# tsRFG297AB RevC 03/30/2011 2

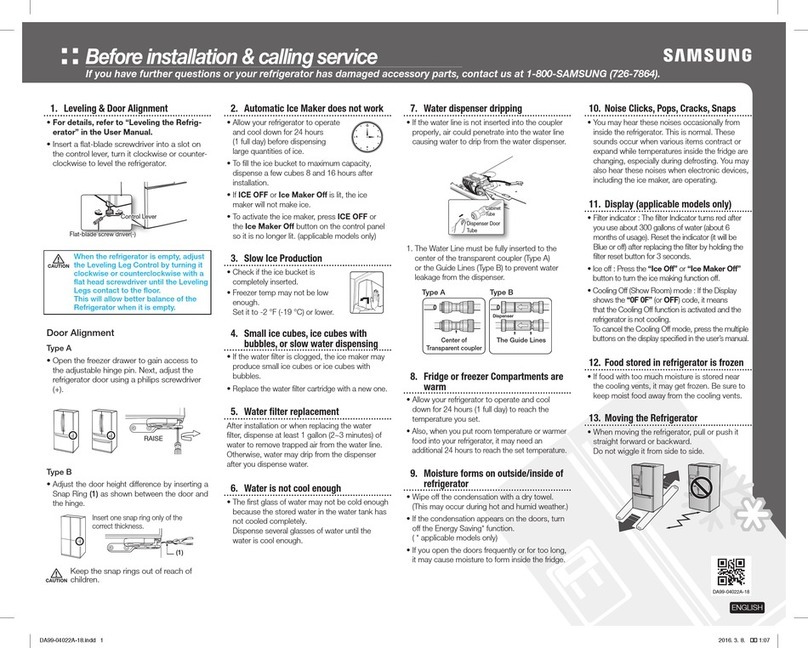

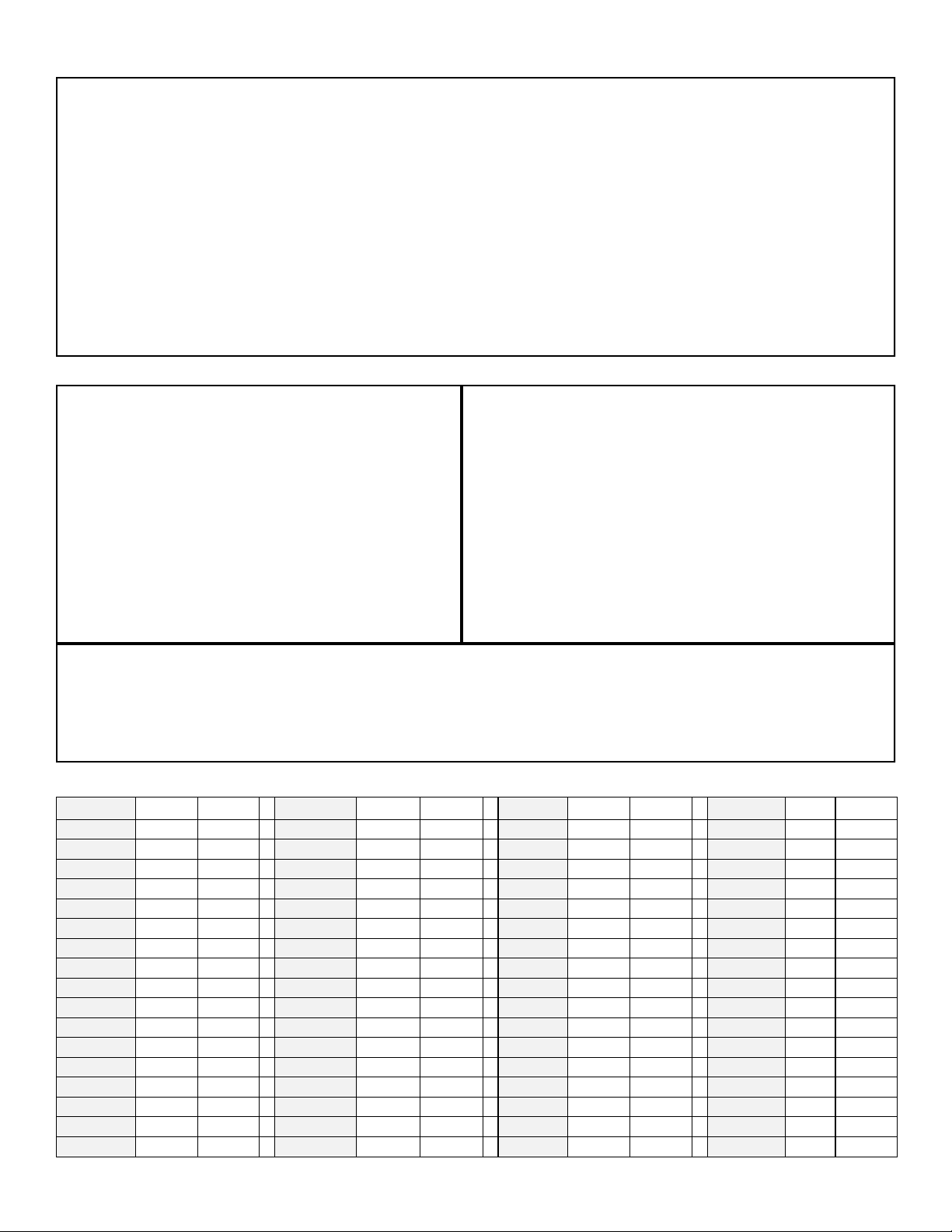

Temperature/Resistance/Voltage Chart for Samsung Refrigerators Sensors

Heat Release I/M Test Mode

Press and hold the ICE TEST S/W for at least 1.5sec, the

harvest function will start. If the ice maker Thermistor is be-

low 0 degrees the Ice maker heater turns on for about 2 min-

utes. If the temperature exceeds 0 degrees, Ice maker

heater turns on for 30 seconds. After the Ice maker heater

turns on for 30 seconds, the heater turns off and then Ice

maker harvest motor turns on. The motor will rotate in right

direction for about 3 minutes, after this, water supply valve is

turned on, then the valve is turned off, the test mode is com-

pleted. If the above operation is not carried out within 6 min-

utes, it will go into a fault mode.

Heat Release Ice production Explanation

38 minutes after the water fill is complete, the control

board will check the temperature of the eject Thermistor,

on the Ice Maker Head, if the Thermistor reads a tem-

perature lower than 18.5 degrees for more than 5 sec-

onds, then the ice production process is completed. The

Ice maker will harvest if the ice bucket is not sensed as

full. If a Fault Mode is detected with the Ice Maker op-

eration, the Ice Maker stops working for 3 hours. Which

means, the Ice Maker checks the operation every 3

hours until it works properly.

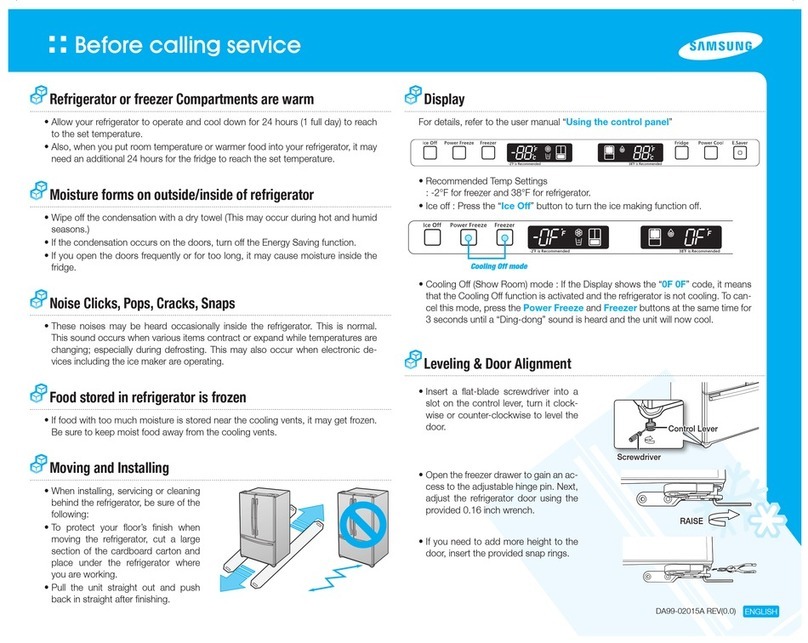

FREEZER TEMPERATURE CONTROL BY THE ICE MAKER

Interior Temperature of the freezer will be set to -14 degrees Fahrenheit until the ice bucket is full. When the ice

bucket is full, the freezer will maintain original set temperature. Also, whenever the ice is used, the freezer will

again set to -14 degrees Fahrenheit. Selecting "Ice Off” will allow the freezer to be controlled by the set tem-

perature. If water is not hooked up, the freezer will always be at –14 unless “Ice Off” is selected.

Temp. (Ω) Volts Temp. (Ω) Volts Temp. (Ω) Volts Temp. (Ω) Volts

-29.2°F 64227 4.326 1.4°F 28021 3.685 32.0°F 13290 2.853 62.6°F 6771 2.019

-27.4°F 61012 4.296 3.2°F 26760 3.64 33.8°F 12749 2.802 64.4°F 6521 1.974

-25.6°F 57977 4.264 5.0°F 25562 3.594 35.6 °F 12233 2.751 66.2°F 6281 1.929

-23.8°F 55112 4.232 6.8°F 24425 3.548 37.4 °F 11741 2.7 68.0°F 6052 1.885

-22.0°F 52406 4.199 8.6°F 23345 3.501 39.2 °F 11271 2.649 69.8°F 5832 1.842

-20.2°F 49848 4.165 10.4°F 22320 3.453 41.0°F 10823 2.599 71.6°F 5621 1.799

-18.4°F 47431 4.129 12.2°F 21345 3.405 42.8°F 10395 2.548 75.2°F 5225 1.716

-16.6°F 45146 4.093 14.0°F 20418 3.356 44.6°F 9986 2.498 77.0°F 5000 1.675

-14.8°F 42984 4.056 15.8°F 19537 3.307 46.4°F 9596 2.449 78.8°F 4861 1.636

-13.0°F 40938 4.018 17.6°F 18698 3.258 48.2°F 9223 2.399 80.6°F 4690 1.596

-11.2°F 39002 3.98 19.4°F 17901 3.208 50.0°F 8867 2.35 86.0°F 4218 1.483

-9.4°F 37169 3.94 21.2°F 17142 3.158 51.8°F 8526 2.301 87.8°F 4072 1.447

-7.6°F 35433 3.899 23.0°F 16419 3.107 53.6°F 8200 2.253 89.6°F 3933 1.412

-5.8°F 33788 3.858 24.8°F 15731 3.057 55.4°F 7888 2.205 91.4°F 3799 1.377

-4.0°F 32230 3.816 26.6°F 15076 3.006 57.2°F 7590 2.158 95.0°F 3547 1.309

-2.2°F 30752 3.773 28.4°F 14452 2.955 59.0°F 7305 2.111 96.8°F 3428 1.277

-0.4°F 29350 3.729 30.2°F 13857 2.904 60.8°F 7032 2.064 100.4°F 3204 1.213

Heat Release Ice Makers

DC FAN MOTORS

Brushless DC Fan motors are used to save energy. The fans operate at two speeds. Fan speed information is read by

the Main PCB. If the fan speed exceeds 600 RPM or the speed is too slow, or stopped the fan drive circuit is disabled,

After 10 seconds the circuit tries again with 3 seconds of DC voltage If the fan continues this activity for 5 cycles, 10

seconds off 3 seconds on, the fan drive circuit is disabled for 10 minutes.

TO TEST THE FAN CIRCUIT VOLTAGE.

Power off and back on to check the DC voltage to the motor, wait from 10 to 60 seconds for the fan voltage to kick in,

and then check fan voltage, the average reading is 9 VDC. If you get 3 seconds of voltage every 10 seconds for the 5

fan power up cycles, then the Main PCB is good.

NOTE: You may need to put unit in FORCED FREEZE mode to activate the fans/compressor.

If the fan blade is blocked by ice, then defrost and check the motor again, after removing power from the unit.

If the evaporator is ice blocked and thus blocking the air flow, the fan will over RPM and is stopped. Remove ice and

check the motor again. If everything is clear around the fan blade then the motor would be at fault. Continuous fan errors

will be displayed on the front panel display. PLEASE NOTE: The door switches control the evaporator fan motors. Have

them closed to test the motors. Delay time 10 –60 seconds.