The batteries will gradually age over time after being made. As the

battery electrode plate surface age and produces sulfides, the batteries

can not undergo the chemical reactions effectively, this is the main

reason the most batteries cannot continue to be used. At this time, the

internal resistance of the batteries increases. The older batteries, the

greater the internal resistance. By accurately measuring the value of

internal resistance, you can determine the aged of the batteries.

Currently, conductance method is the most advanced method to

measure the internal resistance of the batteries.

It has a proven result of electric conductance test and 1/2 CCA

discharging measurement test can be identical. Given result fully

shows the accuracy of this tester. During operation, avoiding large

current to discharge the battery can protect the battery from possible

damages and heat generation. This allow the machine operator

perform tests several times within a short time period. In recent years,

the conductance method to measure the internal resistance of a battery

is being widely used around the world.

PRECAUTIONS

●Read the user manual carefully and use correctly.

●The tester is designed to test 12/24 volt automotive batteries. It can

not be used for other batteries.

●A freshly charged battery will show a higher voltage than normal; if

this is the case, switch on the headlights for 30 seconds to allow the

voltage to stabilize.

●Always connect directly to the leads of the battery terminals;

connection to a remote post or vehicle ground will affect test result.

●Always connect single battery.

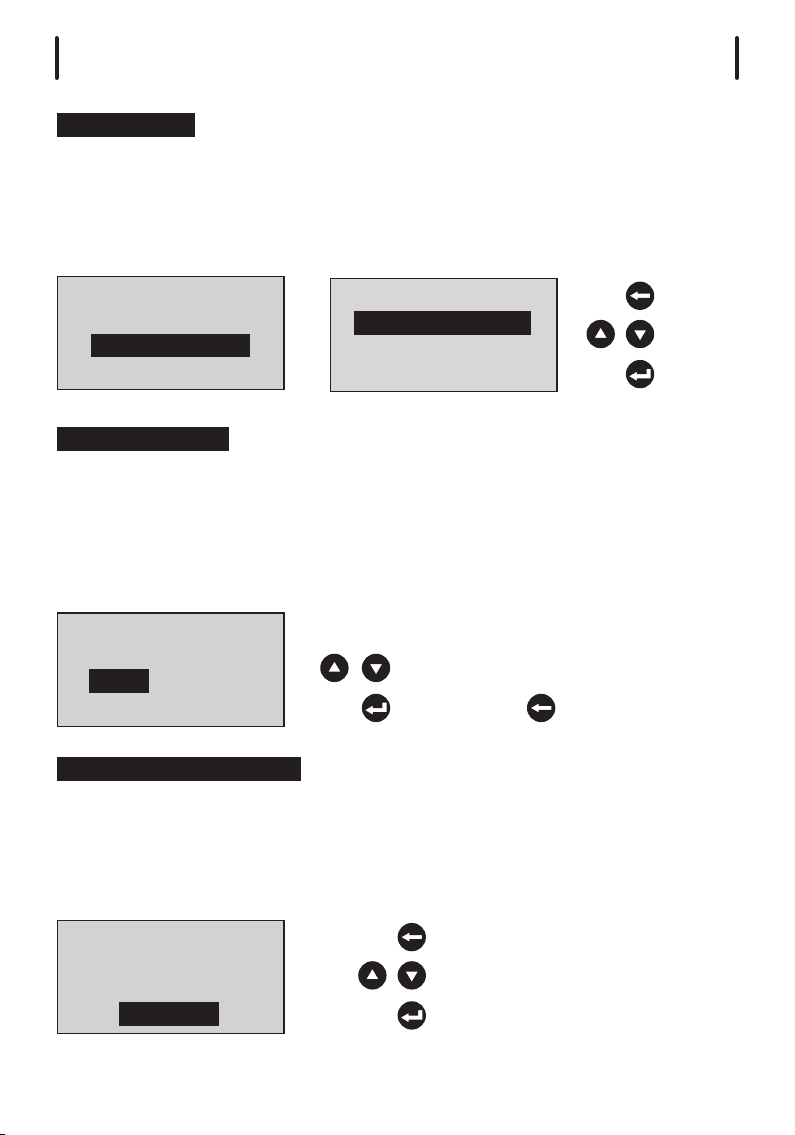

●Connect the tester to the battery, red clip to the positive electrode

and black clip to the negative electrode. The analyzer will start

automatically and show the voltage of the battery. If the analyzer do not

turn on, check whether the clip connect the wrong electrode.

Related knowledge / Precautions

Foreword

01