4www.salda.lt

VEGA 350E/700E/1100E/1100W

Air supply unit VEGA is specially designed for ventilation of the premises with suspended height installation possibilities. Units VEGA comply ErP 2016

norms and stand out with the best possible air tightness class in the market. Supply air ow from 350 to 1000 m3/h.

Easy installation:

• 6 possible mounting positions;

• extremely low height - space saving design.

Simple service:

• qualitative and ergonomic design (integrated control box);

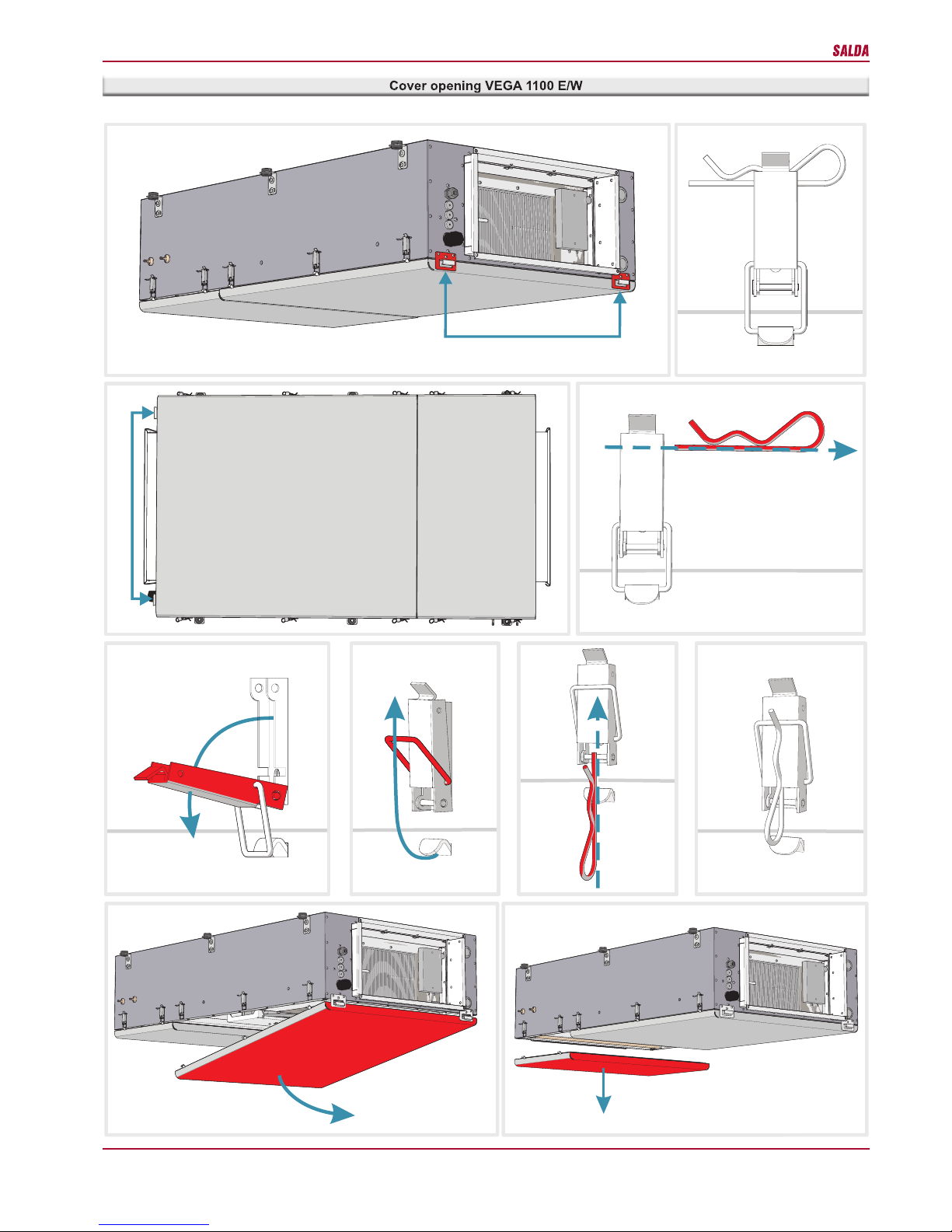

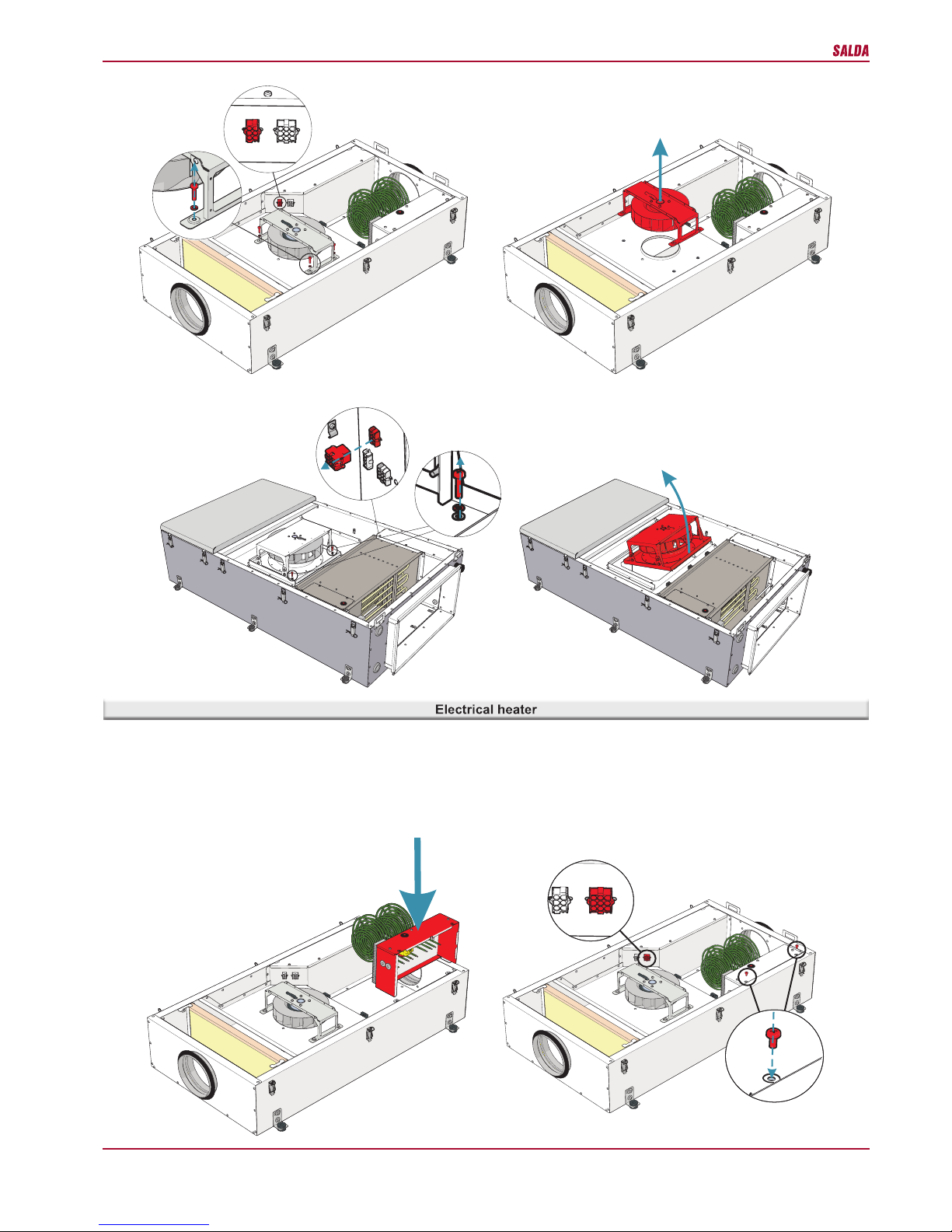

• safe and easy doors opening for lter replacement

Economical usage:

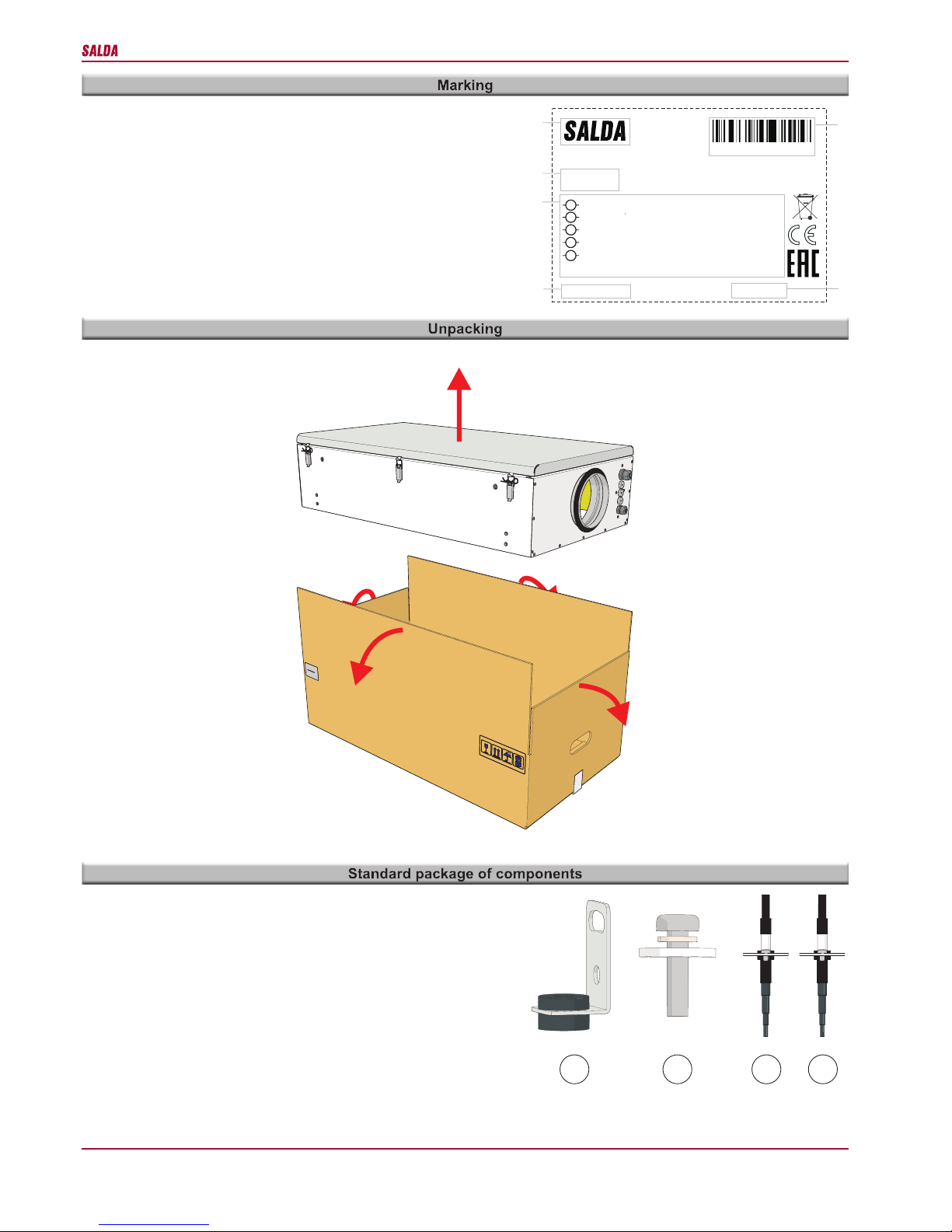

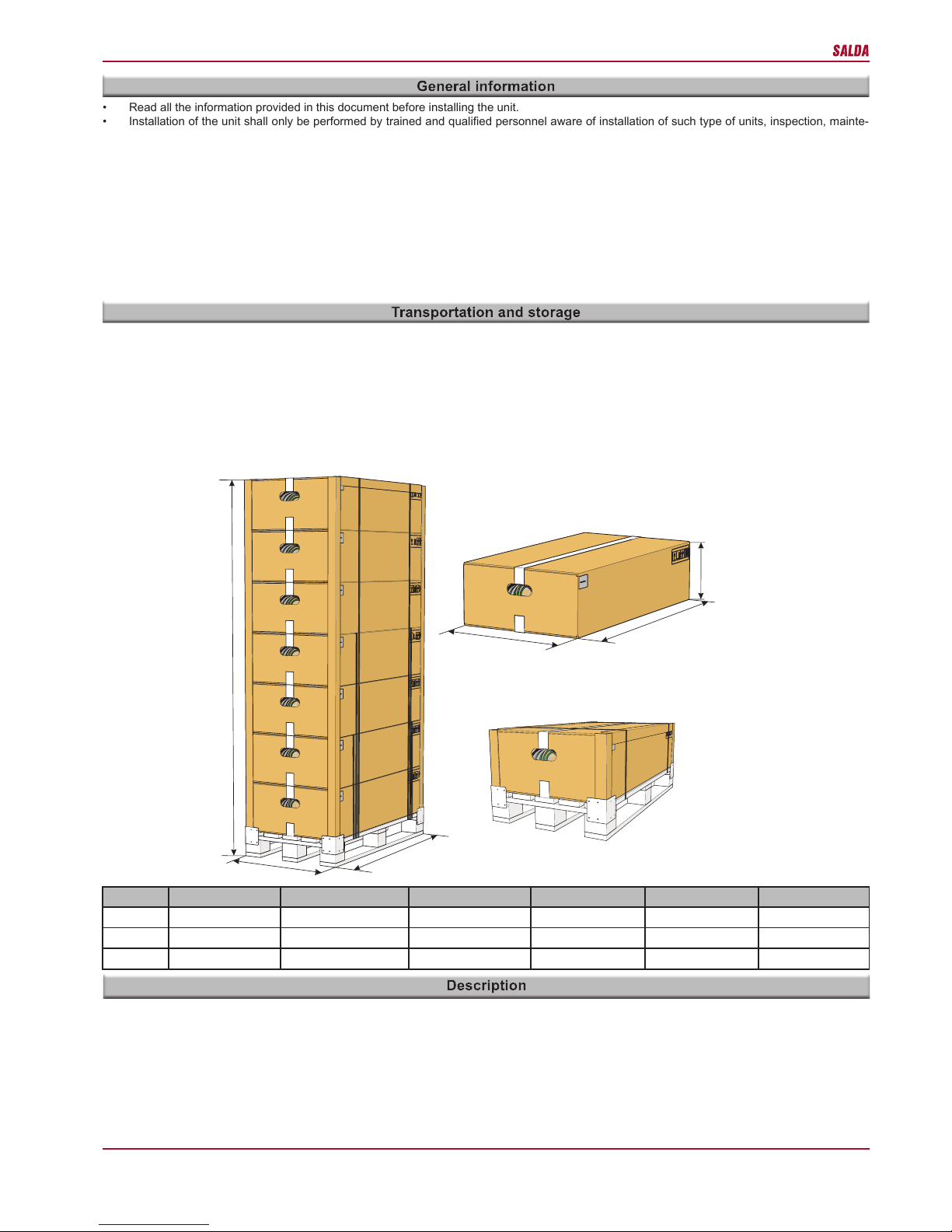

• All units are packed in the factory to withstand regular conditions of transportation.

• Upon unpacking, check the unit for any damages caused during transportation. It is forbidden to install damaged units!!!

• The package is only a protection means!

• At unloading and storing the units, use suitable lifting equipment to avoid damages and injuries. Do not lift units by holding on power supply

cables, connection boxes, air intake or discharge anges. Avoid hits and shock overloads. Before installation units shall be stored in a dry room

with the relative air humidity not exceeding 70% (at +20°C) and with the average ambient temperature ranging between 0°C and +30°C. The

place of storage shall be protected against dirt and water.

• During transportation and storage of the units, the connection anges must be in horizontal position.

• The storage is not recommended for a period longer than one year. In case of storage longer than one year, it is necessary to check free rotation

of bearings before installation (turn the impeller by hand).

• Read all the information provided in this document before installing the unit.

• Installation of the unit shall only be performed by trained and qualied personnel aware of installation of such type of units, inspection, mainte-

nance and tools required for installation works.

• While installing the unit, follow the international and national requirements of mechanical and electrotechnical safety of the country where the

product will be installed and used.

• If the provided information is unclear or any doubts arise regarding safe installation and operation, please contact the manufacturer or its repre-

sentative.

• The unit shall be operated only under the conditions listed below.

• It is strictly forbidden to use the unit for non-designed purposes or in contradiction to the specied working conditions without written permission

of the manufacturer or its representative.

• The manufacturer or its representative shall be notied about any fault, including description of the fault and data specied on the product’s label.

• Any repair or dismantle of the unit in case of fault is forbidden without previous written permission of the manufacturer or its representative.

• Dismantling, repair or modication of the unit shall be performed only upon prior written consent of the manufacturer or its representative.

• The end user shall ensure that the unit is suitable for environmental conditions before ordering and installing the unit.