Table of Contents

Introduction and Installation ............................................................................................................................................... 1

Installer’s Preoperational Check ........................................................................................................................................ 2

Disassembly and Cleaning................................................................................................................................................. 3

Assembly and Lubrication (WB700, WB700-2).................................................................................................................. 7

Assembly and Lubrication (WB7110)............................................................................................................................... 10

Sanitizing ......................................................................................................................................................................... 12

Operation (Filling and Starting) ........................................................................................................................................ 14

Helpful Hints..................................................................................................................................................................... 15

Consistency Adjustment................................................................................................................................................... 16

Routine Maintenance ....................................................................................................................................................... 17

Troubleshooting Guide..................................................................................................................................................... 18

Troubleshooting Glossary ................................................................................................................................................ 19

Service Record................................................................................................................................................................. 20

TABLE OF CONTENTS

iii

Illustrations

Fig. 1 Leg Installation................................................................................................................................................ 1

Fig. 2 Drip Tray Bracket Installation ......................................................................................................................... 1

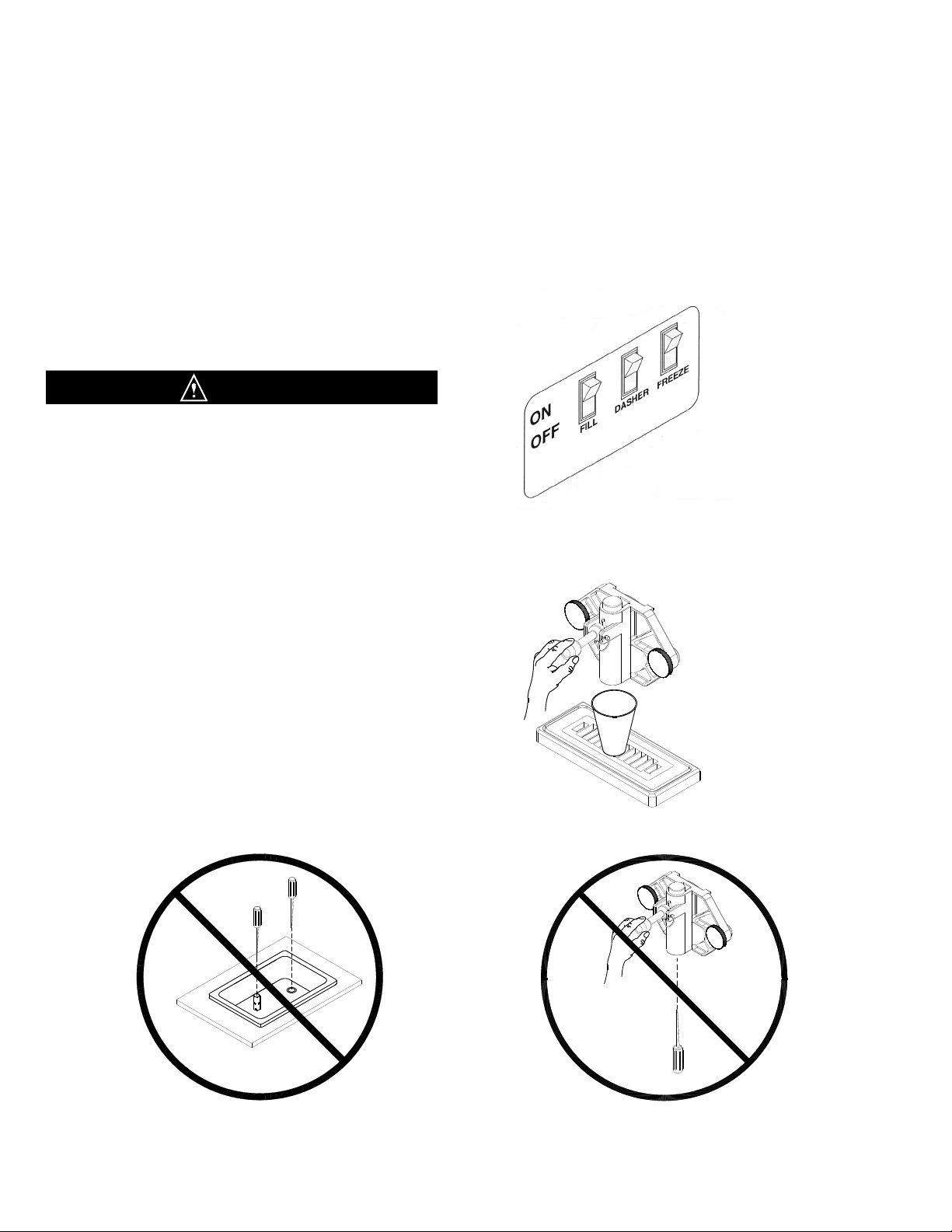

Fig. 3 Control Switch................................................................................................................................................. 2

Fig. 4 Do Not Insert Objects! .................................................................................................................................... 3

Fig. 5 Control Switch................................................................................................................................................. 3

Fig. 6 Dispensing Product......................................................................................................................................... 3

Fig. 7 Control Switch................................................................................................................................................. 4

Fig. 8 Dispensing Product......................................................................................................................................... 4

Fig. 9 Front Plate Assembly (WB700, WB700-2) ..................................................................................................... 4

Fig. 10 O-Ring Removal ............................................................................................................................................. 4

Fig. 11 Dasher Assembly (WB700, WB700-2) ........................................................................................................... 5

Fig. 12 Dasher Assembly (WB7110) .......................................................................................................................... 5

Fig. 13 Scraper Blade Removal.................................................................................................................................. 5

Fig. 14 Drip Tray Assembly ........................................................................................................................................ 5

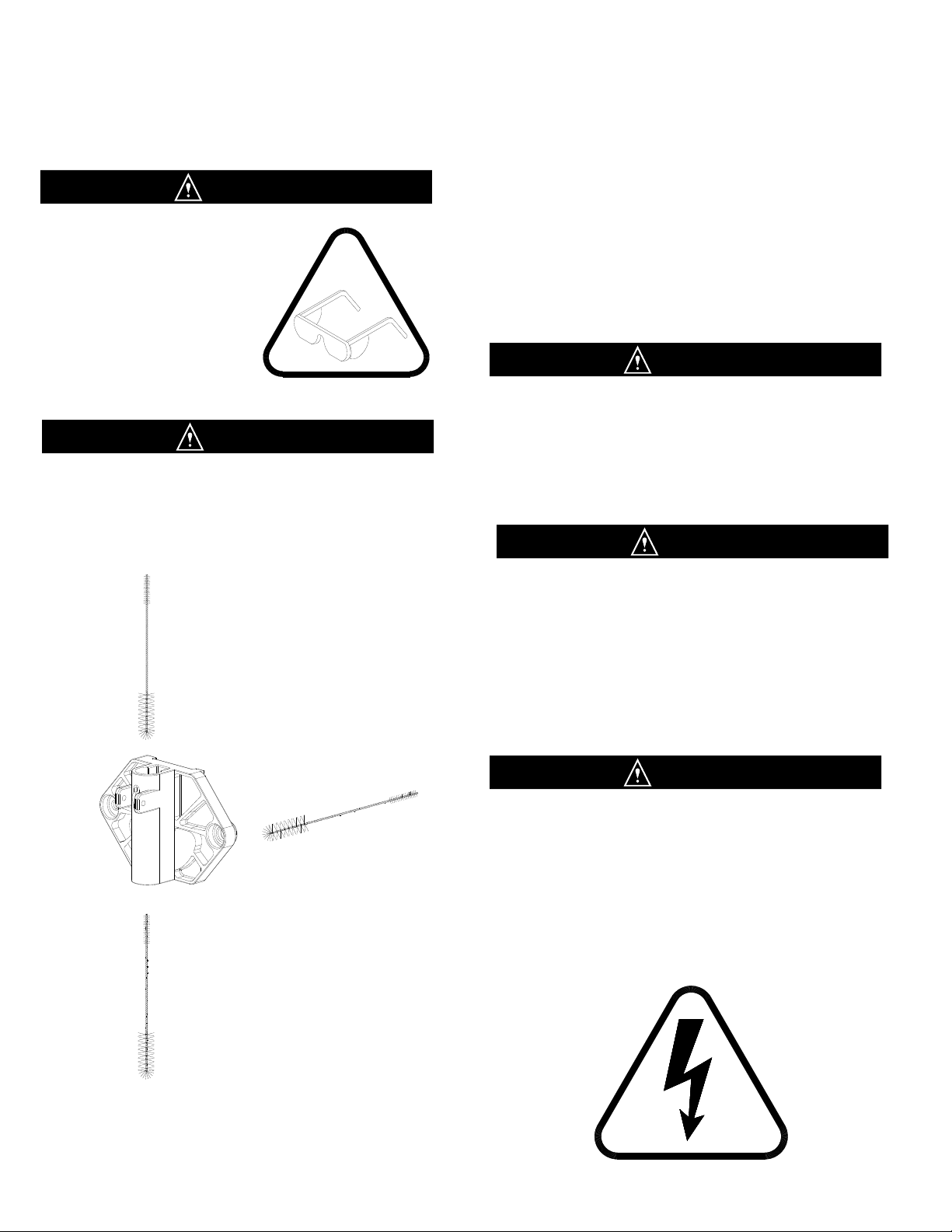

Fig. 15 Clean ALL Ports and Holes ............................................................................................................................ 6

Fig. 16 Stator Rod and Dasher Lubrication (WB700, WB700-2)................................................................................ 7

Fig. 17 Dasher Assembly (WB700, WB700-2) ........................................................................................................... 7

Fig. 18 Scraper Blade Installation............................................................................................................................... 8

Fig. 19 Scraper Blade Installation............................................................................................................................... 8

Fig. 20 Scraper Blade Wear Mark .............................................................................................................................. 8

Fig. 21 Dasher Installation .......................................................................................................................................... 8

Fig. 22 Dasher Installation .......................................................................................................................................... 8

Fig. 23 Dasher With Blade (Front View) ..................................................................................................................... 9

Fig. 24 Spigot Plunger Lubrication ............................................................................................................................. 9

Fig. 25 Front Plate Assembly (WB700, WB700-2) ..................................................................................................... 9

Fig. 26 Drip Tray Assembly ........................................................................................................................................ 9

Fig. 27 Dasher Support and Dasher Lubrication ...................................................................................................... 10

Fig. 28 Dasher Assembly.......................................................................................................................................... 10

Fig. 29 Dasher Installation ........................................................................................................................................ 10

Fig. 30 Front Plate Assembly (WB7110) .................................................................................................................. 11

Fig. 31 Spigot Plunger Lubrication ........................................................................................................................... 11

Fig. 32 Drip Tray Assembly ...................................................................................................................................... 11

Fig. 33 Control Switch............................................................................................................................................... 12

Fig. 34 Do Not Insert Objects! .................................................................................................................................. 12

Fig. 35 Optional Drink Spinner.................................................................................................................................. 13

Fig. 36 Dispensing Product....................................................................................................................................... 14

Fig. 37 MIXOUT Light ............................................................................................................................................... 14

Fig. 38 Wiring Box .................................................................................................................................................... 16

Fig. 39 Hardness Control.......................................................................................................................................... 16

Fig. 40 Scraper Blade Wear Mark ............................................................................................................................ 17