SandenHeatPump–InstallationManual

Page2of36

Contents

Page title..............................................................................................................................1

Contents ..............................................................................................................................2

Introduction..........................................................................................................................3

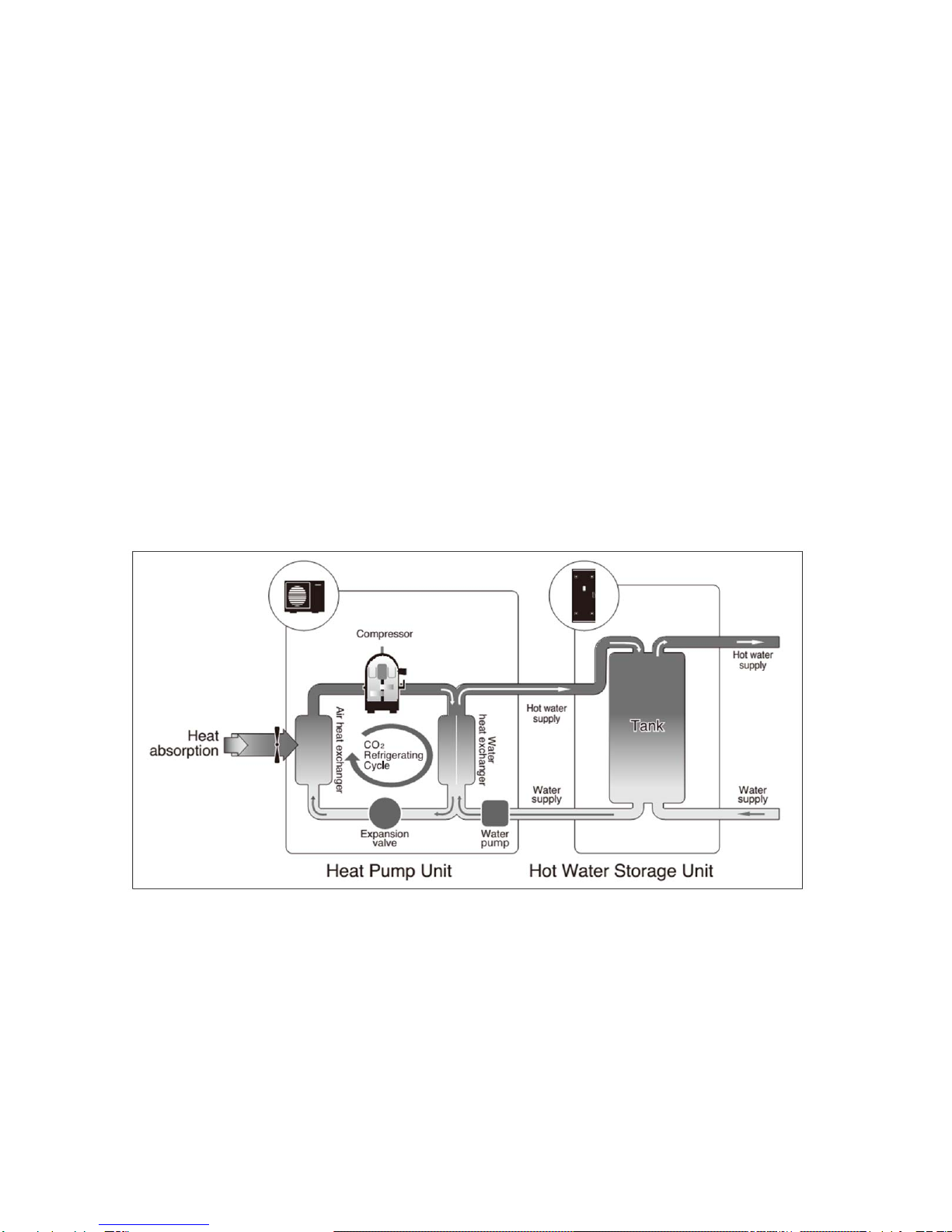

How it works ........................................................................................................................3

Installation details................................................................................................................4

Installation location..............................................................................................................5

Heat pump Unit Installation..................................................................................................6

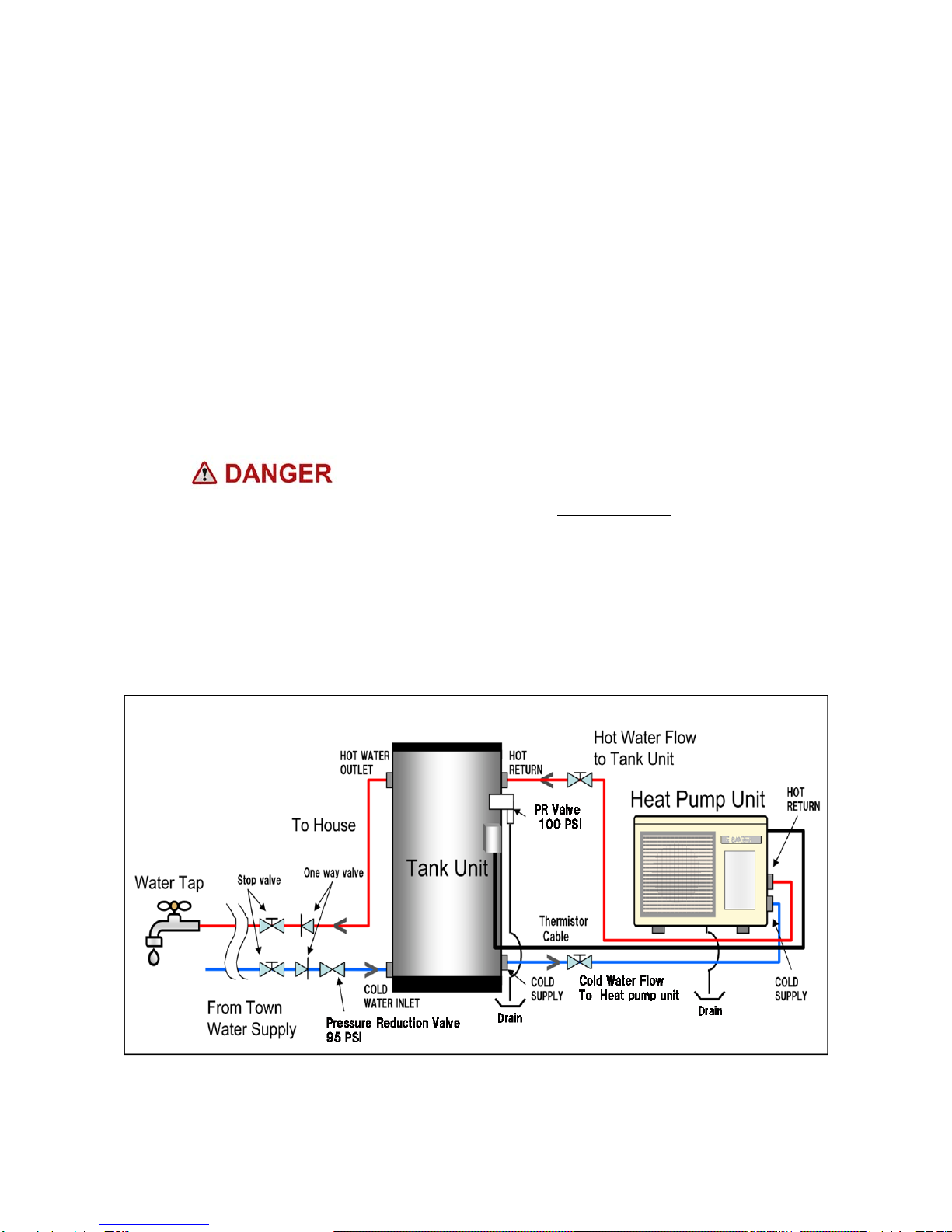

Water Piping Installation – Heat Pump Unit & Tank.............................................................7

Heat Pump Unit Water piping ..............................................................................................9

Mains Power/Electrical Installation ....................................................................................10

Electrical connections........................................................................................................10

How to connect Main Power..............................................................................................10

How to connect Tank thermistor cable to Heat Pump unit.................................................12

System operation using continuous Power Supply............................................................13

System operation if connected to Demand Response Power............................................13

Filling the System & Purging Air ........................................................................................15

Freeze protection...............................................................................................................16

Time setting.......................................................................................................................17

Controller Operation ..........................................................................................................19

Commissioning Mode ........................................................................................................19

How to switch to Commissioning Mode .............................................................................19

Error Codes .......................................................................................................................24

Water Supply Quality (Supplemental)................................................................................26

Change of water supply.....................................................................................................27

Technical data ...................................................................................................................28

Warranty Policy..................................................................................................................32

Warranty period.................................................................................................................33

Check sheet.......................................................................................................................34

Replace controller assembly..............................................................................................35

Memo.................................................................................................................................36

PATENTS

This water heater may be protected by one or more patents or registered designs

in the name of Sanden International (USA), Inc.

TRADE MARKS

® Registered trademark of Sanden International (USA), Inc.

Note: Every care has been taken to ensure accuracy in preparation of this publication.

No liability can be accepted for any consequences that may arise as a result of its application.