Table of ontents

Introduction and Installation................................................................................................................................................ 1

Installer’s Preoperational heck......................................................................................................................................... 2

Disassembly and leaning ................................................................................................................................................. 3

Assembly and Lubrication .................................................................................................................................................. 7

Sanitizing ......................................................................................................................................................................... 10

Operation (Filling and Starting)......................................................................................................................................... 11

Helpful Hints ..................................................................................................................................................................... 12

onsistency Adjustment ................................................................................................................................................... 13

Routine Maintenance........................................................................................................................................................ 14

Troubleshooting Guide ..................................................................................................................................................... 15

Troubleshooting Glossary................................................................................................................................................. 16

Service Record ................................................................................................................................................................. 17

TABLE OF ONTENTS iii

Illustrations

Fig. 1Leg Installation ................................................................................................................................................ 1

Fig. 2ontrol Switch ................................................................................................................................................. 2

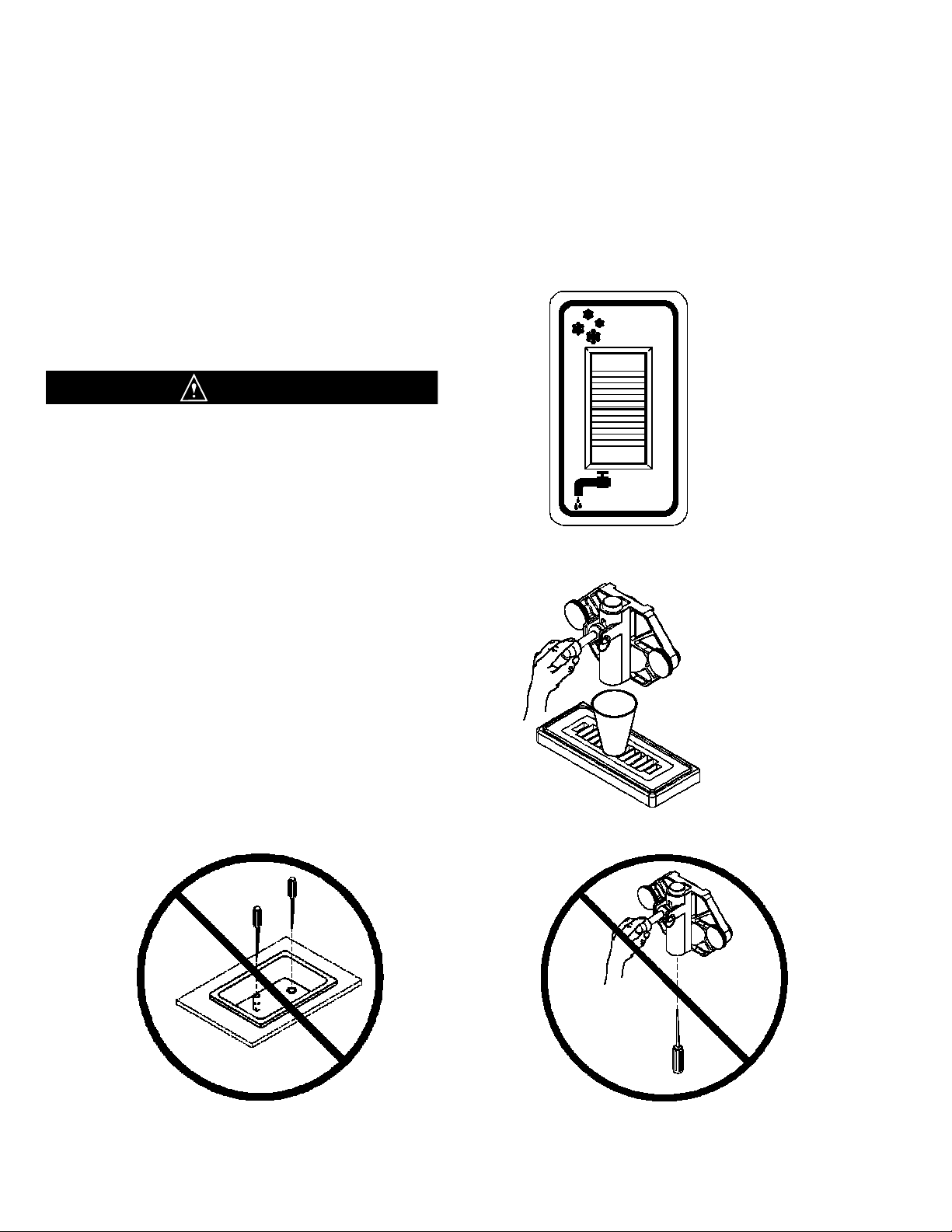

Fig. 3Do Not Insert Objects!..................................................................................................................................... 3

Fig. 4ontrol Switch ................................................................................................................................................. 3

Fig. 5Dispensing Product ......................................................................................................................................... 3

Fig. 6ontrol Switch ................................................................................................................................................. 4

Fig. 7Dispensing Product ......................................................................................................................................... 4

Fig. 8Front Plate Assembly ...................................................................................................................................... 4

Fig. 9O-Ring Removal.............................................................................................................................................. 4

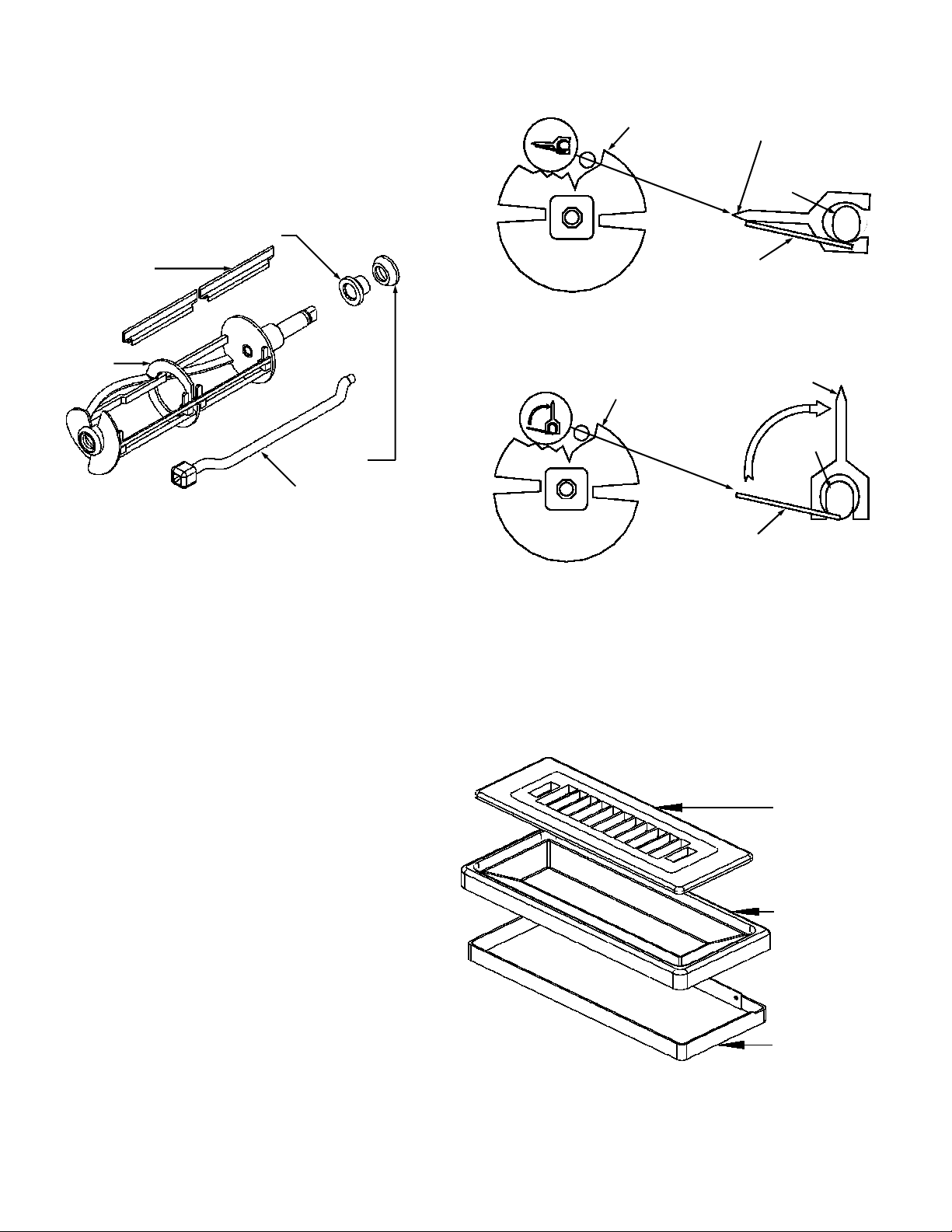

Fig. 10 Dasher Assembly ............................................................................................................................................ 5

Fig. 11 Scraper Blade Removal .................................................................................................................................. 5

Fig. 12 Drip Tray Assembly......................................................................................................................................... 5

Fig. 13 leaning ALL Ports and Holes........................................................................................................................ 6

Fig. 14 Dasher Lubrication .......................................................................................................................................... 7

Fig. 15 Dasher Assembly ............................................................................................................................................ 7

Fig. 16 Scraper Blade Installation ............................................................................................................................... 8

Fig. 17 Scraper Blade Installation ............................................................................................................................... 8

Fig. 18 Scraper Blade Wear Mark............................................................................................................................... 8

Fig. 19 Dasher Installation .......................................................................................................................................... 8

Fig. 20 Dasher Installation .......................................................................................................................................... 8

Fig. 21 Dasher with Blade (Front View) ...................................................................................................................... 9

Fig. 22 Spigot Plunger Lubrication.............................................................................................................................. 9

Fig. 23 Front Plate Assembly...................................................................................................................................... 9

Fig. 24 Drip Tray Assembly......................................................................................................................................... 9

Fig. 25 ontrol Switch ............................................................................................................................................... 10

Fig. 26 Do Not Insert Objects!................................................................................................................................... 10

Fig. 27 Dispensing Product ....................................................................................................................................... 11

Fig. 28 MIXOUT Light ............................................................................................................................................... 11

Fig. 29 Water-ooled ondenser Valve ................................................................................................................... 12

Fig. 30 Wiring Box..................................................................................................................................................... 13

Fig. 31 Electronic onsistency ontrol ..................................................................................................................... 13

Fig. 32 Scraper Blade Wear Mark............................................................................................................................. 14

Fig. 33 lean Sharp ondenser Fins........................................................................................................................ 14