3 3270360_GB

INDEX

GENERALINSTRUCTIONSONDELIVERY.......................................................................5

GENERALWARNINGS..................................................................................................................................5

LISTOFREGUALATIONREFERENCES............................................................................................................5

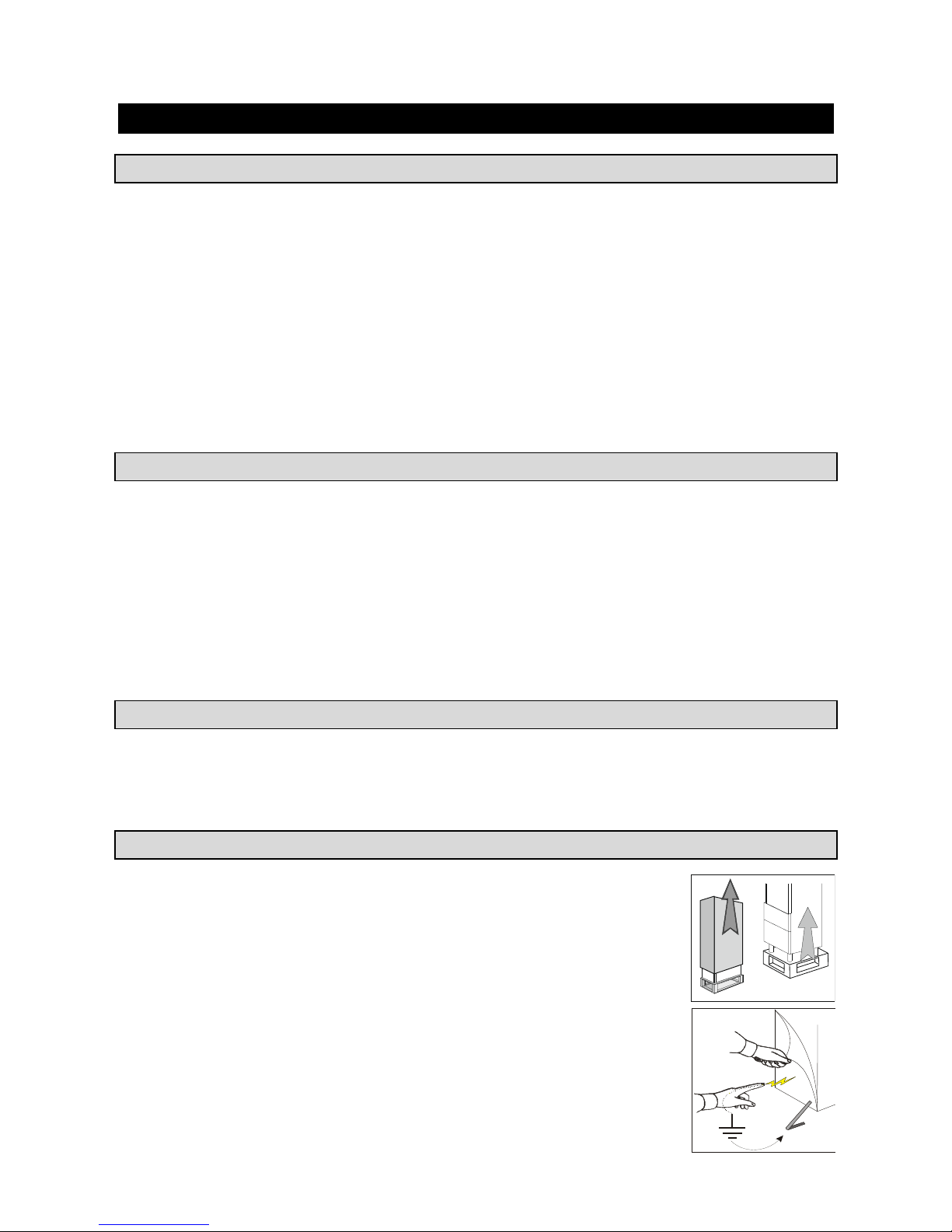

TRASPORTATIONANDHANDLING...............................................................................................................5

UNPACKING................................................................................................................................................5

GENERALSAFETYWARNINGS......................................................................................................................6

INSTALLATION............................................................................................................7

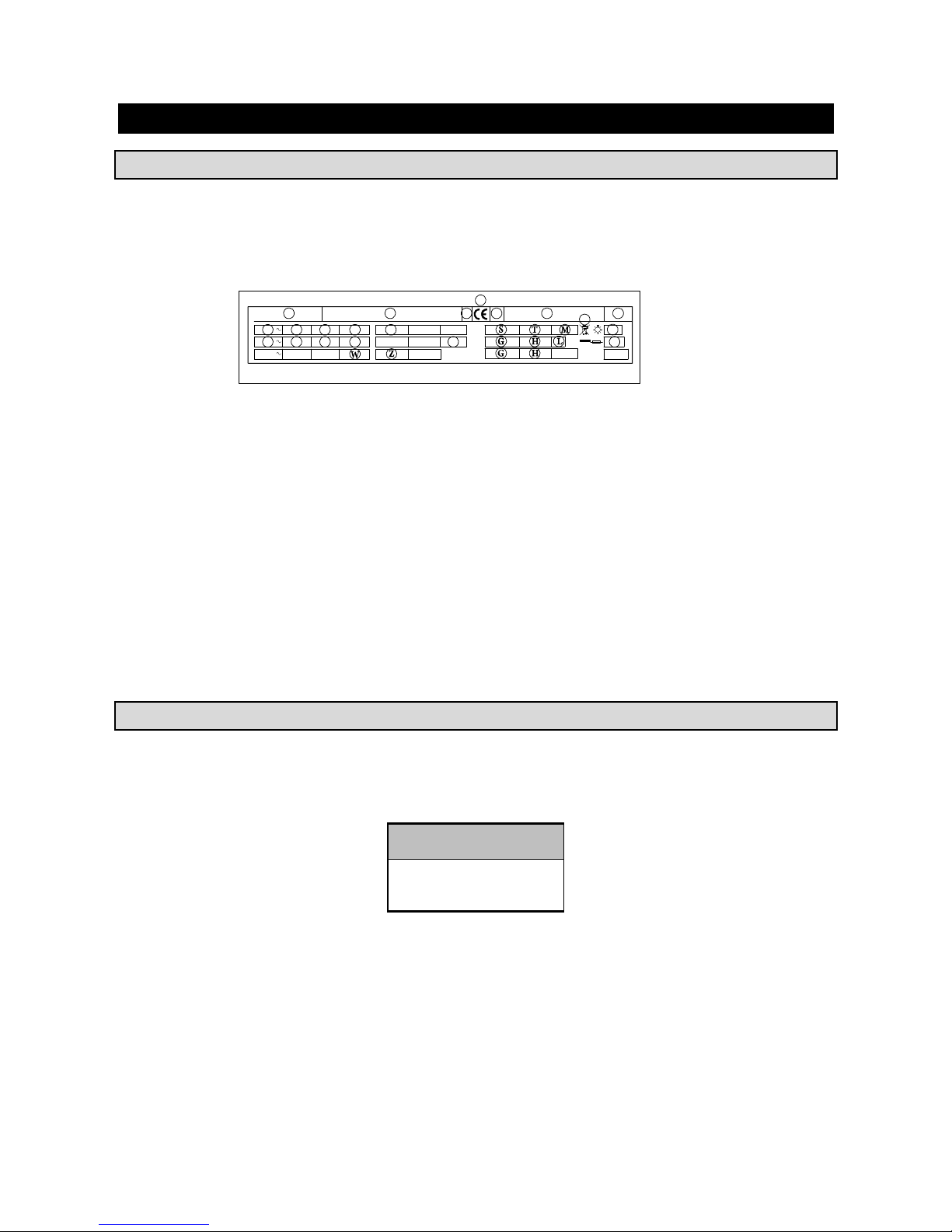

PLATEDATA................................................................................................................................................7

MAXROOMTEMPERATURE........................................................................................................................7

POSITIONING..............................................................................................................................................8

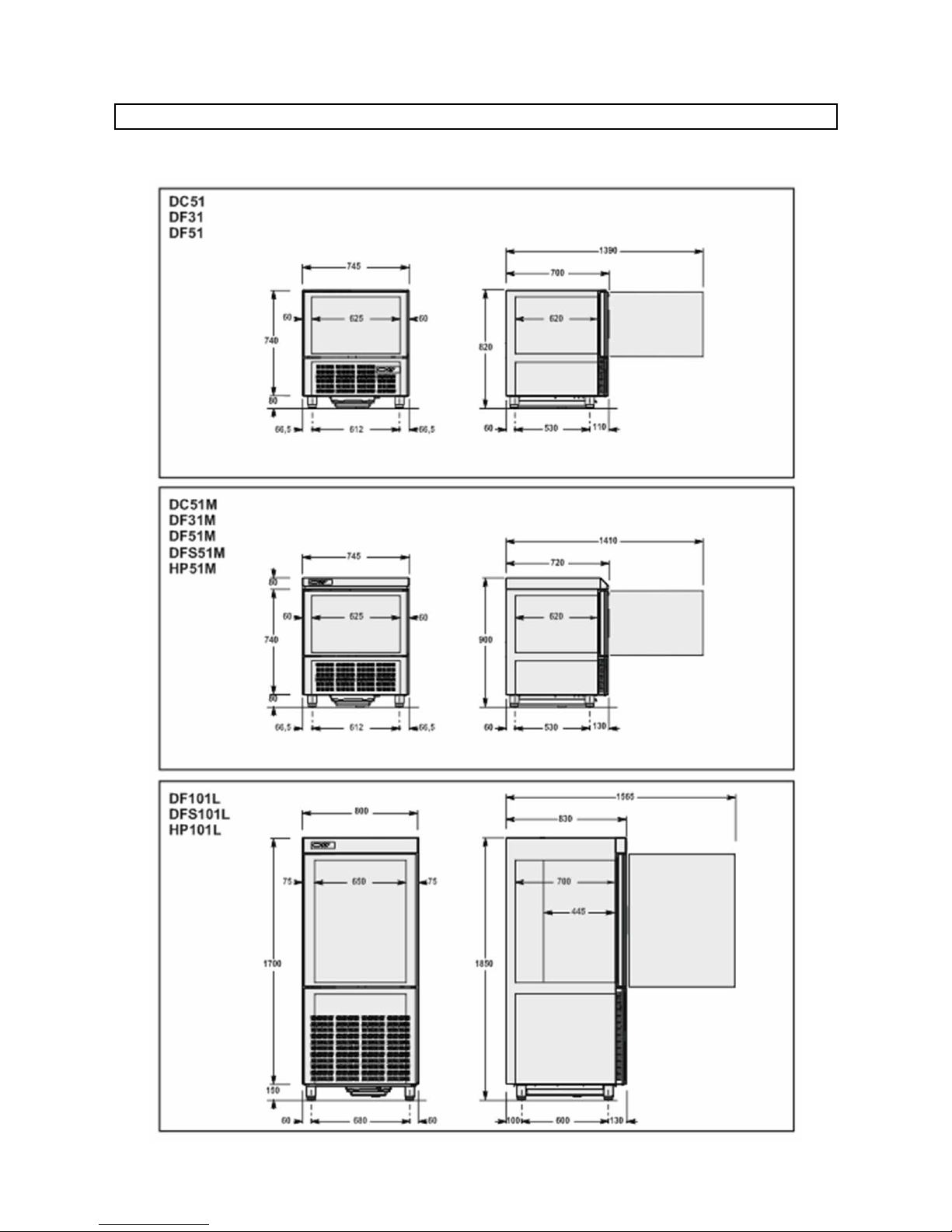

DIMENSIONS....................................................................................................................................................................9

TECHNICALDATA............................................................................................................................................................11

WIRING.....................................................................................................................................................12

CONDENSATEDRAIN.................................................................................................................................12

TESTING....................................................................................................................................................12

CONTROLANDSAFETYSYSTEMS...............................................................................................................13

REFRIGERANTMATERIALSAFETYDATASHEET..........................................................................................13

DISPOSAL..................................................................................................................................................14

OPERATION..............................................................................................................15

GENERALDESCRIPTION.............................................................................................................................15

SETTINGUP....................................................................................................................................................................15

MACHINELOADING........................................................................................................................................................16

POSITIONOFTRAYS........................................................................................................................................................16

COREPROBE...................................................................................................................................................................16

TEMPERATURES.............................................................................................................................................................17

LENGTH..........................................................................................................................................................................17

CONTROLPANEL.......................................................................................................................................18

POSITIVE SOFT QUICK COOLING KEY.............................................................................................18

NEGATIVE QUICK COOLING KEY......................................................................................................18

PROGRAMME............................................................................................................................................20

PRE‐COOLINGCYCLE......................................................................................................................................................21

COREPROBEPOSITIVESOFTQUICKCOOLINGCYCLE....................................................................................................21

COREPROBEPOSITIVEHARDQUICKCOOLINGCYCLE...................................................................................................21

COREPROBENEGATIVESOFTQUICKCOOLINGCYCLE...................................................................................................22

COREPROBENEGATIVEHARDQUICKCOOLINGCYCLE.................................................................................................22

TIME‐CONTROLLEDPOSITIVESOFTQUICKCOOLINGCYCLE..........................................................................................23

TIME‐CONTROLLEDPOSITIVEHARDQUICKCOOLINGCYCLE.........................................................................................23

TIME‐CONTROLLEDNEGATIVESOFTQUICKCOOLINGCYCLE........................................................................................24

TIME‐CONTROLLEDNEGATIVEHARDQUICKCOOLINGCYCLE.......................................................................................24

DEFROSTING.............................................................................................................................................25

CHANGINGPARAMETERS..........................................................................................................................26

ALARMSANDFAULTANALYSIS.................................................................................................................27

SIGNALS..........................................................................................................................................................................27

INDICATIONS..................................................................................................................................................................28

ALARMS..........................................................................................................................................................................28

ERRORS...........................................................................................................................................................................29

MAINTENANCE.........................................................................................................30

MAINTENANCEANDCLEANING.................................................................................................................30