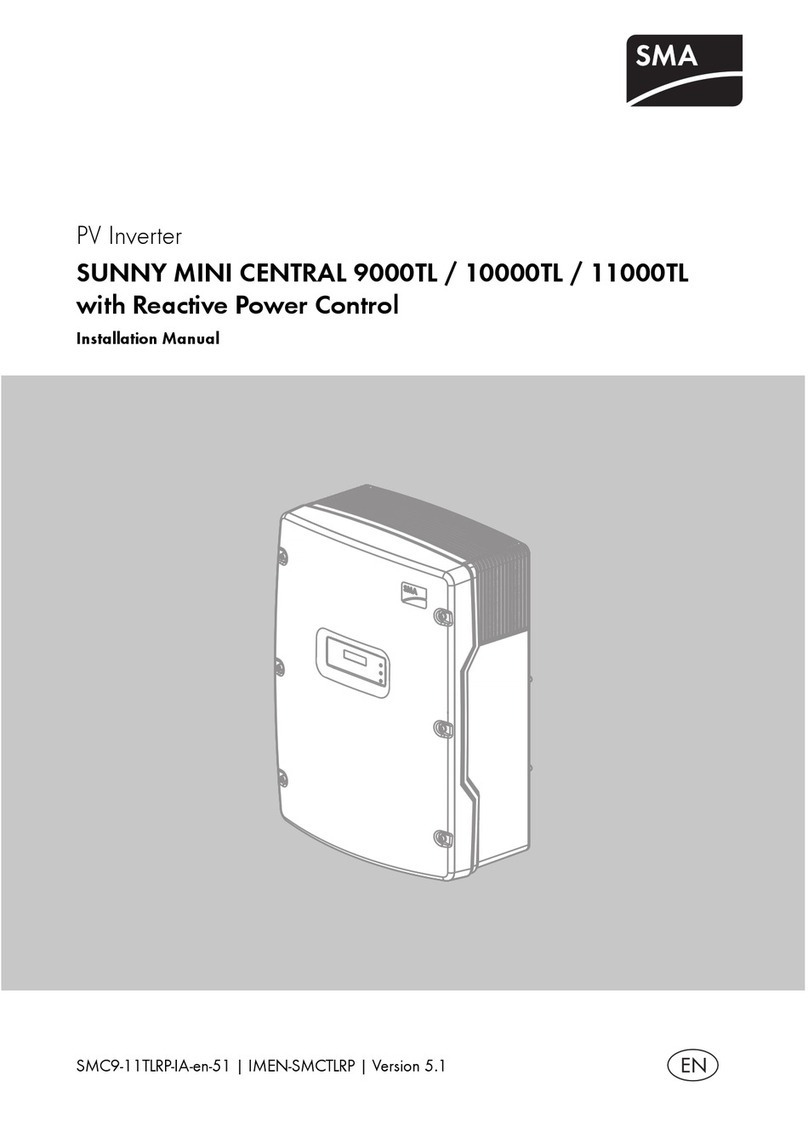

6. Support Assembly

Installation Steps

Connect the girder (pre-assembled with purlin clamps), strut (pre-assembled) and pile together as shown in (Image

6.1). Please refer to the Project Drawings and BOM for the correct type, positioning and small parts used for the

connections. Make sure to observe the right tightening torques.

Note:

Depending on project specifications, an additional strut may be required. Refer to the project-specific drawings.

Image 6.1 General Structure of the Sigma S1 Support

9Sigma S1 Installation Manual

Sigma S1 Installation Manual

7. Purlin Installation

The Sigma S1 System uses purlins mounted on the

girder to hold the modules in place. Purlin clamps

are used to secure the purlins to the girder.

Note:

Depending on project specifications, additional

purlins may be required. Refer to the project-

specific drawings.

7.1. Purlin Placing and Alignment

Installation Steps

1. Position the purlins horizontally on top of the

rafters and align them. Please refer to the

project drawings for the exact position of the

purlins with regards to:

-Spacing between purlins

-Horizontal overhang (cantilever) over

the outer driven piles

2. Loosen the purlin clamps pre-assembled into

the girder. Clamp both sides of the purlin to the

purlin clamps.

3. Check that the spacing of the purlins does not

get shifted with the final tightening of the

bolts. Readjust if necessary.

4. Adhere to the specified tightening torques

7.2. Purlin Connector

The purlins are spliced together using a purlin

connector.

Mounting Steps

1. Slide the purlin connector halfway into the

installed purlin. Secure the connector to the

purlin by drilling 2 self-tapping screws into the

pre-drilled holes in the connector.

2. Slide the next purlin into the connector leaving

no gaps between the 2 purlins. Secure the 2nd

purlin by drilling another 2 self-tapping screws

into the pre-drilled holes in the connector.

3. Adhere to specified tightening torques.

Image 7.1-1 Installing the Purlins

Image 7.1-2 Mounting the Purlins

Image 7.2-1 Installing the Purlin Connector

Image 7.2-2 Connecting 2 Purlins

10 Sigma S1 Installation Manual

Sigma S1 Installation Manual

8. Module Clamp Installation

For framed modules, the module clamps for the

Sigma S1 uses a clickstone to attach the module

clamps to the purlin. The module clamps are

inserted into the top channel of the purlin and

tightened using an Allen key.

For frameless modules, laminate clamps use a T-

head bolt inserted into the top channel of the

purlin.

Installation Steps

1. Before installing the module clamps, loosen

the bolt such that bottom part of the bolt is

above the noses of the clickstone.

2. For module clamps, insert the module clamps

at a slight angle into the top channel of the

purlin. While holding it firmly, rock the

clickstone upright until it clicks into place.

3. For laminate clamps, align and insert the

T-head bolt into the top channel of the purlin.

4. Tighten the clamps using the recommended

torque settings.

Hint!

The clickstone is made undersized so that

it is easy to lock it in the module rail

channel. By tightening the screw, the

clickstone is forced apart ensuring the

right support.

To remove the clickstone, loosen the

screw until it no longer touches the noses

in the click stone, press the legs of the

clickstone together, tilt at an angle, then

remove it from the channel.

CAUTION

Material damage due to incorrect

installation

Incorrectly mounted module clamps can

cause the PV modules to fall and be

damaged.

Mount all module clamps in accordance

with the instructions.

Image 7 –1 Module Clamp Installation

Image 7 –2 Laminate Clamp Installation

Clickstone Nose

11 Sigma S1 Installation Manual

Sigma S1 Installation Manual

9. Module Installation

The procedure below describes the installation of

modules on a single row. This procedure can begin

on the west end of the array moving east or vice-

versa.

9.1. Framed Modules –Portrait

1. Insert a module end clamp into each purlin.

2. Place the first PV module on the purlin and

slide the module frame against the end clamp.

With the module’s clamping points correctly

positioned under the end clamps, tighten the

end clamps onto the module frame.

3. Insert a mid clamp into each the purlin. Push it

flush against the module, ensuring the clamp

body rests on top of the previously installed

module frame. Place the next module on the

purlin and slide it against the mid clamps.

4. Repeat the above steps for the rest of the row

of modules. At the end of a row, install an end

clamp on the outside of the last module to

complete the row.

Hint!

Use of a spare module clamp or other

item as a spacing gauge between the

modules columns ensures that the

spaces between columns are the

same.

Image 9.1 –1 Module End Clamp

Image 9.1 –2 Module Mid Clamp

Image 9.1 –3 Portrait Installation

Image 9.1 –4 Placing the next PV module

12 Sigma S1 Installation Manual

Sigma S1 Installation Manual

9.2. Framed Modules –Landscape

1. Insert a module end clamp into the bottom

purlin.

2. Place the first PV module on the bottom purlin

and slide the module frame against the end

clamp. With the module’s clamping points

correctly positioned under the end clamps,

tighten the end clamps onto the module

frame.

3. Insert a mid clamp into the next purlin. Push it

flush against the module, ensuring the clamp

body rests on the previously installed module

frame. Place the next module onto the next

purlin and slide it against the installed mid

clamp.

4. Repeat the above steps until the top rail is

reached. At the topmost purlin, install an end

clamp on the outside of the last module to

complete the column.

Image 9.2 –1 Landscape Installation

Image 9.2 –2 Installing next column of modules

13 Sigma S1 Installation Manual

Sigma S1 Installation Manual

9.3. Frameless Modules –Portrait

1. Insert a laminate end clamp into the purlins.

2. Place the frameless module on the purlin and

insert it into the laminate end clamp leaving at

least a 1mm gap.

3. Insert a laminate mid clamp into the previously

installed module. Place the next module on the

purlin and insert it on the installed laminate

mid clamp. When inserting the modules into

the laminate mid clamp, remember to leave at

least a 1 mm gap.

4. With the module’s clamping points correctly

aligned with the laminate clamps, tighten the

clamp to the module.

5. Repeat the above steps for the rest of the row

of modules. At the end of the row, install a

laminate end clamp on the outside of the last

module to complete the row.

9.4. Frameless Modules –Landscape

1. Insert a laminate end clamp into the bottom

purlin. Place the frameless module on the

purlin and insert it into the laminate end clamp

leaving a 1mm gap.

2. Insert a laminate mid clamp into the next

purlin and insert the installed module into it.

Install the next module by inserting it to the

installed laminate mid clamp. When inserting

the modules into the laminate mid clamp,

remember to leave at least a 1mm gap.

3. With the module’s clamping points correctly

aligned with the laminate clamps, tighten the

clamp to the modules

4. Repeat the above steps until the topmost

purlin is reached. At the end of the column,

install a laminate end clamp on the outside of

the last module to complete a column.

5. Repeat steps 1-4 to install another column of

modules.

Image 9.3 –1 Laminate End Clamps in Portrait

Image 9.3 –2 Laminate Mid Clamps in Portrait

Image 9.3 –3 Portrait Installation

Image 9.4 –1 Laminate Clamps in Landscape

Image 9.4 –2 Installing next column of modules

14 Sigma S1 Installation Manual

Sigma S1 Installation Manual

10. Maintenance

When properly assembled, the Sigma S1 is a reliable

and trouble-free system that requires minimal

maintenance. Nevertheless, S-Rack Australia Pty

Ltd recommends performing regular inspections

and creating a maintenance schedule. By doing so,

potential problems can be detected and resolved

before they can become serious, ensuring the

system’s excellent long-term durability and

reliability.

The following procedure pertains only to the Sigma

S1 System structure. Maintenance and repair of

other PV system components should be carried out

in accordance with the respective manufacturers’

recommendations.

9.1. Inspection

The system should be visually inspected for obvious

loose connections, missing components, modules

which appear to have shifted, vegetation

overgrowth, wind-blown debris, and other

indications of abnormality annually. Any problems

detected at this time should be addressed and

repaired as necessary.

9.2. Testing

After one year in service, it is good practice to check

the torque settings of a representative sample of

system connections including module clamps and

rail clamps. Do not exceed the recommended

torque settings. If a disproportionate number of

loose connections (more than 10% of connections)

are found, it may be an indication of an improper

assembly and it may be necessary to take

comprehensive corrective action.

S-Rack Australia Pty Ltd recommends keeping

records of connections sampled each year and

checking untested connections in the succeeding

years. Once all connections have been tested,

sample sizes and test frequency can be reduced.

Table of contents