Safety Precautions

2

1. Relocation and Transportation Precautions

CAUTION

Be careful to avoid falling or dropping the DC-AC Inverter during relocation or transportation, as bodily injury could

result.

Be careful to avoid back strain when handling the DC-AC Inverter.

2. Installation Precautions

CAUTION

The DC-AC Inverter should be installed only by a service technician. Furthermore, it should be

installed in accordance with the instructions in the instruction manual.

Improper installation can result in electric shock, bodily injury, and/ or fire.

Never operate or store the DC-AC Inverter in the following environmental conditions.

Doing so may cause the DC-AC Inverter to malfunction, sustain damage or deteriorate,

which could result in a fire.

a. In ambient environmental conditions other than those specified in the product brochure and instruction manual

(temperature 5 to 40C (41 to 104゚F), relative humidity 5 to 85%), such as in extremely high or low

temperature and high humidity.

b. Where the DC-AC Inverter is exposed to direct sunlight.

c. Where the DC-AC Inverter is directly exposed to the heat from a heat source, such as a stove.

d. Where the DC-AC Inverter may be subject to vibration or physical shock.

e. Near a device that may emit sparks.

f. In the presence of dust, salt or corrosive or flammable gas.

g. Outdoors

This DC-AC Inverter is for rack-mounted use only. Please consult our sale office or your distributor

when the device needs to be removed from the rack.

Be careful not to block the air intake and exhaust vents of the DC-AC Inverter.

Mount the DC-AC Inverter in a rack that can be well ventilated, and keep the front and back of the DC-AC

Inverter at least 20 cm (7.9 inches) away from the wall. Be careful not to block the air intake and exhaust

vents of the rack and DC-AC Inverter. If the air intake or exhaust vent is blocked, the internal temperature

of the DC-AC Inverter will rise, which may cause a fire. For maintenance, the DC-AC Inverter requires at

least 1 m (39.4 inches) of space at the front, and at least 50 cm (20 inches) at the back.

The space around the DC-AC Inverter must be ventilated.

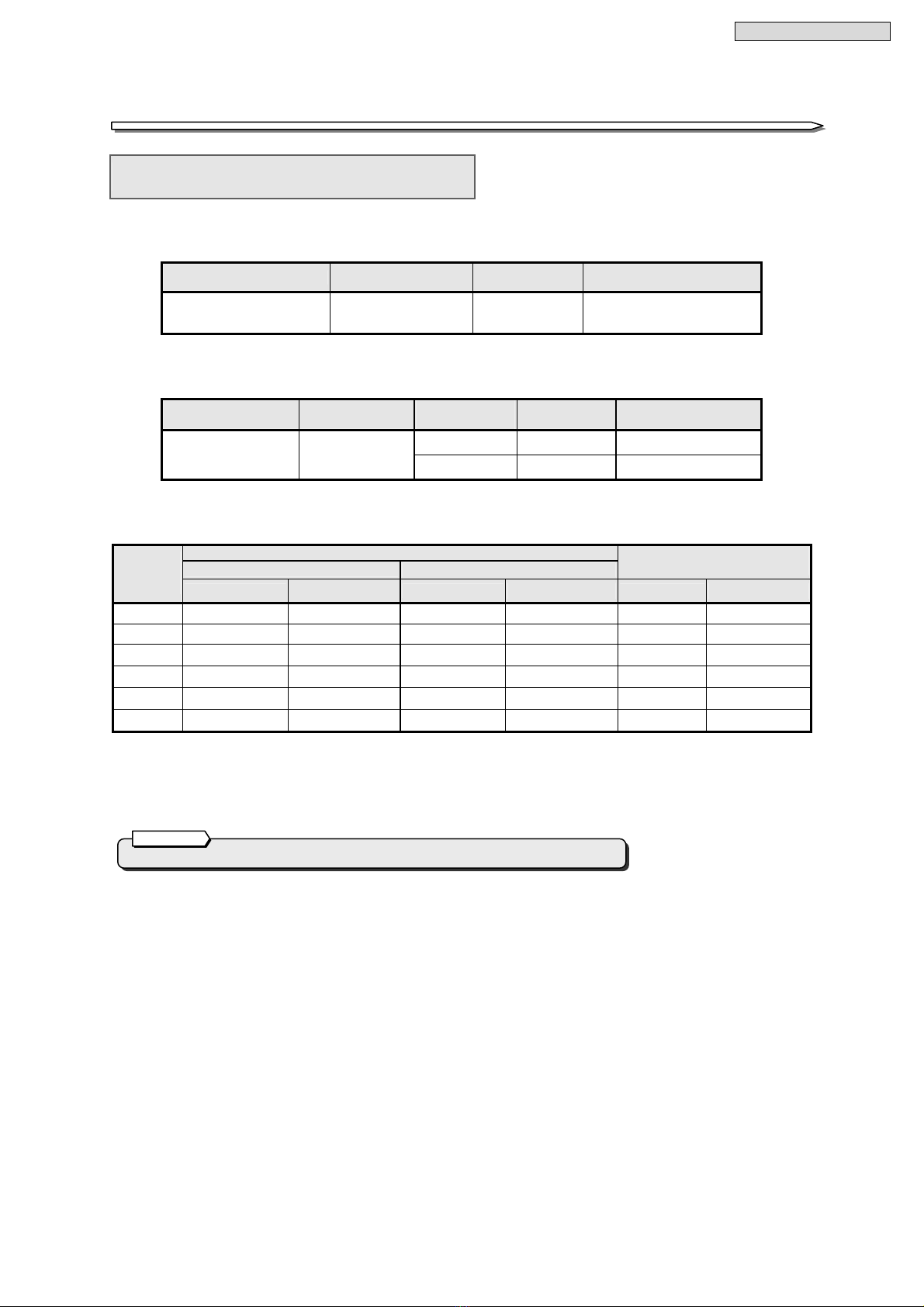

In accordance with the instructions in the manual, install the DC-AC Inverter on a stable surface capable

of bearing the weight (approximately 8 kg (17.6 lbs) for one unit, approximately 10 kg (22.1 lbs) for a

parallel operation cabinet for 3 units, approximately 12 kg (26.5 lbs) for a parallel operation cabinet for 5

units, and approximately 13 kg (28.7 lbs) for a parallel operation cabinet for 6 units).

If the DC-AC Inverter is installed incorrectly, it may fall or move inadvertently, resulting in bodily injury. Be

careful to avoid back strain when handling the DC-AC Inverter.

3. Wiring Precautions

CAUTION

Wiring should be performed only by technically qualified personnel. Furthermore, it should be

performed in accordance with the instructions in the manual.

Incorrect wiring can result in electric shock and/or fire.

A readily accessible disconnect device shall be incorporated external to the equipment.

Protection in primary circuits against over currents, short circuits and earth faults is not provided

inside this DC-AC Inverter. Protection in primary circuit against over currents short circuits and

earth faults shall be provided as part of the building installation.

Connect the grounding cable securely in the manner specified.

This DC-AC Inverter requires class D grounding work.

Failure to connect the grounding cable may result in electric shock.

The grounding cables of all load devices connected to the output of the DC-AC Inverter must be

securely connected to the grounding terminal. Failure to connect the grounding cables correctly may

result in electric shock.

Install the disconnect device whose contact gap is 2 mm (0.08 inches) or more in DC Input.

Install the disconnect device whose contact gap is 3 mm (0.12 inches) or more in AC Input.

(In the case of the PD-D11AB13US, PD-D11AB15US and PD-D11AB16US model.)

!

!

!

!

!

!