S&S Northern Merlin 1000V User manual

Merlin 1000V Product Data Sheet

S&S Northern Ltd 1

Gas Safety Products

Merlin 1000V Gas Proving & Ventilation Interlocking System

Installation, operating and maintenance

13/02/2017

Merlin 1000V Product Data Sheet

S&S Northern Ltd 2

Table of contents

1General information ..........................................................................................3

2Installation .........................................................................................................3

2.1 Panel Mounting...............................................................................................................3

2.2 Mains Supply...................................................................................................................3

2.3 Gas solenoid valve..........................................................................................................3

2.4 BMS Connections. ..........................................................................................................3

2.5 Gas Pressure Transmitter...............................................................................................3

2.6 Timeout Facility...............................................................................................................3

2.7 Remote Emergency Shut Off Buttons.............................................................................3

2.8 CO2/Gas Detected..........................................................................................................4

2.9 FS 123.............................................................................................................................4

2.10 Fan PD Switch. ...............................................................................................................4

2.11 12v DC............................................................................................................................4

2.12 Internal Buzzer................................................................................................................4

3Operation Instructions......................................................................................4

3.1 How to turn the system on and off..................................................................................4

3.2 Explanation of LED status...............................................................................................4

Power LED......................................................................................................................4

Gas on LED.....................................................................................................................4

Testing LED ....................................................................................................................4

Test Fail LED ..................................................................................................................4

Pressure Low LED..........................................................................................................5

Timeout LED...................................................................................................................5

EM Stop LED ..................................................................................................................5

CO2/Gas Detected LED..................................................................................................5

Fan Fault LED.................................................................................................................5

3.3 Using the emergency shut off.........................................................................................5

3.4 BMS integration ..............................................................................................................5

3.5 Fire alarm integration......................................................................................................6

3.6 Fan switch integration.....................................................................................................6

3.7 Gas fill and prove time....................................................................................................6

3.8 Auto reset........................................................................................................................6

1000V Wiring Diagram..............................................................................................7

Merlin 1000V Product Data Sheet

S&S Northern Ltd 3

1 General information

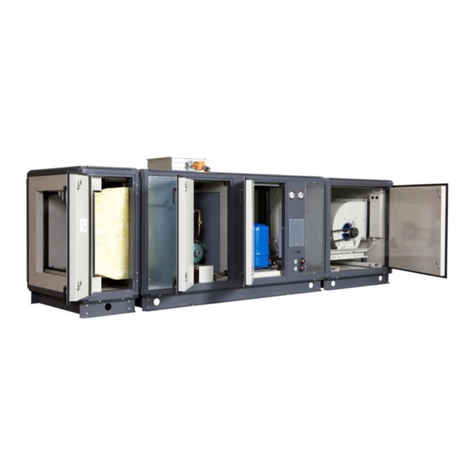

The Merlin 1000V is a gas proving panel with ventilation interlocking.

The system comprises of a control panel and a gas pressure sensor. The Merlin 1000V

can receive connections from remote air pressure differential switches or external current

monitors, remote emergency shut-off buttons, gas detectors and a CO2 monitor. It can also

be integrated with a BMS and fire alarm.

It is recommended that the user reads this guide before using the system. Please do NOT

attempt to operate the unit until the contents of this document have been read and are

thoroughly understood.

2 Installation

2.1 Panel Mounting. The control panel is designed for surface mounting using 4 mounting screws.

Removing the cover on the panel gives access to the circuit board. The PCB should be

removed before drilling entry holes into the case.

2.2 Mains Supply. A 230-volt electrical supply should be supplied to the panel. This should be

externally fused at 3 Amps using a fused spur and should be connected to the terminals

marked ”LNE Power IN”

2.3 Gas solenoid valve. The gas solenoid valve should be powered using the terminals on the

Merlin 1000V marked “LNE to VALVE” and will be internally fused at 3 Amps.

2.4 BMS Connections. Terminal connections are available on the circuit board for connections to

Building Management systems etc. Detailed on the circuit board as “BMS N/C, Com and N/O”

these are volt free connections.

2.5 Gas Pressure Transmitter. The terminals marked pressure sensor “+ - in “.These wire to the

gas pressure transmitter which is screwed into the downstream port on the gas solenoid valve.

Red + positive, Black –negative and Blue IN. Please ensure this is wired as instructed.

Minimum Operating Pressure = 12Mbar

Maximum Operating Pressure = 100Mbar.

2.6 Timeout Facility.The Merlin 1000V has a built-in Auto-shut down feature and it will turn

itself off after predefined time. Auto-shut down timeout is selectable.

There are two blue dip-switches located on the inside facia of the Merlin 1000V

labelled “Time1” and “Time2”. They are factory set in the ‘off’ position. On installation, they can

be switched to the ‘on’ position to select required timeout.

Time1 Off, Time2 Off –2 hours

Time1 On, Time2 Off –4 hours

Time1 Off, Time2 On –8 hours

Time1 On, Time2 On –no timeout (auto-shut down disabled)

On Auto-shut down gas supply will be turned Off.

2.7 Remote Emergency Shut Off Buttons. The terminal for remote emergency shut-off buttons

is detailed on the circuit board as “EM Remote”. These connections are linked out as a

factory setting. Remote emergency shut-off buttons should be volt free and wired to the Merlin

1000V using two-core cable.

Merlin 1000V Product Data Sheet

S&S Northern Ltd 4

2.8 CO2/Gas Detected. The terminals detailed on the circuit board as “Gas Detector”. These

connections are “+,-“ and ” ” these can be wired to a Merlin Natural gas, Carbon monoxide

or LPG detector. This terminal can also be wired to a CO2 monitor to shut off the system in the

event of High CO2 levels. If no detector is being used leave the link in between the “ ”.

2.9 FS 123. This terminal switches 12v when the key is turned on and off. This can be linked to a

fan switch (panel supplied separately) which can provide power to the fans when the control

panel is switched on.

2.10 Fan PD Switch. This terminal is used to receive an input signal from external air pressure

switches or external current monitors. This terminal is linked out as factory setting. Wiring to

the air pd switches & current monitors should be made using a two-core cable and volt free

connections.

2.11 12v DC. This is a permanent 12v DC output when there is power at the panel.

2.12 Internal Buzzer. Operates at 65dB measured 30cm from closed panel.

Note: all low voltage connections should be made using a screened cable to

avoid electrical interference should not be in the same conduit as per the low

voltage directive.

3 Operation Instructions

3.1 How to turn the system on and off

1. Turn off all open appliances.

2. Turn the key switch to on position.

3. To turn the system off, turn the key switch to off position.

3.2 Explanation of LED status

Power LED

When the system is connected to the mains supply, the Red LED of the S&S Logo

located in the bottom right corner of the panel will illuminate. When no power is

present, this LED will not light up.

RED = OK

OFF = No power to 1000V

Gas on LED

When the gas service touch button has been activated the Merlin 1000V will check the

installation for gas leaks. If gas proving is successful, the gas valve will open and the

green ‘Gas On’ LED will illuminate.

GREEN = Gas On

OFF = Gas Off

Testing LED

This LED will illuminate GREEN for approximately 30 seconds when the panel is

checking the integrity of the gas installation upon start up.

GREEN = proving the gas line, do NOT operate any appliances.

Test Fail LED

Under normal working conditions this LED is off. When the panel detects a gas leak

on start-up or incorrect wiring at the gas pressure transmitter the LED will illuminate

AMBER and the gas valve will remain closed.

OFF = OK

AMBER = gas proving failed

Merlin 1000V Product Data Sheet

S&S Northern Ltd 5

Pressure Low LED

Under normal working conditions the LED is off. The LED will illuminate AMBER when

pressure of the gas supply drops below 12mBar for 10 secs. The gas valve will close. (The

system will only go to pressure low from gas on).

OFF = OK

AMBER = gas supply pressure low.

Timeout LED

Under normal working conditions this LED is off. This LED will illuminate AMBER when

auto-shut down has occurred.

OFF = OK

AMBER = auto-shut down

EM Stop LED

If an emergency shut off button (either remote or on the panel) is pressed, the LED will

illuminate AMBER and the gas will be turned off. The EM Stop button must be re-set before

restarting the system.

OFF = OK

AMBER = EM Stop button pressed

CO2/Gas Detected LED

Under normal working conditions this LED is off. If the external Merlin detector/ CO2

connected detects gas this will show RED and the Gas valve will turn off.

OFF = OK

RED = Gas detected / high ppm levels of CO2

Fan Fault LED

Under normal working conditions this LED is off. If a fan fault is present for more than 10

seconds, the LED will illuminate RED. The system will only go into fan fault from gas on.

OFF = OK

RED = the gas supply has been shut off due to a ventilation fault.

WHEN A FAULT IS PRESENT YOU WILL NEED TO CONTACT YOUR

SERVICE/MAINTENANCE COMPANY.

YOU SHOULD NOT ATTEMPT TO CARRY OUT A REPAIR OR RECTIFY THE FAULTS

UNLESS YOU ARE QUALIFIED TO DO SO.

3.3 Using the emergency shut off

The Emergency shut off button is located on the front of the panel.

There is also a facility for remote shut off buttons to be wired in series.

The Emergency shut off button(s) will cut off the gas supply when activated.To

reinstate the system, the Emergency shut off button(s) will need to be reset and the panel

restarted.

3.4 BMS integration

The Merlin 1000V can be integrated with a BMS to make or break a circuit on gas

on/gas off, (valve open or valve closed). This will tell the BMS whether or not the room

has use of the gas supply.

There is a dip-switch located on the inside facia of the Merlin 1000V labelled ‘BMS

Selection’. This is factory set in the ‘off’ position which signals the BMS on gas on/gas

off. When switched to the ‘on’ position, the 1000V will only signal the BMS on a

fault, i.e. CO2 high level detected, gas detected, EM Stop pressed, etc.

Merlin 1000V Product Data Sheet

S&S Northern Ltd 6

3.5 Fire alarm integration

The Merlin 1000V can be integrated with a fire alarm to close the gas supply

automatically in the event of a fire.

The volt free fire alarm signal can be wired in series with any remote emergency shut

off buttons. If there is no remote emergency stop buttons installed wire this directly to

the terminal marked ‘EM REMOTE’

3.6 Fan switch integration

There is the facility to connect a Fan Switch (FS1 or FS2 sold separately).

The Fan Switch provides the facility to turn on the fan(s) when the key switch on the

Merlin 1000V is in the on position and turn the power off to the fan(s) when the

key switch on the Merlin 1000V is in the off position. There is a dip-switch located

inside the facia of the Merlin 1000V labelled EM Selection.

This is factory set in the ‘off’ position which instructs the system to shut down the

fan(s) and gas supply on activation of the Emergency shut off button(s). On

installation, this can be switched to the ‘on’ position if required. This will instruct the

system to leave the fans on and only shut off the gas supply on activation of the

Emergency shut off button(s). Note: This option is not available if Fan Switch is not

installed.

3.7 Gas fill and prove time

Gas fill and prove times are adjustable. There are two dip-switches located on the

inside facia of the Merlin 1000V labelled “Fill Time” and “Prove Time”. They are

factory set in the ‘off’ position. Fill and prove time can be changed by turning the

relevant dip switch to on position.

Fill time: Off –5 secs, On –10 secs

Prove time: Off –30 secs, On –50 secs

Once the settings has been changed, please remove power from the fuse spur for 10

seconds.

3.8 Auto reset

The Merlin 1000V has a built-in auto reset feature. There is a dip-switch located on

the inside facia of the Merlin 1000V labelled “Auto Reset”. This is factory set in the

‘off’ position. When the power is restored after the power cut, the panel has to be

restarted manually. On installation, this can be switched to the ‘on’ position if required.

This will instruct the system to restart automatically when power is restored after the

power cut.

Merlin 1000V Product Data Sheet

S&S Northern Ltd 7

1000V Wiring Diagram

1. Mains Input 230V Single Phase.

2. Gas Solenoid Valve Power Output, 230VAC, Max 3A.

3. This terminal is disabled on this system.

4. This terminal is disabled on this system.

5. Supply Fan PD Switches terminal, this is disabled on this system.

6. Extract Fan PD Switches terminal, this is disabled on this system.

7. BMS output contacts. Normally Closed, Common and Normally Open. Max.1A @ 230VAC.

8. Gas pressure transducer, Red + positive, Black –negative and Blue IN.

9. Remote EM Stop buttons and Fire Alarm input wired in series (purchased separately). VOLT

FREE INPUT

10. Methane, CO or LPG Detector, power supply and volt free input (purchased separately).

CO2 Monitor (purchased separately). VOLT FREE INPUT

11. Fan Switch output (purchased separately). For wiring instruction, see Fan Switch user manual.

12. Fan PD Switches terminal (purchased separately). VOLT FREE INPUT

13. Permanent 12VDC output when there is power at the panel.

Please note, Mains wires and low voltage wires should

not be run in the same conduit as per the LOW

VOLTAGE DIRECTIVE

1

2

5

3

6

7

8

9

10

11

L

N

E

Gas Valve

Pressure

Transducer

EM

Stop

Gas Detector/

CO2 Monitor

3

4

5 6 7 8 9 10 11 12 13

PD Switches or Current Switches

(Volt Free)

F

A

N

P

D

S

W

I

T

C

H

Merlin 1000V Product Data Sheet

S&S Northern Ltd 8

CONTACT US:

S&S Northern Head Office

Tel: +44(0) 1257 470 983

Fax: +44(0) 1257 471 937

www.snsnorthern.com

info@snsnorthern.com

South East Division

Tel: +44(0) 1702 291 725

Fax: +44(0) 1702 299 148

south@snsnorthern.com

Rev

Date

Author

Description

01

13/02/2017

S&S Northern

BT

Merlin 1000V Product Data Sheet –First issue

S&S Northern is the owner of this document and reserves all rights of modification without prior notice.

Table of contents

Other S&S Northern Fan manuals

Popular Fan manuals by other brands

Vortice

Vortice VORT PRESS 110 LL Instruction booklet

Cellini

Cellini CMF75 instruction manual

Stanley

Stanley ST-12F-E User's manual and operating instructions

M&G

M&G Duravent Duratech Canada HT Installation and operation instruction

Ellington

Ellington MXW36ABZ5 installation guide

Hunter

Hunter 20168 Parts guide

Monte Carlo Fan Company

Monte Carlo Fan Company 5LLR56 Owner's guide and installation manual

Vents

Vents TwinFresh Comfo RA1-25 user manual

Dimplex

Dimplex DCTF96WT instruction manual

Monte Carlo Fan Company

Monte Carlo Fan Company 5BUR52XXD Series owner's manual

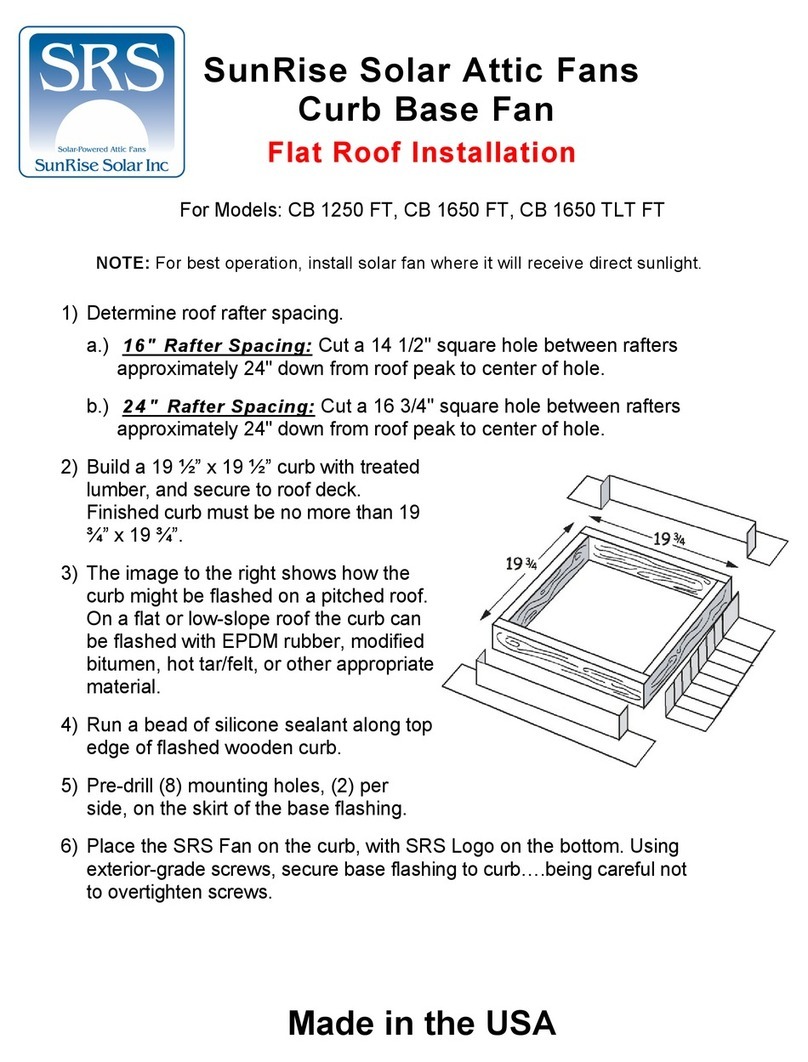

SRS Labs

SRS Labs CB 1250 FT Installation

Maico

Maico DPK 50 EC Operating instruction