SandenHeatPump–InstallationManual

Page2of26

Contents

Contents..............................................................................................................................................................................2

Introduction......................................................................................................................................................................3

Howitworks.....................................................................................................................................................................3

Installationdetails..........................................................................................................................................................4

Installationlocation.......................................................................................................................................................5

Powerrequirement........................................................................................................................................................6

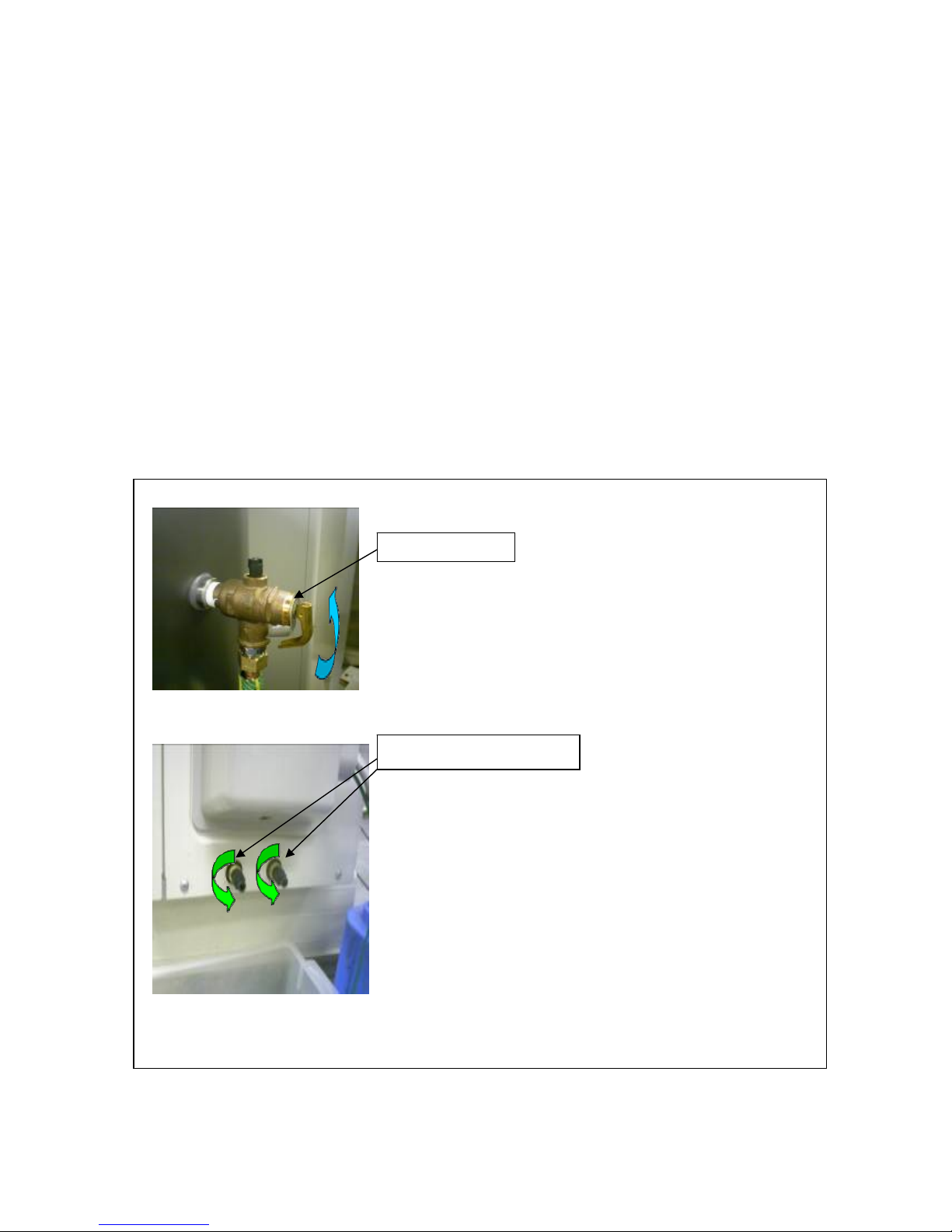

PipingConnections........................................................................................................................................................7

Heatpumpunitpiping..................................................................................................................................................8

Removingairfromthesystem..................................................................................................................................9

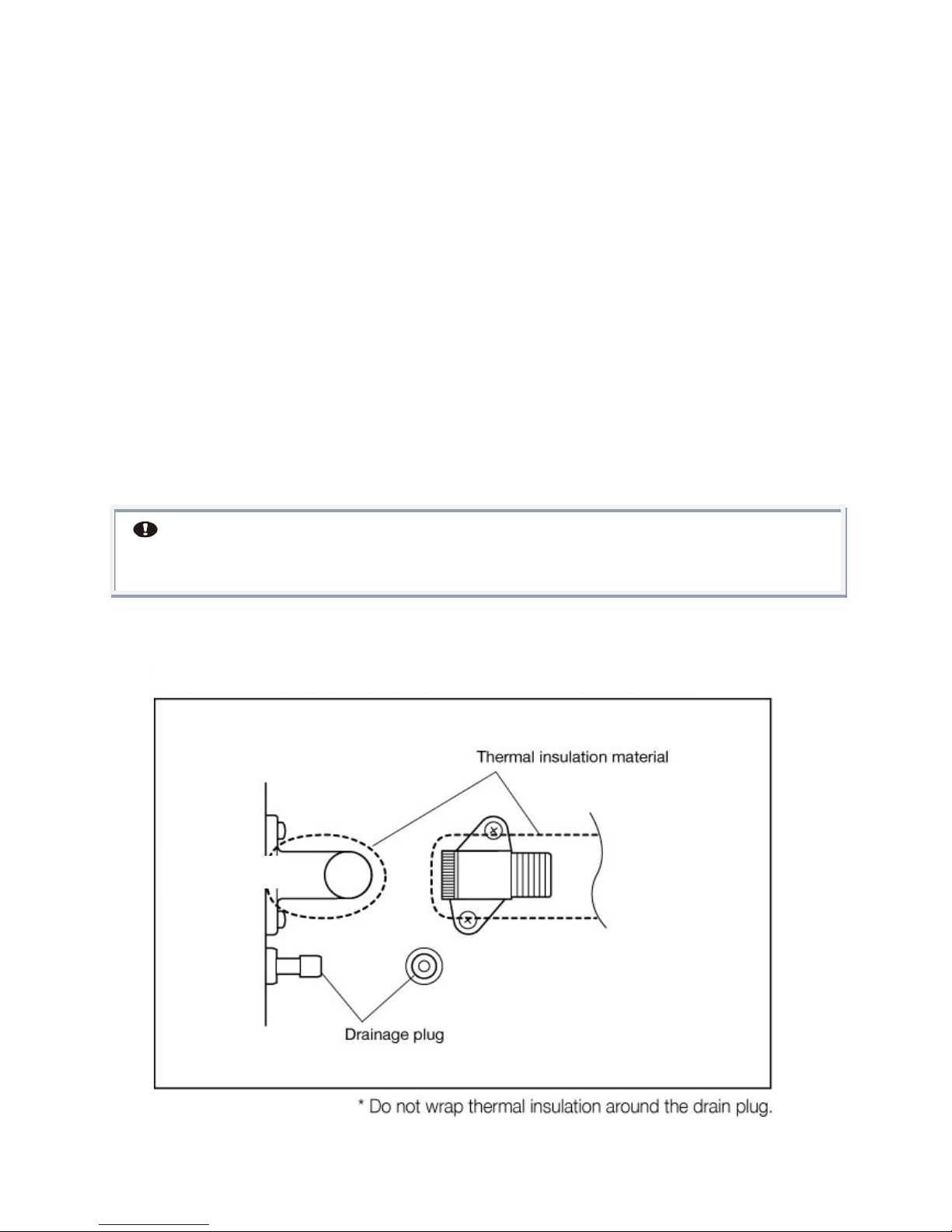

Freezeprotection.........................................................................................................................................................10

Electricalconnections................................................................................................................................................11

Systemoperationoutlinecontinuouspower..................................................................................................11

Systemoperationifconnectedtooff‐peakelectricity.................................................................................11

Howtoconnecttankunitthermistorcable......................................................................................................13

Timesettingandblockouttimesetting............................................................................................................14

Blockouttimesettingmode....................................................................................................................................15

MaintenanceMode......................................................................................................................................................16

HowtoswitchtoMaintenanceMode..................................................................................................................16

ErrorCodes....................................................................................................................................................................17

Changeofwatersupply.............................................................................................................................................19

Dimensionsandtechnicaldata..............................................................................................................................20

WarrantyPolicy............................................................................................................................................................23

WarrantyPeriod..........................................................................................................................................................24

Postinstallationinspectionchecklist.................................................................................................................24

Checksheet.....................................................................................................................................................................25

Memo.................................................................................................................................................................................26

Warranty.........................................................................................................................................................................25

PATENTS

This water heater may be protected by one or more patents or registered designs

in the name of Sanden Australia Pty Ltd

TRADE MARKS

® Registered trademark of Sanden Australia Pty Ltd

.

Note: Every care has been taken to ensure accuracy in preparation of this publication.

No liability can be accepted for any consequences that may arise as a result of its application