Salda AmberAir Compact 4 CX P Guide

AIR HANDLING UNIT WITH HEAT RECOVERY SYSTEM

Mounting and installation instructions

Subject to technical modifcation

AmberAir

Compact 4 CX P

AmberAir Compact 4 CX P

2www.salda.lt

Contents

Safety instructions and precautions 3

Information about the product 5

Description 5

Casing 6

Dimensions and weight 7

Technical data 8

Air flow diagram 10

Operating conditions 11

Standard package of components 11

Components 12

Accessories 13

Installation 15

Reception of goods 15

Transportation and storage 15

Unpacking 17

Mounting diagram 19

Place requirements for the equipment 21

Mounting 21

Mounting position 22

Drainage 26

Connection of air duct 27

Connection of accessories 28

Arrangement of controller connections in MCB 28

Arrangement of controller connections in EX1 31

Arrangement of controller connections in EX2 33

Abbreviation in electrical circuit diagrams 36

Electrical external pre-heater 37

External water pre-heater 38

External water cooler 39

External DX cooler 40

Fire protection connection 41

Motorised air dampers 42

CO2 arba RH sensors 43

Unit status indication / mode change / fire alarm inlet / fireplace

function input 44

Connection of the unit to electric network 45

Start-up recommendations 45

System protection 45

Recommendations before the start of the unit (before the final user) 45

Possible faults and troubleshooting 46

Declaration of conformity 47

Notes 48

AmberAir Compact 4 CX P

www.salda.lt 3

Safety instructions and precautions

Device is manufactured in compliance with the following directives:

Machinery Directive, 2006/42/EC;

Low Voltage Directive, EEC 2006/95;

Electromagnetic Compatibility Directive, 2004/108/EC;

Ecodesign Directive, No 1253/2014.

Read this instruction very carefully before installing and using this equipment. Installation, connection and maintenance should be carried out

by a qualifed technician and in accordance with the local rules and legal acts.

The company shall take no responsibility for the injuries suffered by the people or for the damaged property, if the safety requirements are not

followed or the device is modifed without the permission of the manufacturer.

Main safety rules

Danger

• Before performing any electricity or maintenance tasks make sure, that the device is disconnected from the mains, that all

moving parts of the device have stopped.

• Make sure that the fans can not be entered through air ducts or branch openings.

• If you notice liquids on electric parts or connections that bear voltage, stop the operation of the appliance.

• Do not plug the device into the mains, that differs from the one indicated on the label or on the housing.

• Voltage of the mains should comply with the electrotechnical parameters indicated on the label.

• The device should be earthed in accordance with the rules of installation of electric appliances. It is forbidden to turn on and

use unearthed device. Follow the requirements of the device’s labels that indicate Danger.

Warnings

• Connection of electricity and maintenance of the device should be performed only by a qualifed personnel, in accordance with

the manufacturer’s instructions and valid safety requirements.

• In order to reduce the risk during installation and maintenance, suitable protective clothes should be worn.

• Beware of sharp angles while performing installation and maintenance tasks.

• Do not touch heating elements until they haven’t cooled down.

• Some devices are heavy, thus one should be very careful while transporting and installing. Use suitable lifting equipment.

• While connecting electricity to the mains a circuit breaker of suitable size is necessary.

Warning!

• If the device is installed in a cold environment, make sure that all connections and tubes are properly isolated. Intake and

discharge air ducts should be isolated in all cases.

• Openings of the ducts should be covered during transportation and installation.

• Make sure not to damage the heater when connecting the piping of the water heater. For tightening up, use a wrench/spanner.

Before starting the equipment

• make sure, that there are no strange objects inside;

• manually check whether fans are not stuck or blocked;

• if rotary heat exchanger is installed in the device, make sure that it is not stuck or blocked;

• check the grounding;

• make sure that all components and accessories are connected in accordance with the project or provided instructions.

Danger: Fumes

"Salda Antifrost" system uses dis-balancing of the air flow and it may cause negative pressure in premises. Great care should be

taken when using at the same time in premises as another heating appliance what depend on the air in premises. Such

appliances include gas, oil, wood or coal-fred boilers and heaters, freplaces, continuous flow or other water heaters, gas hobs,

cookers or ovens which draw air in from the room and duct exhaust gases out through a chimney or extraction ducting. The

heating appliance can be starved of oxygen, impairing combustion. In exceptional cases harmful gases could be drawn out of the

chimney or extraction ducting back into the room. In this case we strictly recommend to turn off "Salda Antifrost" and use an

external preheater for heat exchanger anti-frost protection (see "Salda Antifrost" function on the Remote controller manual).

AmberAir Compact 4 CX P

4www.salda.lt

Warning – pay attention Additional information

Stick the auxiliary label on the unit (on an easily accessible place) or on the

dashed place of a technical manual in order to keep the important

information about the unit.

STICK HERE

1 – Logo

2 – Internal usage code

3 – Brand name

4 – Technical data

5 – Units number

6 – Web address

Units tested and produced according to EC directives

AmberAir Compact units are Eurovent Certita Certification certified in AHU program.

SALDA – associated member of the Eurovent association (Europe’s Industry Association for Indoor Climate

(HVAC), Process Cooling, and Food Cold Chain Technologies)

AmberAir Compact SD50+ units designed of the VDI 6022 Part 1 guideline (Hygiene requirements for

ventilation and air-conditioning systems and units)

SALDA world like to inform you that based on the Commission Regulation (EU) No 1253/2014 for enforcing

directive 2009/125/EC (hereinafter referred to as ErP diretive), the operational area of certain AHU within

the European Union is regulated by certain conditions

The AHU can only be used within the EU when it meets the requirements of the ErP directive. If certain

AHU doesn’t have CE mark on it, it is strictly forbidden to use it in the EU.

AmberAir Compact 4 CX P

www.salda.lt 5

Information about the product

Description

AmberAir Compact is a compact-class ventilation unit with a heat recovery system. Its technical parameters are provided in the tables below.

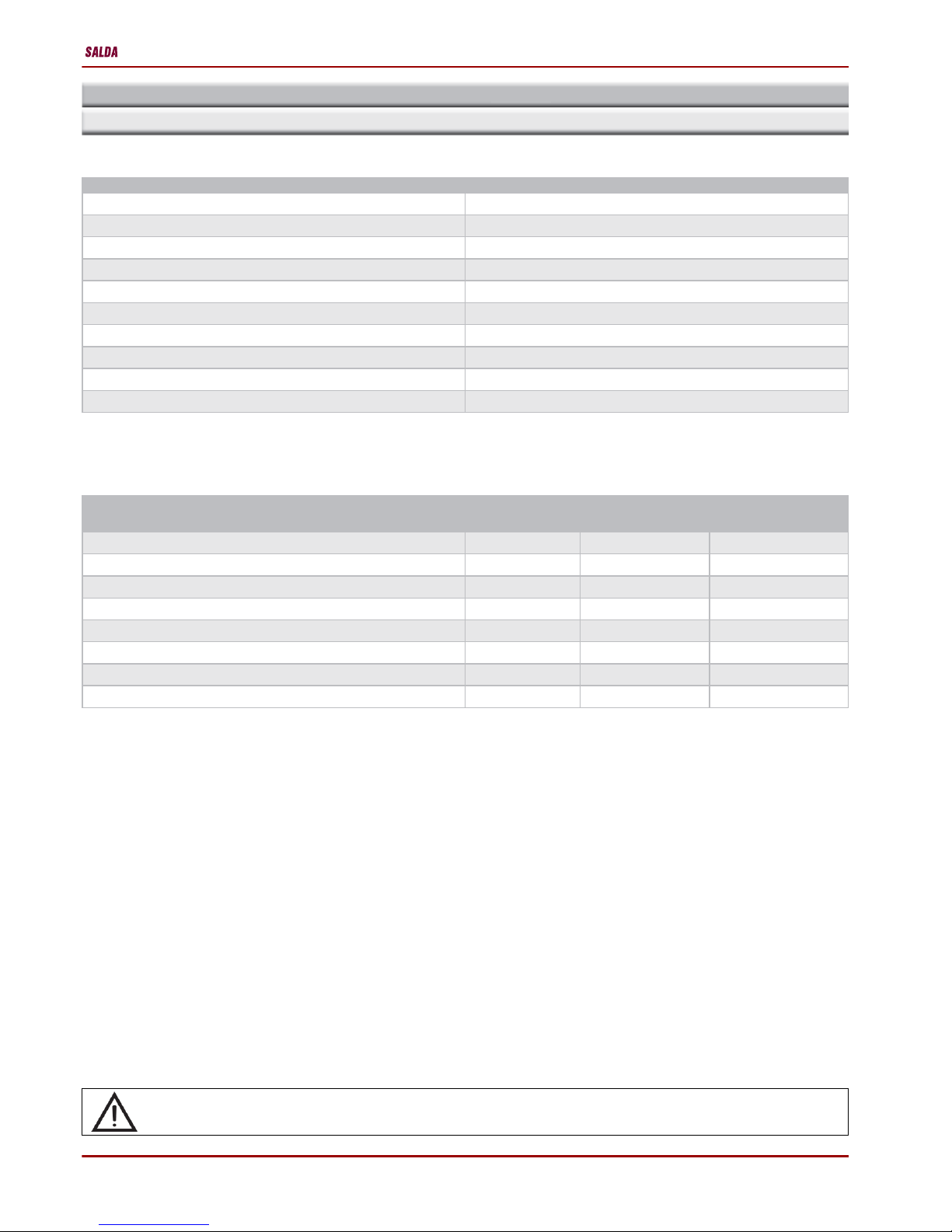

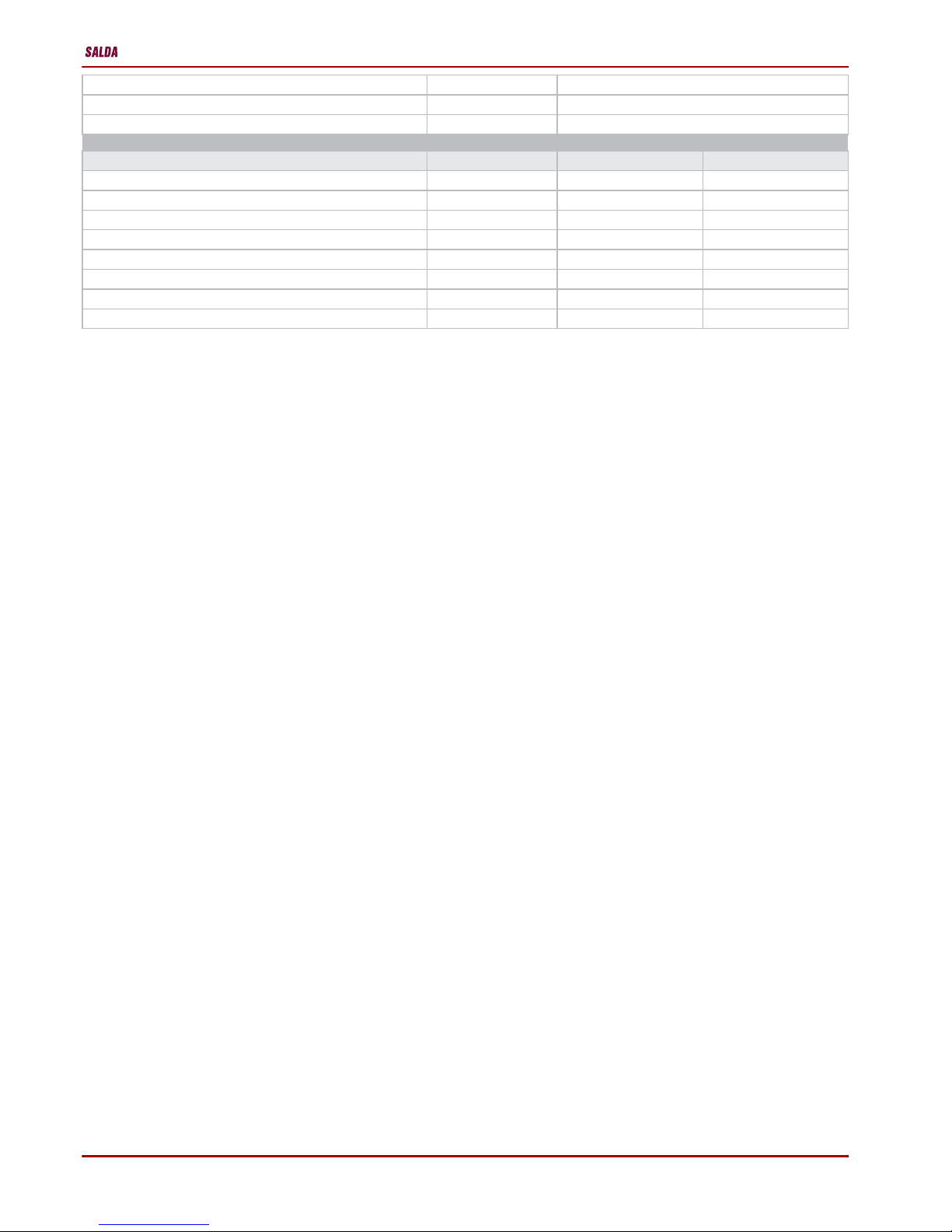

Parameter Value

Model size 4-CXP CD50 LF1B1W1C1P

Heat exchange type Counterflow

Installation type Ceiling

Service side Left

Fan type EC

By-pass damper 100%

Integrated heater Water

Control type Comfort MCB

Filter type Panel

Outdoor installation version Indoor

Selected parameters

Parameter Unit of measurement Value

Winter Summer

Air flow (supply) [m³/h] 2590 2590

Air flow (extract) [m³/h] 2590 2590

External pressure (supply) [Pa] 250 250

External pressure (extract) [Pa] 250 250

Outdoor air temperature [ºC] -10 30

Outdoor air humidity [%] 90 50

Extract air temperature [ºC] 21 24

Extract air humidity [ºC] 50 50

Thank you for purchasing the devices of our company!

Not suitable for swimming pools, saunas and other

similar facilities.

AmberAir Compact 4 CX P

6www.salda.lt

Casing

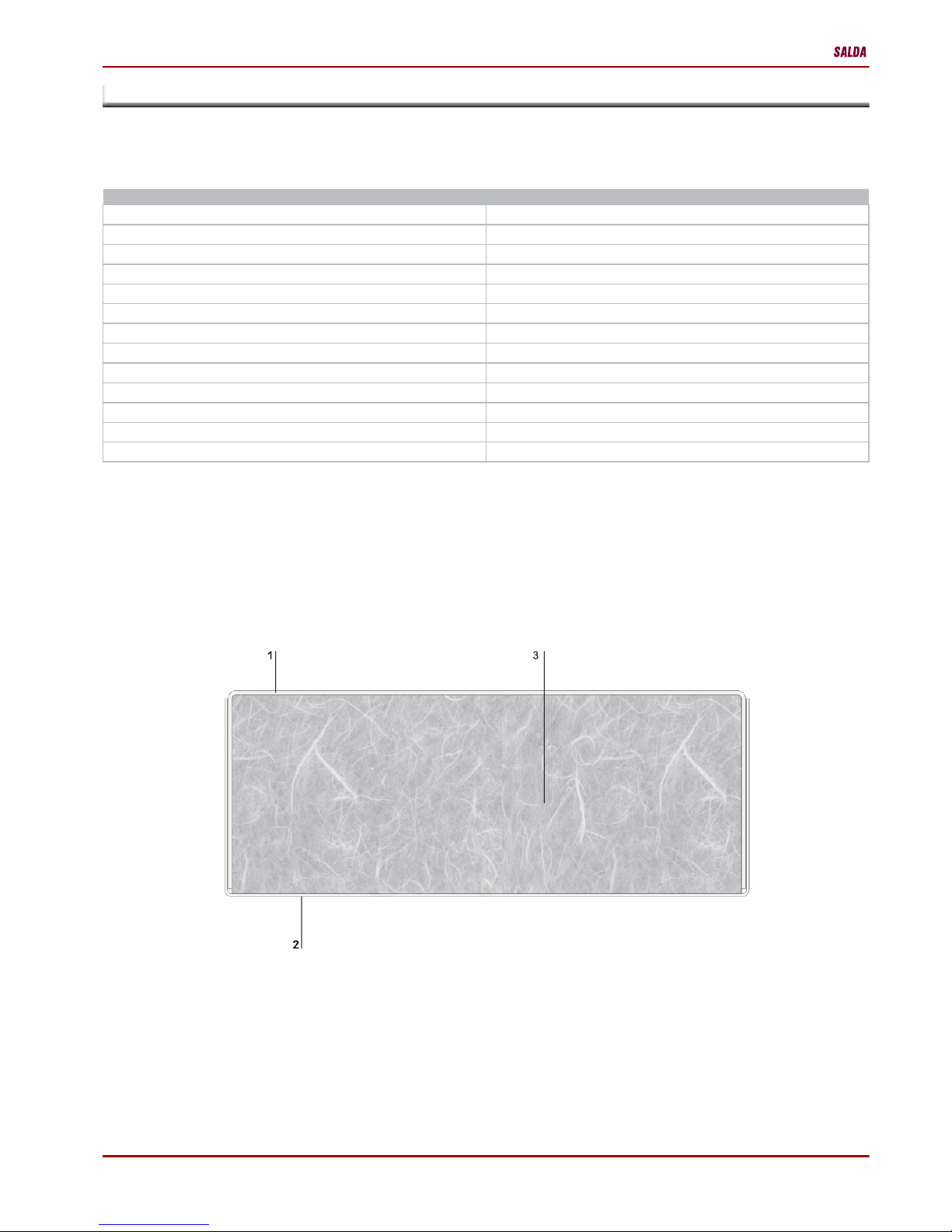

The casing of AmberAir Compact CD50 shows exclusive tightness and thermal characteristics. More detailed information is provided in the tables

below.

EN 1886:2008 parameters

Model box CD50

Casing strength class D2*

Casing air leakage class at - 400 Pa L2

Casing air leakage class at + 700 Pa L3

Filter bypass leakage class F7*

Thermal transmittance class T3*

Thermal bridging factor class TB4

Thickness of double skin panel 50 mm

Insulation material Mineral wadding

Insulation material density 40 kg/m3

Insulation material thermal conductivity 0,036 W/mK

Insulation material fre reaction class (EN 13501-1:2007) A1

External sheet metal thickness and coating options 0,7 mm Zn polyester painting RAL 7040

Internal sheet metal thickness and coating options 0,7 mm Zn

AmberAir Compact CD50 cross-section

1 – external sheet metal; 2 – internal sheet metal; 3 – Mineral wool insulation

AmberAir Compact 4 CX P

www.salda.lt 7

Dimensions and weight

ODA

outdoor air

SUP

supply air

EHA

extract air

ETA

exhaust air

Weight (without package and accessories) [kg] 442

AmberAir Compact 4 CX P

8www.salda.lt

Technical data

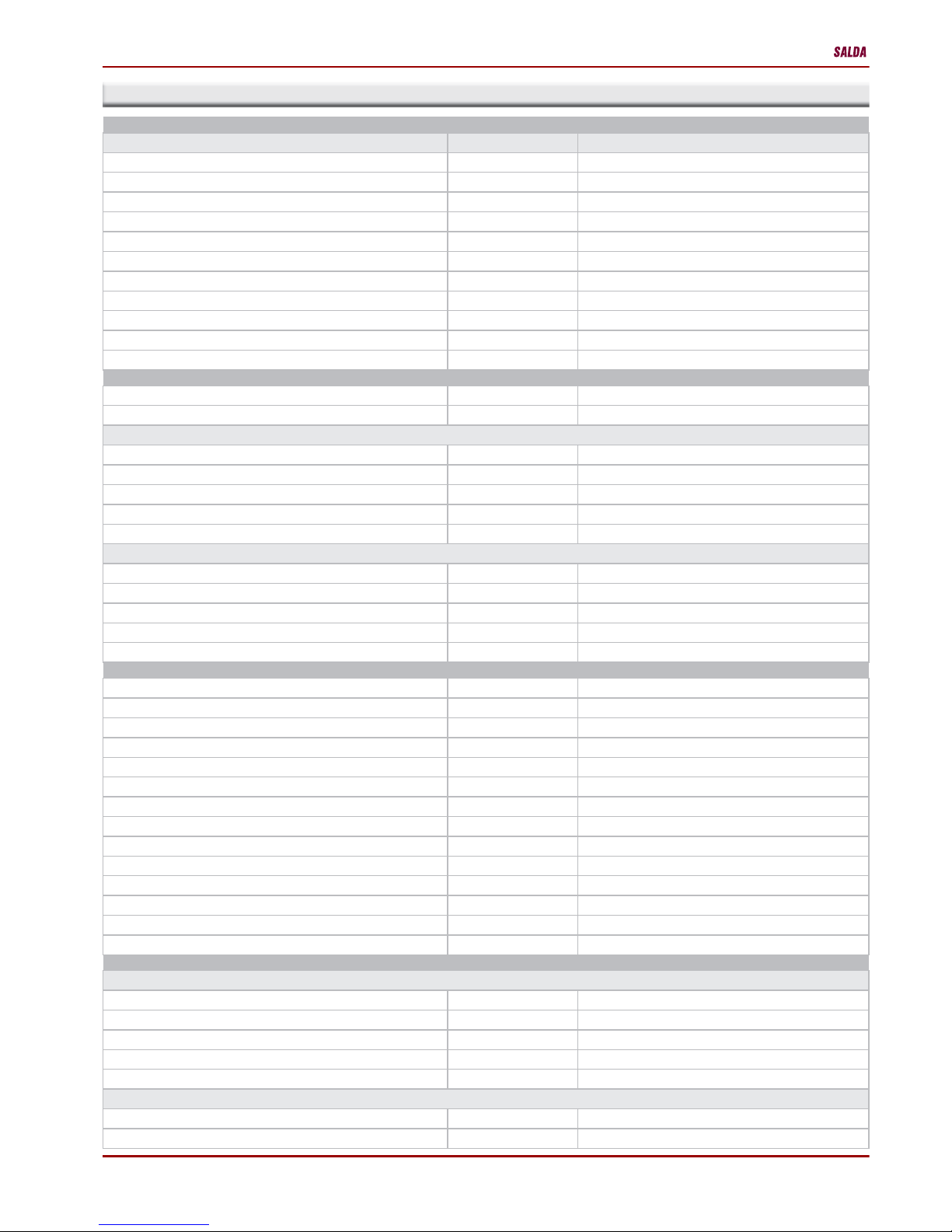

General parameters

Parameter Unit of measurement Value

Thermal input (EN 308) [%] 80.7

SFPv class (clean flters) [ kW/m3/s] 2.22

SFPe class (design load) [ kW/m3/s] 2.49

Energy efciency class (Eurovent 2016) A

System pressure [Pa] 250/250

Maximum external leakage [%] <1

Maximum internal leakage [%] <1

Total power/current consumption [kW/A] 4.65/6.71

Phase/voltage/frequency [f/VAC/Hz] 3/400/50

Control board Comfort MCB

Insulation of walls [mm] 50/30

Fans

Fan type EC

Impeller type Backward curved

Supply air fan

Phase/voltage/frequency [f/VAC/Hz] 3/400/50

Power/current [kW/A] 0.90592/3.5

Speed [min-1]2642

Control input [VDC] 0-10

Protection class IP54

Exhaust air fan

Phase/voltage/frequency [f/VAC/Hz] 3/400/50

Power/current [kW/A] 0.90592/3.5

Speed [min-1]2627

Control input [VDC] 0-10

Protection class IP54

Integrated water heater

Model H-WH-865-390-130-01-11-35-01-L1ZN-1xDN15-S

Air flow [m3/h] 2590

Input temperature [°C] 18.1

Input relative humidity [%] 11.3

Output temperature [°C] 25

Output relative humidity [°C] 6.95

Airspeed [m/s] 2.41

Pressure drop [Pa] 17

Power [kW] 5.99

Water pressure drop [kPa] 7.19

Input water temperature [°C] 70

Output water temperature [°C] 49.3

Water flow [l/s] 0.08

Connection dimensions [mm] 1xDN15

Filters

Supply air flter

Class F7

Width [mm] 1113

Height [mm] 379

Thickness [mm] 46

Model MPL 1113x379x46-F7

Exhaust air flter

Class M5

Width [mm] 1113

AmberAir Compact 4 CX P

www.salda.lt 9

Height [mm] 379

Thickness [mm] 46

Model MPL 1113x379x46-M5

Pressure losses

Assembly Unit of measurement Supply air Exaust air

Heat exchanger [Pa] 93 120

Heater [Pa] 17 -

Filter [Pa] 162 85

Dampers [Pa] 19 -

Total [Pa] 291 205

Total system pressure [Pa] 250 250

Fan pressure losses [Pa] 119 190

Stationary pressure produced by fans [Pa] 541 455

AmberAir Compact 4 CX P

10 www.salda.lt

Air flow diagram

operational limits

power consumption

Supply air

Exhaust air

Table of contents

Other Salda Air Conditioner manuals

Popular Air Conditioner manuals by other brands

CIAT

CIAT Magister 2 Series Installation, Operation, Commissioning, Maintenance

Bestron

Bestron AAC6000 instruction manual

Frigidaire

Frigidaire FFRE0533S1E0 Use & care guide

Samsung

Samsung AS09HM3N user manual

Frigidaire

Frigidaire CRA073PU11 use & care

Soleus Air

Soleus Air GB-PAC-08E4 operating instructions

McQuay

McQuay MCK020A Technical manual

Webasto

Webasto Frigo Top 25 DS Instructions for use

Frigidaire

Frigidaire FAZ12ES2A installation instructions

Mitsubishi Electric

Mitsubishi Electric MSC-GE20VB operating instructions

Mitsubishi Electric

Mitsubishi Electric PLA-M100EA installation manual

Daikin

Daikin Split Sensira R32 Service manual