Spigot Handle

Spigot Plunger

(3) O-Rings

Front Plate O-Ring

DO NOT LUBRICATE

Front Plate Knob

Front Plate Knob

Faspin

Front Plate

Pressure Relief Plug

with 2 O-rings

(2) O-Rings

DISASSEMBLY and CLEANING

Fig. 7

O-Ring

PAGE 4

CAUTION

DO NOT USE ANY TOOLS OR SHARP OBJECTS TO RE-

MOVE ANY O-RINGS FROM THIS MACHINE. SHARP OB-

JECTS WILL DAMAGE THE O-RINGS.

Disassembly and Cleaning Procedure

1. Turn lever on “Smart Coupler” to the "OFF" position.

Untap barrel and connect the 5 gallon cleaning canister

filled with fresh cool water.

2. Place Auto/Clean switch in "CLEAN" position.

3. Turn the lever on the "Smart Coupler" to the "CLEAN"

position.

4. Draw off and discard the frozen contents of the freezing

cylinder.

5. Place the Auto/Clean switch in the "OFF" position.

6. Draw off the liquid contents of the freezing cylinder with

the relief valve in the upward (open) position to aid in

draining of the cylinder.

7. Untap canister and remove any residual pressure in the

cylinder by opening the spigot.

8. BE SURE THE AUTO/CLEAN SWITCH IS IN THE

“OFF” POSITION PRIOR TO REMOVING THE FRONT

PLATE AND DASHER ASSEMBLIES.

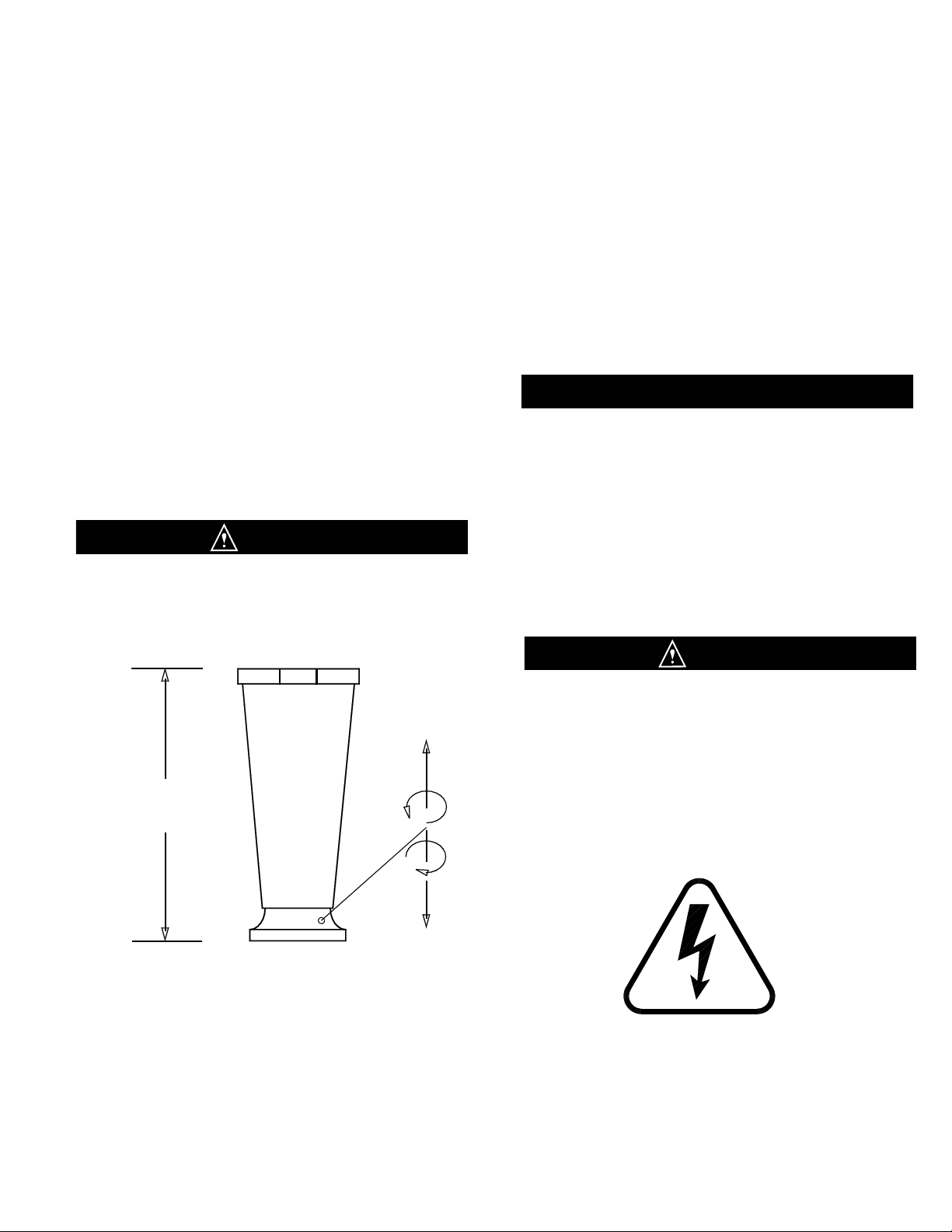

9. Remove the front plate (Fig. 6) by turning the black plas-

tic knobs in a counterclockwise direction.

Disassemble the front plate in the following manner:

a. Remove the faspin and spigot handle.

b. Remove the front plate o-ring.

c. With the spigot handle removed, push the spigot

plunger out the top of the front plate and remove all

lubricant from the spigot plunger.

d. Remove the three o-rings from the spigot plunger

(Fig. 7) by grasping the part with one hand and with

a dry cloth in the other hand, squeeze the o-ring up-

ward. When a loop is formed, grasp the o-ring with

the other hand and roll it out of its groove and off the

spigot plunger .

e. Remove pressure relief plug and remove the two O-

rings from the plug.

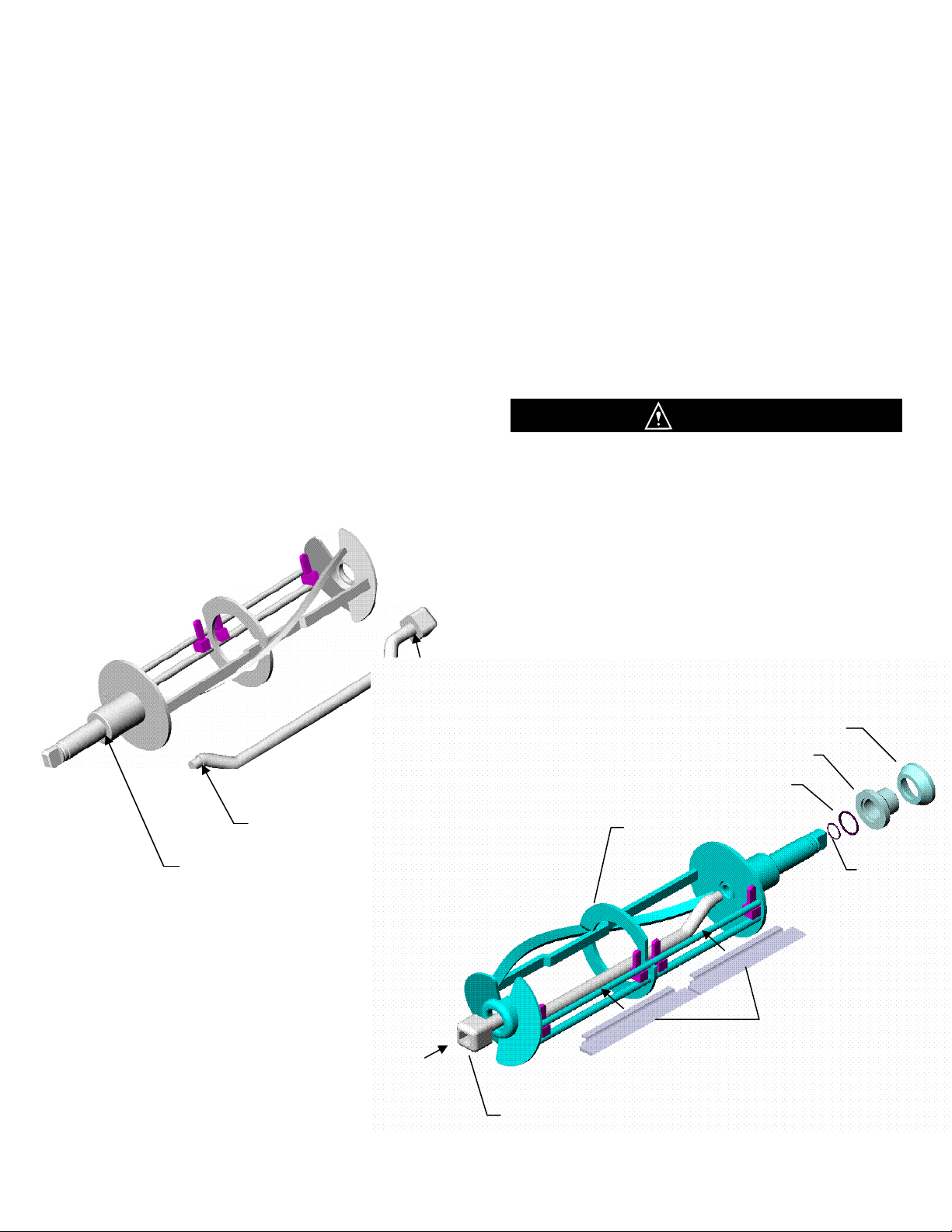

9. Remove the dasher assembly (Fig. 8) being careful not to

damage the scraper blades, then disassemble in the follow-

ing manner:

a. Remove the rear seal assembly

b. Remove the stator rod from the dasher.

c. Remove the blades from the dasher by first rotating

blade upward and then unsnapping one end from the

support rod (see Fig. 9).

d. Remove o-ring from the rear of the dasher.

e. Separate the GREY rubber rear seal from the rear bear-

ing and remove the rear bearing O-ring.

Fig. 6

Front Plate

Fig. 8

Scraper Blades (2)

Dasher

Stator Rod

Rear Bearing O-Ring

Rear Seal

Dasher O-Ring

BLADES

MUST BE

REMOVED FOR CLEANING

Rear Bearing

Plunger O-Rings