CONTENTS

Copyright / Disclaimer - SANIFOS®Installation and Maintenance

Manual - Original operating instructions.

All rights reserved. The contents of this document must not be

reproduced, modified or disclosed to third parties except upon written

consent from the manufacturer.

This document may be subject to change without notice.

SFA - 41 Bis Avenue Bosquet - 75007 PARIS

1. SAFETY....................................................................... pg.1

1.1 Identifying the warning signs ............................................ pg.2

1.2 General information ........................................................ pg.2

1.3 Intended use.................................................................... pg.3

1.4 Qualification and training of staff....................................... pg.3

1.5

Safety instructions for maintenance,inspection and installation

. pg.3

1.6 Consequences and risks of non-compliance......................... pg.4

with the operating manual

2. TRANSPORT / TEMPORARY STORAGE

RETURN / DISPOSAL.................................................... pg.4

2.1 Receiving inspection......................................................... pg.4

2.2 Transport ........................................................................ pg.4

2.3 Temporary storage / Packaging......................................... pg.5

2.4 Return ............................................................................ pg.5

2.5 Disposal at the end of life ................................................. pg.5

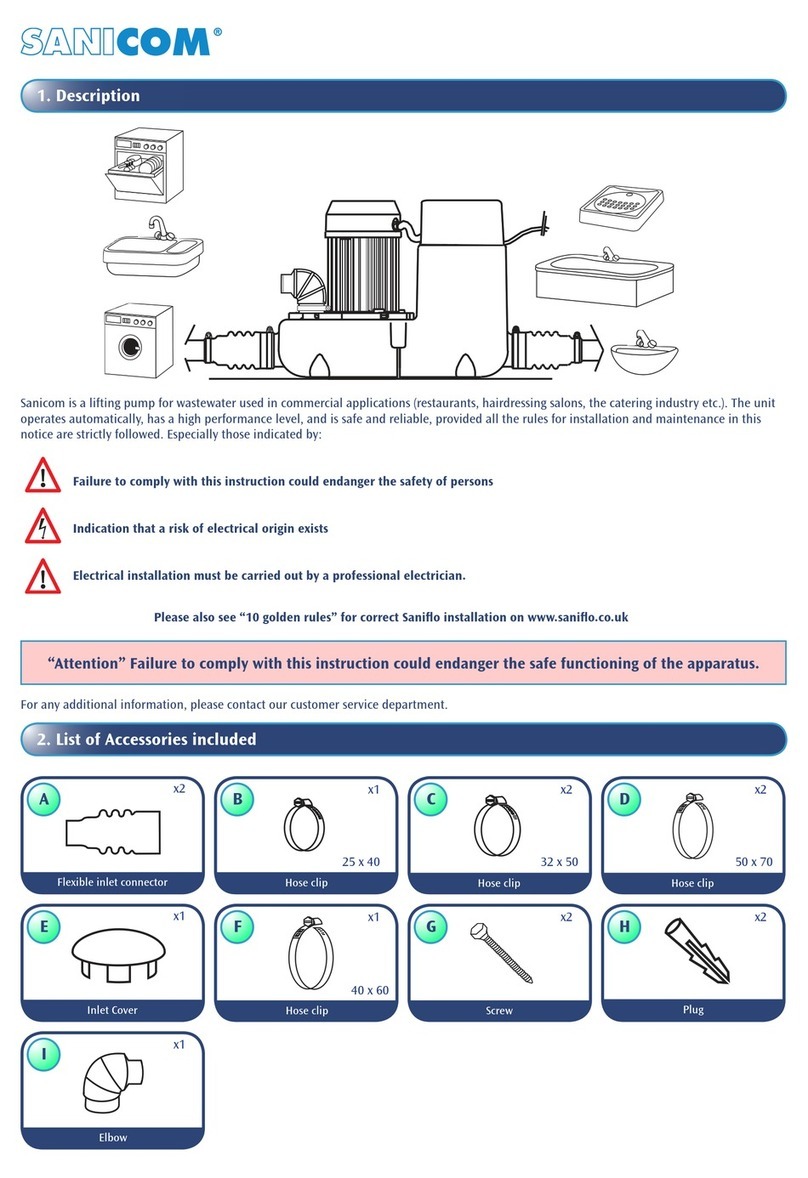

3. DESCRIPTION ............................................................ pg.5

3.1 General description.......................................................... pg.5

3.2 Scope of supply ............................................................... pg.6

3.3 Rating plate..................................................................... pg.7

3.4 Design and operating mode .............................................. pg.7

3.4.1

SANIFOS

®

110 P, SANIFOS

®

280, SANIFOS

®

610 (1 pump)

. pg.7

3.4.2 SANIFOS®610 (2 pumps) and SANIFOS®1300........... pg.7

3.4.3 Technical specifications .............................................. pg.8

3.4.4 Pump curves ............................................................. pg.9

3.4.5 Product dimensions................................................... pg.10

3.5 Sump tank..................................................................... pg.12

3.6 Noise level.................................................................... pg.12

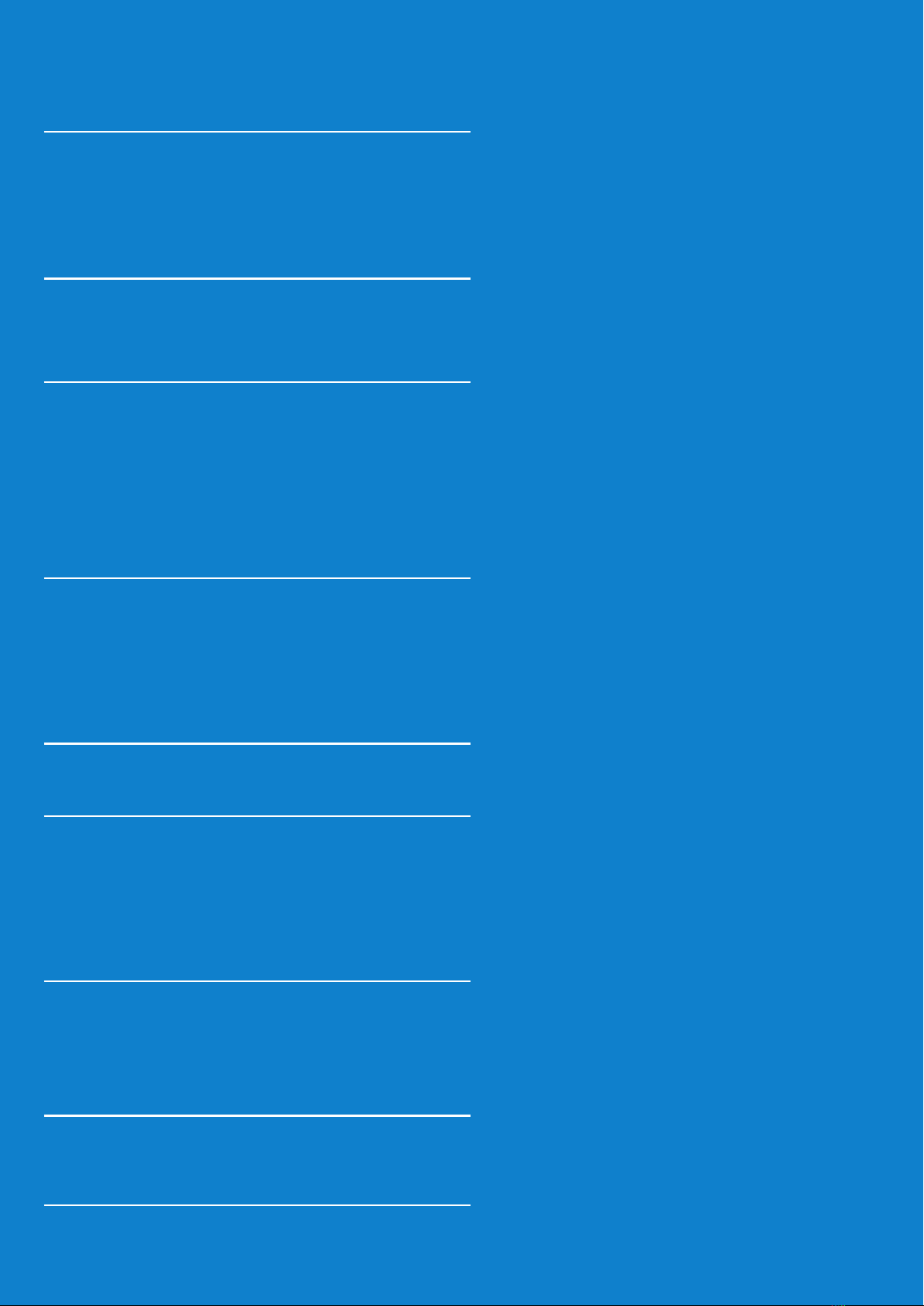

4. PREPARATION OF THE TANK ...............................pg.12

4.1 Preparation for the water inlet pipe ................................. pg.12

4.2 Installation of the pump in the tank .................................. pg.12

4.3 Electrical wiring ............................................................ pg.13

4.3.1 Wiring of pumps and floats ...................................... pg.13

4.3.2 Cable Output ......................................................... pg.15

4.4 Installing the tank cover ................................................. pg.16

4.5 Ventilation .................................................................... pg.16

4.6 Discharge hole ............................................................. pg.17

4.7 Water inlet holes ........................................................... pg.17

5. INSTALLATION / ASSEMBLY ................................pg.17

5.1 Installing the pumping station, floor-standing.................. pg.18

5.2 Installing the pumping station, underground ..................... pg.18

5.3 Adjusting the height of the cover to the ground ................. pg.20

6. SMART CONTROL BOX..........................................pg.21

6.1 Electrical characteristics of the control unit ........................ pg.21

6.2 Technical characteristics of the detection device ................. pg.21

6.3 Dimensions of the SMART remote control box .................... pg.22

6.4 Transport ...................................................................... pg.22

6.5 Connecting the control unit ............................................. pg.22

6.6 Using the SMART Control unit ......................................... pg.24

6.7 Option of connection to an external alarm ....................... pg.26

6.8 Remote wireless alarm box ............................................. pg.27

(delivered with SANIFOS®610 and SANIFOS®1300)

7. COMMISSIONING ..................................................pg.27

7.1 Prerequisites for commissioning........................................ pg.27

7.2 Application limit............................................................. pg.27

7.3 Starting and stopping .................................................... pg.28

7.4 Starting frequency ......................................................... pg.28

7.5 Commissioning with the control box ................................. pg.28

7.6 Operations required for commissioning ............................ pg.28

7.7 Decommissioning ........................................................... pg.29

8. MAINTENANCE .......................................................pg.29

8.1 General information / Safety instructions .......................... pg.29

8.2 Maintenance and inspection operations............................ pg.29

8.3 Maintenance contract ..................................................... pg.30

9. CHECKLIST FOR COMMISSIONING /

INSPECTION (1) AND MAINTENANCE (2)

......................pg.30

9.1 Checklist for commissioning SANIFOS®............................ pg.30

9.2 Checklist for maintenance of SANIFOS®........................... pg.31

Glossary

Clearance

The clearance is the space that needs to be provided for

interventions.

Discharge piping

Piping for raising wastewater above the back-flow level routing

it to the sewer.

Dual station

Pumping station for wastewater equipped with a second pump of

the same power that starts automatically when needed.

Effective volume

Volume to be discharged between the start level and the stop

level.

EN 12050-1

Current European standard for pumping stations for effluents

containing faecal material intended for discharge below the

back-flow level in buildings and on land.

Inlet piping

Line through which wastewater from sanitary fixtures is routed to

the pumping station.

ND (NOMINAL DIAMETER)

Parameter used to characterise parts that are suitable for each

other, for example: pipes, connections, sleeves.

Noise level

Expected sound emissions, expressed in sound pressure level

LpA in dB(A).

Pumping station for wastewater

Facilities for the automatic collection and pumping of

wastewater and blackwater above the back-flow level.

Separator

Equipment which prevents, by gravity, the penetration of

harmful substances into the discharge system by separating

them from wastewater, for example: grease trap.

Ventilation pipe

Ventilation duct limiting pressure variations inside the

wastewater pumping station. The pumping station must be

ventilated from above the roof (when it is installed inside the

house).

Wastewater

Water changed by the use that was made of it (for example:

domestic wastewater).