Contents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Page

1. General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1.1 Notes for the user . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

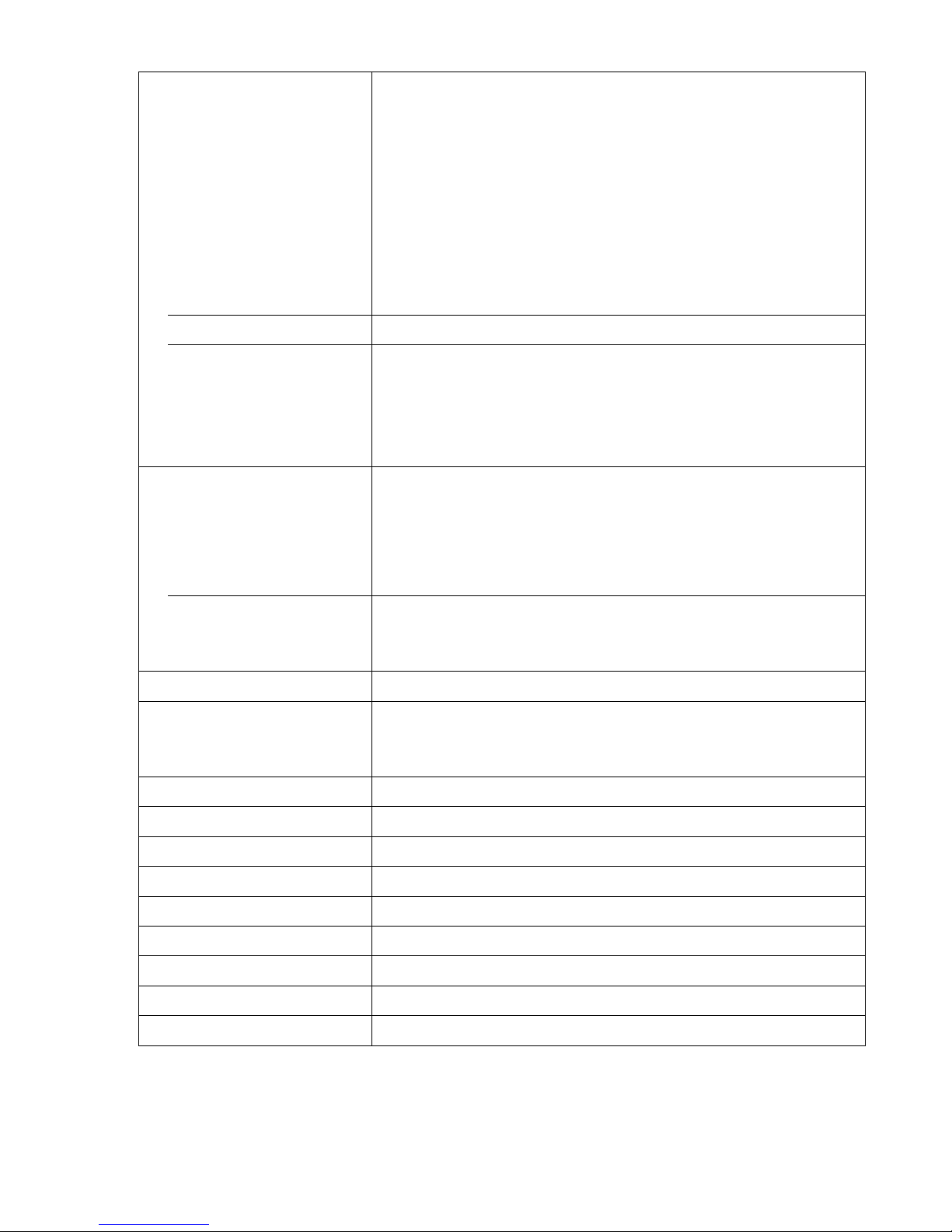

1.2 Te hni al data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.3 Sensor resistan e values . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

. Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

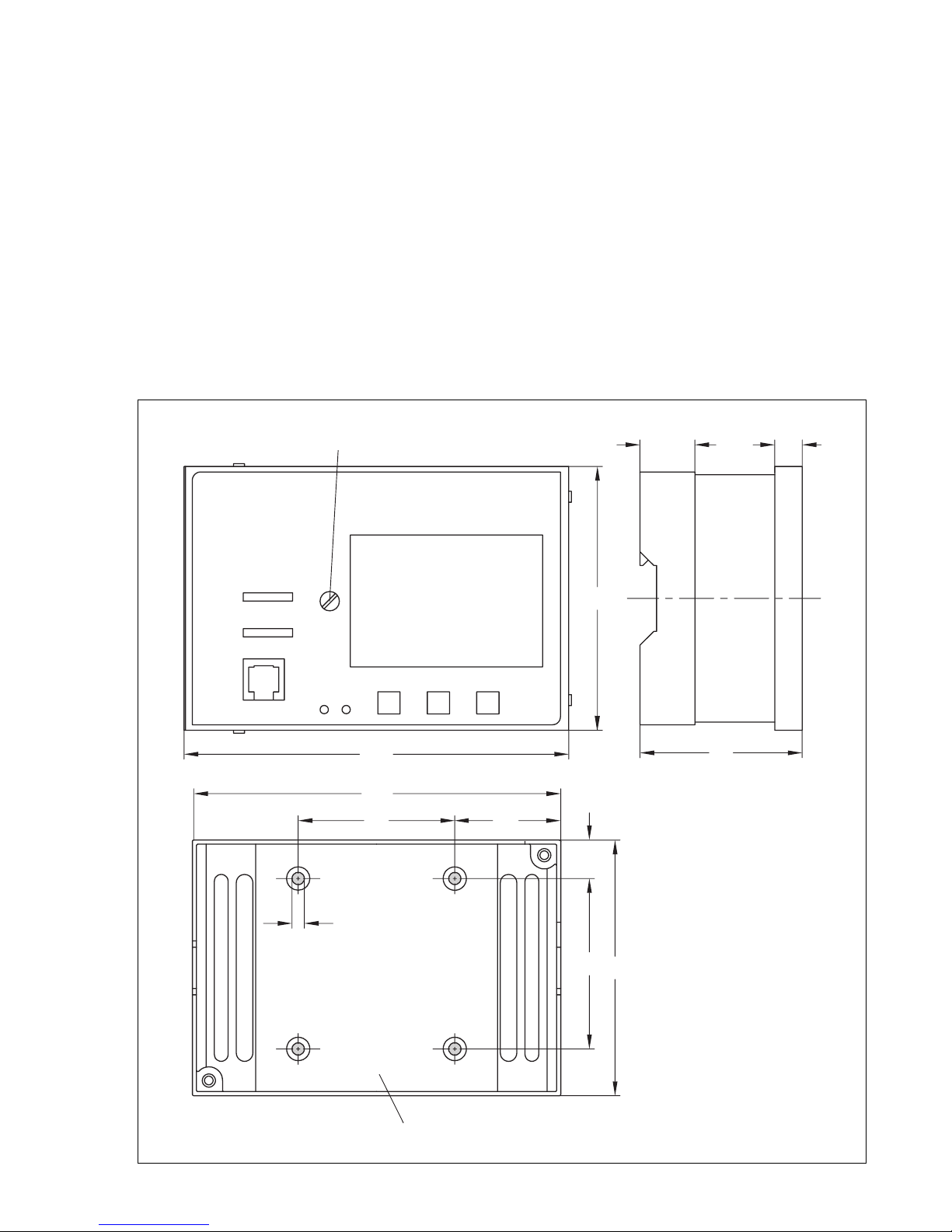

2.1 Installing the ontroller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.2 Installing the sensors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

3. Electrical connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

3.1 General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

3.2 Conne ting the ontroller . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

3.3 Conne ting the sensors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

3.4 Terminal wiring diagrams . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

4. Description of the controller functions . . . . . . . . . . . . . . . . . . . . . . 13

4.1 Optimize . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

4.2 Adaptation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

4.3 Redu ed operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

4.4 Summer time operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

4.5 Automati lo k reset summer time/winter time . . . . . . . . . . . . . . . . . . 15

4.6 Publi holidays and va ations . . . . . . . . . . . . . . . . . . . . . . . . . . 15

4.7 Delayed outdoor temperature adaptation . . . . . . . . . . . . . . . . . . . . 15

4.8 Limitation of the return flow temperature . . . . . . . . . . . . . . . . . . . . . 16

4.9 Limitation of the system deviation for OPEN signal . . . . . . . . . . . . . . . . 17

4.10 For ed harging of the drinking water storage tank . . . . . . . . . . . . . . . . 17

4.11 Thermal disinfe tion of the drinking water storage tank . . . . . . . . . . . . . . 17

4.12 Frost prote tion . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

4.13 Defe tive sensors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

4.14 For ed operation of the pumps . . . . . . . . . . . . . . . . . . . . . . . . . 18

4.15 Limitation of flow rate or apa ity . . . . . . . . . . . . . . . . . . . . . . . . 19

5. System descriptions and diagrams . . . . . . . . . . . . . . . . . . . . . . . 20

5.1 System ode number 1.0 . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

5.2 System ode number 2.0 . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

System ode number 2 .0 with hangeover valve . . . . . . . . . . . . . . . . . 21

System ode number 2.1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

5.3 System ode number 3.0 . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

5.4 System ode number 4.0 . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

System ode number 4 .1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

System ode number 4.2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

5.5 System ode number 5.0 . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

5.6 System ode number 6.0 . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

2