7

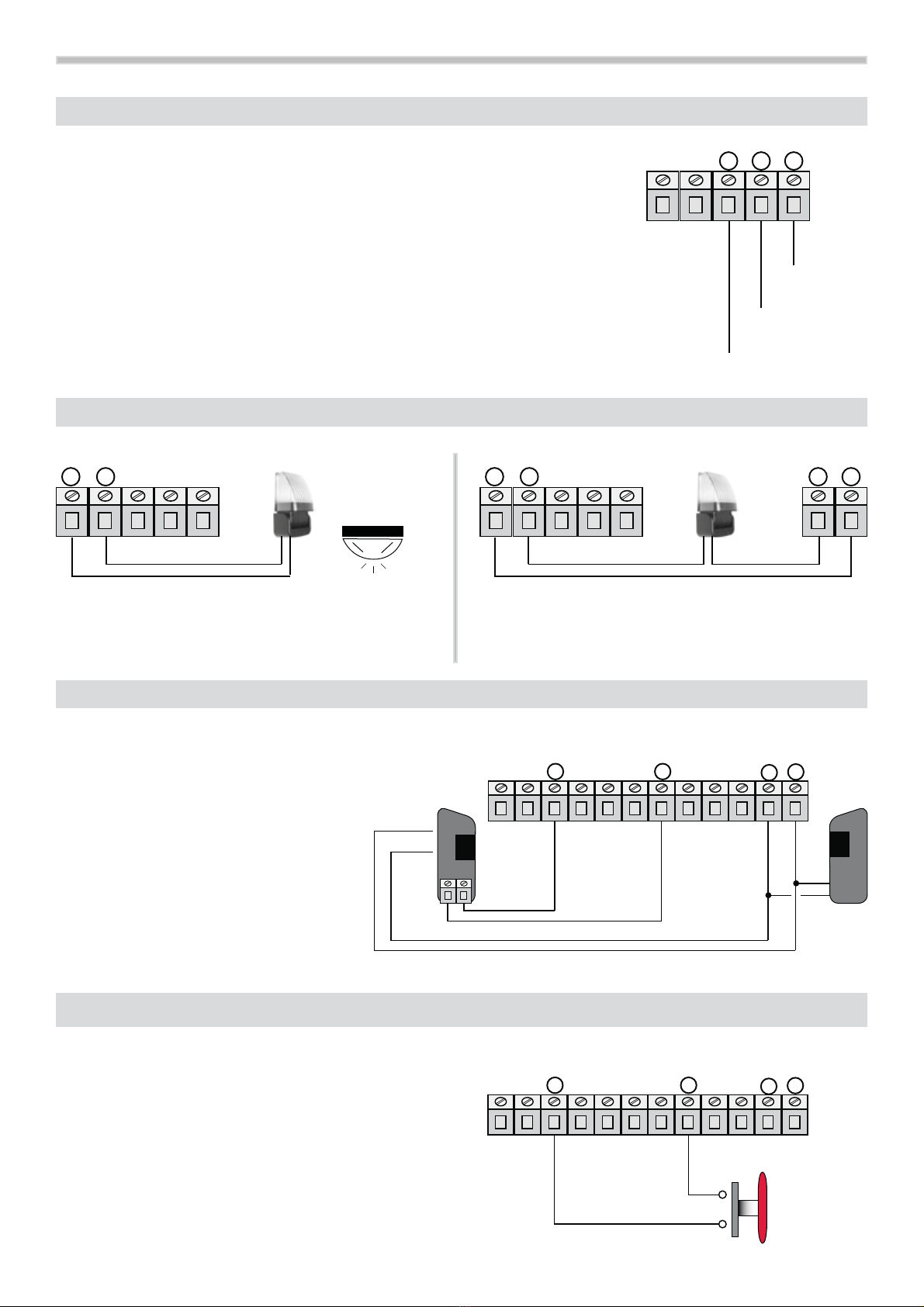

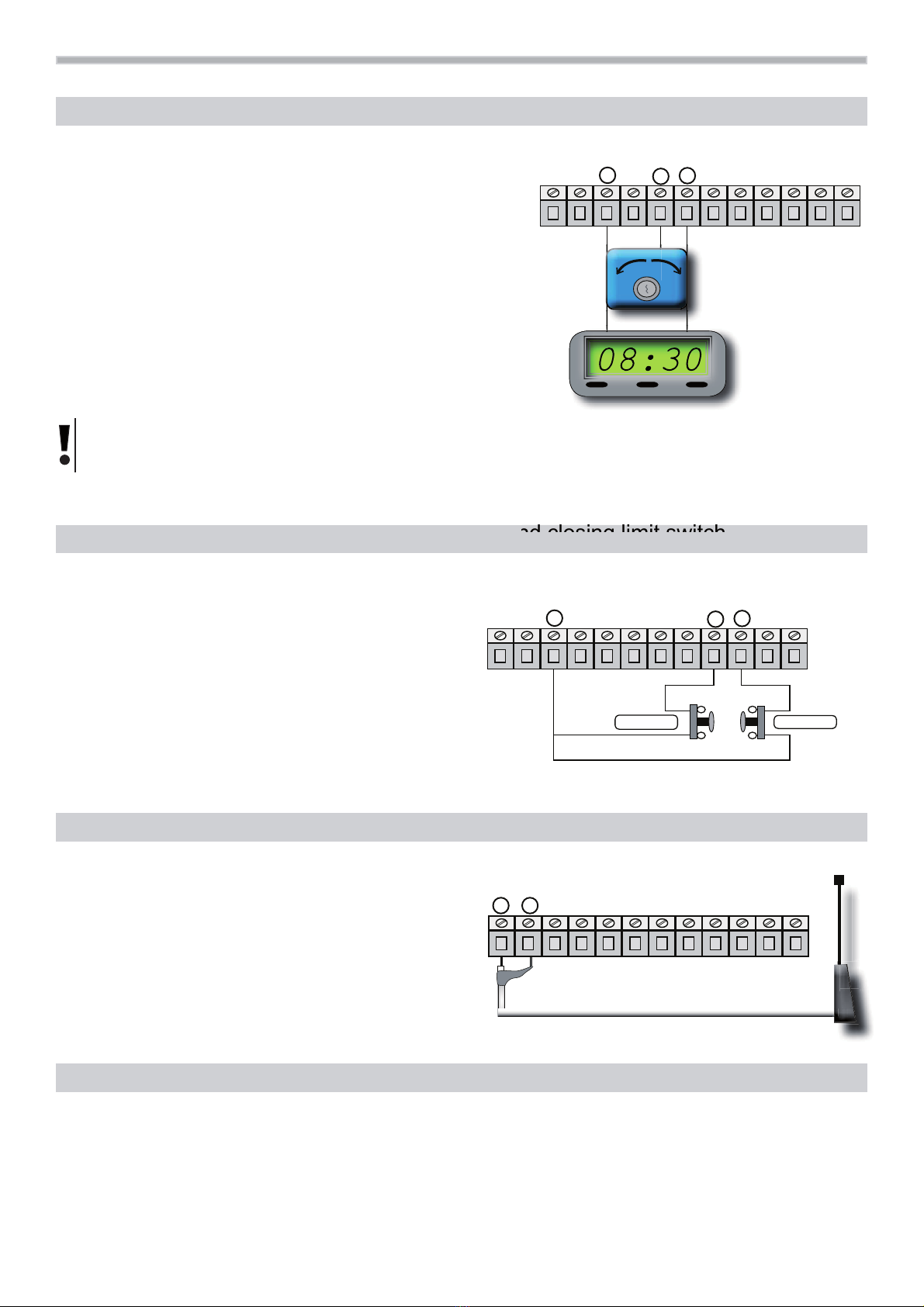

2.05 Connection of the opening limit switches and closing limit switches

OPEN

CLOSE

In the picture the limit switches are shown,

but in this control unit you can use separately.

So you can use for example “Opening limit switch” or

“Closing limit switch”.

The contacts of the limit switches are normally closed.

If the input of the FCA ( opening limit switches)

and FCC ( closing limit switches) are not used,

put the DIP 1 and 2 in ON and exclude FCA and FCC in the DIPA

21 20 19 18 17 16 15 14 13 12 11 10

21 20 19 18 17 16 15 14 13 12 11 10

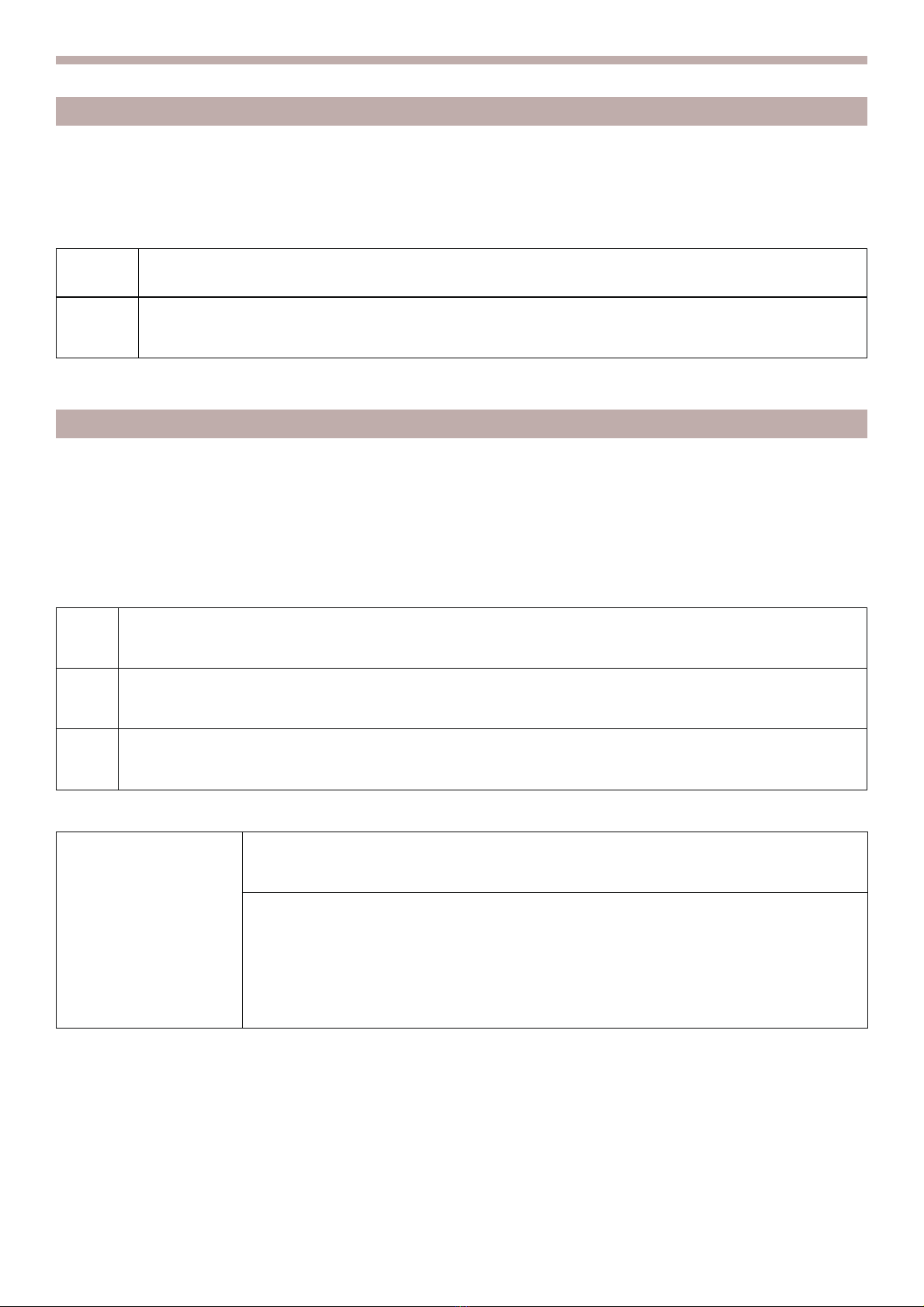

2.06 Connection of the antenna

If you use only a small cable for the antenna,

for the frequency 433.92 Mhz, cut it at 17cm

and connect it to the terminal board no.21

21 20 19 18 17 16 15 14 13 12 11 10

COM.

COM.

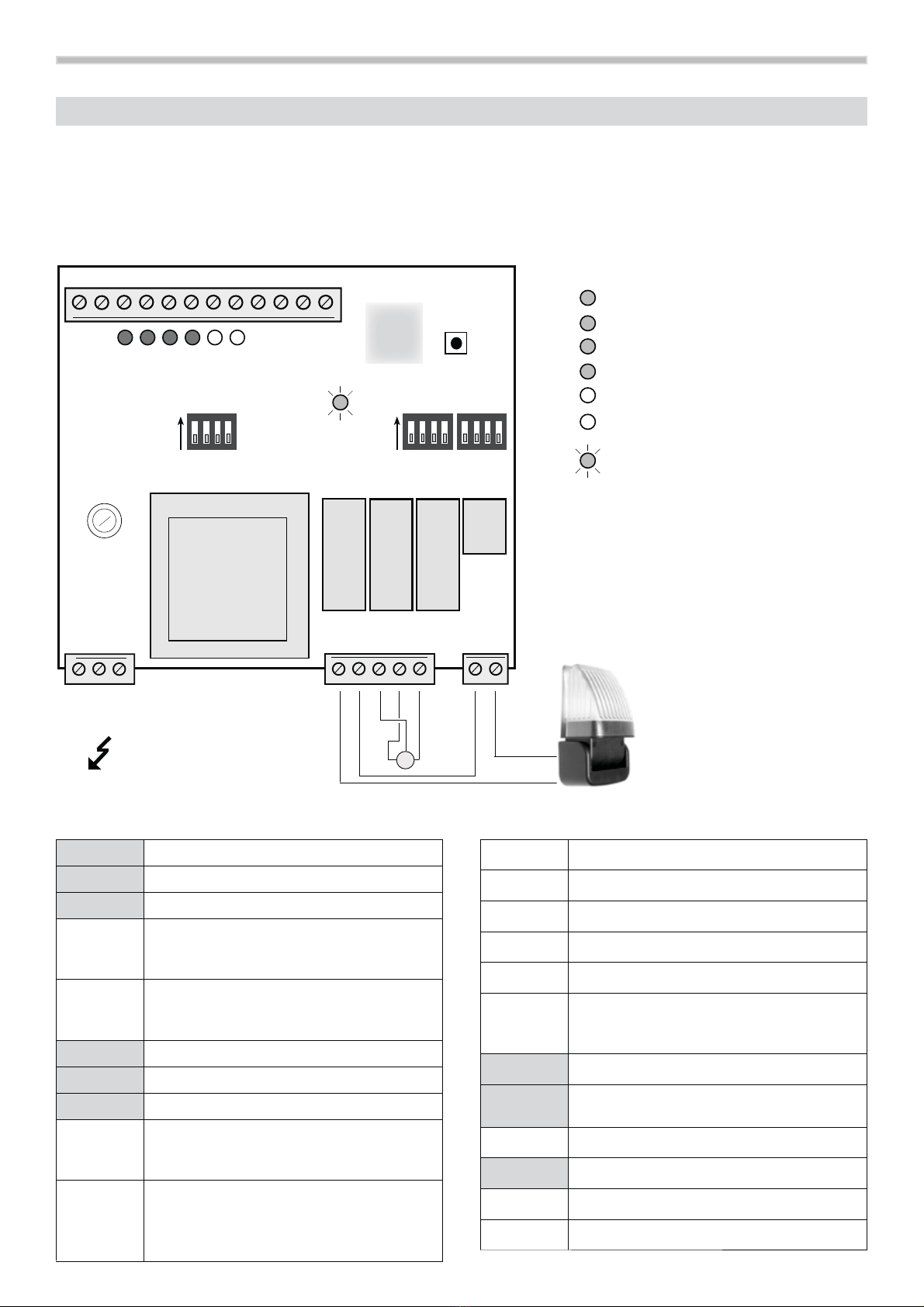

2.07 Check of the connection

Check the exactly tensionin the terminal boards, all NC red l.e.d. should be turned on.

When the control unitis powered , the lights L.E.D. which are in the inputs,are turnedon when there is a closing common contact.

Normally the red led in the inputs STOP-FOTO-FCC –FCA are always turned on.

Normally the green led in the control START – PARTIAL OPENING are turned off.

Look LED L1TEST when correct programmed, should flashes constantly or with a single/double flashing.

Check the safeties, the gate should go in the right direction, it should open firstly.

.

The connection of the opening control START (16-19) or closing (17-19)

can be done with any button or with a normally open contact.

In case of more devices, they should be serial connected.

If you use the terminal board START (16-19) it is possible

to connect a TIMER to program the opening of the gate.

It is possible to use a timer with automatic re-closing or

in step-by-step function (see TIMER WITH STEP-BY-STEP FUNCTION)

The contact of the TIMER should be normally open, and the contact should

be closed when the gate is opening. If the opening connection is available,

the terminal board no.16 should be parallel connected.

TIMER WITH STEP-BY-STEP FUNCTION ( DIP B 1 OFF - 2 ON)

If you connect a timer in the input START ( no.16-no.19), the gate closes when the timer contact is in OFF position (open

contact) but only in case the gate is open and the timer is connected for more than 10 seconds .

2.04 Connection of the control OPENING AND CLOSING